A kind of method and application thereof by biomass liquefaction preparation wood oil

A bio-heavy oil and biological technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of failing to meet the standards of marine oil and limiting the conversion rate of biomass tar, and achieve the reduction of post-processing technology and low equipment requirements , The effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

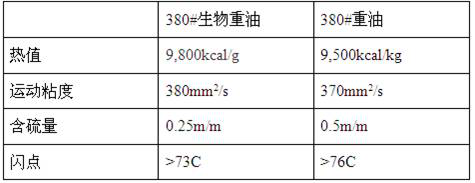

[0029] Example 1 This example provides a method for bio-heavy oil from corn stalks

[0030] 1) The contents of cellulose, hemicellulose, lignin and ash in corn stalks are 32wt%, 15wt%, 18wt% and 35wt%, respectively. The specific steps of biomass liquefaction are: collect 10kg of corn stalks, and its moisture content is 10wt %, after mechanical treatment, the particles are less than 20mm, and they are put into the reactor by vacuum feeding to ensure that the oxygen volume content is lower than 1%; the mass ratio of water and ethanol in 50kg of water supply solvent is 1:2, and the mass of sulfuric acid is 1.3% of the water co-solvent mass is 0.663kg98% concentrated sulfuric acid, the ratio of straw to liquid is 1:5, react at 160°C for 20 minutes, the cellulose, hemicellulose and lignin in the corn straw are all liquefied, The solid residue is 35wt% ash in the biomass, adding 1kg of 50% calcium hydroxide slurry to neutralize the sulfuric acid in the solution, and filtering to obt...

Embodiment 2

[0039]Embodiment 2 pine wood

[0040] This embodiment provides a method for liquefaction of pine wood to produce heavy biological oil. The cellulose in pine wood, hemicellulose, lignin and ash content are 32wt%, 25wt%, 18wt% and 5wt%, respectively. Biomass liquefaction, specifically The steps are: collect 10kg of pine wood chips with a moisture content of 5wt%, after mechanical treatment, the particle size is less than 20mm, and put them into the reaction kettle by vacuum feeding, and add 70kg of water co-solvent, the mass ratio of wood chips to liquid is 1: 7. The mass ratio of water and furan in the water co-solvent is 1:2, the mass of sulfuric acid is 2.0% of the mass of the water co-solvent, that is, 1.663kg of 98% concentrated sulfuric acid, and react at 200°C for 30 minutes. The cellulose, hemicellulose and lignin of pine wood chips were all liquefied, and the solid residue was 5wt% ash. Add 2.4kg50% calcium hydroxide slurry to neutralize the sulfuric acid in the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com