Patents

Literature

142 results about "Zinc sulphate heptahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc Sulfate Heptahydrate is a moderately water and acid soluble Zinc source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogens with a metal.

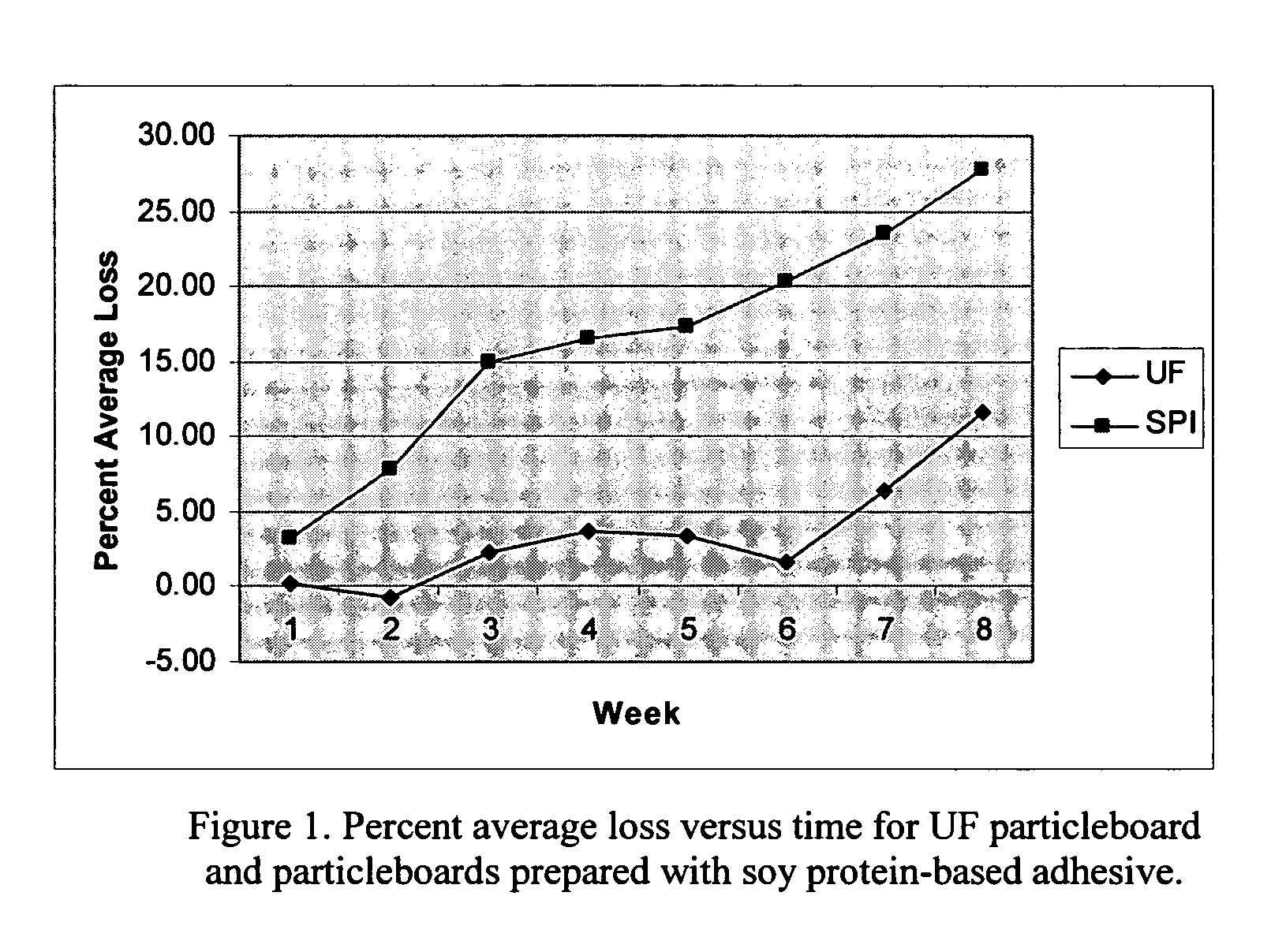

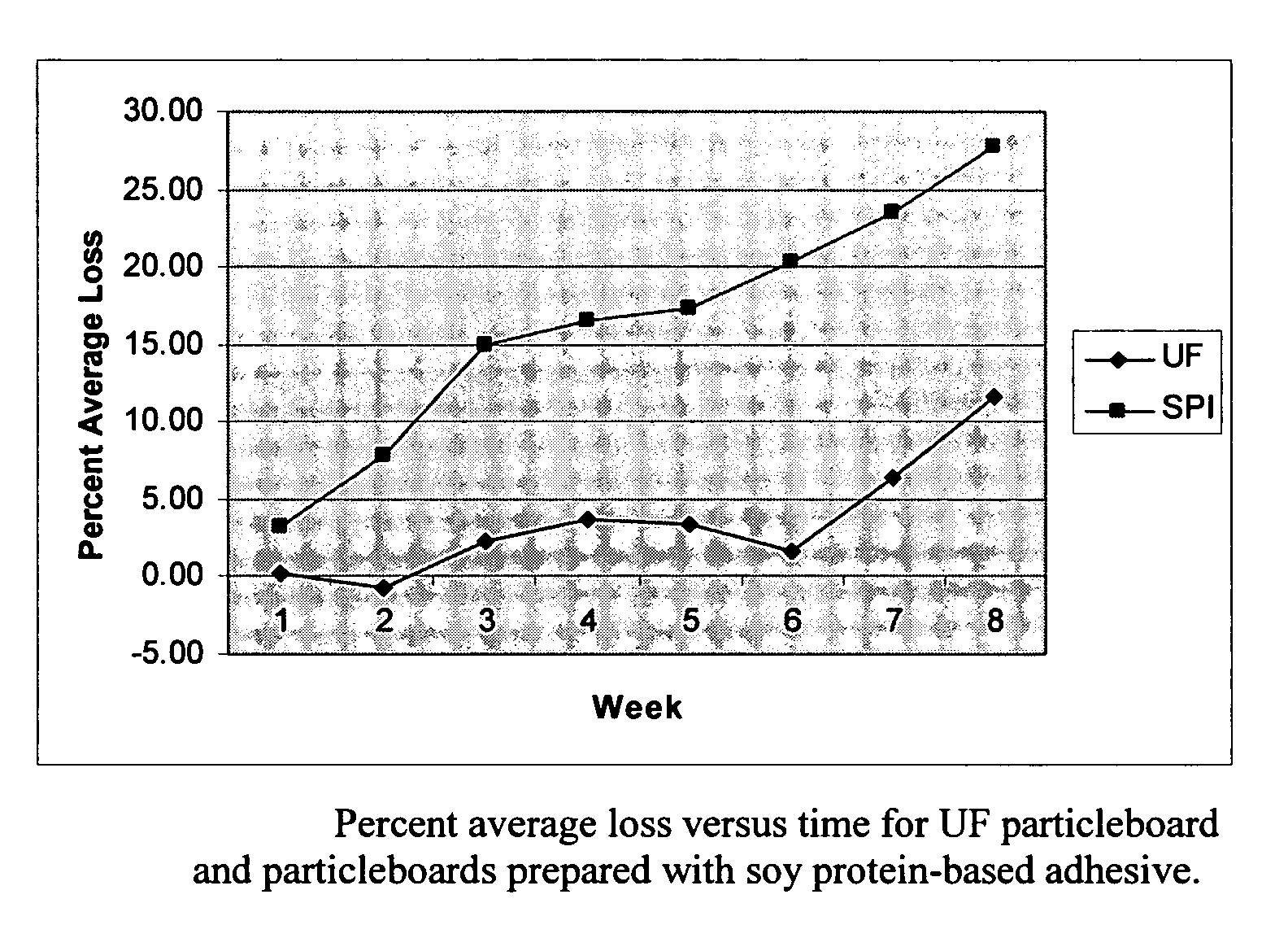

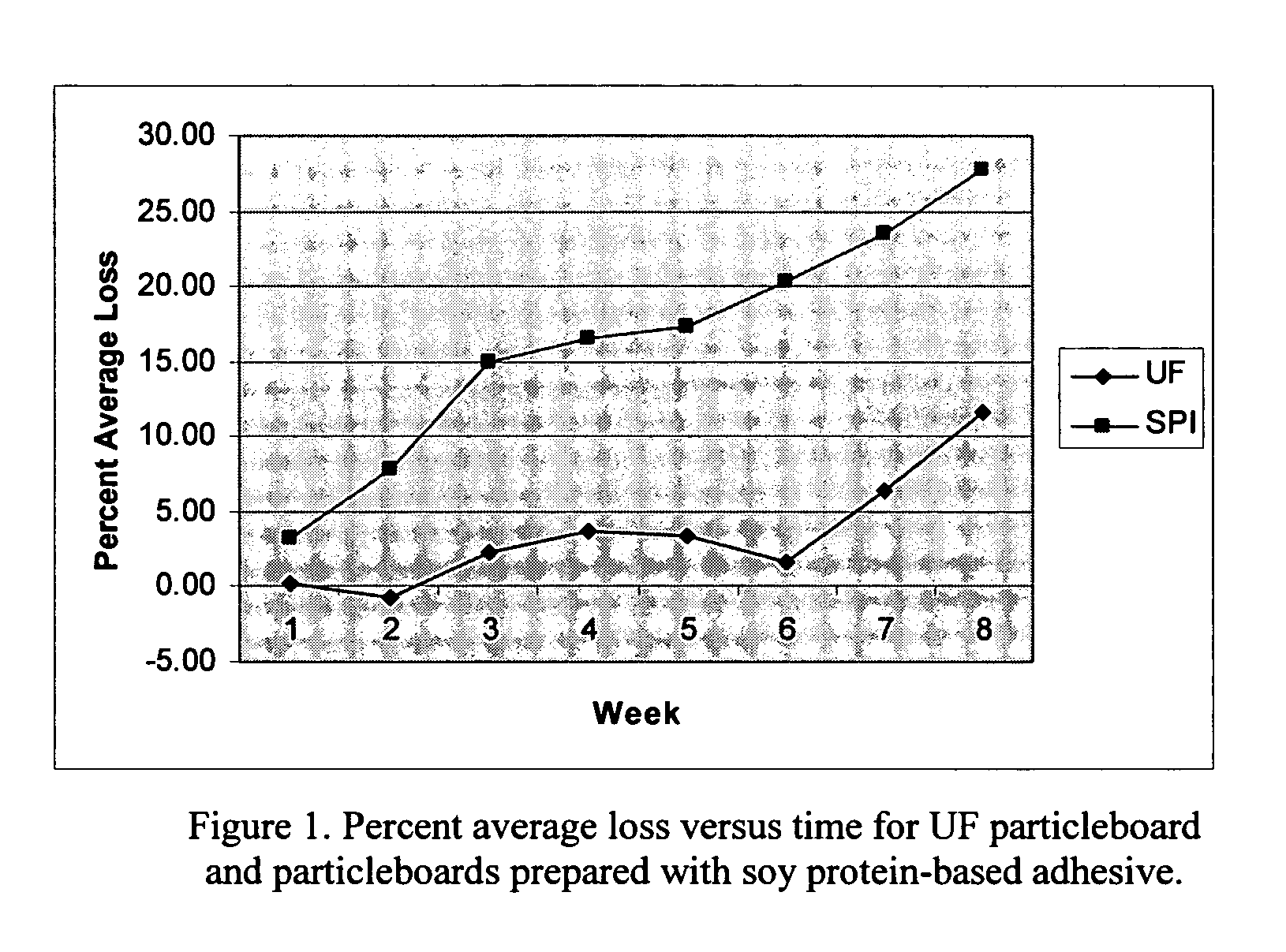

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Soy protein based adhesive and particleboard

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water and preparation method thereof

InactiveCN102718329AGood anti-scaling effectGood dispersionTreatment using complexing/solubilising chemicalsPhosphateDiethylenetriamine

The invention provides a composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water. The composite corrosion inhibition antisludging agent comprises the following raw materials in parts by weight: 5-15 parts of amino trimethylene phosphonic acid, 5-15 parts of hydroxyethylidene diphosphonic acid, 1-15 parts of diethylenetriamine pentamethylene phosphonic acid, 5-15 parts of hydrolytic polymaleic anhydride, 2-15 parts of terpolymer, 2-20 parts of heptahydrate, 0.1-2 parts of hydroxy benzotriazole and 3-79.9 parts of pure water. The hydroxy benzotriazole is added after the amino trimethylene phosphonic acid, the hydroxyethylidene diphosphonic acid, the diethylenetriamine pentamethylene phosphonic acid, the hydrolytic polymaleic anhydride and the terpolymer are stirred and mixed; and the composite corrosion inhibition antisludging agent is obtained by adding the water and the heptahydrate until the hydroxy benzotriazole is entirely dissolved. The hydrolytic polymaleic anhydride and the terpolymer used by the invention have a good diffusion effect, and can effectively prevent carbonates, phosphates and the like from being deposited and scaled. Meanwhile, the hydrolytic polymaleic anhydride and the terpolymer belong to a non-phosphate monomer, so that the agent phosphate content is reduced. Therefore, the composite corrosion inhibition antisludging agent is beneficial to environmental protection.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

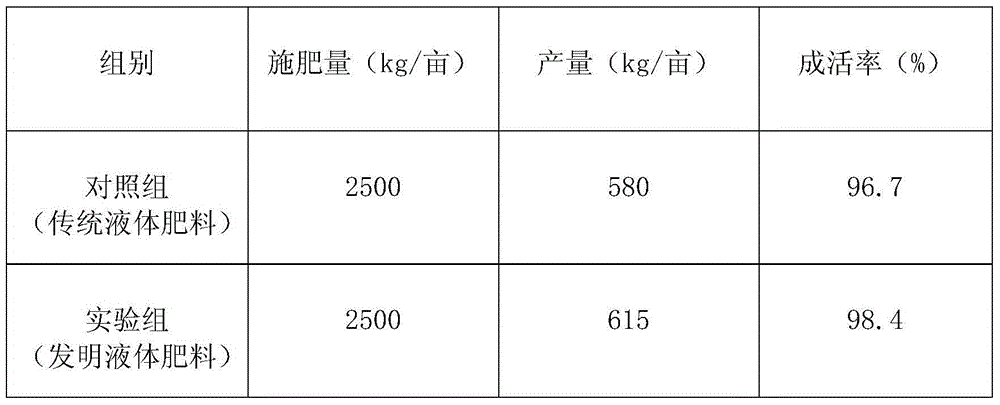

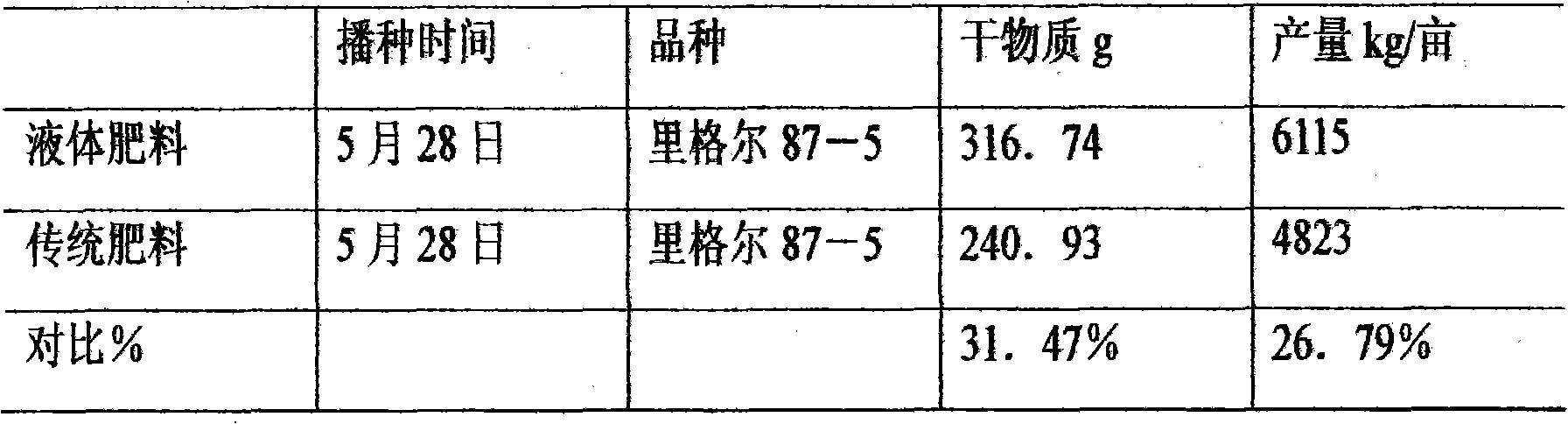

Root-promoting liquid fertilizer and preparation method thereof

The invention discloses a root-promoting liquid fertilizer, which is prepared from the following raw materials in parts by weight: 2-4 parts of ferrous sulfate, 2-3 parts of ammonium molybdate tetrahydrate, 1-3 parts of potassium pyrophosphate, 5-7 parts of short rhizome of spathiphyllum, 6-9 parts of castor cake, 15-20 parts of bran, 5-8 parts of potassium sulfate, 7-10 parts of urea, 2-4 parts of matrine, 2-3 parts of zinc sulphate heptahydrate, 0.1-0.2 part of 6-benzylaminopurine, 0.1-0.2 part of triiodobenzoic acid, 4-8 parts of rose, 10-14 parts of brewer's grains and 8-12 parts of an ingredient. Due to the addition of the 6-benzylaminopurine, the triiodobenzoic acid and the like, the liquid fertilizer disclosed by the invention has the function of adjusting the raw materials with a crop growth function, and is capable of effectively promoting rooting and formation of flower buds of the crops; the nutrient components of a microelement fertilizer can be increased by extract liquids such as chaff and brewer's grains; and the root-promoting liquid fertilizer is convenient to use, and obvious in yield-increasing effect, and has a good application prospect.

Owner:周作艳

Clear liquid complex fertilizer special for high concentration drip irrigation and method of preparing the same

ActiveCN101318858ALower pHImprove utilizationOrganic fertilisersUrea compound fertilisersHigh concentrationPhosphoric acid

The invention relates to a high-concentration clear liquid compound fertilizer special for drop irrigation and a production method thereof. The fertilizer is prepared by dissolving urea, liquid phosphoric acid and potassium chloride, green vitriol, zinc vitriol, boric acid and fulvic acid in water with different temperatures in two steps and then mixing the compositions. The liquid compound fertilizer has the advantages that: the liquid compound fertilizer has good physical characteristics, can not deposit for long-term storage, has full nutrients to fully supplement various elements required by crops, can accelerate the growth of a crop root system and prevent precipitation reaction from blocking drop holes, in particular, the liquid compound fertilizer can obviously activate inorganic phosphorus pool of soil and reduce pH value of limy soil so as to greatly improve utilization efficiency of nitrogen and phosphorus nutrient resources. The clear liquid compound fertilizer can be separately applied for basal application and dressing, also can be used as a foliar fertilizer after diluted, and also can be mixed with other fertilizers for application, in particular has wide application respect in drop irrigation areas with the limy soil.

Owner:沃达农业科技股份有限公司

Water culture nutrient solution of blueberry and preparation method thereof

InactiveCN102101803APromote absorptionReturn to normal growthFertilizer mixturesBiotechnologyCalcium nitrate tetrahydrate

The invention belongs to the technical field of fruit tree culture, in particular to a water culture nutrient solution prescription of a blueberry and a preparation method thereof. In the technology, the water culture nutrient solution of a blueberry comprises the following elements: 95-110mg / L of N, 10-15mg / L of P, 125-135mg / L of K, 80-90mg / L of Ca, 20-28mg / L of Mg, 4-6mg / L of Fe, 0.3-0.6mg / L of B, 0.4-0.6mg / L of Mn, 0.04-0.06mg / L of Zn, 0.02-0.04mg / L of Cu and 0.002-0.004mg / L of Mo. A pH value of the water culture nutrient solution is 4.8 to 5.5. The preparation method of the nutrient solution comprises the following steps of: weighing EDTA (Ethylene Diamine Tetraacetic Acid) ferrisodium, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, copper sulfate pentahydrate and ammonium molybdate tetrahydrate for dissolving into water and blending into 100 times of trace element mother liquor for storage and later use; additionally weighing calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate for dissolving into water; absorbing the trace element mother liquor into the solution according to the consumption; adding water for quantifying to needed volume; uniformly stirring; and adjusting the pH value of the solution to be 4.8 to 5.5 with 0.1mg / L dilute H2SO4 or dilute NaOH. By utilizing the technology, the water culture aims of growing a plurality of aquatic roots in 20 days after a blueberry seedling is transplanted and having the plant survival rate of more than 90 percent can be achieved.

Owner:JINLING INST OF TECH

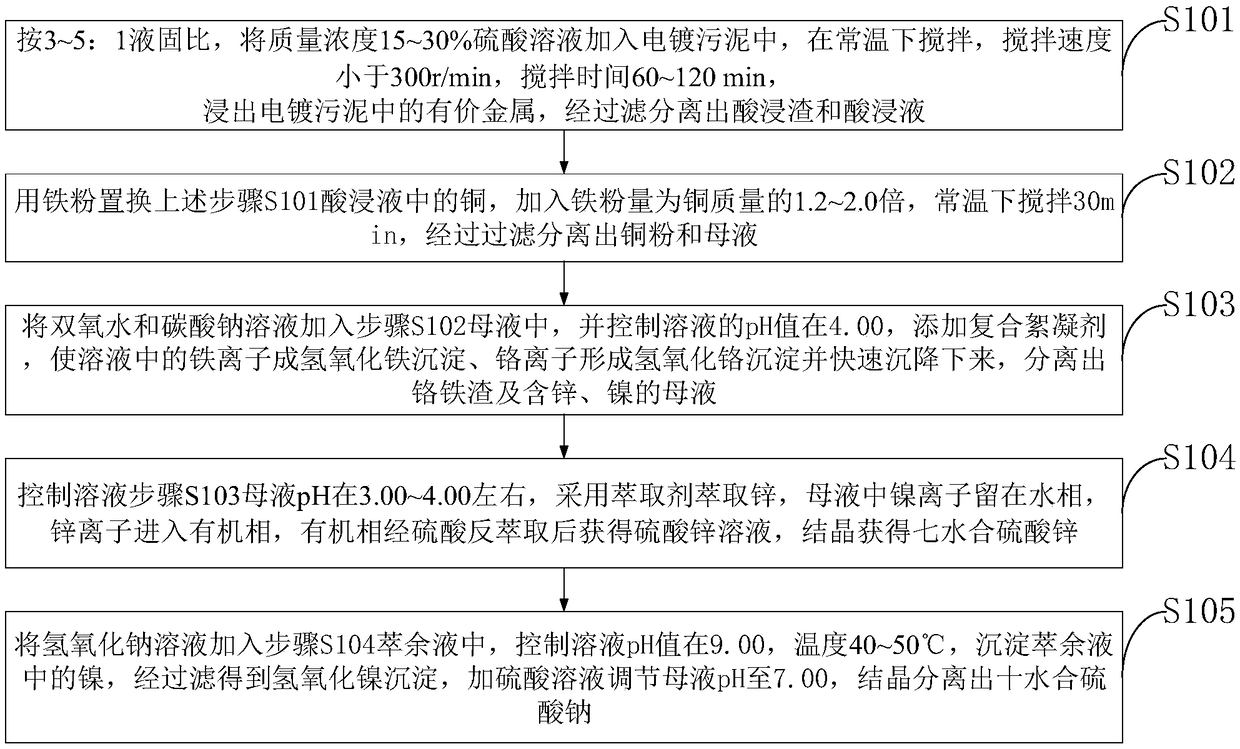

Method of comprehensively recycling valuable metals in plating sludge

The invention belongs to the technical field of plating sludge treatment and discloses a method of comprehensively recycling valuable metals in plating sludge. The method comprises: extracting value metals from plating sludge by leaching, and isolating acid leaching residue and acid leaching liquid; adding iron powder, stirring, and filtering to isolate copper powder and a mother liquid; adding hydrogen peroxide and sodium carbonate solution, adding a composite flocculating agent so that iron ions in the solution form iron hydroxide precipitate and chromium ions form chromium hydroxide precipitate, wherein the precipitates settle fast, and isolating ferrochromium slag and a mother liquid containing zinc and nickel; using P507 extracting agent to extract zinc in the mother liquid containingzinc and nickel, back-extracting an organic phase via sulfuric acid to obtain zinc sulfate solution, and crystallizing to obtain zinc sulfate septahydrate; adding the sodium hydroxide solution into nickel raffinate, filtering to obtain nickel hydroxide precipitate, adjusting mother liquid pH to 7 for the filtrate through sulfuric acid, and crystallizing to isolate sodium sulfate decahydrate. Precipitate washing liquids herein are cyclically used, emission of wastewater is decreased, and significant economic and social benefits are created.

Owner:JIANGXI UNIV OF SCI & TECH

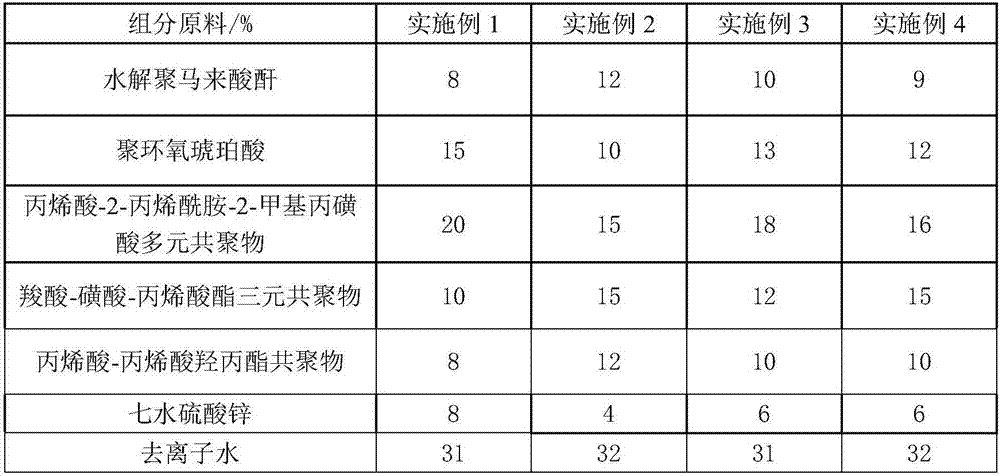

Non-phosphorus corrosion and scale inhibitor

InactiveCN108002558AGood chemical stabilityImprove thermal stabilitySpecific water treatment objectivesScale removal and water softeningEutrophicationZinc sulphate heptahydrate

The invention discloses a non-phosphorus corrosion and scale inhibitor. The non-phosphorus corrosion and scale inhibitor is prepared from the following components in percentage by weight: 8 to 12 percent of hydrolytic polymaleic anhydride, 10 to 15 percent of polyepoxysuccinic acid, 15 to 20 percent of acrylic acid-2-acrylamido-2-methylpropanesulfonic acid multipolymer, 10 to 15 percent of carboxylic acid-sulfonic acid-acrylate terpolymer, 8 to 12 percent of acrylic acid-hydroxypropyl acrylate copolymer, 4 to 8 percent of zinc sulphate heptahydrate and the balance of deionized water. The invention further discloses a preparation method of the corrosion and scale inhibitor. The preparation method comprises the following steps: weighing the components according to the formula; adding the components into a stirrer in sequence; stirring at normal temperature and under normal pressure to obtain the corrosion and scale inhibitor. The corrosion and scale inhibitor disclosed by the invention has the advantages of freeness from phosphorus, adoption of safe and environment-friendly components, simple production process, high scale-inhibiting efficiency, high corrosion-inhibiting performance, prevention of eutrophication of a water body caused by discharge of phosphorus, and very high compatibility; the adhesion of microorganisms to equipment can be reduced effectively, and the corrosionand and scale inhibiting performance can be enhanced greatly.

Owner:新疆水处理工程技术研究中心有限公司

Liquid foliage fertilizer and its producing method

InactiveCN1994980AImprove solubilityImprove buffering effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDipotassium hydrogen phosphatePhosphoric acid

The invention discloses a liquid leaf fertilizer and manufacturing method, which comprises the following parts: 230g solid polyammonium phosphoric acid, 300g dipotassium hydrogen phosphate with 3 crystal water (k2HPO4 .3H2O), 20g aquacare, 430g water, 12g octal-sodium boric kernite, 5g zinc sulphate heptahydrate and 3g sodium nitride solution.

Owner:王连祥 +2

Efficient fruits nutrition physiology hyperchromic fertilizer and preparation thereof

InactiveCN101274864ANon-toxicNo pollution in the processOrganic fertilisersPotassium fertilisersNutritionAdditive ingredient

The invention relates to a high-efficiency fruit-nutritive physiological hyperchromic fertilizer and a preparation method thereof. Currently, the hyperchromic products in the market such as phytohormone, including products of ethane, abscisic acid, daminozide, most of such products adopt or contain hormone, have instable effect and easily cause adverse side effects, thus leading fruits to be soft and lowered in bin stability. The invention is a high-efficiency fruit-nutritive physiological hyperchromic fertilizer, the active ingredients of which comprise aminofusin, potassium sulfate, potassium chloride, borax, zinc vitriol, iron vitriol (FeSO4 question mark 7H2O), compound sodium nitrophenolate, chlormequat chloride with 50 percent of aqua and white sugar; the ingredients do not contain hormone, are non-poisonous and pollution-free, and have no adverse side effects. The high-efficiency fruit-nutritive physiological hyperchromic fertilizer contains various aminophenols, active substances for plant growth, a plurality of major elements and chelate trace elements, which are necessary for the growth and development of the fruit trees and vegetables, and is a novel organic and inorganic hyperchromic product integrating the advantages of various foliar fertilizers of inorganic nutrition type, organic type and growth conditioner type, etc. into a whole.

Owner:翟丙年

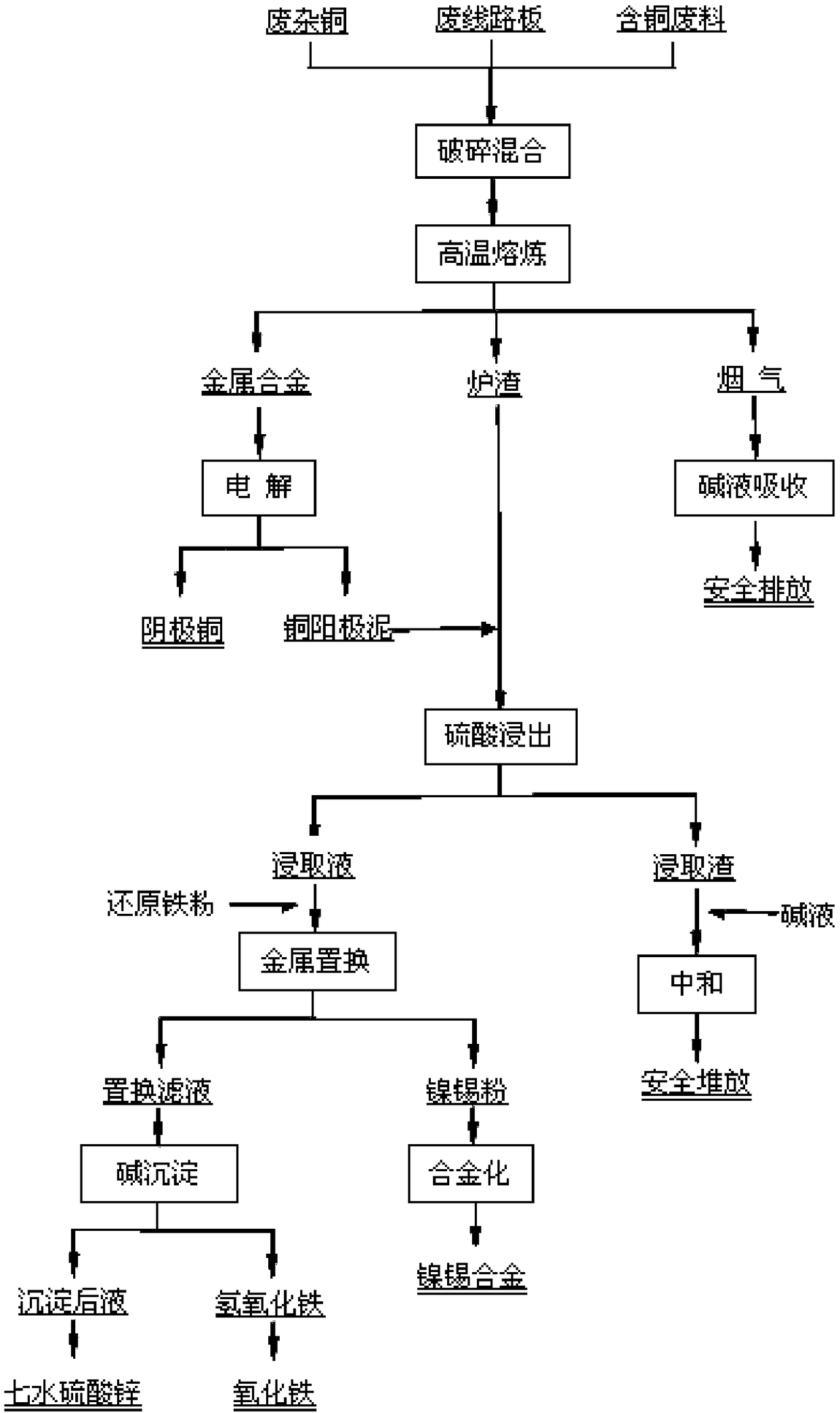

Method and system for collaborative smelting and recycling valuable metal from waste circuit board, scrap copper and copper-containing waste residue

InactiveCN108165751ASolve storage problemsSolve environmental problemsPhotography auxillary processesProcess efficiency improvementFerric hydroxideElectrolysis

The embodiment of the invention discloses a method and system for collaborative smelting and recycling valuable metal from a waste circuit board, scrap copper and copper-containing waste residue. Themethod comprises the steps that the waste circuit board, the scrap copper and the copper-containing waste residue are mixed and are subject to high-temperature smelting to obtain a metal alloy and slag; an anode plate is made of a metal alloy, and through electrolysis, a cathode copper product is obtained; copper anode mud and slag are combined, and through sulfuric acid leaching, leaching liquidis obtained; the leaching liquid is subject to metal replacement, nickel tin powder is separated out, and through alloying smelting, and a nickel and tin alloy product is obtained; filter liquid replacement is carried out, through alkali deposition, ferric hydroxide is separated out, and through burning, a ferric oxide product is obtained; liquid obtained after sedimentation is subject to evaporative crystallization, and a heptahydrate product is obtained. According to the method, the fire method and wet method combined collaborative smelting manner is adopted, the treatment problem of the waste circuit board, the scrap copper and the copper-containing waste residue is solved, the waste source is wide, the cost is low, the obtained product is good in quality, the recycling rate is high, the environment friendly aim reaches the standard, no secondary pollution exists, and a certain economic benefit and the industrial significance are achieved.

Owner:CHINA GEZHOUBA GRP LVYUAN TECH CO LTD

Polypeptide humic acid chelate sustained-release fertilizer

The invention relates to a polypeptide humic acid chelate sustained-release fertilizer, which consists of the following ingredients in part by weight: 95 to 110 parts of potassium chloride, 170 to 185 parts of monoammonium phosphate, 15 to 25 parts of ammonium bicarbonate, 240 to 260 parts of ammonium sulfate, 260 to 280 parts of urea, 80 to 95 parts of humic acid, 35 to 45 parts of boron calcium powder, 3 to 8 parts of zinc sulphate heptahydrate, 15 to 30 parts of amino acid, 2 to 5 parts of sodium molybdate dehydrate, 1 to 5 parts of chelator, 8 to 15 parts of polypeptide sustained-release agent and 3 to 8 parts of film coating agent. A preparation process comprises the following steps of: mixing and stirring the ingredients in a ratio to obtain powder; and conveying the powder into a granulating machine for granulating, drying, cooling and sieving to obtain the finished product. The polypeptide humic acid chelate sustained-release fertilizer has the advantages of economy, environment friendliness and the like, labor and time are saved, and a preparation method is simple.

Owner:李勇

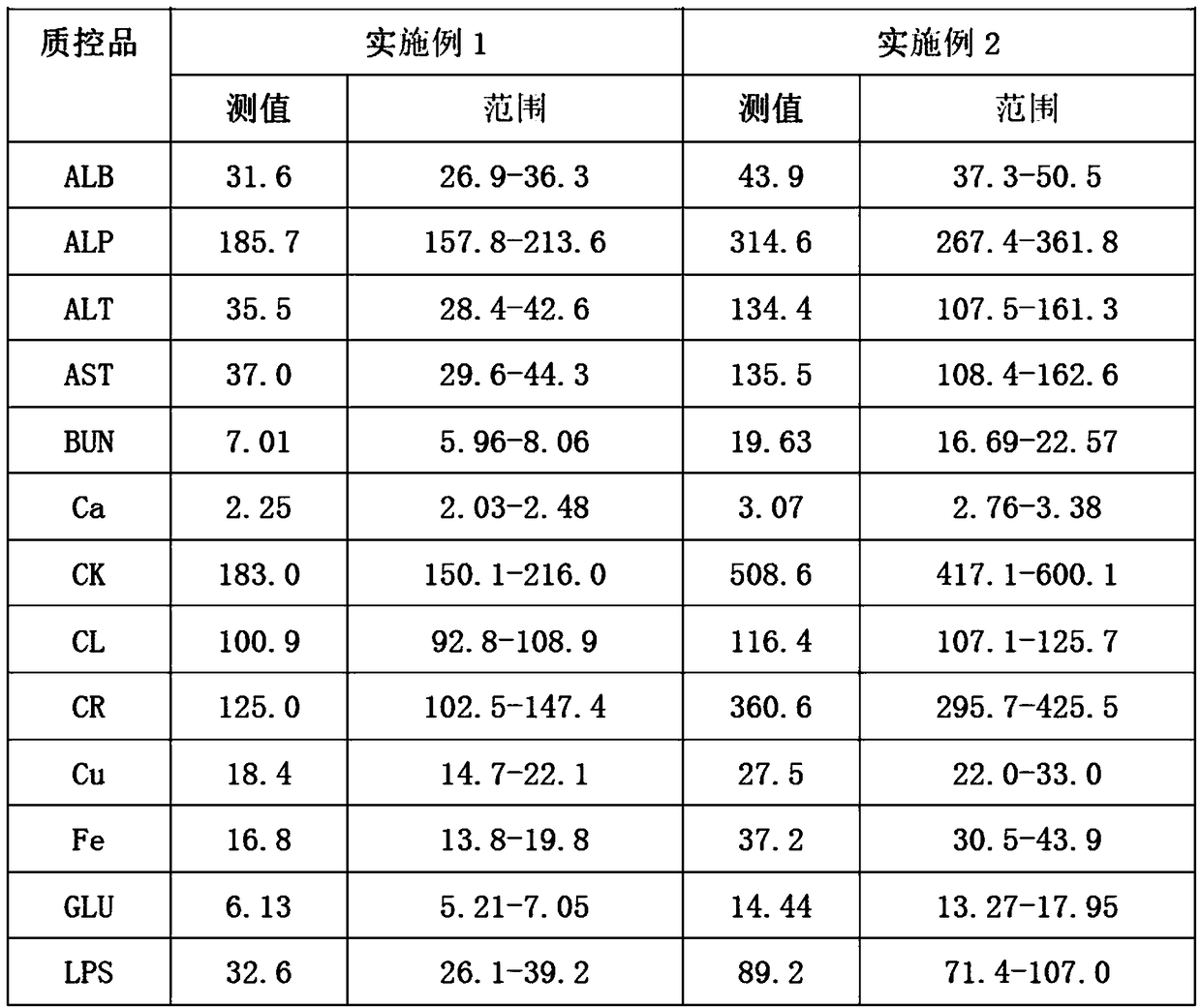

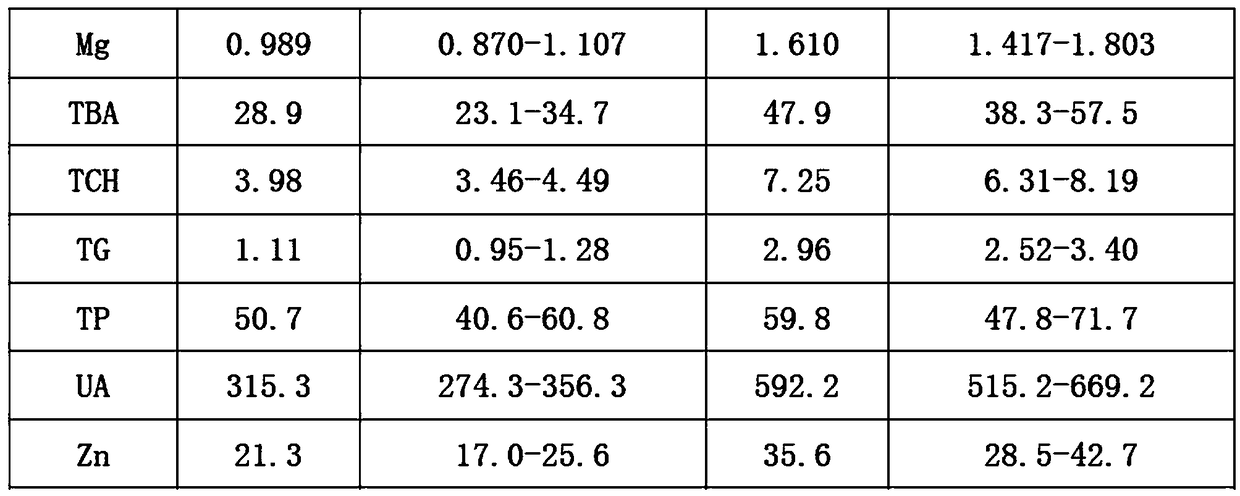

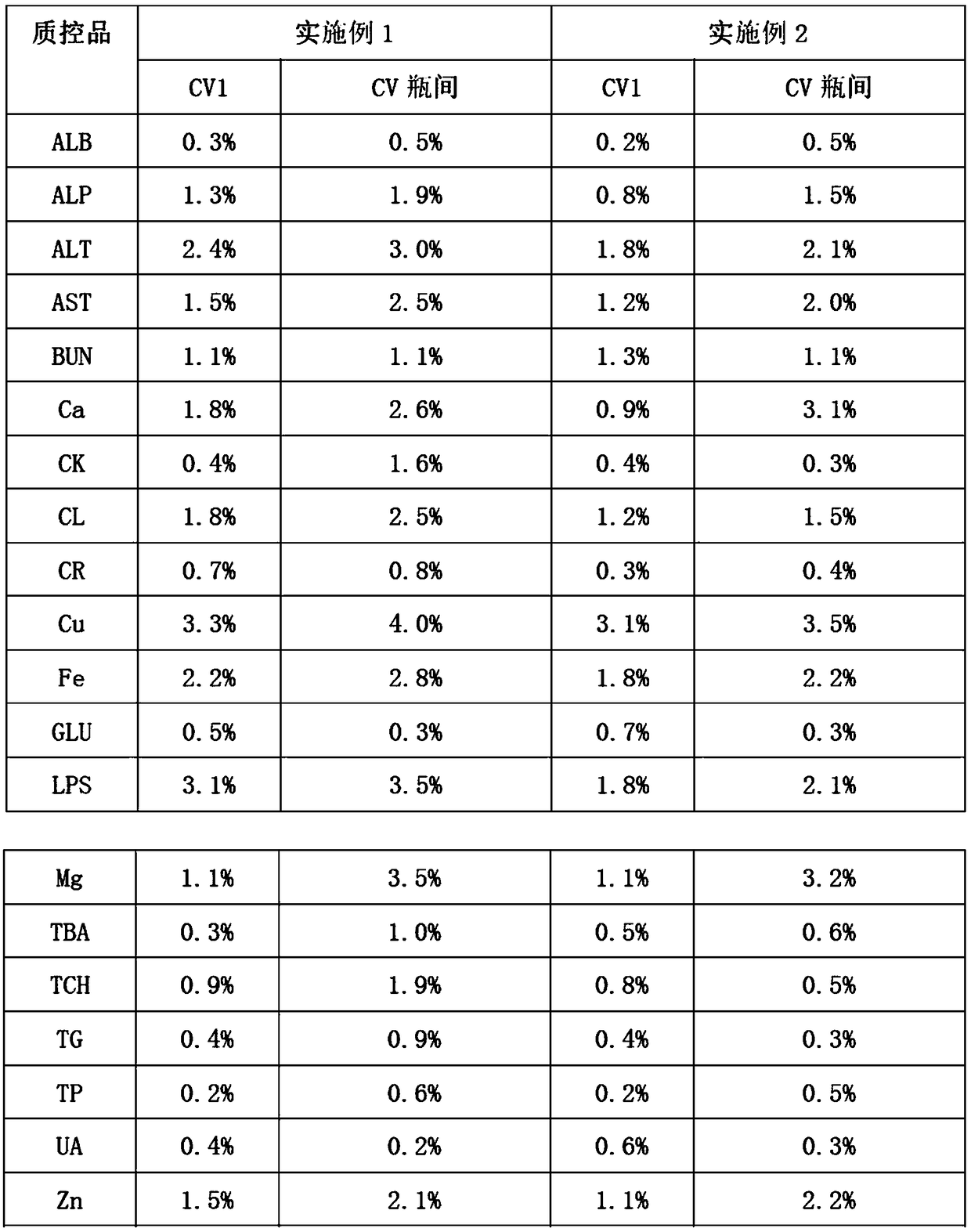

Preparation method of quality control serum for quality control of centrifugal microfluidic chips

ActiveCN108152519ASufficient sourceEasy to getBiological testingFreeze-dryingMonopotassium phosphate

The invention discloses a preparation method of quality control serum for quality control of centrifugal microfluidic chips. The method comprises the following steps: adding 0.6 to 1.0 percent of cholesteryl sodium sulfate into bovine plasma, and adding 0.02 to 0.06 percent of monopotassium phosphate; sequentially adding 0.04 to 0. 08 percent of ammonium ferric sulfate dodecahydrate, 0.5 to 0.9 percent of calcium chloride, 0.2 to 0.6 percent of bitter salt, 0.6 to 1 percent of urea, 9 to 13 percent of sodium chloride, 0.01 to 0.03 percent of zinc vitriol, 0.01 to 0.03 percent of chalcanthite,0.06 to 0.2 percent of glycocholic acid, 2 to 4 percent of glucose, 0.03 to 0.06 percent of creatinine, 0.08 to 0.2 percent of uric acid, and 0.07 to 0.11 percent of triolein into water; uniformly mixing obtained solution; adding glycol, saccharose and triton X-100, and uniformly mixing; sequentially adding albumin bovine serum, sodium azide, alanine aminotransferase, aspartic transaminase, alkaline phosphatase, lipase and creatine kinase, uniformly mixing, and performing freeze drying. The method has the advantages that the source of the raw materials is sufficient, the raw materials are easyto get, possible matrix effect is furthest avoided, and precipitation of the raw materials is prevented.

Owner:NINGBO MEIKANG BAOSHENG BIOMEDICAL ENG

Liquid fertilizer containing humic acid and preparation method thereof

ActiveCN103804073AHigh content of active ingredientsAvoid easy cloggingFertilizer mixturesActive agentPotassium hydroxide

The invention provides a liquid fertilizer containing a humic acid. The liquid fertilizer containing the humic acid comprises the following components in parts by mass: 45-50 parts of water, 30-40 parts of monopotassium phosphate, 8-9 parts of potassium hydroxide, 20-35 parts of urea, 1-5 parts of heptahydrate, 2-5 parts of borate decahydrate, 0.5-1 part of ammonium molybdate tetrahydrate, 5-10 parts of potassium fulvate, 0.1-0.5 part of growth modifier, and 0.1-0.5 part of surfactants. The nitrogen, phosphorus and potassium content in each liter of the liquid fertilizer obtained by using the method disclosed by the invention is increased to 460g, the content of the humic acid can be up to 45g, no sediment is generated, the pipe is not easily blocked, the content of effective ingredients of the liquid fertilizer is greatly increased, and crop growth is facilitated.

Owner:黑龙江省禾森农业科技开发有限公司

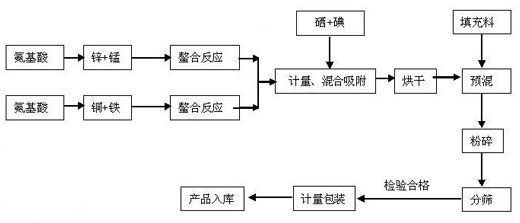

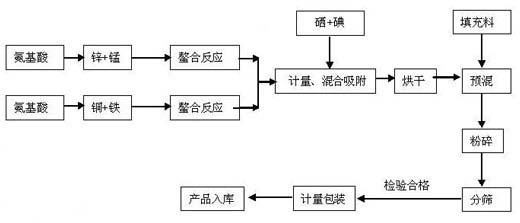

Amino acid chelating compound organic feed additive and production method thereof

ActiveCN102626180AHas a chelating effectImprove stabilityAnimal feeding stuffCompound organicFood additive

The invention discloses an amino acid chelating compound organic feed additive, which is characterized in that the amino acid chelating compound organic feed additive comprises the following raw materials in parts by weight: 0.5-2 of copper sulphate, 5-12 of zinc sulphate heptahydrate, 3-8 of manganese sulphate, 0.1-5 of ferrous sulphate heptahydrate, 10-50 of amino acid, 30-50 of calcium, 0.05-1 of trace elements, and 5-10 of filling material. The amino acid chelating compound organic feed additive disclosed by the invention has electric neutrality and more complete absorption; molecules can directly enter blood to be utilized for whole-body circulation through cell walls more smoothly; and the amino acid chelating compound organic feed additive has the advantages of steady chemical property, high biological value, low additive amount, good palatability, safety and high efficiency. The invention further discloses a production method of the amino acid chelating compound organic feed additive.

Owner:南宁市泽威尔饲料有限责任公司

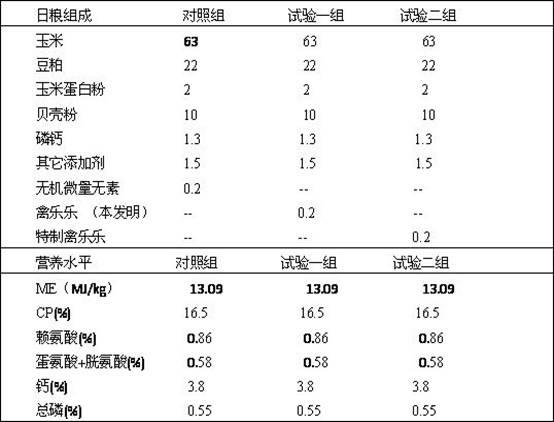

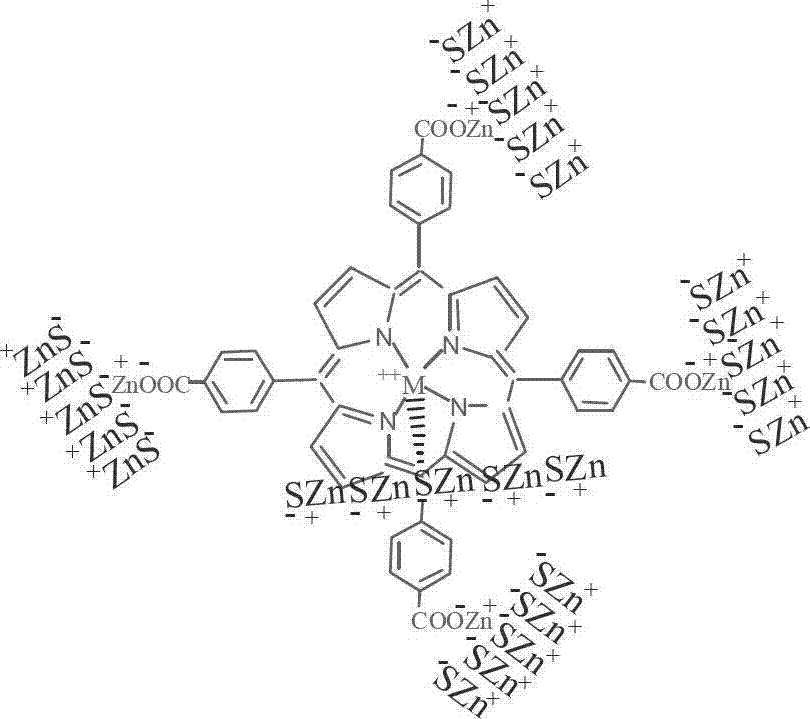

Nano zinc sulfide metalloporphyrin catalyst and preparation method and application thereof

InactiveCN102921463AIncrease conversions per passHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsOxygen compounds preparation by hydrocarbon oxidationPorphyrinRaw material

The invention discloses a nano zinc sulfide metalloporphyrin catalyst and a preparation method and application thereof. The method comprises the following steps of: reacting zinc vitriol and sodium sulfide to obtain zinc sulfide precipitation, and reacting the zinc sulfide and metalloporphyrin to prepare the nano zinc sulfide metalloporphyrin catalyst, wherein the catalyst comprises the the following main raw materials in parts by weight: 16.198 parts of zinc vitriol, 13.529 parts of sodium sulfide, 0.006 part of metalloporphyrin, 26.350 to 32.297 parts of organic solvent and a proper quantity of deionized water. The catalyst can be used for obviously improving the conversion per pass of cyclohexane and the yield of primary products, wherein the conversion rate of the cyclohexane is 72.9 percent, the turn over number of the catalyst is 9.4*105, and the yield of ketol is 27.0 percent. The catalyst can be repeatedly recycled, the preparation method is simple, the cost is low, the metalloporphyrin is less in quantity and easy to separate, and the catalyst is an ideal bionic industrial catalyst and has good economic benefits and social benefits.

Owner:GUANGXI UNIV

Sustained-release organic fertilizer special for peanuts and preparation method thereof

The invention provides a sustained-release organic fertilizer special for peanuts and a preparation method thereof. The sustained-release organic fertilizer special for the peanuts consists of lignin, diatomite, attapulgite, humic acid, calcium-based silicate mineral, a nitrogen fertilizer, a phosphate fertilizer, a potassic fertilizer, trace elements and water, wherein the trace elements consist of agricultural rare-earth, borax, ammonium molybdate, manganese sulfate and zinc sulphate heptahydrate; the sustained-release organic fertilizer special for the peanuts is prepared according to the preparation method of dissolving the components, stirring, mixing and granulating. The sustained-release organic fertilizer special for the peanuts has a reasonable formula; the utilization rate of the organic fertilizer as well as the yield and the oil yield of the peanuts is greatly improved by the synergistic effect of the components; meanwhile, the problems of eutrophication or nutrient deficiency symptoms of crops are solved; the taste of the peanuts is greatly improved; meanwhile, the problem of water body pollution caused by fertilizer loss is prevented effectively; the soil is improved; resources are saved; the cost is reduced; the preparation method is simple and meets the requirements on large-scale industrial production.

Owner:金华万里神农农业科技有限公司

Special fertilizer for paddy with unclosed glumes and production method thereof

ActiveCN101823912AImprove fertilizer retention and supply capacityImprove fertility levelsFertilizer mixturesPhosphateZINC SULFATE HEPTAHYDRATE

The invention belongs to a special fertilizer for paddy, in particular to a special fertilizer for paddy with unclosed glumes and a production method thereof. Unclosed glumes cause the reduced yield of the paddy and enormous economic loss. The special fertilizer for the paddy with unclosed glumes comprises the following components in parts by weight: 350-450 parts of organic fertilizer, 140-200 parts of potash magnesium sulphate fertilizer, 80-120 parts of monoammonium phosphate, 160-200 parts of urea and 10-30 parts of heptahydrate zinc sulphate. The production method comprises the following steps of: drying and crushing raw materials of the organic fertilizer; composting and fermenting the organic fertilizer; mixing an inorganic fertilizer; and pelleting, drying, cooling, screening and packing. The invention has the advantages of promoting the glumes of the paddy to close, improving the ripening rate and the yield of the paddy, having wide application range, easily obtained raw materials and easy production, being suitable for fields of paddy with the unclosed glumes all around the world, and improving the content of organic matters and the fertilizer retaining capability of the soil.

Owner:安徽莱姆佳生物科技股份有限公司 +1

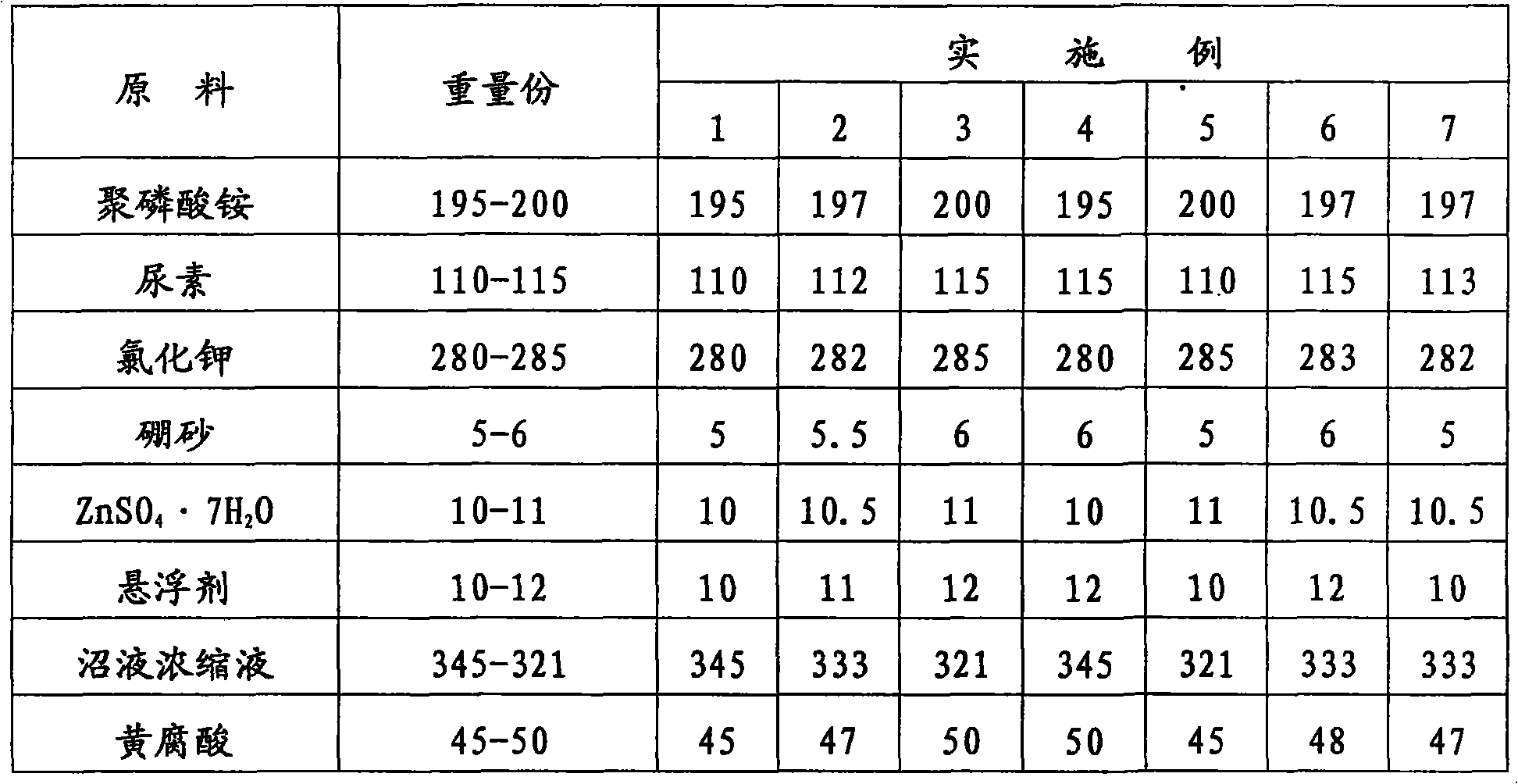

Maize fulvic acid polyelement composite liquid base fertilizer taking concentrated biogas slurry as base solution

InactiveCN101602626AOvercome secondary pollutionOvercome rationalityClimate change adaptationSewage/sludge fertilisersWater insolublePotassium

The invention relates to a maize fulvic acid polyelement composite liquid base fertilizer taking concentrated biogas slurry as a base solution, which is prepared from the following raw materials in portion by weight: 195 to 200 portions of ammonium polyphosphate, 110 to 115 portions of urea, 280 to 285 portions of potassium chloride, 5 to 6 portions of borax, 10 to 11 portions of heptahydrate zinc sulphate, 10 to 12 portions of suspending agent, 345 to 321 portions of the concentrated biogas slurry and 45 to 50 portions of fulvic acid. The liquid base fertilizer contains 352 to 368 g / L of macroelement, 53 to 57 g / L of the fulvic acid, and 11 to 21 g / L of water-insoluble matters; and the pH value of the fertilizer subjected to dilution by 250 times is 6.2 to 6.5. The production of the fertilizer comprises the following steps: comprehensive analysis of soil agricultural-chemistry characteristics, maize fertilization experiment, calculation of fertilizer proportion, selection of raw materials, material preparation, and mixing and preparation; and water is used for diluting the fertilizer by 200 times, and hole application is performed on the diluted fertilizer when hole sowing is performed on maize seeds at the same time, or the fertilizer is applied at a dosage of 65 kilogram / mu when water is irrigated to field. The fertilizer has no secondary pollution, and has reasonable and even application; and the invention provides a base fertilizer containing the macroelement, microelement and fulvic acid active substances to promote the growth and production increase of maize.

Owner:ZHEJIANG FORESTRY UNIVERSITY

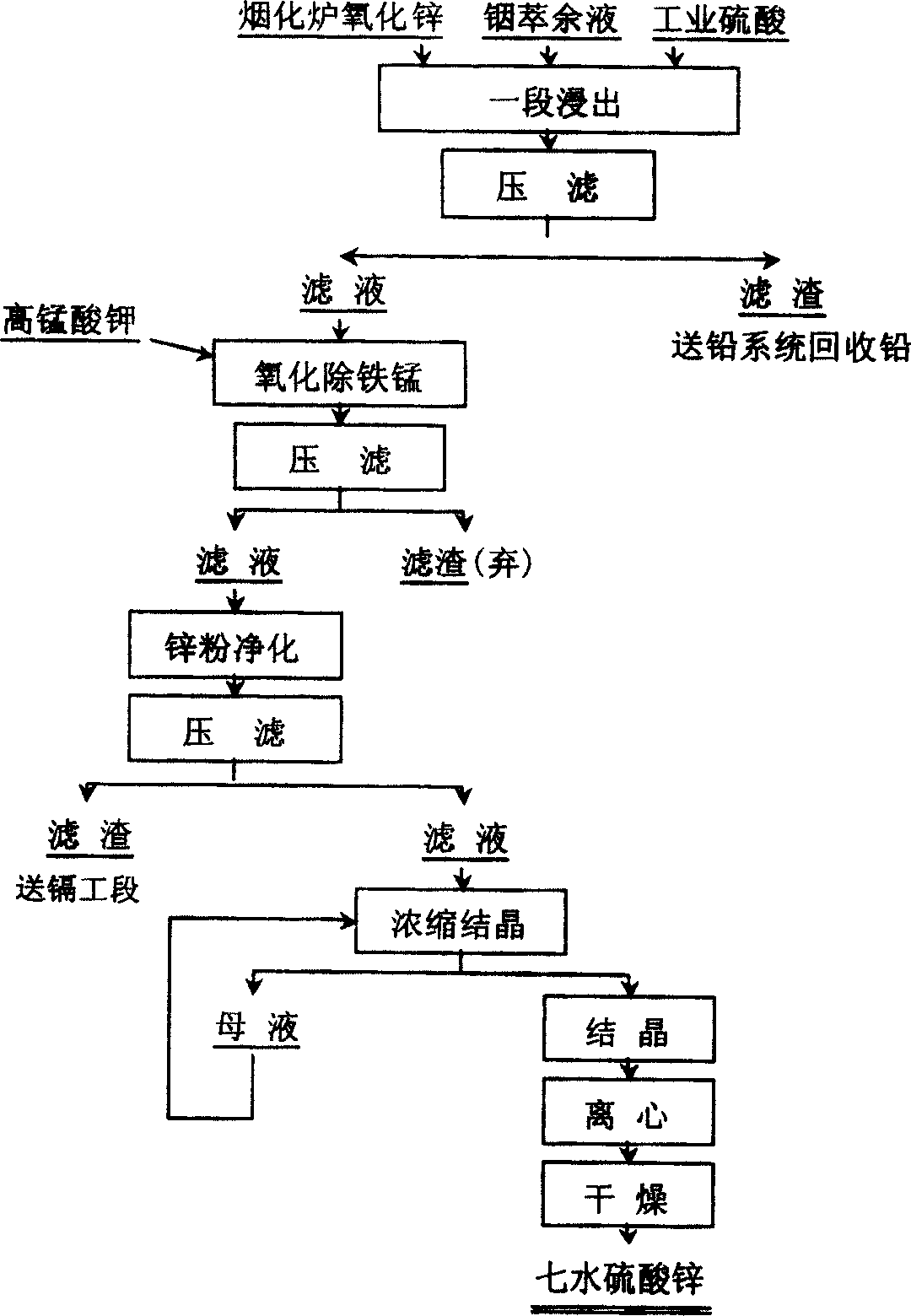

Method of producing zinc vitriol using indium extraction raffinate and zinc oxide

A process for preparing heptahydrated zinc sulfate from the residual liquid after extracting indium and zinc oxide includes such steps as preparing the extracting liquid from said residual liquid and sulfuric acid, heating, extracting zinc oxide while stirring, laying aside, filtering, oxidizing the filtrate by potassium permangnate for removing Fe and Mn, cleaning by using zn powder for displacement, concentrating, crystallizing, separating and drying.

Owner:株洲冶炼集团有限责任公司

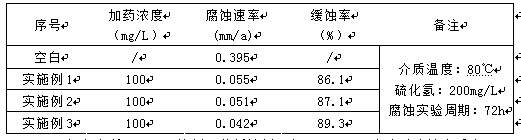

Water-soluble corrosion inhibitor for resisting hydrogen sulfide

ActiveCN103409122ADense filmImprove adsorption capacityBorehole/well accessoriesSodium molybdateHydrogen

The invention discloses a water-soluble corrosion inhibitor for resisting hydrogen sulfide, and relates to the technical field of chemical agent formulations for an oil field. The water-soluble corrosion inhibitor comprises the following materials in mass concentration: 20%-30% of heptadecyl ethoxyl imidazoline, 10%-20% of sodium benzoate, 5%-10% of zinc vitriol, 5%-10% of sodium molybdate and 30%-60% of water. The water-soluble corrosion inhibitor disclosed by the invention has the characteristics of small usage amount, low cost, no environment pollution, good protection effect in a water phase, good inhibition capacity on hydrogen brittleness caused by H2S, very good compatibility with the conventional chemical agent for the oil field, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Active medium trace element mineral fertilizer and preparation method thereof

InactiveCN103708918ASolve UtilizationImprove supply capacityFertilizer mixturesTrace elementZinc sulphate heptahydrate

The invention provides an active medium trace element mineral fertilizer, comprising the following components by weight: 75-90 parts of 150-250 mesh maifanite powder, 3-5 parts of 150-250 mesh calcium carbonate powder, 3-7 parts of 150-250 mesh magnesium sulfate powder, 0.5-1 part of 150-250 mesh borax powder, 0.5-2 parts of 150-250 mesh zinc vitriol powder and 3-8 parts of a bacterium liquid. The invention relates to the technical field of biological fertilizer and solves the problems that the medium trace elements are difficult to absorb and use by plants and utilization rate is low in the prior art. The invention also provides a preparation method of the active medium trace element mineral fertilizer, and solves the production problem of the active medium trace element mineral fertilizer.

Owner:SHANDONG JINKE TIANYUAN BIOLOGICAL FERTILIZER

Crop universal base fertilizer containing secondary and minor elements and preparation method thereof

InactiveCN105084983AMeet normal growth needsStrong stress resistanceFertilizer mixturesMinor elementPhosphate

The invention discloses a crop universal base fertilizer containing secondary and minor elements and a preparation method thereof. The base fertilizer comprises the following raw materials in parts by weight: 18-24 parts of urea, 30-35 parts of monoammonium phosphate, 45-50 parts of polyhalite, 0.4-0.6 part of boric fertilizer and 0.8-1.0 part of zinc fertilizer. The boric fertilizer is sodium borate, and the zinc fertilizer is white vitriol. The preparation method comprises the following steps: carrying out physical crushing, screening and metering on the obtained raw materials, proportionally and thoroughly mixing in a stirrer to obtain a product, and carrying out metered packaging to obtain the finished product. The fertilizer contains the nitrogen, phosphorus and potassium, and also contains rich calcium, magnesium and other secondary and minor elements. When being used as a base fertilizer, the fertilizer can satisfy the demands for nutrients in the whole crop growth period, enhance the stress tolerance and immunity and increase the crop yield.

Owner:HEFENGRUI SUZHOU AGRI TECH DEV CO LTD

Water culture and planting method for selenium-rich lettuces

InactiveCN108739328AIncrease production capacityImprove qualityMagnesium fertilisersGrowth substratesCalcium nitrate tetrahydrateNutrient solution

The invention belongs to the technical field of fruit planting, and particularly relates to a water culture and planting method for selenium-rich lettuces. A water culture technology is adopted, a seedling culture substrate is prepared by mixing Chinese medicine residues, perlite and vermiculite according to the ratio of 2: 1: 1, seeds are sown in seedling culture plates, seedlings are inserted inplanting cups, a formula nutrient solution is supplemented for the lettuces in a growth period, growth of buds and absorption to other fertilizer microelements can be accelerated, and thus, the high-yield and high-quality selenium-rich lettuces are obtained. The formula nutrient solution consists of calcium nitrate terahydrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ferrous sulfate heptahydrate, disodium ethylene diamine tetraacetate, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, cupric sulfate pentahydrate, ammonium molybdate and sodium selenate; and the pH value is 6.0-6.5.

Owner:广东日可威富硒食品有限公司

Blueberry organic fertilizer utilizing waste and preparation method thereof

The invention discloses blueberry organic fertilizer utilizing waste and a preparation method thereof. The blueberry organic fertilizer is prepared from 45-55 parts by weight of wheat straw, 24-36 parts by weight of biogas residue, 20-30 parts by weight of golden mushroom slag, 16-24 parts by weight of bean hull powder, 12-18 parts by weight of chestnut shell powder, 9-13 parts by weight of humic acid, 8-10 parts by weight of phosphogypsum, 6-8 parts by weight of red bed rock, 5-6 parts by weight of ferrous sulfate, 4-5 parts by weight of monopotassium phosphate, 3-5 parts by weight of zinc sulphate heptahydrate, 3-5 parts by weight of copper sulfate pentahydrate, 3-4 parts by weight of monoammonium phosphate, 2-3 parts by weight of JT composite bacteria, 9-11 parts by weight of a soil conditioner and a proper amount of water. The blueberry organic fertilizer is prepared from waste such as wheat straw, biogas residue and golden mushroom slag as main raw materials so that the blueberry organic fertilizer provides a virtuous cycle use approach for solving the problem that the agricultural and industrial production waste pollutes the environment. Through use of wheat straw, fungus slag and phosphogypsum as fertilizer additives, the high-quality nuisance-free organic fertilizer can be provided. The blueberry organic fertilizer is conducive to environmental protection, solves waste problems for production enterprises, realizes waste recycling and realizes harmonious coexistence of human and environment.

Owner:ANHUI RIRICHUN AGRI DEV

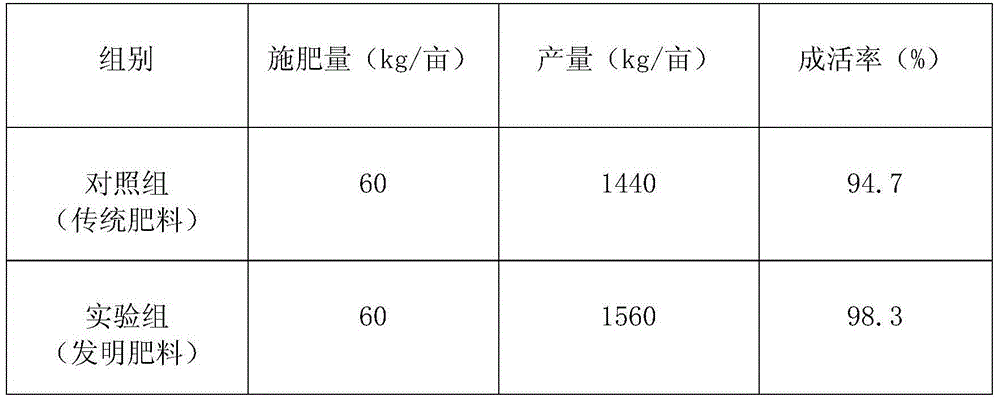

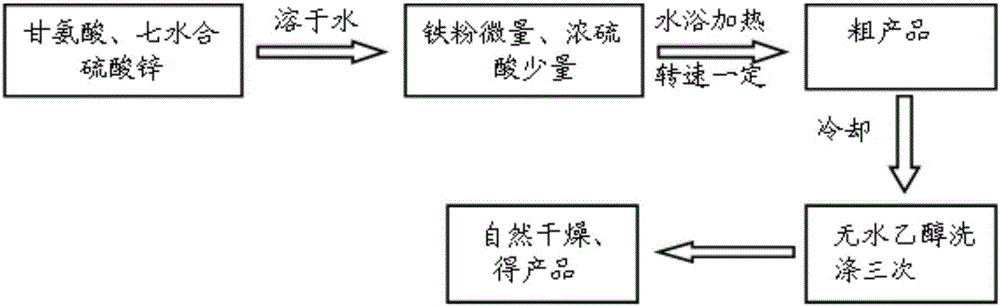

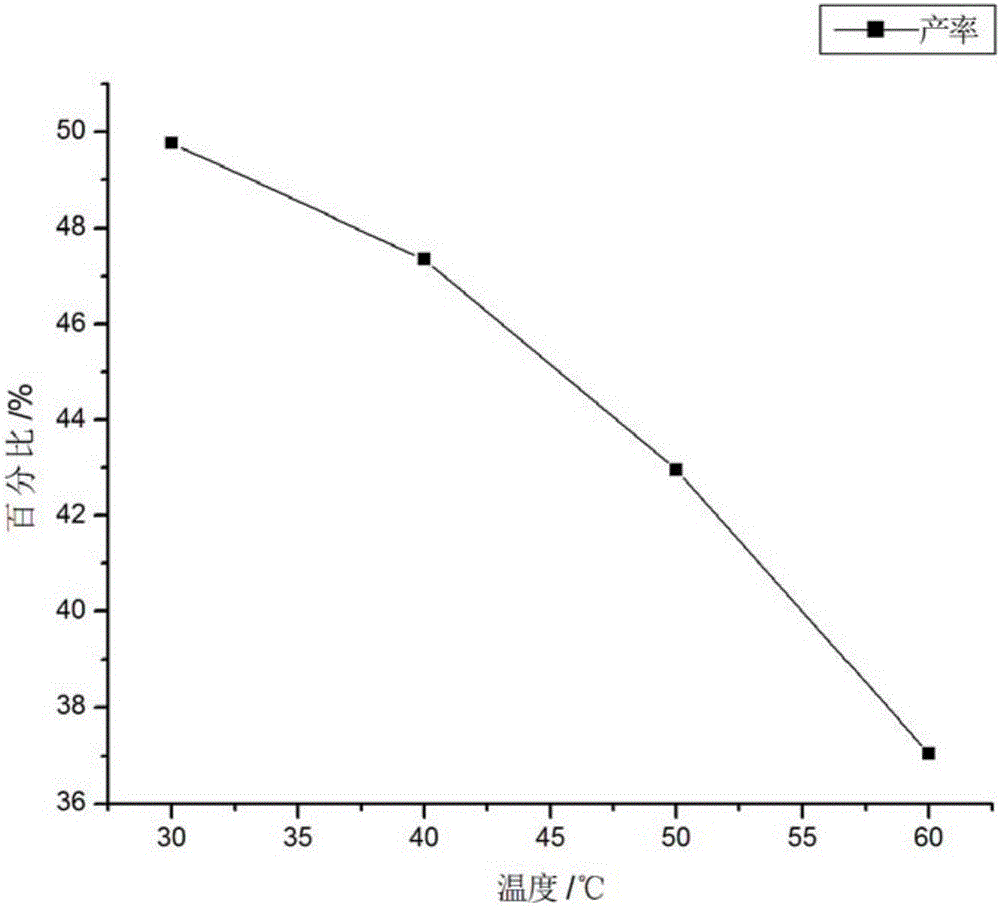

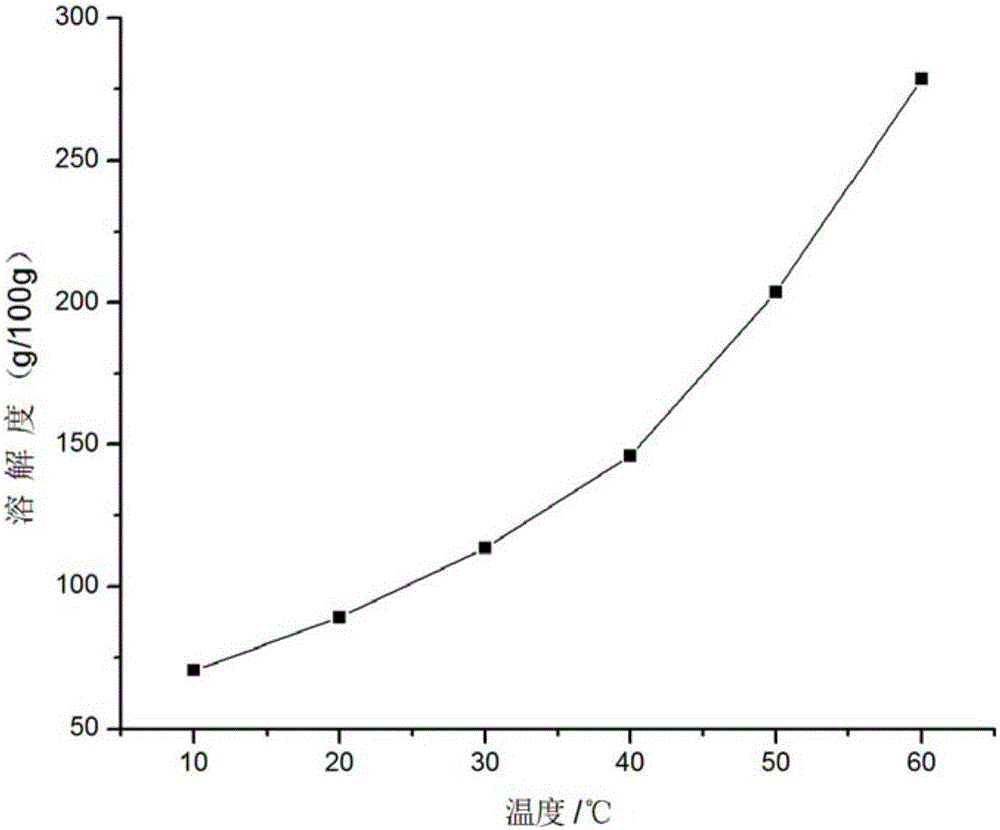

Preparation method of glycine zinc complex

ActiveCN106187796AHigh yieldShorten the timeOrganic compound preparationAmino-carboxyl compound preparationGlycineIron powder

The invention provides a preparation method of a glycine zinc complex. The preparation method comprises the steps of dissolving glycine and zinc sulfate heptahydrate into water, adding a small amount of iron powder and multiple drops of concentrated sulfuric acid, rotationally reacting at 70-90 DEG C, cooling to a temperature of 50-65 DEG C, carrying out crystallization and suction filtration to obtain crystalline solids, washing the crystalline solids for several times with absolute ethyl alcohol, and naturally airing, so as to obtain the glycine zinc complex. According to the preparation method, the crystallization temperature is 50-65 DEG C and is 25 DEG C higher than that of an existing method, so that the time consumed in a cooling crystallization process is shortened, and the cooling energy consumption is reduced; and meanwhile, the glycine zinc complex prepared by virtue of the preparation method is high in yield and contains a small amount of crystal water, and the subsequent drying energy consumption is low.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

Nucleotide-containing fertilizer and preparation method thereof

ActiveCN103708891AFertilizer effect lasts for a long timeReduce workloadFertilizer mixturesSulfate zincNucleotide

The invention discloses a nucleotide-containing fertilizer. The nucleotide-containing fertilizer is prepared from the following components in parts by weight: 90-110 parts of nucleotide, 95-110 parts of potassium chloride, 170-185 parts of monoammonium phosphate, 15-25 parts of ammonium bicarbonate, 240-260 parts of ammonium sulfate, 250-270 parts of urea, 35-45 parts of boron calcium powder, 40-60 parts of amino acid, 3-8 parts of zinc sulfate heptahydrate and 3-8 parts of water-soluble silicone. The preparation method comprises the following steps: mixing and smashing water-soluble silicone, monoammonium phosphate, ammonium bicarbonate, ammonium sulfate, urea and boron calcium powder in proportion, uniformly stirring, adding water for dissolving to obtain a mixed solution; after adding nucleotide, amino acid, zinc sulfate heptahydrate and water-soluble silicone in the mixed solution, stirring uniformly, carrying out rotary pelleting, and drying to produce a finished product. The nucleotide-containing fertilizer has the advantages of being lasting in fertilizer efficiency, improving the rate of emergence, promoting the growth of seedlings, improving the yield and the like.

Owner:SHENYANG SIXIONGDI FERTILIZER

Soil conditioner for repairing soda type saline-alkali soil as well as preparation method and use method thereof

InactiveCN108753308AIncrease the amount of substitutionImprove buffering effectCalcareous fertilisersOther chemical processesPorosityPhosphate

The invention belongs to the technical field of soil improvement, and particularly relates to a soil conditioner for repairing soda type saline-alkali soil as well as a preparation method and a use method thereof. The soil conditioner for repairing the soda type saline-alkali soil is prepared from furfural residues, composted organic fertilizer, an organic material, brown sugar, zeolite powder, lignite powder, calcium chloride, aluminum sulfate, potassium sulfate, ardealite, monoammonium phosphate, heptahydrate and cation exchange resin. Organic improvement and inorganic improvement are efficiently combined, so that the physical and chemical properties of the soda type saline-alkali soil are improved, the PH value and the salt content are reduced, the harm of alkali-causing ions is relieved, the soil substitution amount and the soil buffer property are improved, and the soil improvement and alkali reduction effects are good; the content of organic matters in the soil is increased to improve the physical property of the soil, increase the porosity of the soil, prevent and treat hardening of the soil and improve the breathability of the soil; meanwhile, the soil fertility of the sodatype saline-alkali soil is improved; the soil conditioner can be applied to soil of both a dry farmland and a paddy field and cooperates with conventional fertilization to promote growth of plants and increase the yield of crops.

Owner:黑龙江省安心土壤肥料研究院

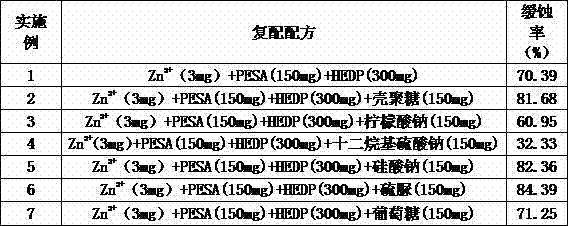

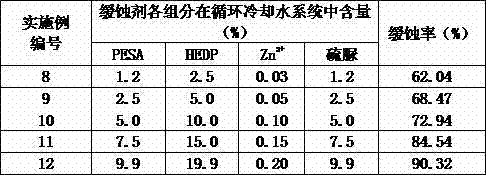

Compound corrosion inhibitor and application of compound corrosion inhibitor in carbon steel material circulating cooling water system

The invention discloses a compound corrosion inhibitor and application of the compound corrosion inhibitor in a carbon steel material circulating cooling water system, and relates to the technical field of corrosion prevention in the cooling liquid used for all circulating cooling in smelting production. The compound corrosion inhibitor consists of polyepoxysuccinic acid, zinc vitriol, hydroxy ethidene diphosphonic acid and thiourea. The compound corrosion inhibitor is mixed into circulating cooling liquid to form a circulating cooling water system, and the circulating cooling is carried out with a carbon steel material. According to the compound corrosion inhibitor and the application thereof, the oneness of the collocation of whole organic phosphorus salt formula is avoided, and the collocation of surfactant thiourea and green and environment-friendly organic phosphorus salt is selected, so that synergistic effect among medicaments can be preferably played, the inhibition rate can reach above 90%, the biological degradability is good, the price is low and the materials are easy to obtain.

Owner:YANGZHOU UNIV

Method for preparing industrial ferrous sulfate and zinc sulfate by using pyrite cinders

The invention provides a method for preparing industrial ferrous sulfate and zinc sulfate by using pyrite cinders. The method comprises the following steps of: fully reacting the pyrite cinders with excessive sulfuric acid, filtering to obtain a mixed solution I containing sulfuric acid, ferrous sulfuric, cuprous sulfate and zinc sulfate, and a lead-containing filter cake; adding an appropriate amount of ferrous hydroxide into the mixed solution I for neutralizing the excessive sulfuric acid; distilling the solution under a reduced pressure into a saturated ferrous sulfate solution, cooling the saturated ferrous sulfate solution to 25 DEG C until the ferrous sulfate is supersaturated, separating a large quantity of crystals out, and filtering to obtain a ferrous sulfate filter cake and a mixed solution II containing cuprous sulfate pentahydrate, zinc sulphate heptahydrate and a small amount of ferrous sulfates; washing, drying and smashing the ferrous sulfate filter cake to obtain a ferrous sulfate product; heating the mixed solution II to 30-40 DEG C, precipitating zinc sulfate in a form of zinc sulfate heptahydrate crystals, and filtering to obtain zinc sulfate heptahydrate crystals and a mixed solution III containing copper sulfate and ferrous sulfate; and washing, drying and smashing the zinc sulfate heptahydrate crystals to obtain a zinc sulfate crystal product.

Owner:张胜勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com