Method of comprehensively recycling valuable metals in plating sludge

A technology for electroplating sludge and valuable metals, applied in the direction of improving process efficiency, etc., can solve the problems of high sealing and corrosion resistance requirements of leaching devices, low leaching rate, lengthy separation process, etc., and achieve significant economic benefits and social benefits, process conditions are easy to control, and the effect of strong process versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

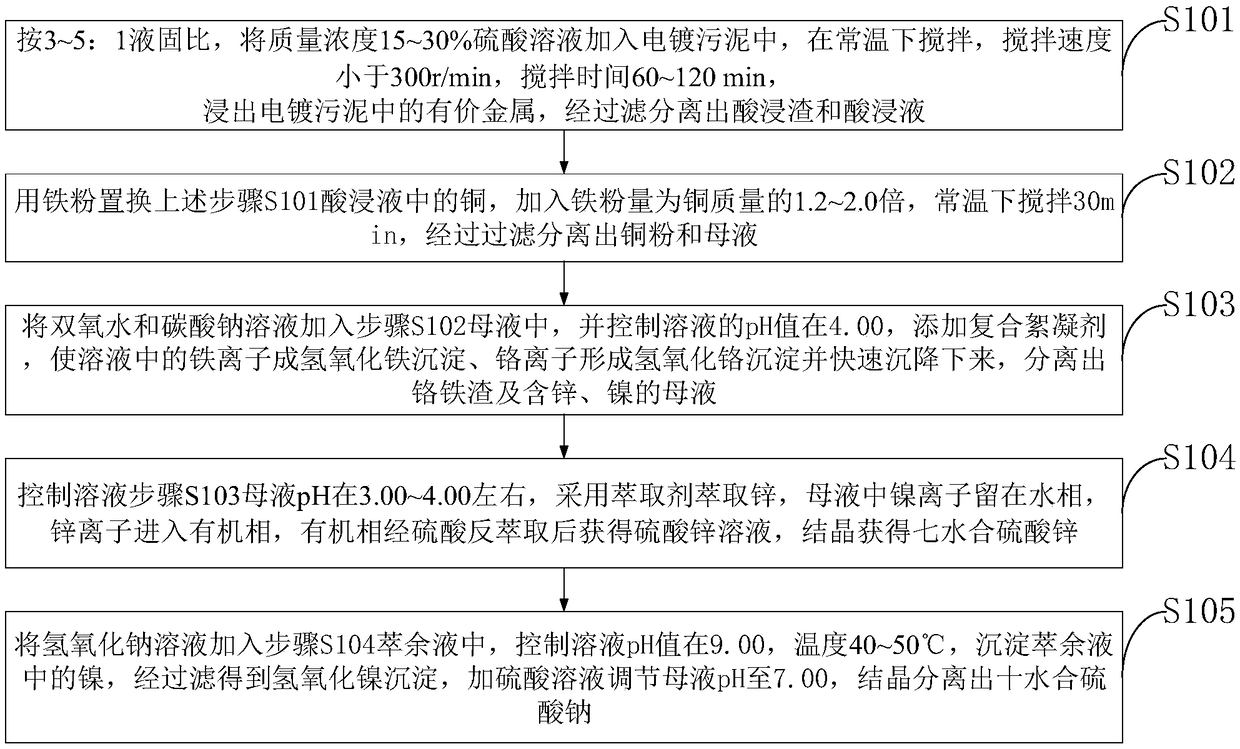

Method used

Image

Examples

Embodiment 1

[0053] The method for the comprehensive recovery of valuable metals in the electroplating sludge provided by the embodiments of the present invention includes:

[0054] (l) 800g of electroplating sludge wet material with a moisture content of 70% (containing Ni 4.07% by dry weight; Cu 3.57%; Cr2.60%; Zn 1.6%; Fe 15.56%) was added to 600mL with a mass concentration of 30% The sulfuric acid solution was stirred at room temperature for 90 minutes, filtered, and the acid leaching solution was processed in the next step; the acid leaching slag was washed, and the washing solution was concentrated and treated uniformly, and the leaching slag was solidified after washing.

[0055] (2) Add 800mL of pickling solution obtained in step (1) to 1.6 times the iron filings of the copper powder mass, stir at room temperature for 30 minutes, filter, and the mother liquor enters the next step for processing; the filter residue is washed with water, and the washing solution is concentrated and pr...

Embodiment 2

[0061] The method for the comprehensive recovery of valuable metals in the electroplating sludge provided by the embodiments of the present invention includes:

[0062] (1) Add 400g of dry electroplating sludge raw material (containing Ni 4.40%; Cu 5.62%; Zn 2.76%; Cr 2.56%; Fe5.83%) to 1350mL mass concentration of 25% dilute sulfuric acid solution, and stir at room temperature for 120min, Filtration, the pickling solution enters the next step of treatment; the pickling residue is washed with water, the washing solution is concentrated and treated uniformly, and the washed leaching residue is solidified.

[0063] (2) 1000mL pickling solution that step (1) obtains is added 1.4 times iron filings of copper powder quality, under normal temperature stirring reaction 45min, filter, and mother liquor enters next step processing; Filter residue is washed, and filter residue is 22.3g copper powder, The washing water is concentrated and treated uniformly.

[0064] (3) 15% sodium carbo...

Embodiment 3

[0069] The method for the comprehensive recovery of valuable metals in the electroplating sludge provided by the embodiments of the present invention includes:

[0070](1) 400g of dry electroplating sludge raw material (containing Ni 6.58%; Cu 7.35%; Zn 1.36%; Cr 1.83%; Fe8.63%) was added into 1350mL mass concentration of 25% dilute sulfuric acid solution, stirred at room temperature for 120min, Filtration, the pickling solution enters the next step of treatment; the pickling residue is washed with water, the washing solution is concentrated and treated uniformly, and the washed leaching residue is solidified.

[0071] (2) Add the 1000mL pickling liquid obtained in step (1) to 1.6 times the iron filings of the copper powder quality, stir and react for 30min at room temperature, filter, and the mother liquor enters the next step for processing; the filter residue is washed, and the filter residue is 29.2g as copper powder , and the washing liquid is concentrated and processed u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com