Maize fulvic acid polyelement composite liquid base fertilizer taking concentrated biogas slurry as base solution

A corn fulvic acid, multi-compound technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems that have not been found yet, and achieve the effect of promoting growth and increasing production, overcoming secondary pollution, and reasonable matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

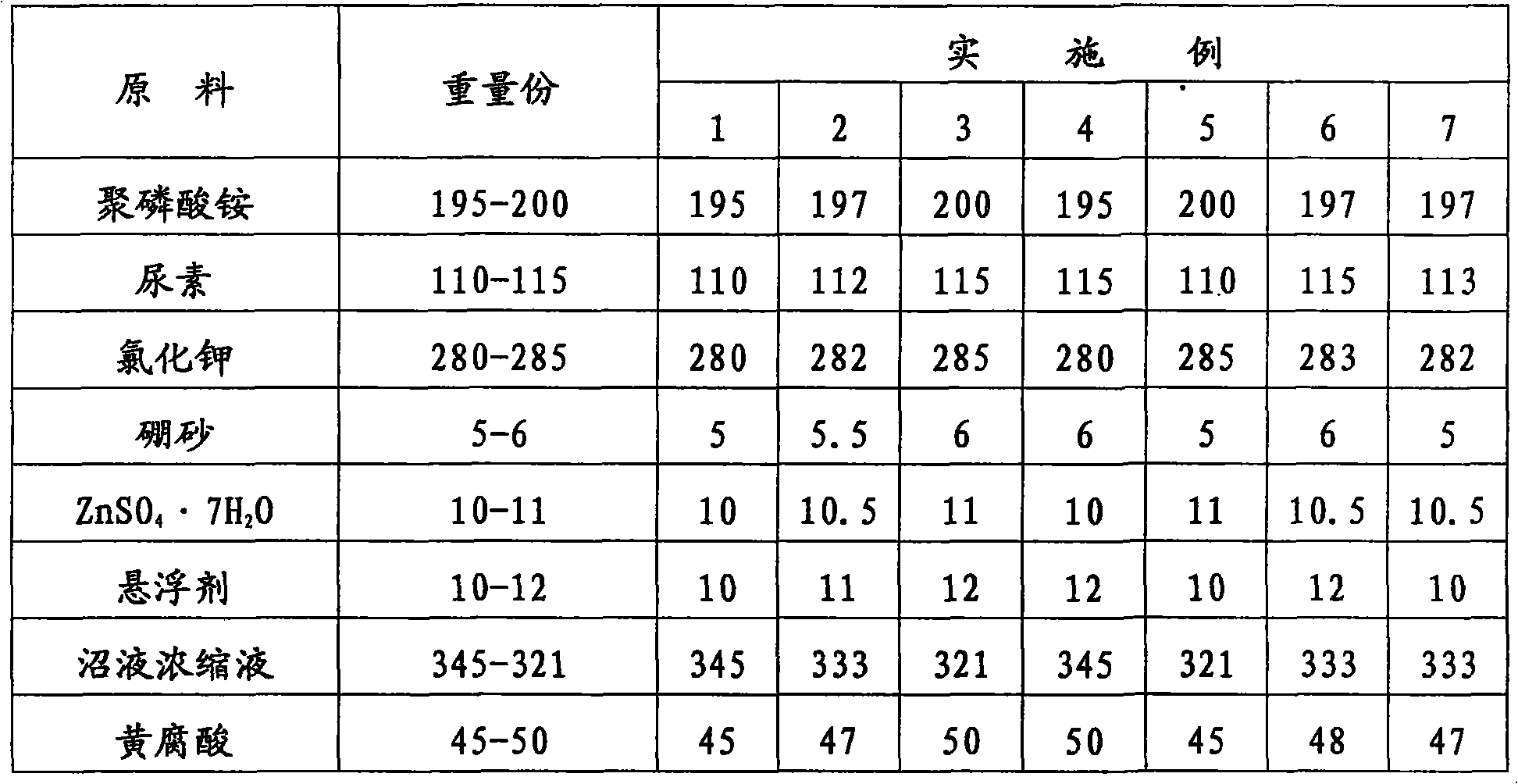

[0022] Embodiment 1 (referring to the corresponding raw materials and parts by weight of Embodiment 1 in Table 2): Pour 345 parts of biogas slurry concentrates into the mixing tank, add 10 parts of suspending agent, stir for 5 minutes, leave standstill for 5 hours, and stir while stirring Add 110 parts of urea, 195 parts of ammonium polyphosphate, 280 parts of KCI, 5 parts of borax, 10 parts of ZnSO 4 ·7H 2 O, finally slowly add 45 parts of fulvic acid, stir well and serve.

[0023] All the remaining examples 2-7 are made with reference to the corresponding raw materials and parts by weight of Example 2-7 in Table 2, and are made in the same way as in Implementation 1, except that the stirring time of adding suspending agent in the biogas slurry concentrate is 5-10 minutes and it is considered uniform The degree of selection, the standing time is within 5-10 hours, depending on the suspension situation. Among the seven examples, examples 1, 2, and 3 are preferred.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com