Oil-containing high-concentration phenol-ammonia wastewater treatment device and process

A waste water treatment, high concentration technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of high energy consumption, high input cost, oily and high phenolic ammonia wastewater treatment effect Poor, environmental secondary pollution and other problems, to achieve the effect of strong sewage adaptability, good economic and social benefits, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

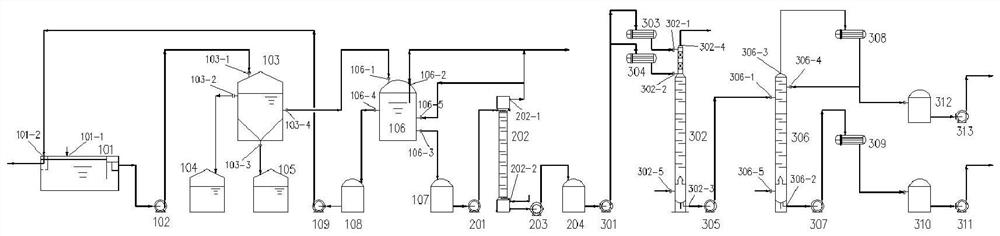

[0035] refer to figure 1 , a treatment device for oily and high-concentration phenol ammonia wastewater, comprising: an oil removal unit, a dephenolization unit, and a deacidification and ammonia distillation unit.

[0036] Wherein, the deoiling unit comprises a deoiling reaction tank 101, a deoiling waste water feed pump 102, a deoiling separation tank 103, a pre-extraction tank 106 and a deoiling water outlet tank 107 connected in sequence; the deoiling separation tank 103 is also connected with The light oil tank 104 is connected with the heavy oil tank 105; the pre-extraction tank 106 is also connected with the extraction layer treatment tank 108, the extraction layer reflux pump 109 and the oil removal reaction tank 101 in sequence.

[0037] The deoiling reaction tank 101 is provided with a demulsifier inlet 101-1 and an extraction layer reflux port 101-2; the deoiling separation tank 103 is provided with a tank top feed inlet 103-1, an upper light oil outlet 103-2, a bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com