Patents

Literature

42results about How to "Overcome unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

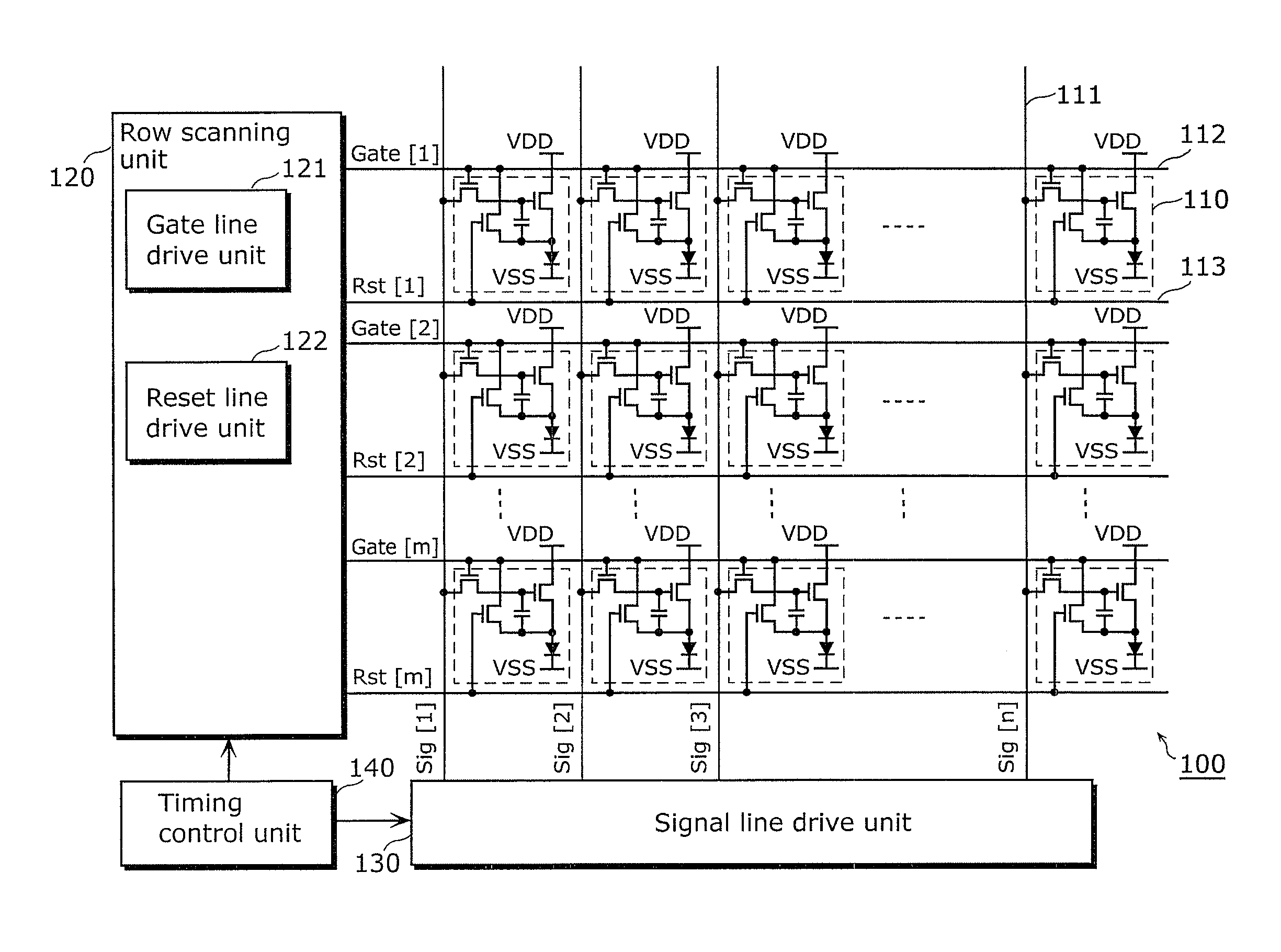

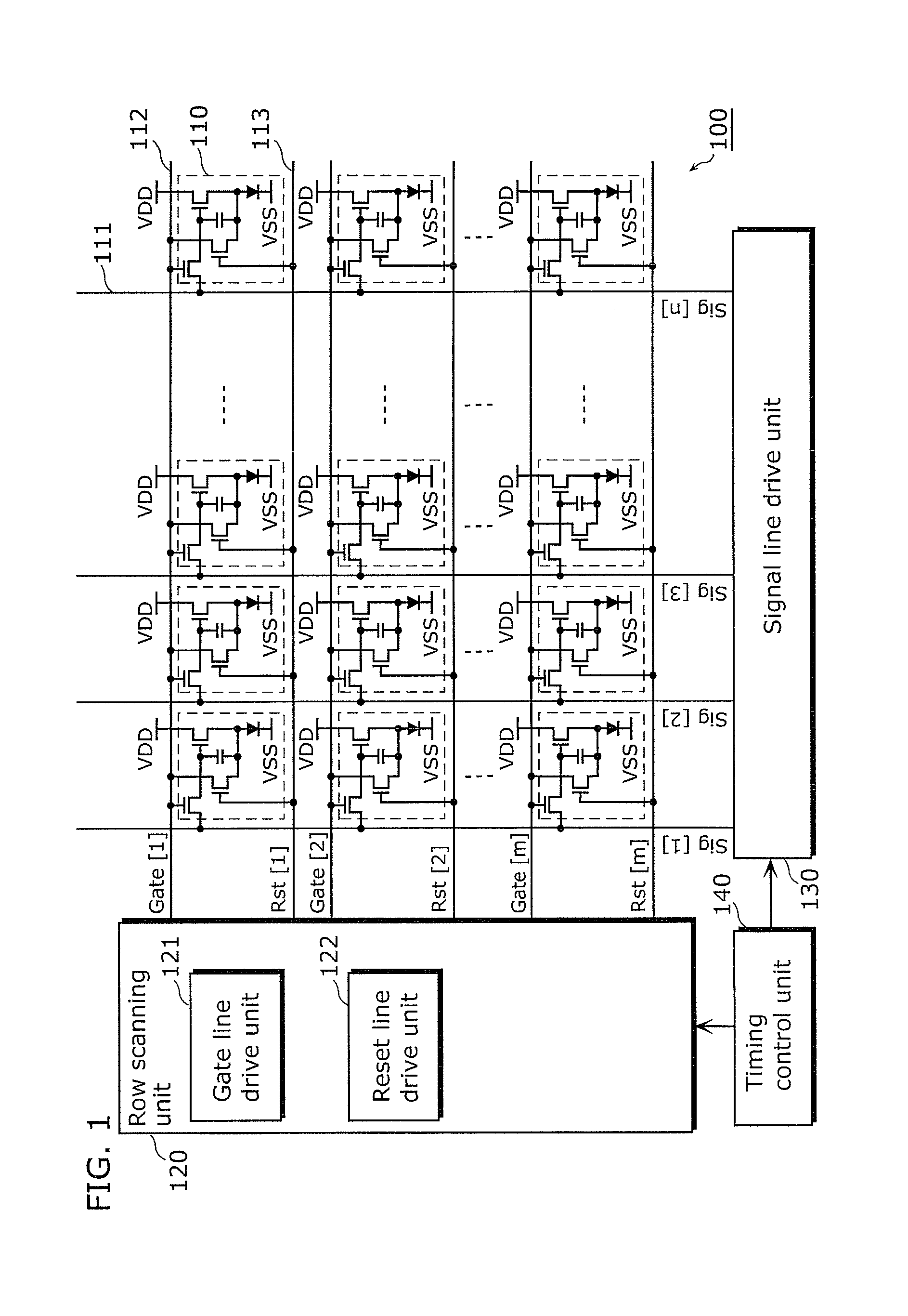

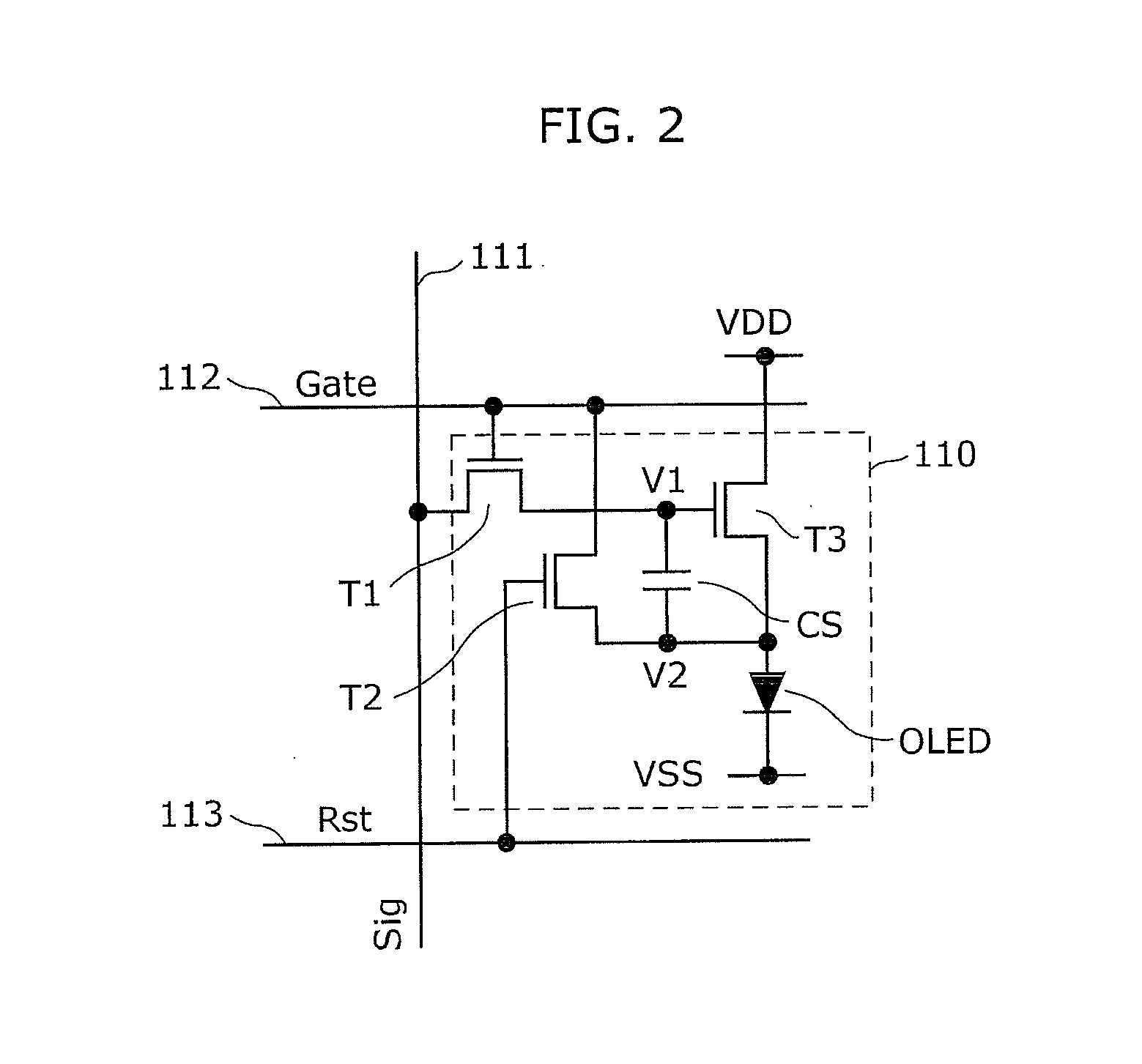

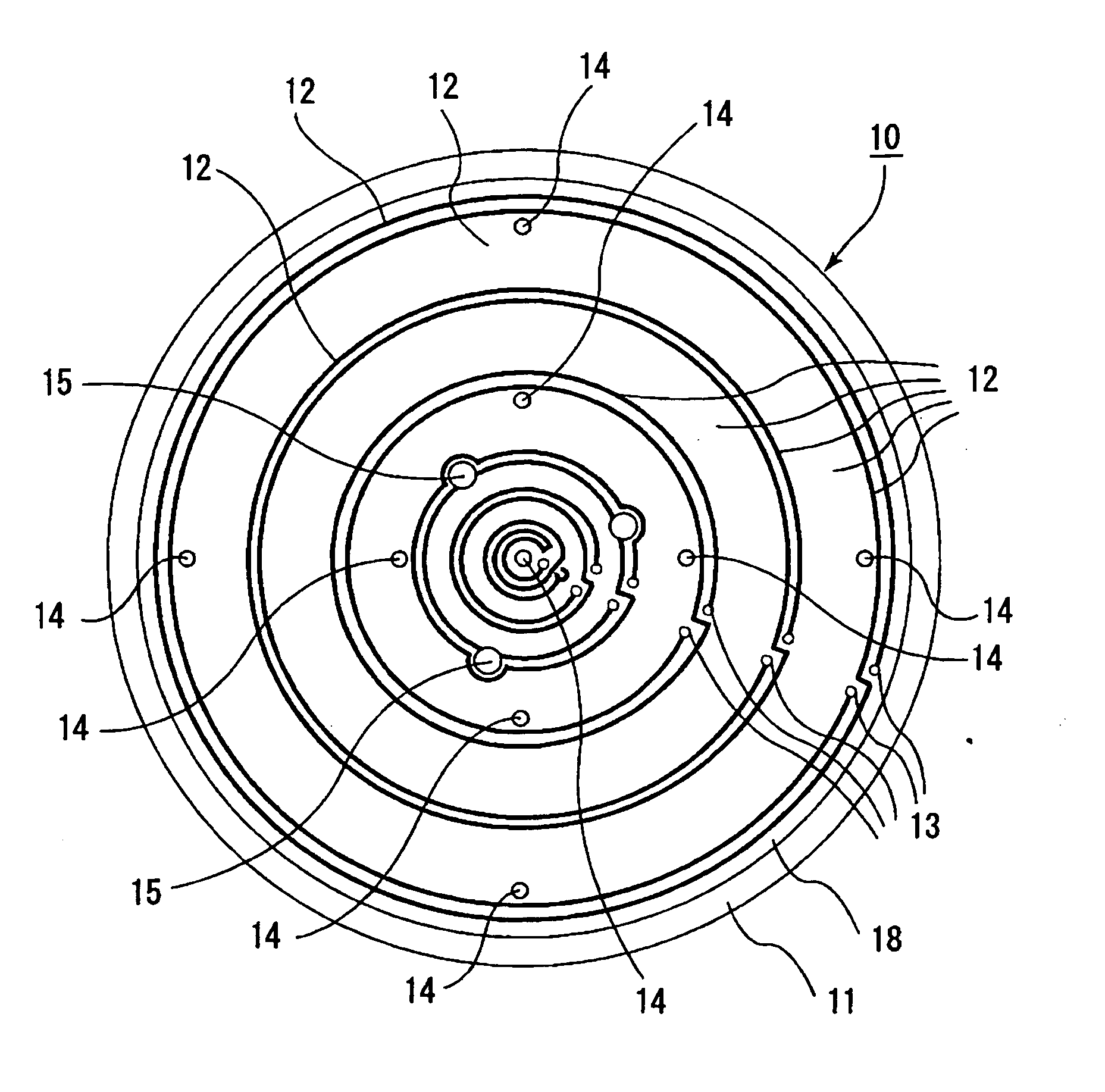

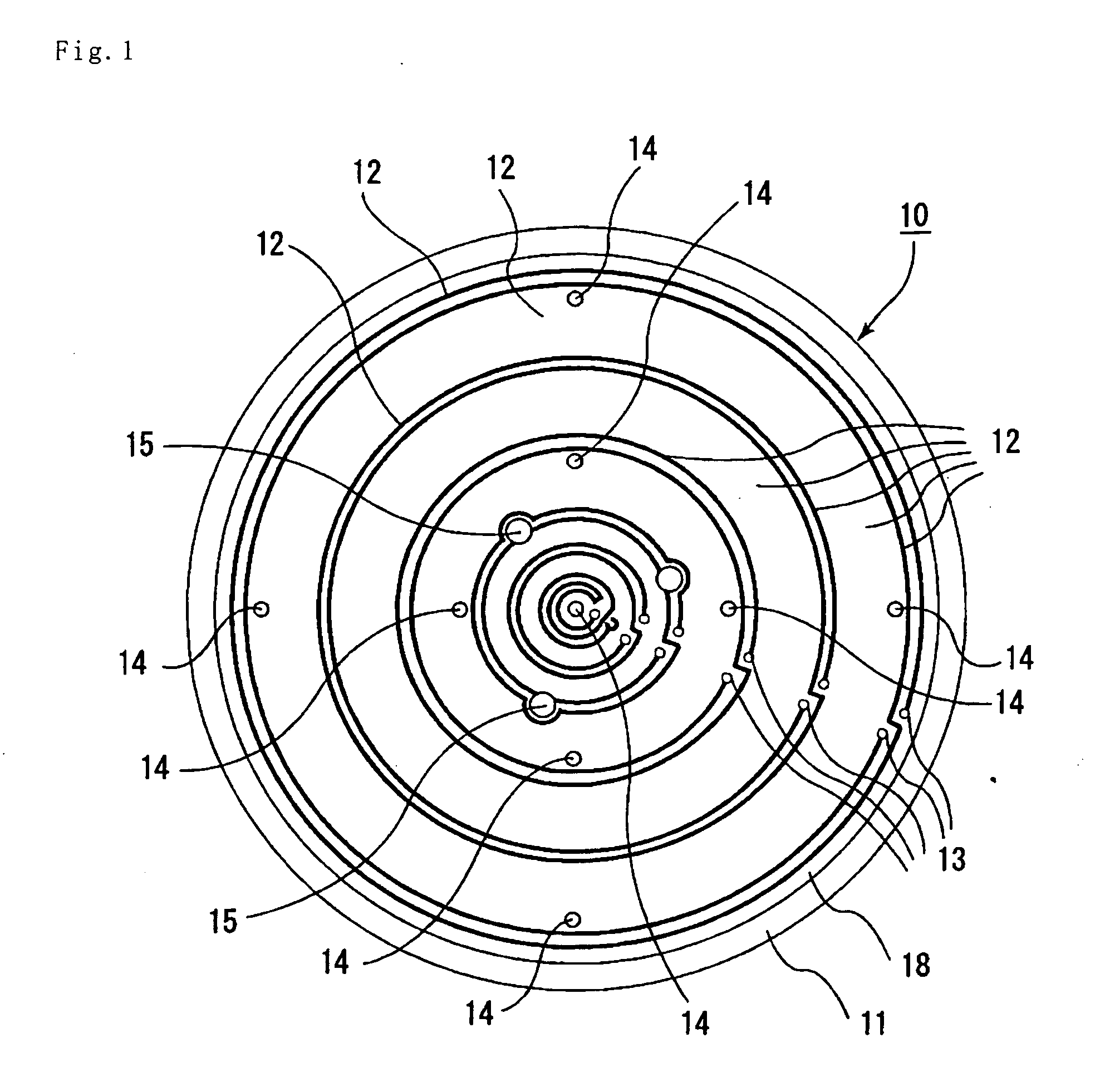

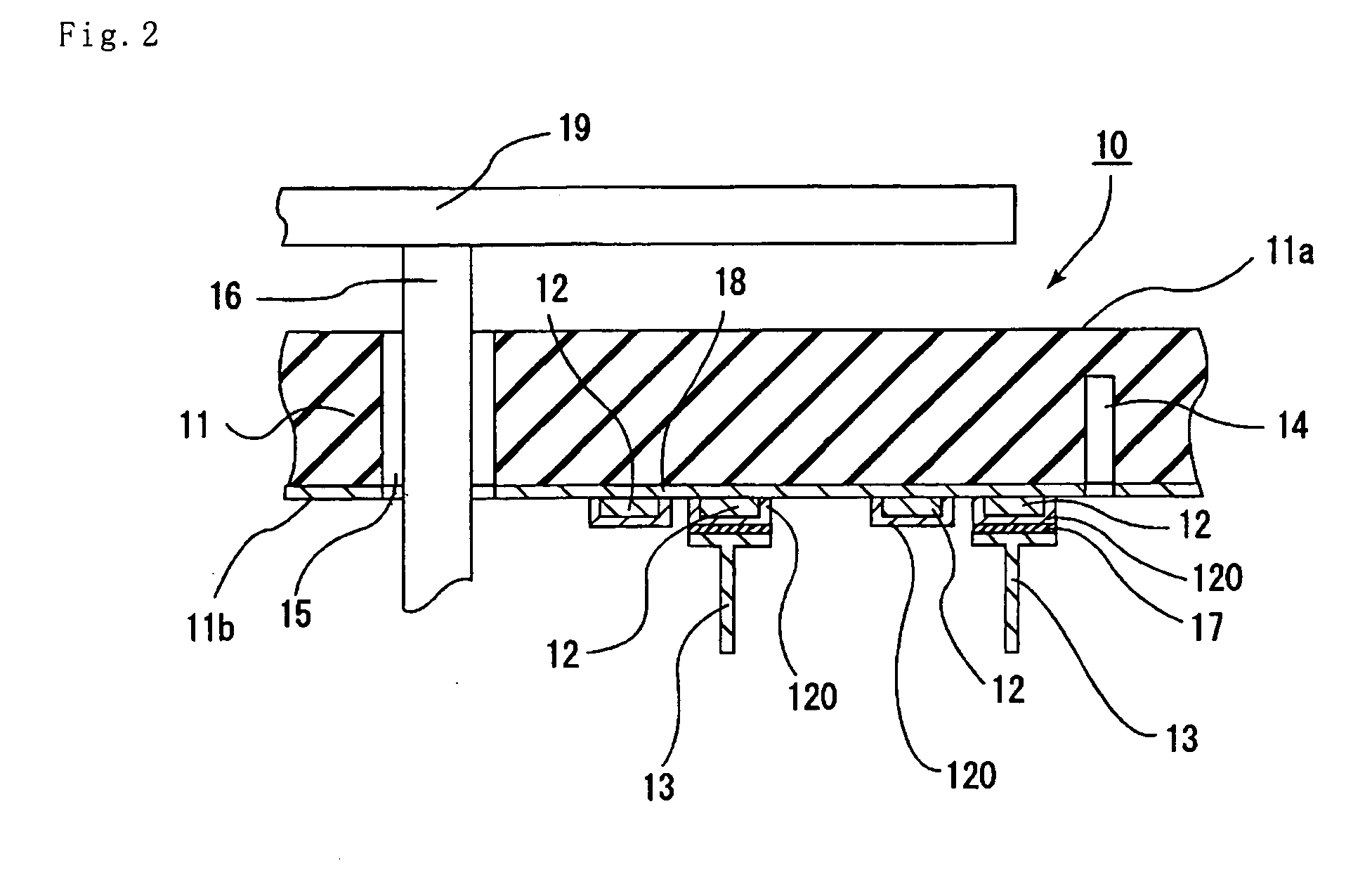

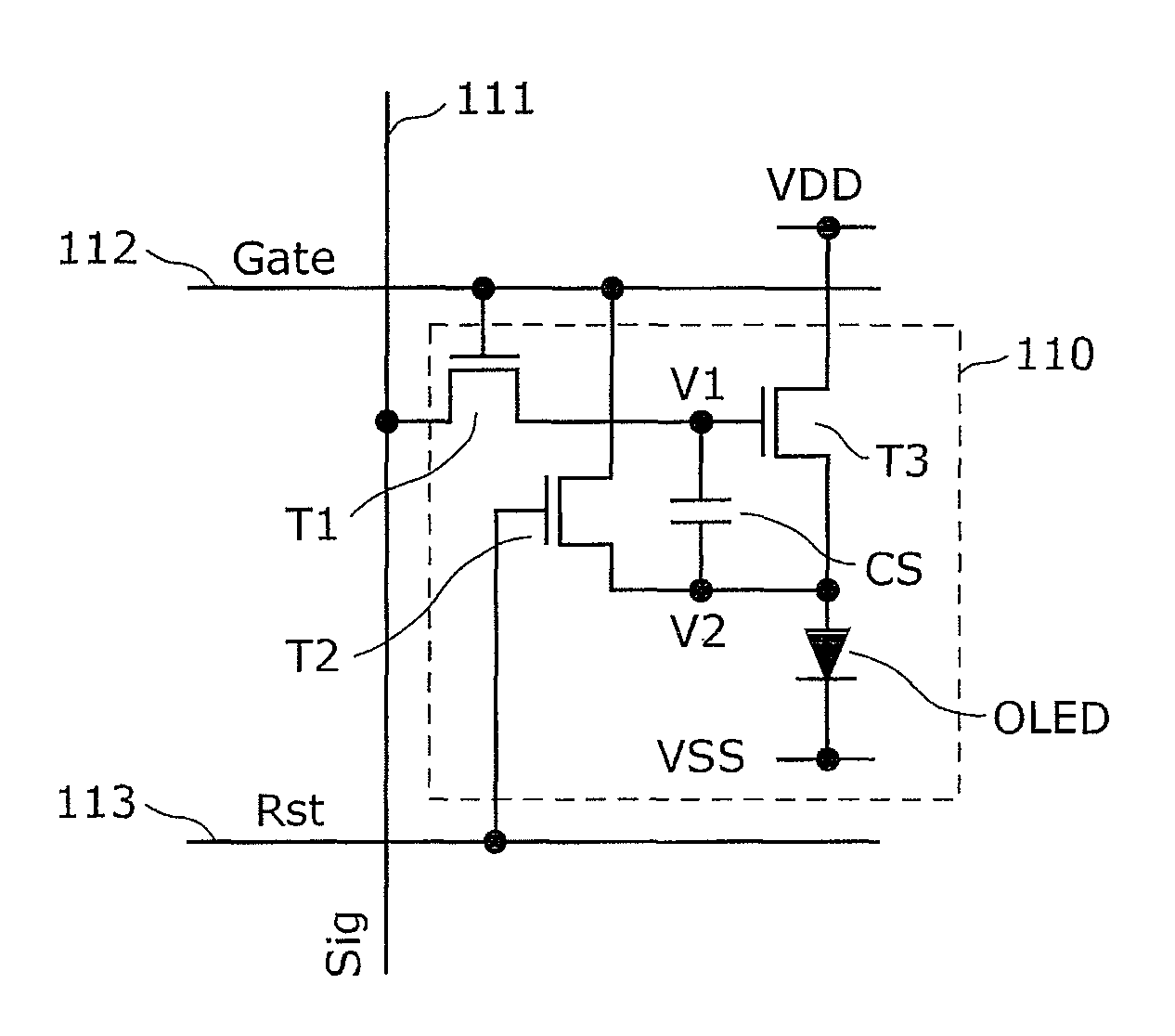

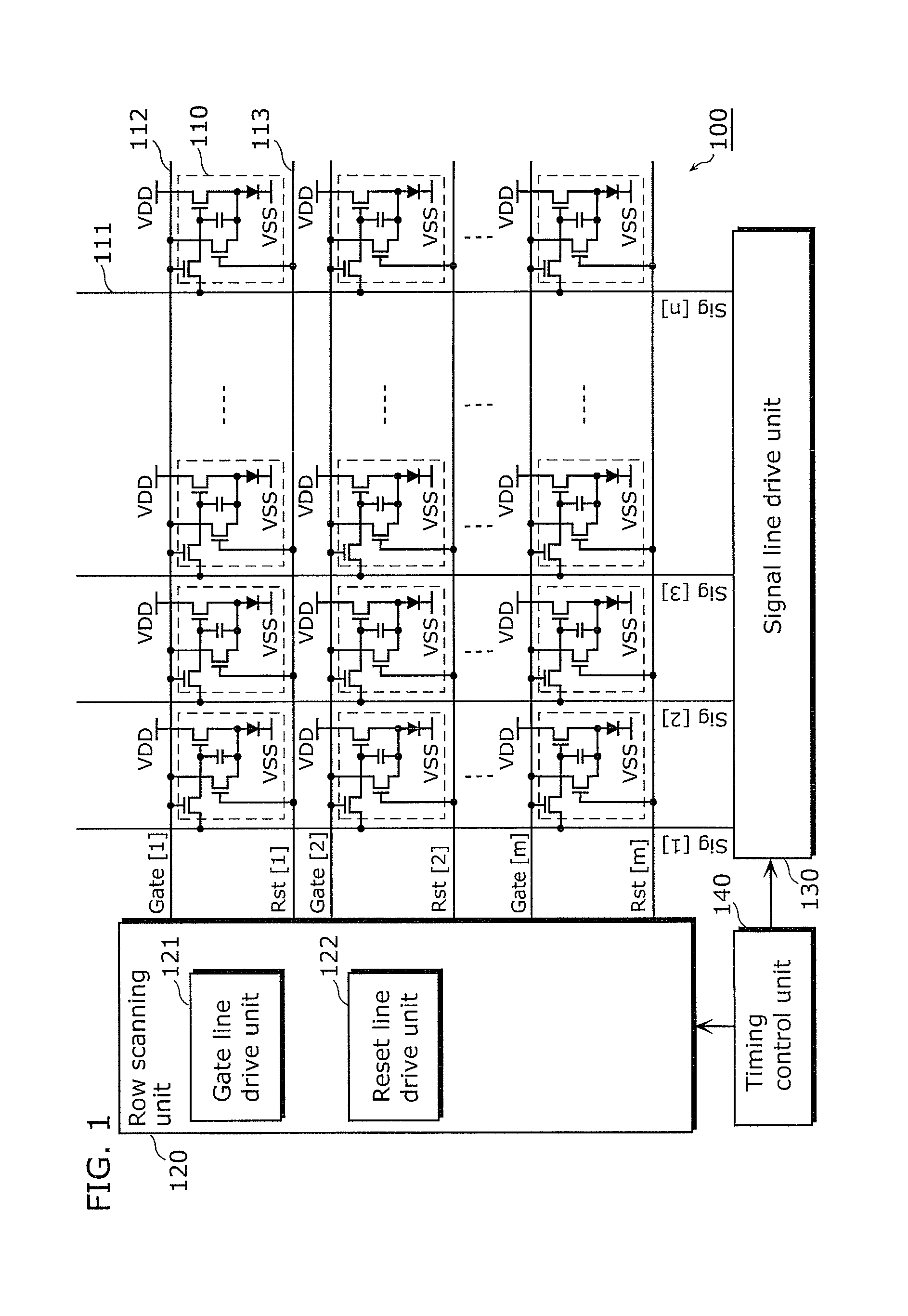

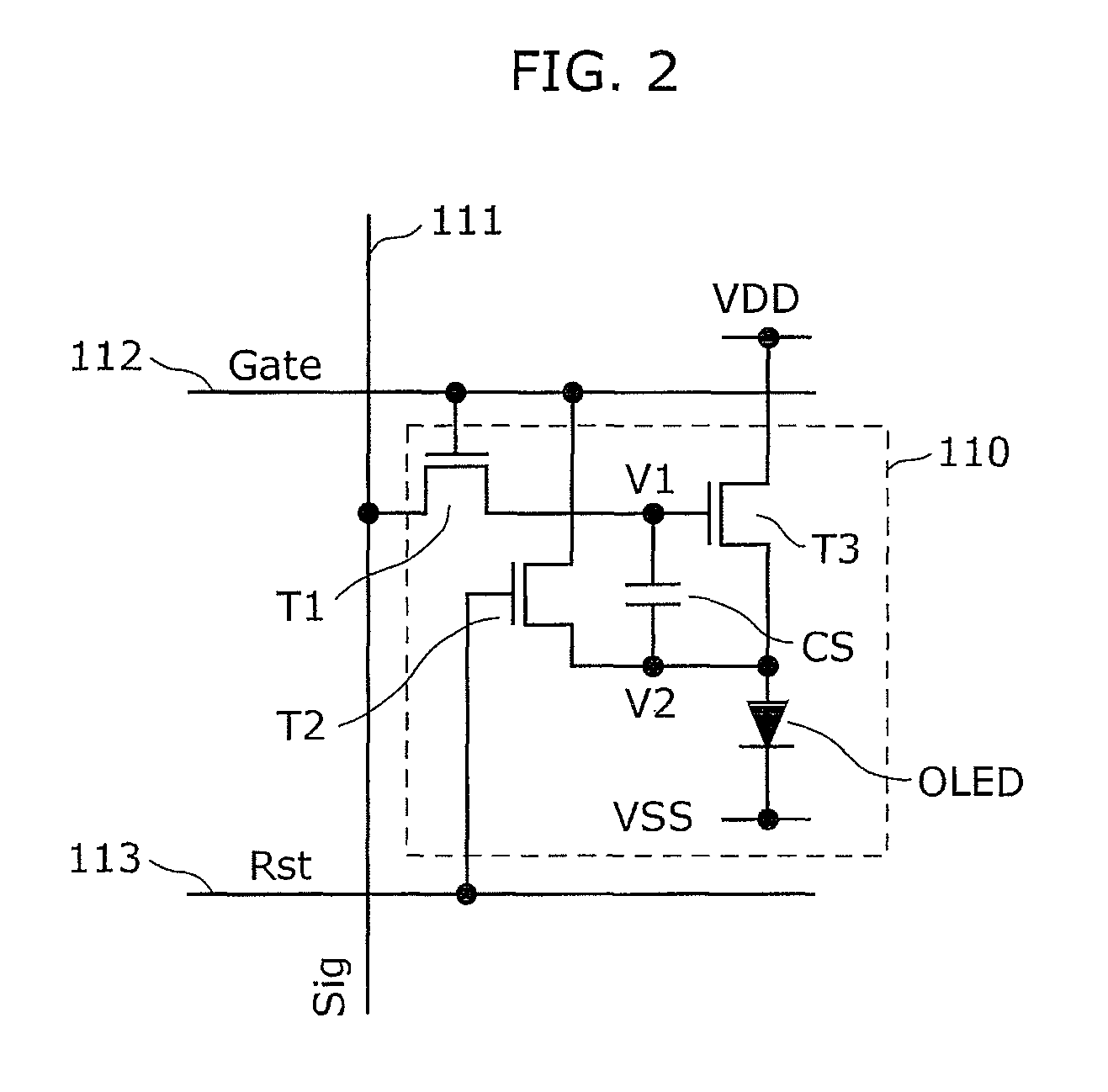

Display device and method of driving the same

ActiveUS20120050350A1Compensation Threshold VoltageOvercome unevennessCathode-ray tube indicatorsInput/output processes for data processingPower flowDisplay device

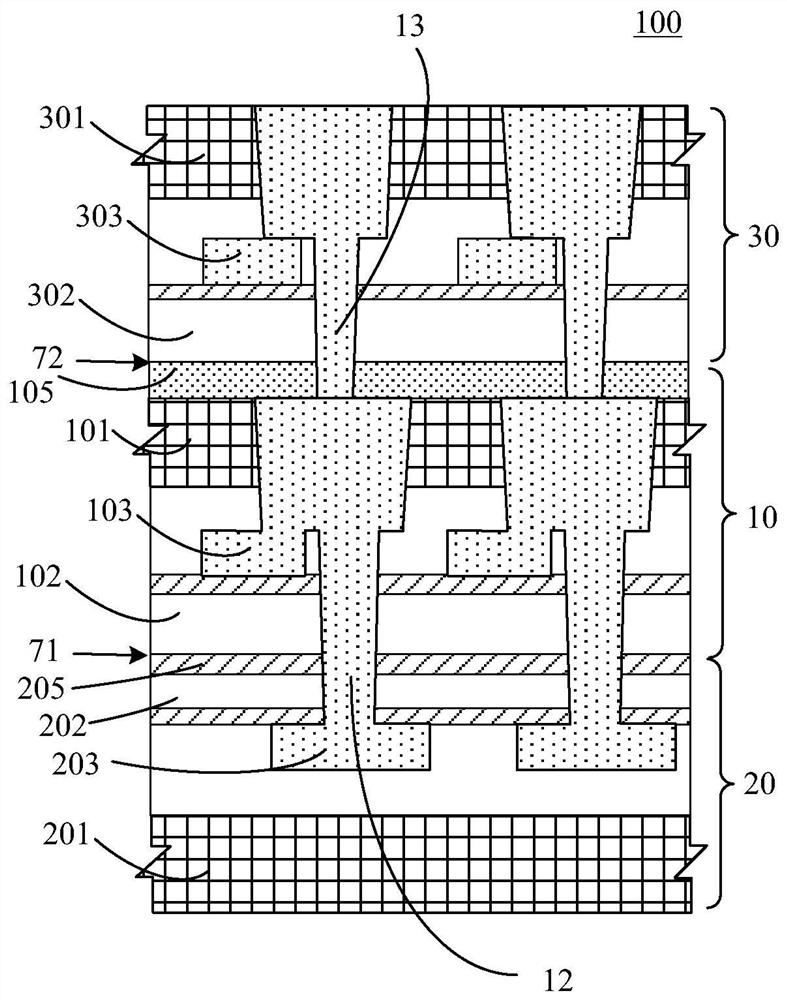

A display device includes luminescence pixels arranged in rows and columns. Each of gate lines and reset lines correspond to one of the rows, and signals lines each correspond to one of the columns. Each luminescence pixels includes a luminescence element, a switching transistor, a drive transistor which supplies current to the luminescence element, and a reset transistor. The reset transistor includes a gate terminal connected to a corresponding reset line, one of a source and drain terminal connected to a source or drain terminal of the drive transistor, and the other of the source and drain terminal connected to a corresponding gate line. A capacitor is connected between the gate terminal and the source terminal of the drive transistor.

Owner:JOLED INC

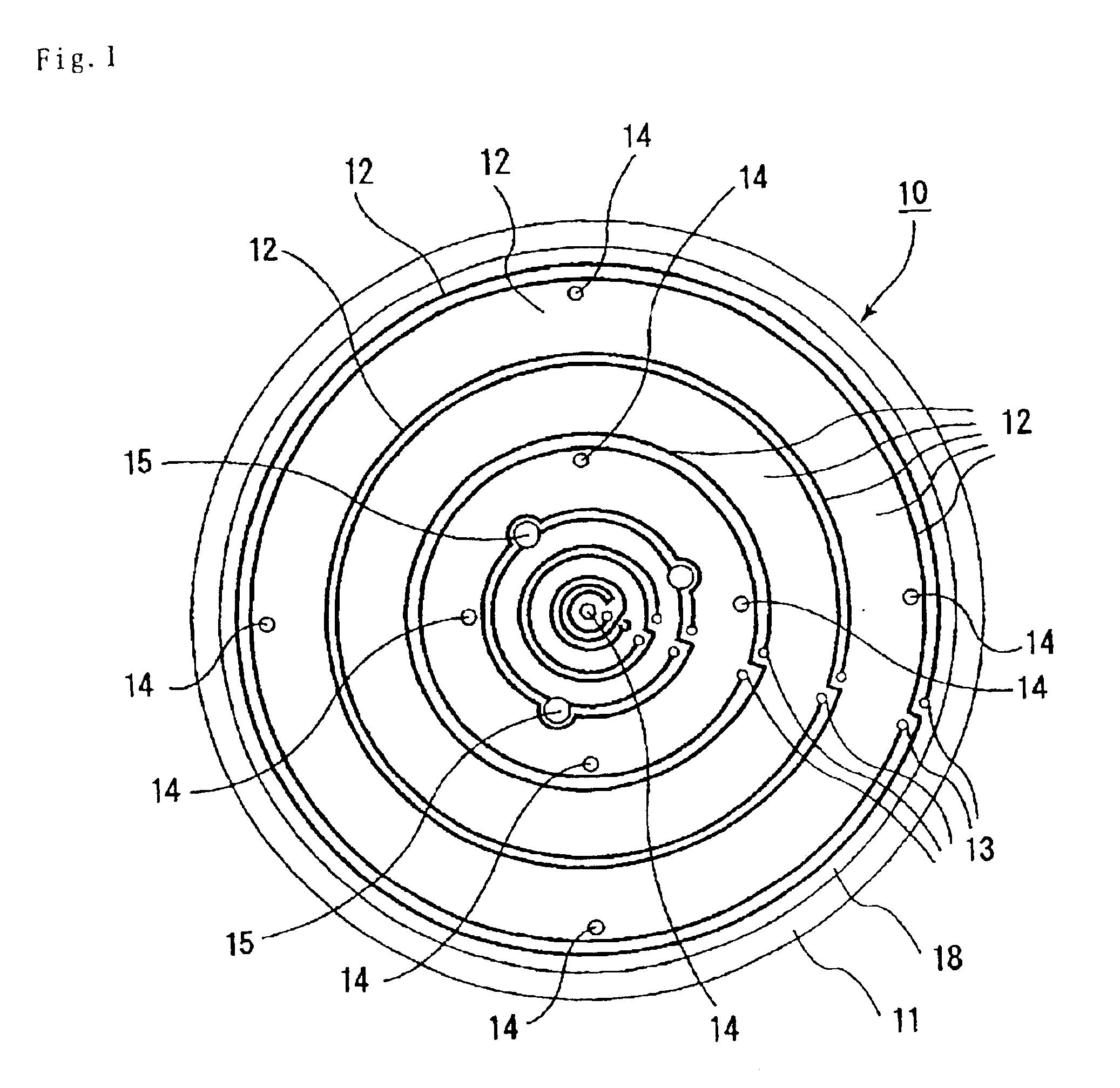

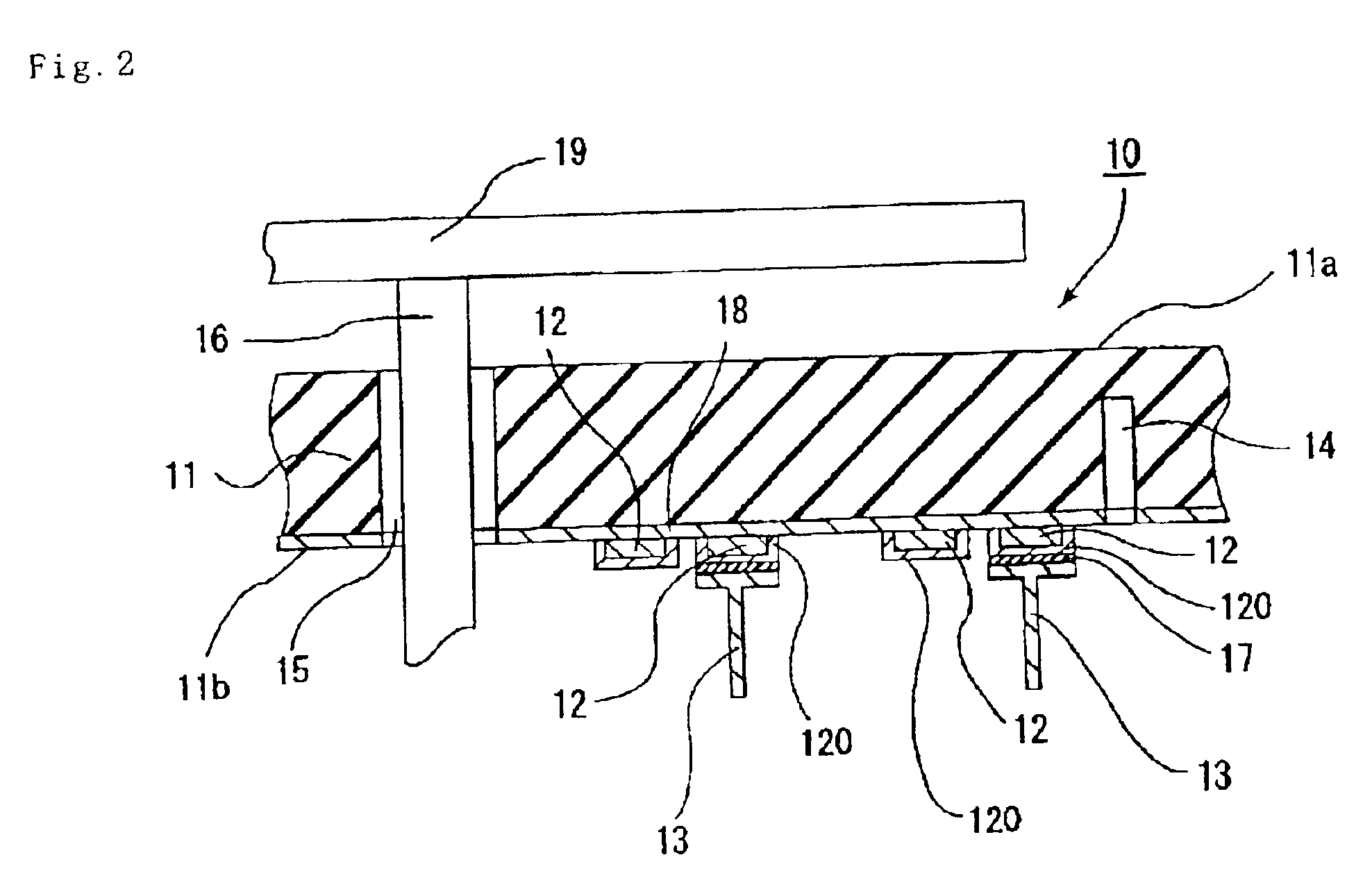

Ceramic heater

InactiveUS6888106B2Overcome unevennessOvercome imbalanceSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgySemiconductor

A ceramic heater making it possible to prevent a short circuit in its resistance heating element and heat a semiconductor wafer evenly. The ceramic beater includes a ceramic substrate, an insulating layer having volume resistivity higher than that of the ceramic substrate, being formed on at least a part of the ceramic substrate, and a resistance heating element formed on the insulating layer.

Owner:IBIDEN CO LTD

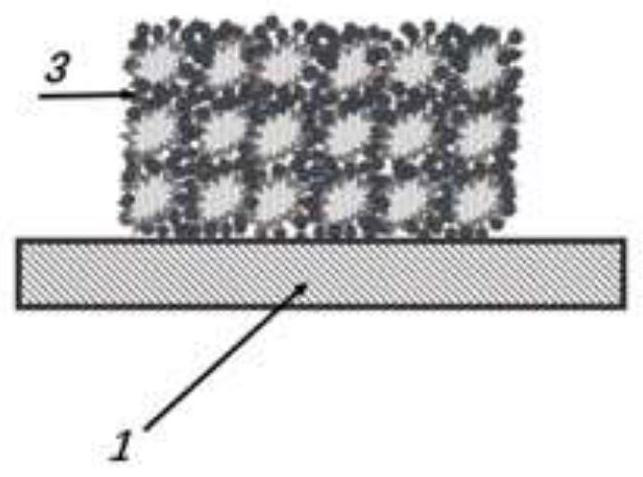

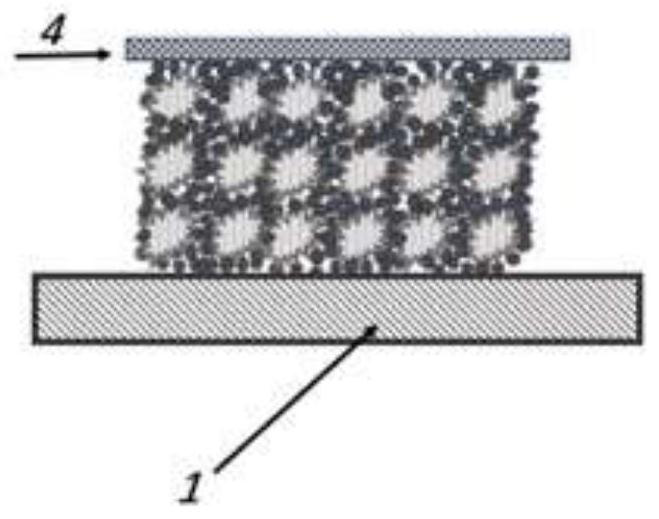

Natural fiber-reinforced polyurethane elastomer composite material and preparation method thereof

The invention discloses a natural fiber-reinforced polyurethane elastomer composite material. The natural fiber-reinforced polyurethane elastomer composite material is prepared from the following components in parts by weight: 30-70 parts of natural fibers and 70-30 parts of polyurethane elastomers, wherein the natural fibers are selected from jute, sisal, hemp, flax and ramie, and the polyurethane elastomers are selected from hard polyurethane elastomers, soft polyurethane elastomers or half-hard polyurethane elastomers. The invention further discloses a preparation method of the natural fiber-reinforced polyurethane elastomer composite material. According to the natural fiber-reinforced polyurethane elastomer composite material and the preparation method, as the degradable natural fiber is taken as the raw material, the environmental protection is benefited; and the raw materials of a component A and a component B of liquid polyurethane are mixed to soak a natural fiber felt and then the natural fiber felt is cured and formed, so that the problem of the uneven surface of a product, caused in the conventional pouring process of the glass fibers and the polyurethane elastomers, is overcome, and the prepared composite material has the characteristics that the abrasive resistance is good and the shock strength is improved and can be used for replacing the conventional glass fiber-reinforced composite material to be used in automotive interior decoration parts.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

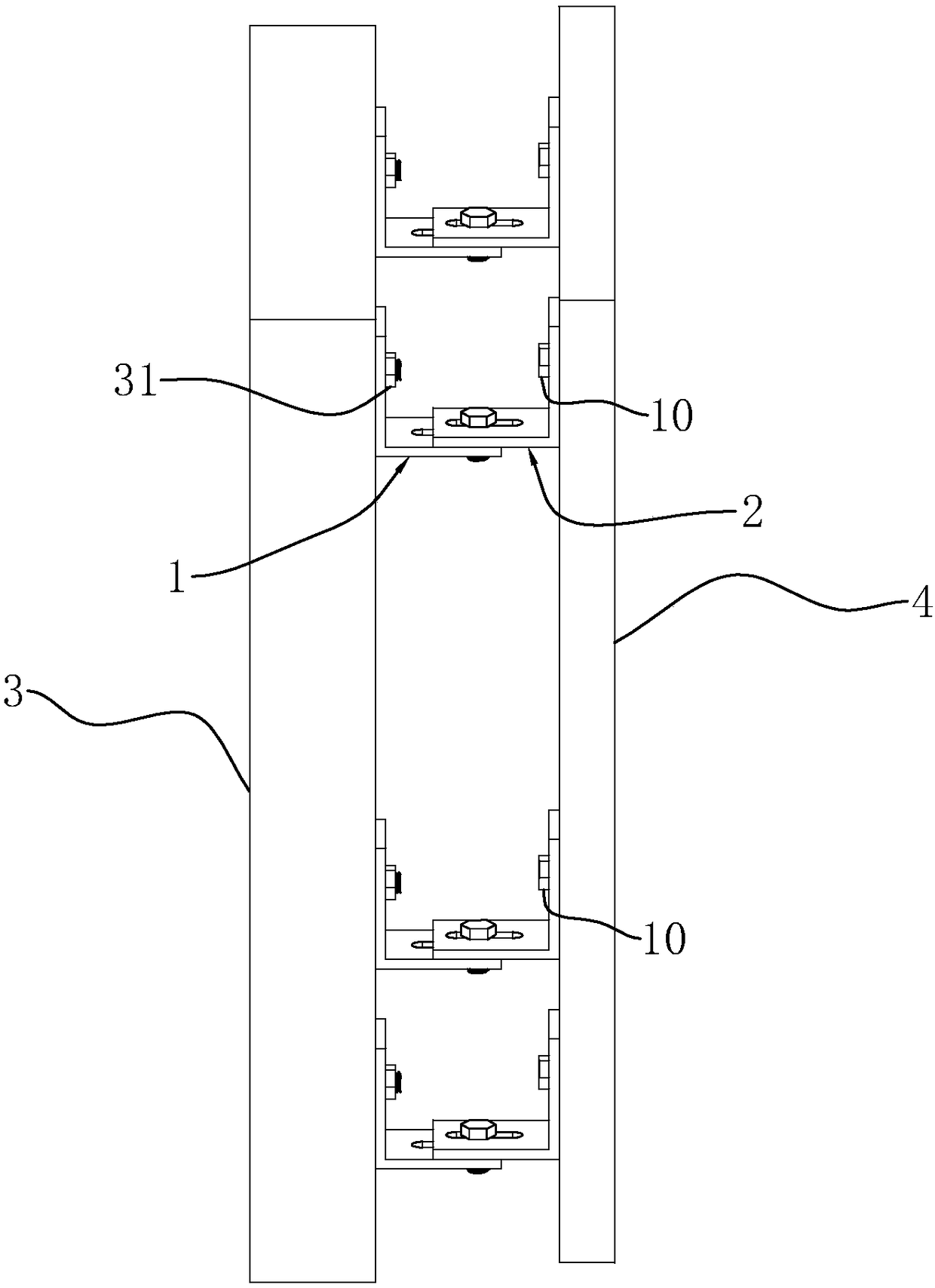

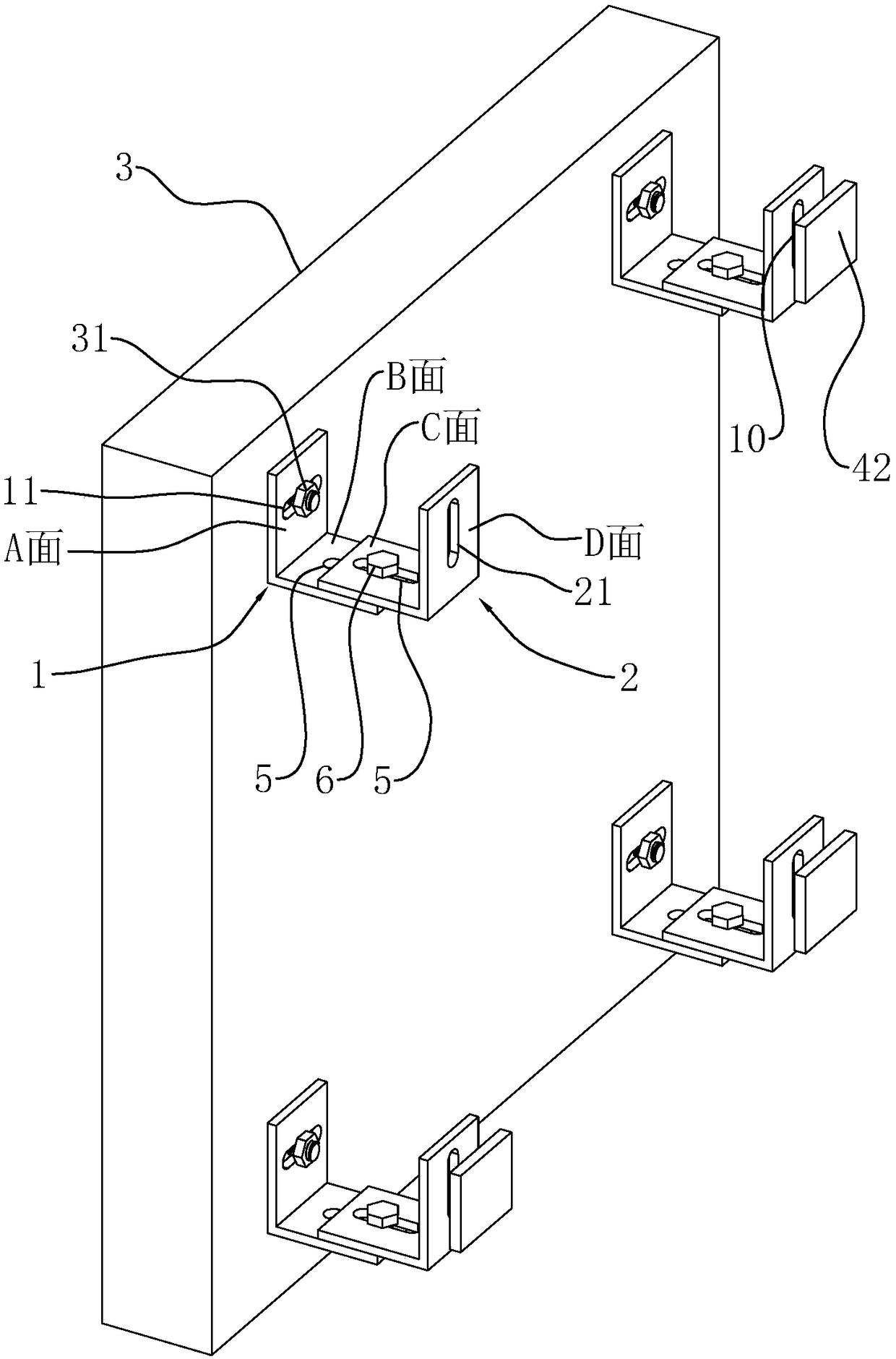

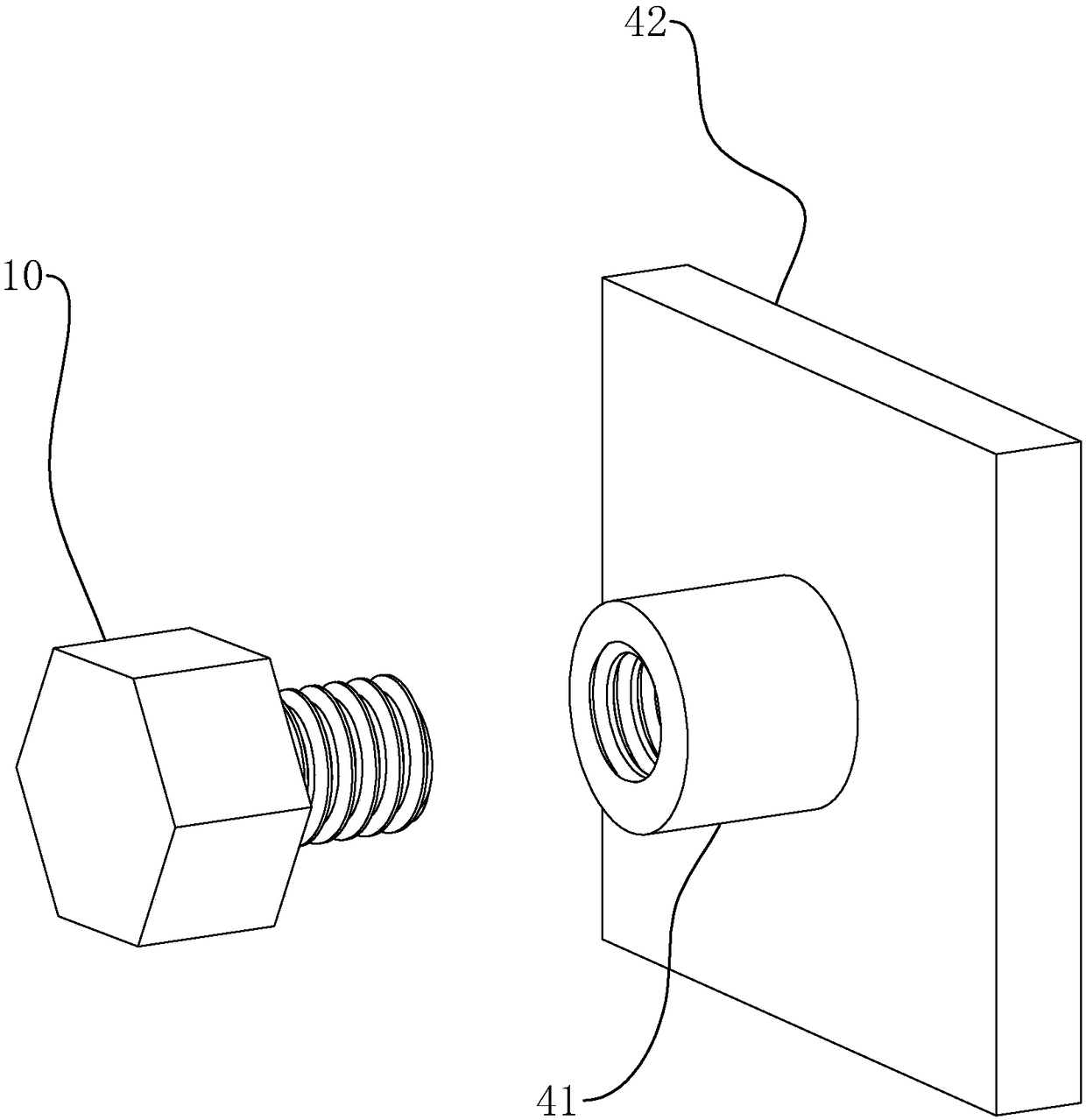

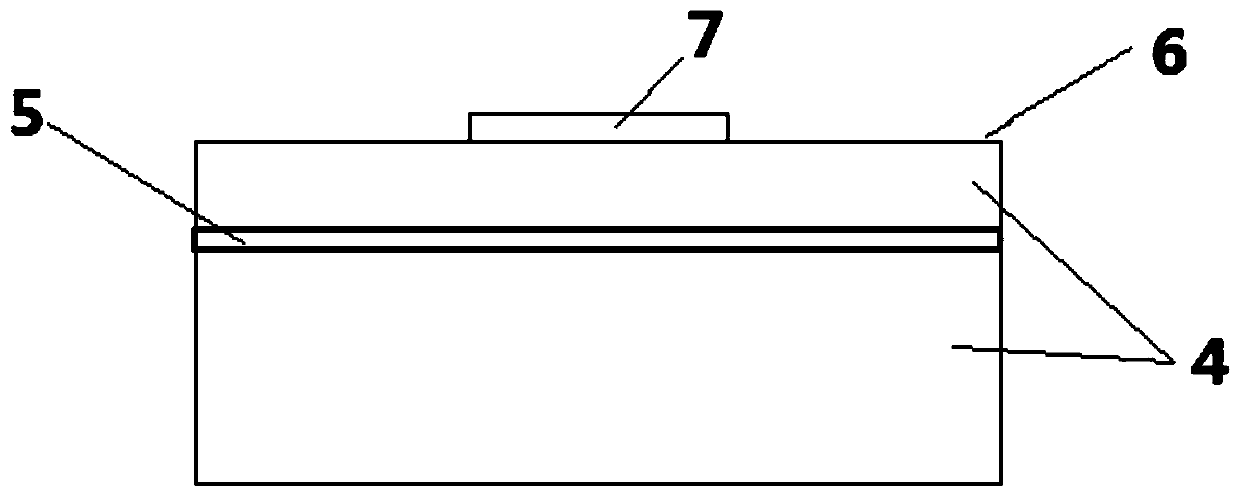

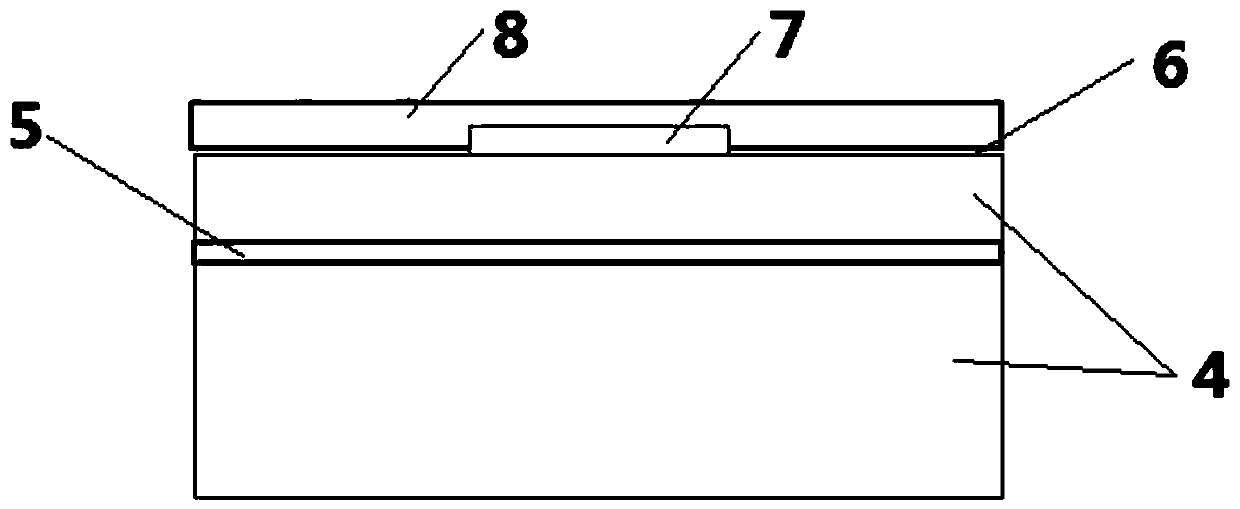

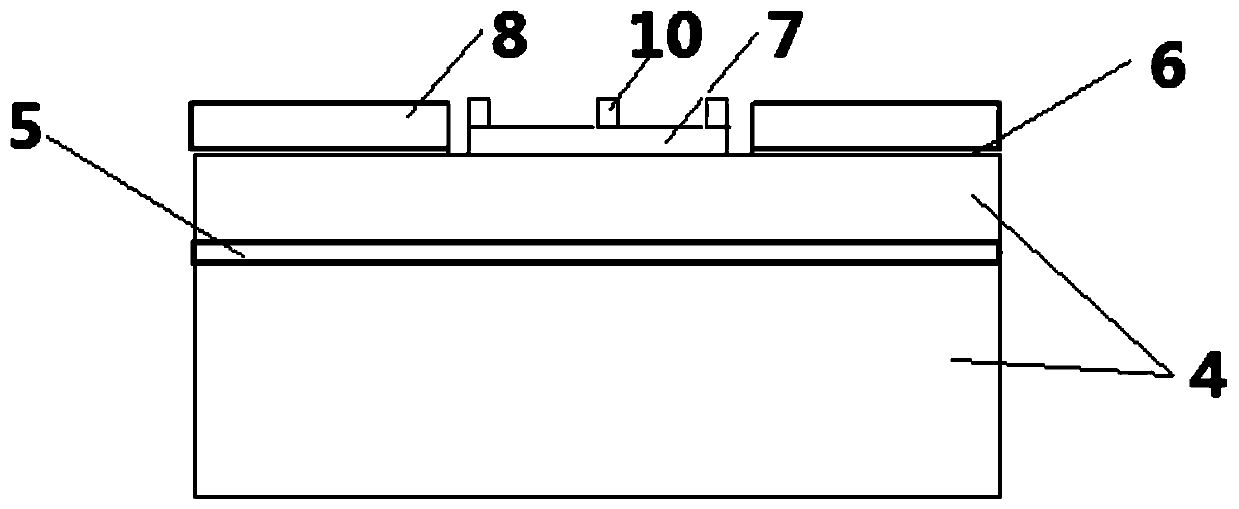

Outer wall plate connecting piece and construction method

The invention discloses an outer wall plate connecting piece and a construction method. According to the main points of the technical scheme, the outer wall plate connecting piece comprises a plurality of pieces of first angle steel, a plurality of pieces of second angle steel, first bolts and second bolts, each piece of first angle steel comprises a face A and a face B, each piece of second anglesteel comprises a face C and a face D, and the faces B and the faces C are attached mutually, so that the multiple pieces of first angle steel and the multiple pieces of second angle steel form a U-shaped groove structure with openings facing upwards or downwards; the faces A are provided with long-strip-shaped horizontal adjusting bolt holes, and pre-embedded bolts pre-embedded in a building outer wall penetrate through the horizontal adjusting bolt holes to fix the first angle steel; the faces B and the faces C are provided with near and far adjusting holes correspondingly, the first boltspenetrate through the near and far adjusting holes in the faces B and the faces C, and each piece of second angle steel is fixed to the corresponding piece of first angle steel; and the faces D are provided with vertical adjusting bolt holes, and the second bolts are screwed into the outer wall plate for fixing the outer wall plate. The outer wall plate connecting piece can achieve adjusting of the outer wall plate relative to the building outer wall in the three dimensions of horizontal, vertical, and near and far distance, the structure is simple, machining is convenient, operation is simpleand convenient, and construction is efficient.

Owner:GRAND FACADE DECORATION ENG CO LTD

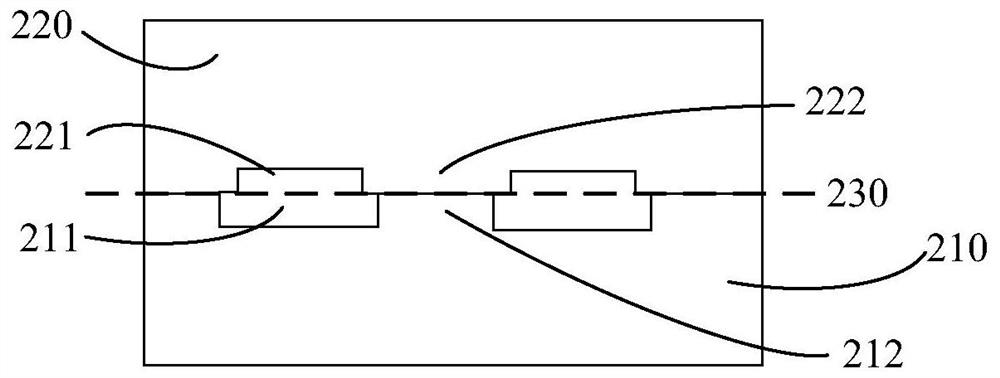

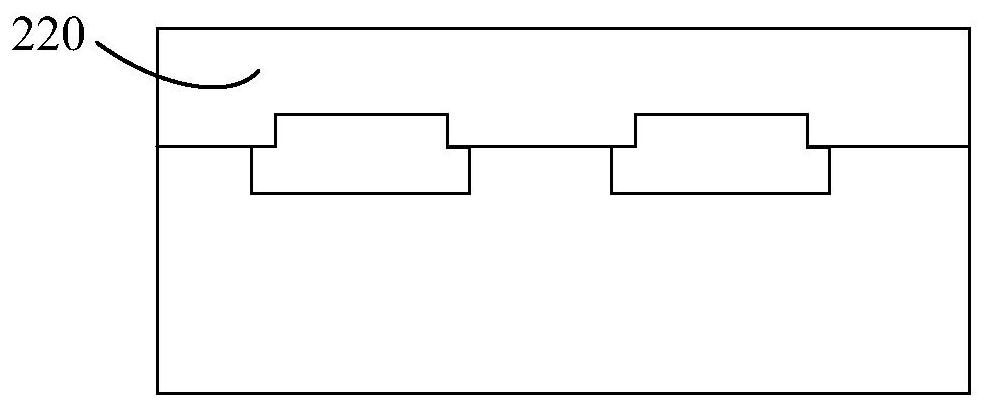

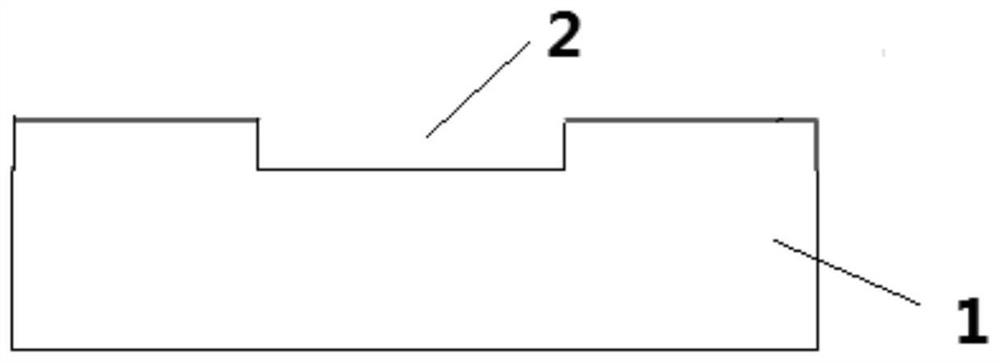

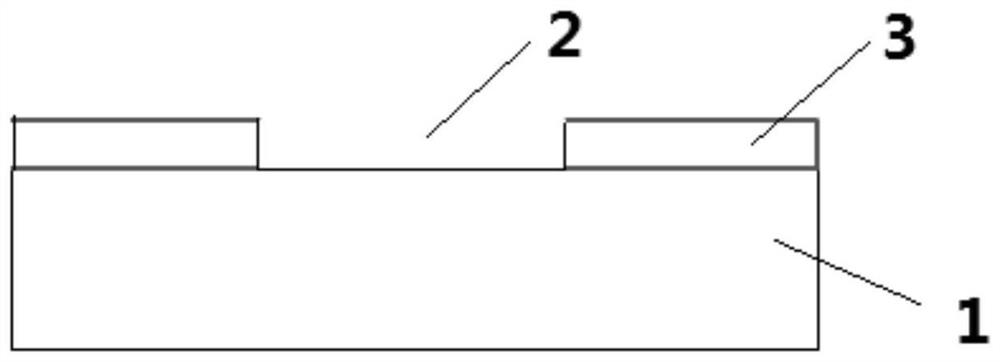

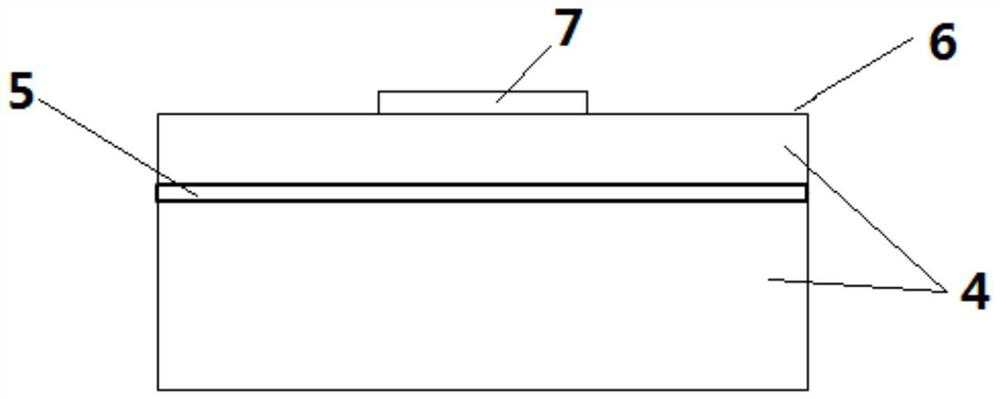

Cavity type bulk acoustic wave resonator with pillar and preparation method thereof

The invention provides a cavity type bulk acoustic wave resonator with a support column and a preparation method of the cavity type bulk acoustic wave resonator. The method comprises the following steps of: taking a piezoelectric single crystal wafer which is subjected to ion implantation and is provided with a bottom electrode; forming a plurality of supporting columns on one side, with the bottom electrode, of the piezoelectric single crystal wafer; forming a cavity at the gap of supporting columns, taking the substrate, bonding the substrate with one side of the piezoelectric single crystalwafer with the cavity, carrying out heat treatment on the substrate after bonding, stripping a film of the piezoelectric single crystal wafer, and producing a top electrode on the stripped side of the piezoelectric single crystal wafer to obtain the piezoelectric single crystal wafer. According to the technical scheme provided by the invention, a sacrificial layer does not need to be grown, etching and trepanning are not carried out on the thin film, the mechanical strength of the device is improved, and the thin film is not easily damaged; the cavity structure is formed before film formation, the rate of finished products is high, residues left by etching after film formation do not exist, and the influence of incomplete release on the device does not need to be considered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

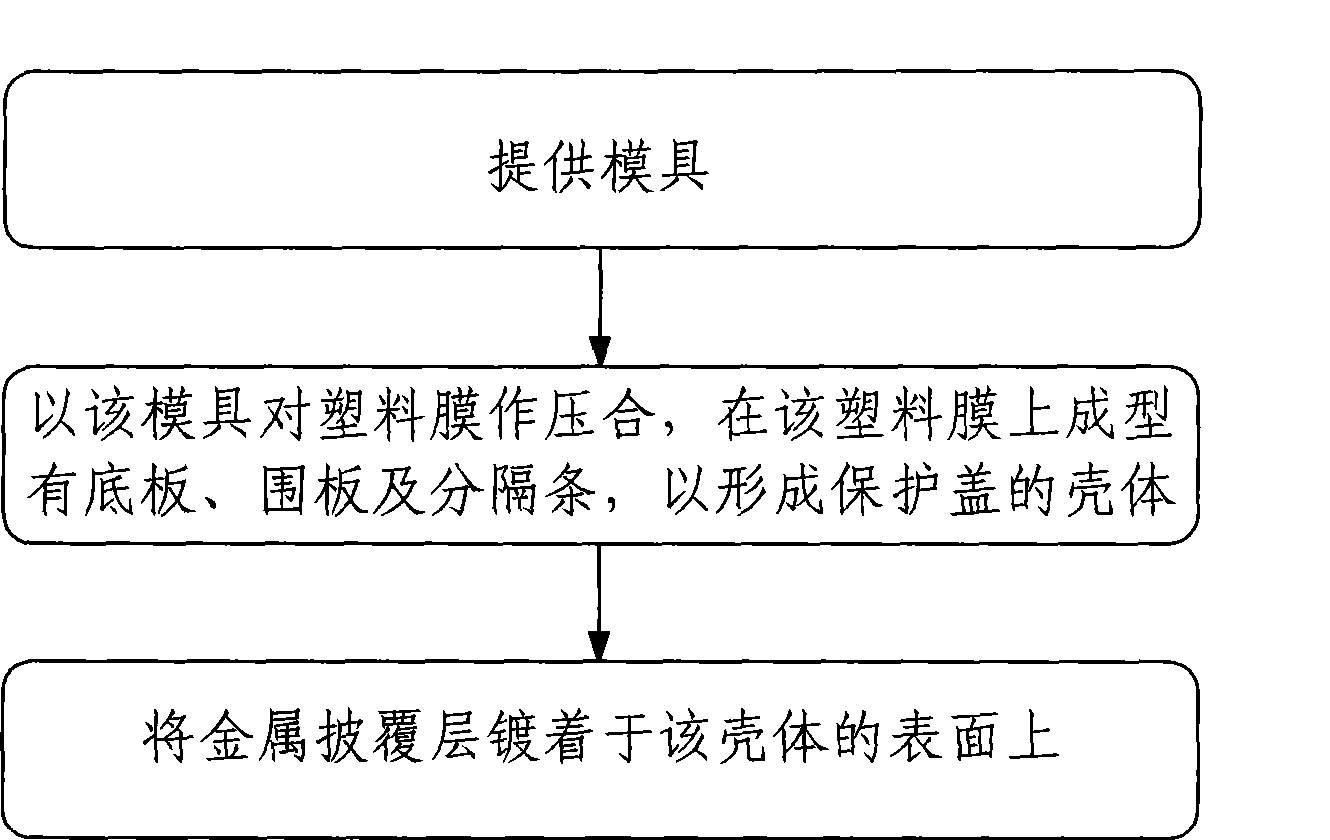

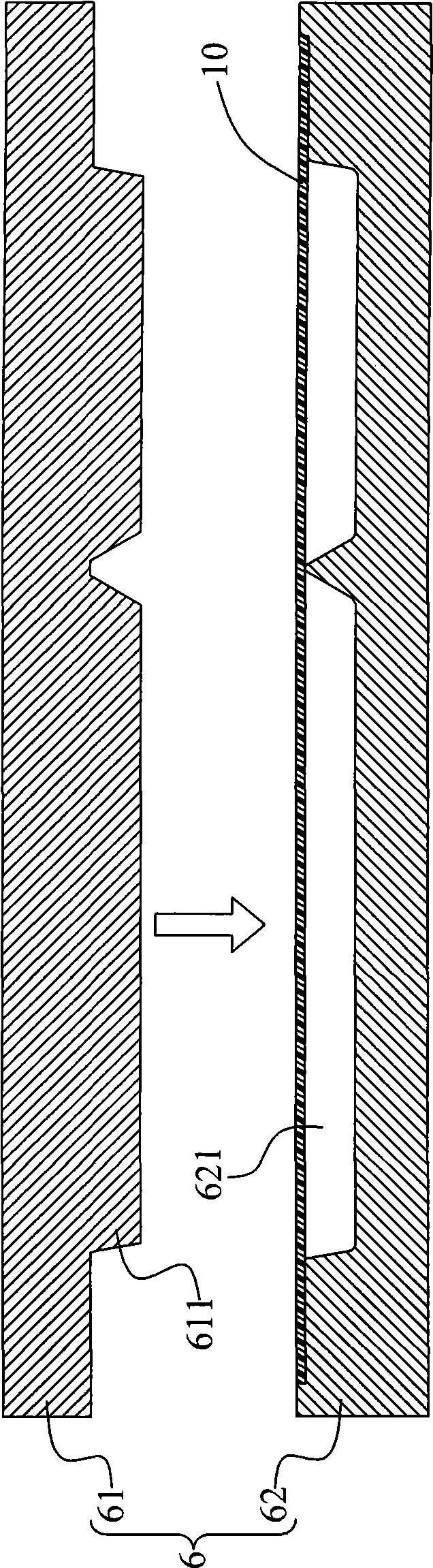

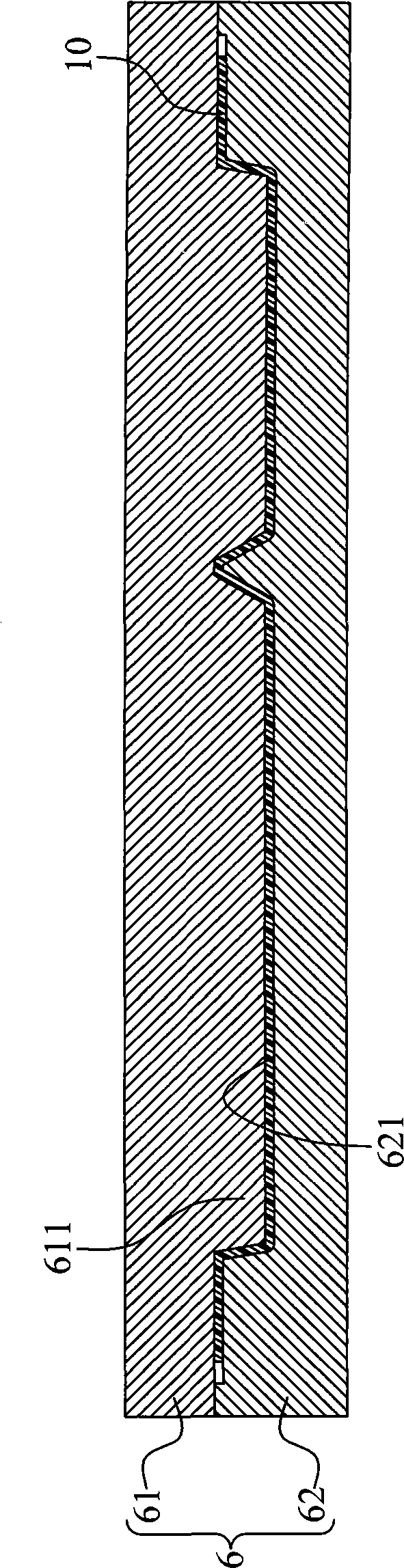

Protection cover manufacturing method capable of preventing electromagnetic wave interference

InactiveCN101489372AAvoid mutual interferenceOvercome unevennessMagnetic/electric field screeningVacuum evaporation coatingMetal coatingElectromagnetic electron wave

The present invention relates to a method for manufacturing a protecting cover which can prevent the electromagnetic wave interference, wherein the method comprises the following steps: preparing a mold; executing compression fitting with the mold to the plastic film which is formed with a base board, side boards and dividing strips for forming the casing with a protecting cover; and plating the metal coating layer on the surface of casing. Therefore the mutual interference of electromagnetic wave of each module in different areas can be effectively prevented.

Owner:郑育仁

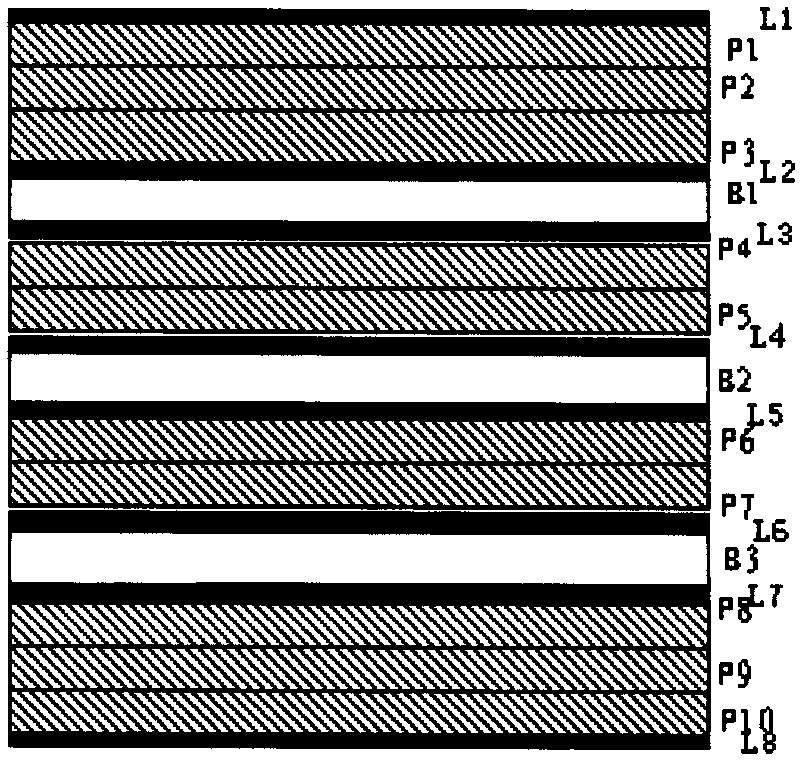

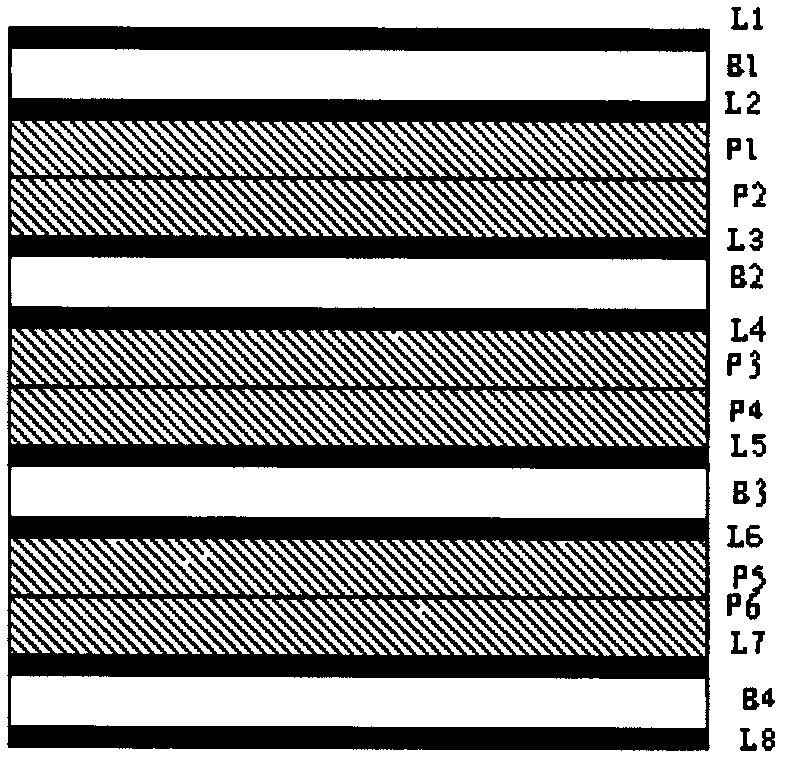

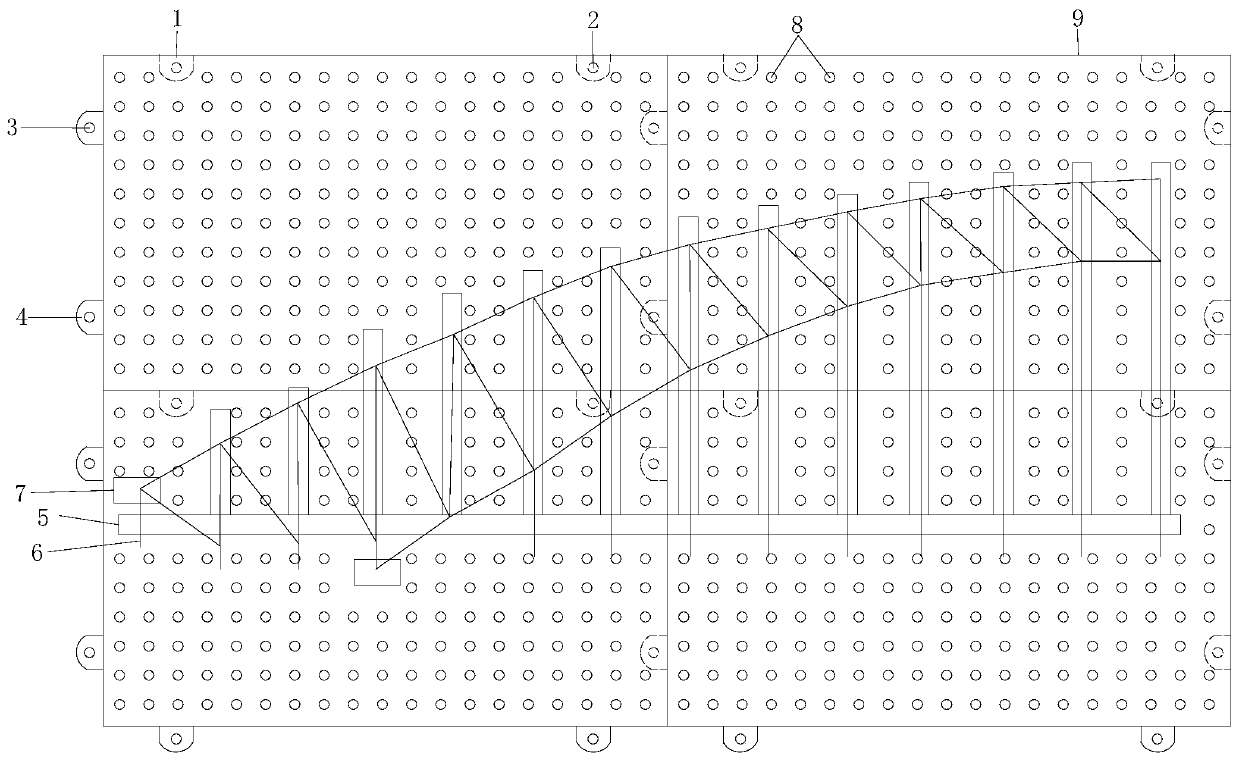

Method for laminating multilayer printed circuit board

InactiveCN103369872AImprove product qualityOvercome unevennessMultilayer circuit manufacturePrinted circuit boardManufacturing quality

The invention provides a method for laminating a multilayer printed circuit board. An outer layer of the multilayer printed circuit board (PCB) is manufactured by adopting a prefabricated core board, wherein the core board is formed by two conductive layers and a solidification piece, the solidification piece is located between the two conductive layers, and the two conductive layer form an outer layer and a secondary outer layer of the multilayer PCB respectively. The method provided by the invention overcomes a problem of unevenness of the PCB surface, and improves the manufacturing quality of the PCB.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Ceramic heater

InactiveUS20050016987A1Easy to masterOvercome unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgySemiconductor

An objective of the present invention is to provide a ceramic heater making it possible to prevent a short circuit in its resistance heating element and heat a semiconductor wafer evenly. The ceramic heater of the present invention is a ceramic heater comprising: a ceramic substrate; an insulating layer having volume resistivity higher than that of said ceramic substrate, being formed on at least a part of said ceramic substrate; and a resistance heating element formed on said insulating layer.

Owner:IBIDEN CO LTD

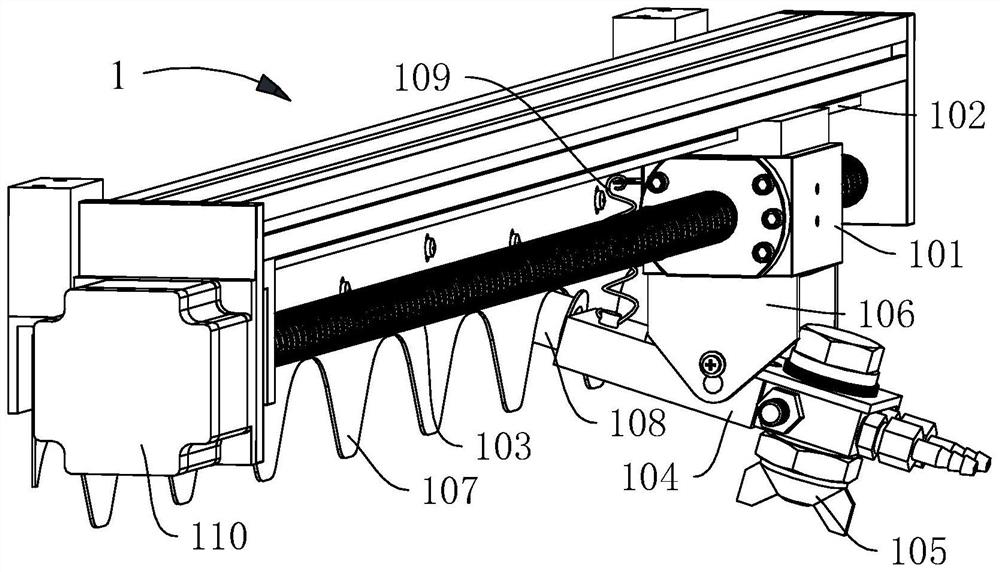

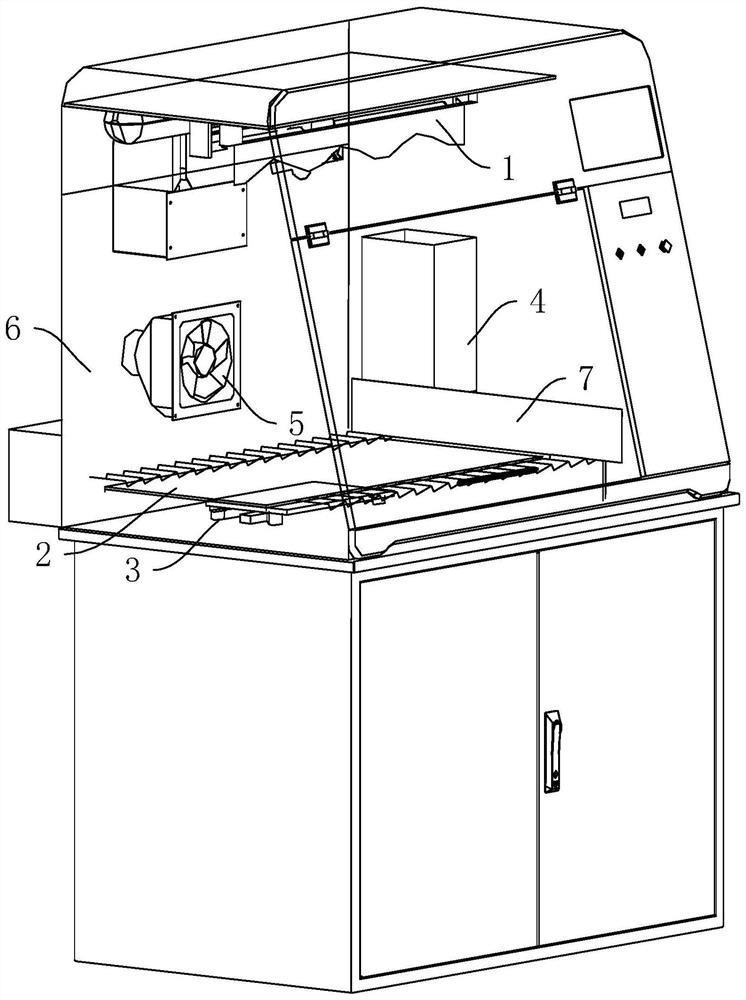

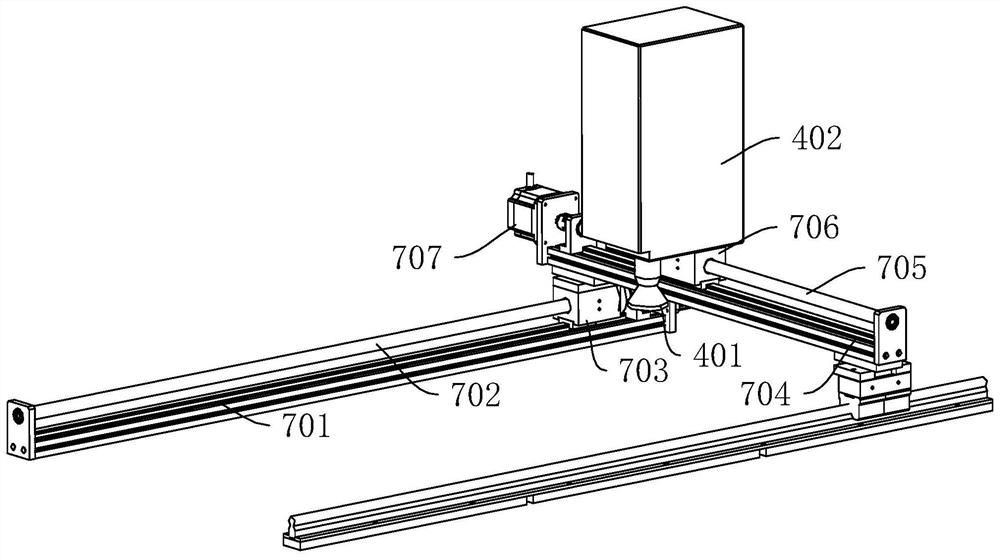

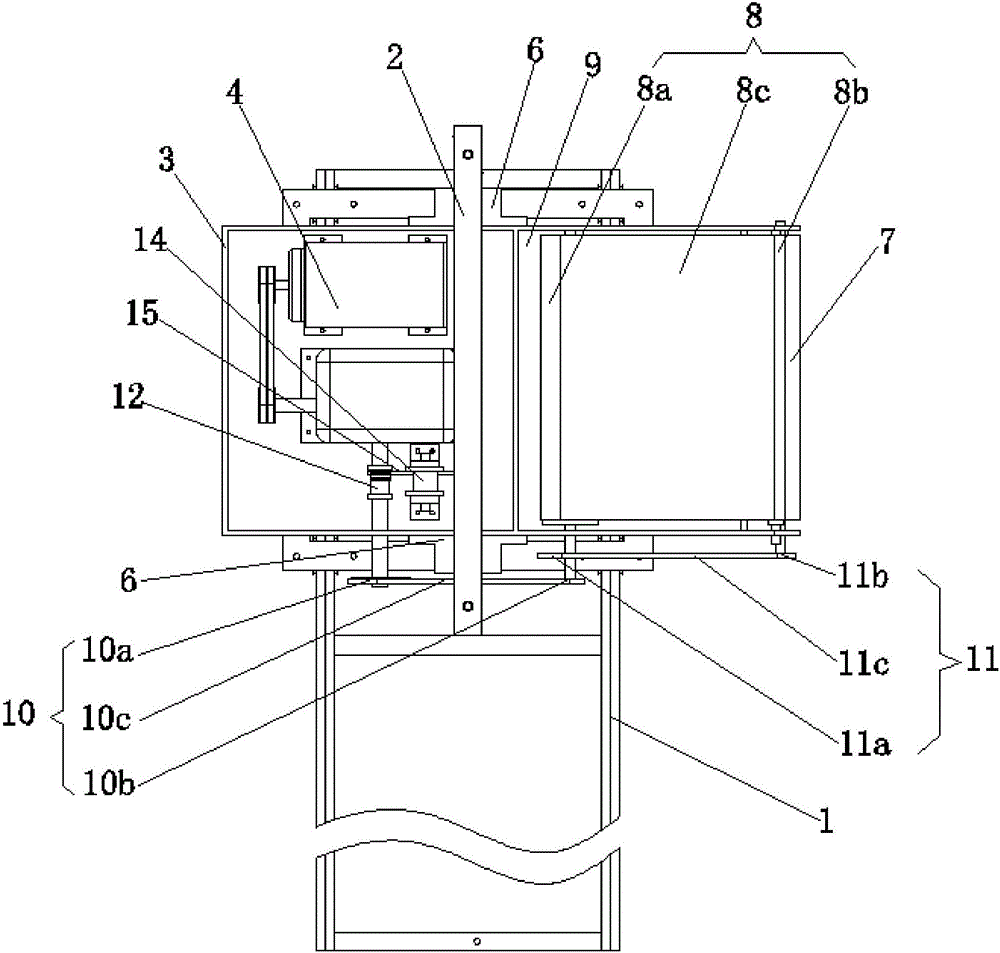

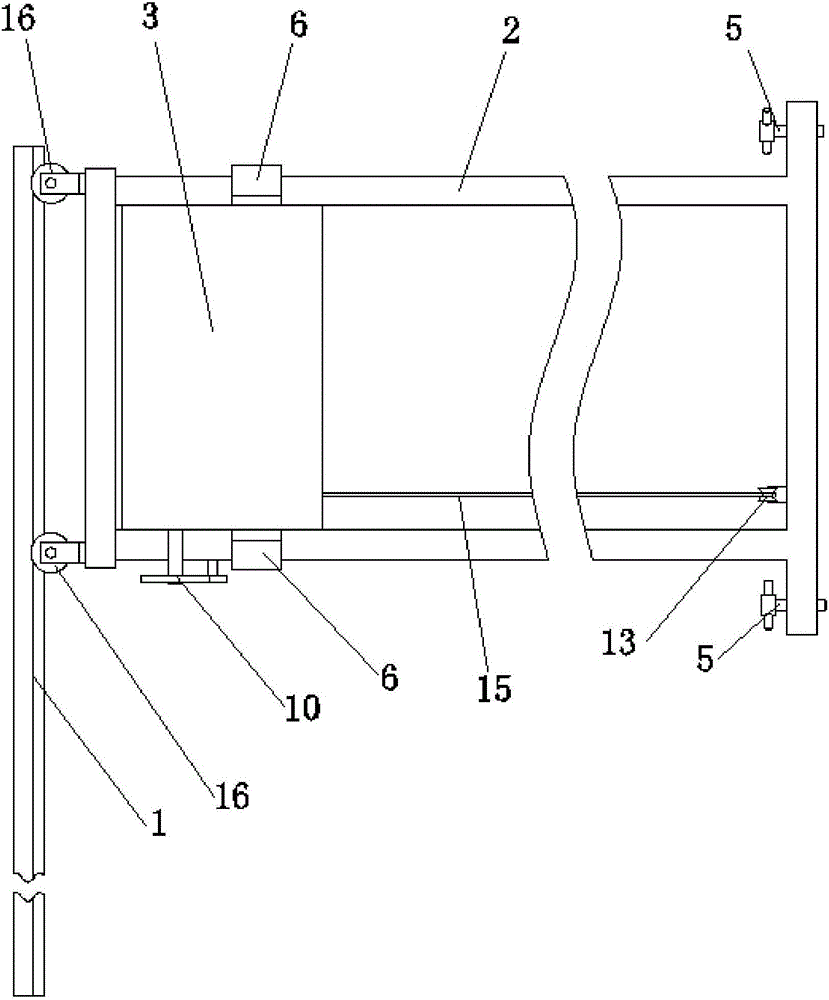

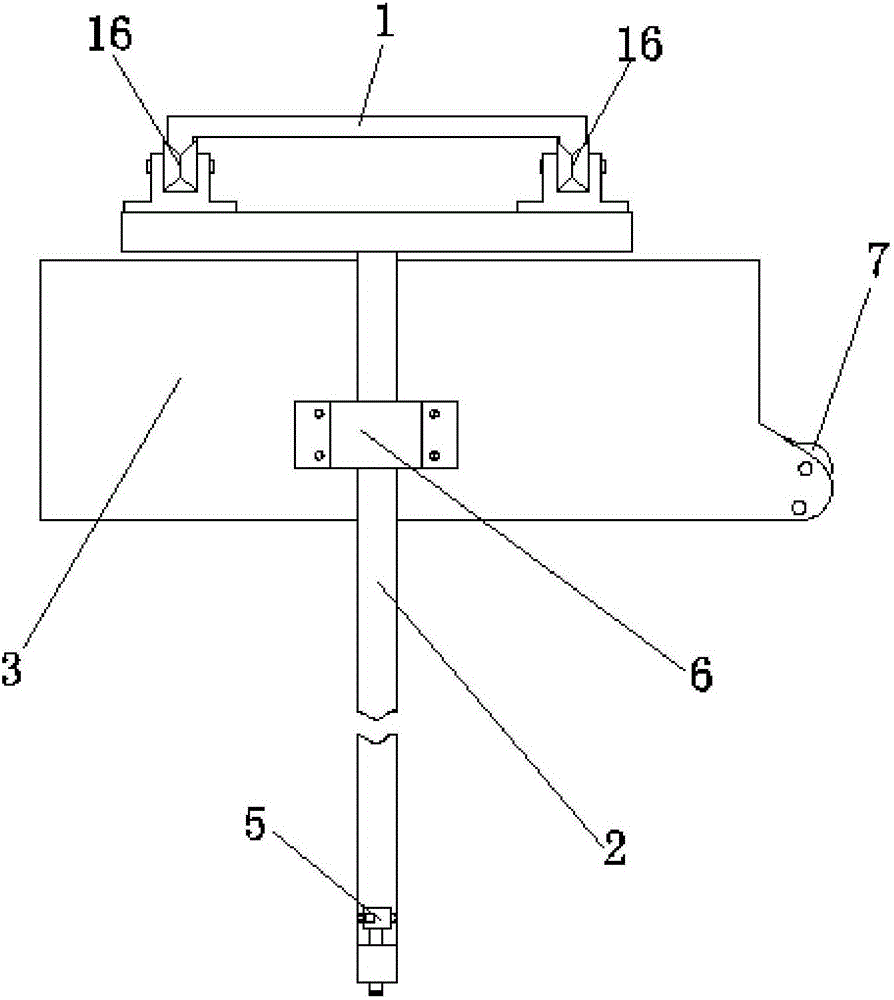

Deacidification spraying device and spraying deacidification machine

PendingCN111809446AOvercome unevennessEvenly distributedOld paper after-treatmentStructural engineeringManufacturing engineering

The invention provides a deacidification spraying device and a spraying deacidification machine. The deacidification spraying device comprises a sliding rail, a screw rod, a screw rod sliding die arranged on the screw rod in a penetrating manner, a nozzle bracket, deacidification nozzles and a driving mechanism; the lead screw sliding die is connected with the sliding rail in a sliding mode, the nozzle bracket is hinged to the lead screw sliding die, the deacidification nozzles are fixedly connected with the nozzle bracket, and the driving mechanism can drive the deacidification nozzles to swing leftwards and rightwards relative to the moving direction of the lead screw sliding die. Due to the structural design, the problem of non-uniform fan-shaped spraying is effectively solved, the sprayed deacidification agent mist can be uniformly distributed on the surface of an object to be deacidified, and the atomization is very uniform.

Owner:HANGZHOU ZHONGCAI TECH CO LTD

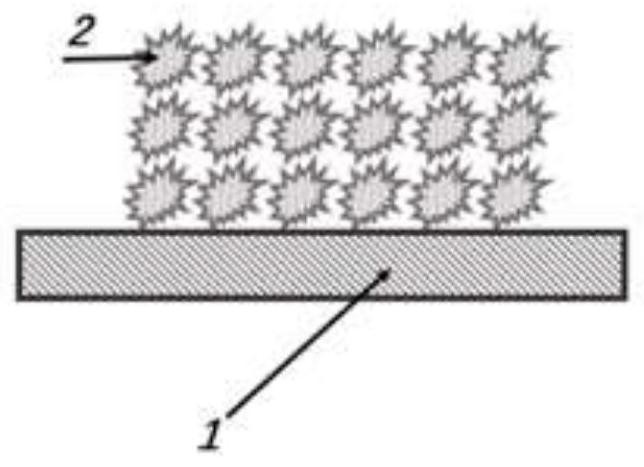

Lead salt film structure for infrared photoelectricity and preparation method thereof

ActiveCN112531065ACompact structureShort growth timeFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringLead sulfide

The invention belongs to the field of photoelectronic devices, and particularly relates to a composite-structure lead salt film for infrared photoelectricity and a preparation method thereof. The leadsalt film comprises a base, a lead salt crystal grain layer prepared by a physical vapor deposition method, and small-crystal-grain lead salt prepared by a chemical method; the lead salt crystal grain layer covers the base, and gaps exist among lead salt crystal grains; the small-crystal-grain lead salt is embedded into the gaps; the lead salt film is lead sulfide or lead selenide; and the base is a quartz substrate or a sapphire substrate or a silicon wafer containing an oxide layer. The preparation method comprises a physical vapor deposition method and a chemical method. The composite structure lead salt film provided by the invention is more compact in structure and high in uniformity; as a photoelectric detector, the annealed composite structure lead salt film is low in noise, high in specific detection rate, short in time consumption of the preparation method and simple in process.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

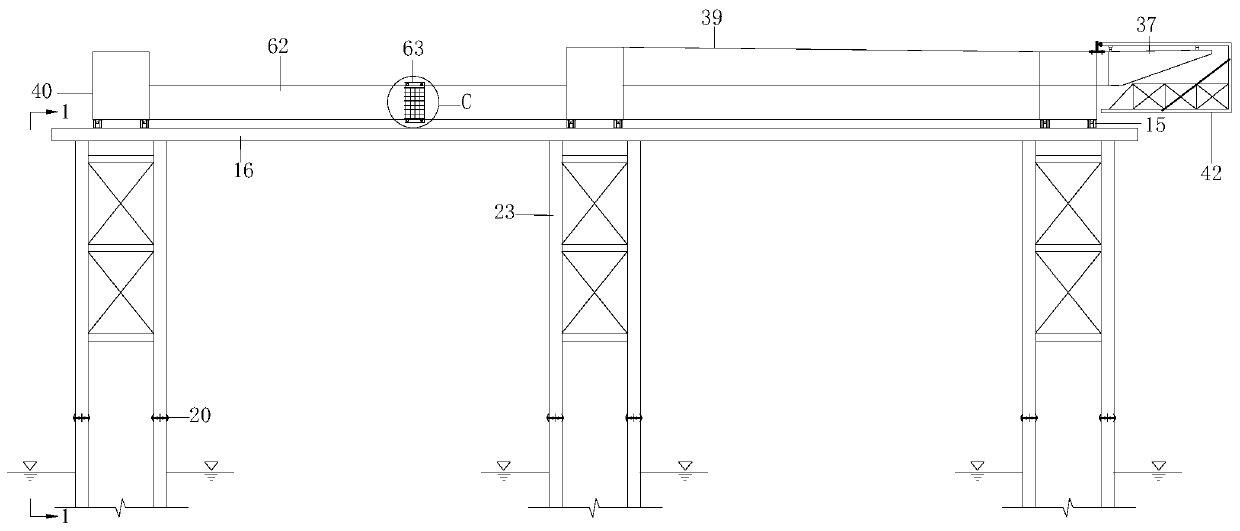

Steel truss arch bridge installation system and construction method thereof

ActiveCN110258294AOvercome unevennessQuick fittingBridge erection/assemblyBraced frameHanging basket

The invention relates to a steel truss arch bridge installation system. The steel truss arch bridge installation system involves a steel truss assembling and splicing base frame, a steel truss in-water installing support, a steel truss installing attaching type construction platform and a steel truss arch bridge pick arm hanging frame construction platform; the steel truss assembling and splicing base frame comprises connecting grooves, connecting steel sheets, base frame steel plates, base frame supporting legs and supporting leg lifting adjusting devices; the steel truss in-water installing support comprises top adjusting devices, steel pipe connecting devices and steel pipe piles; the steel truss installing attaching type construction platform comprises hanging baskets, upper rolling wheels, lower rolling wheels, upper face plates, lower face plates and steel beam splicing plates; and the steel truss arch bridge pick arm hanging frame construction platform comprises hanging frame rails, universal rolling wheels, pick arms, bottom plates and rail clamping devices. The steel truss arch bridge installation system has the beneficial effects that the arranged steel truss assembling and splicing base frame can solve the problem that a pre-assembling site is not flat, a base is stable and does not slip, and the base frame with the corresponding size can be quickly assembled according to the size of a pre-assembled unit so that steel truss components can be rapidly trial-assembled.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

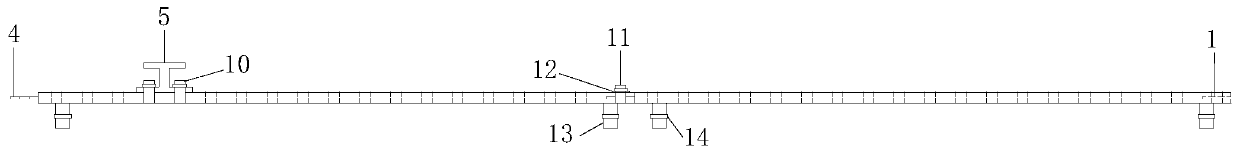

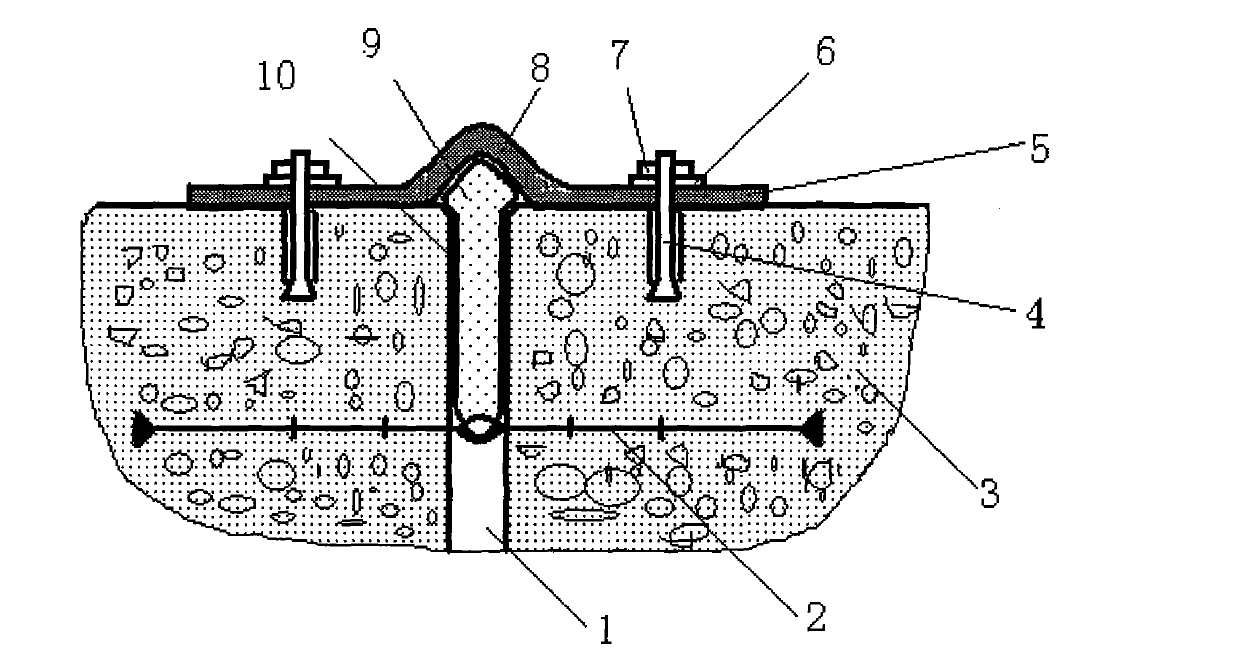

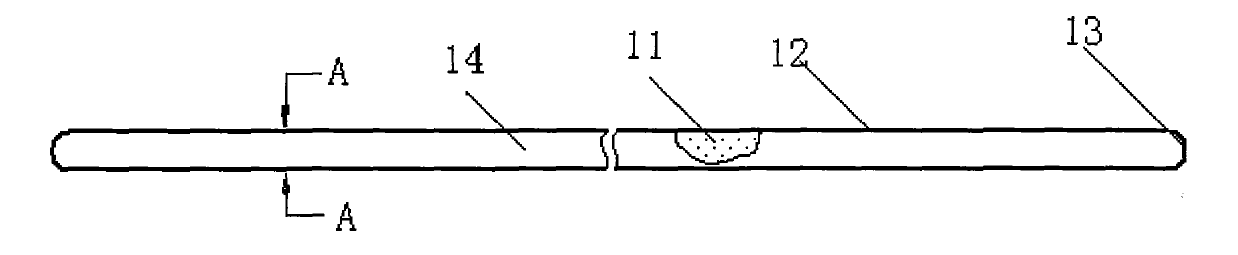

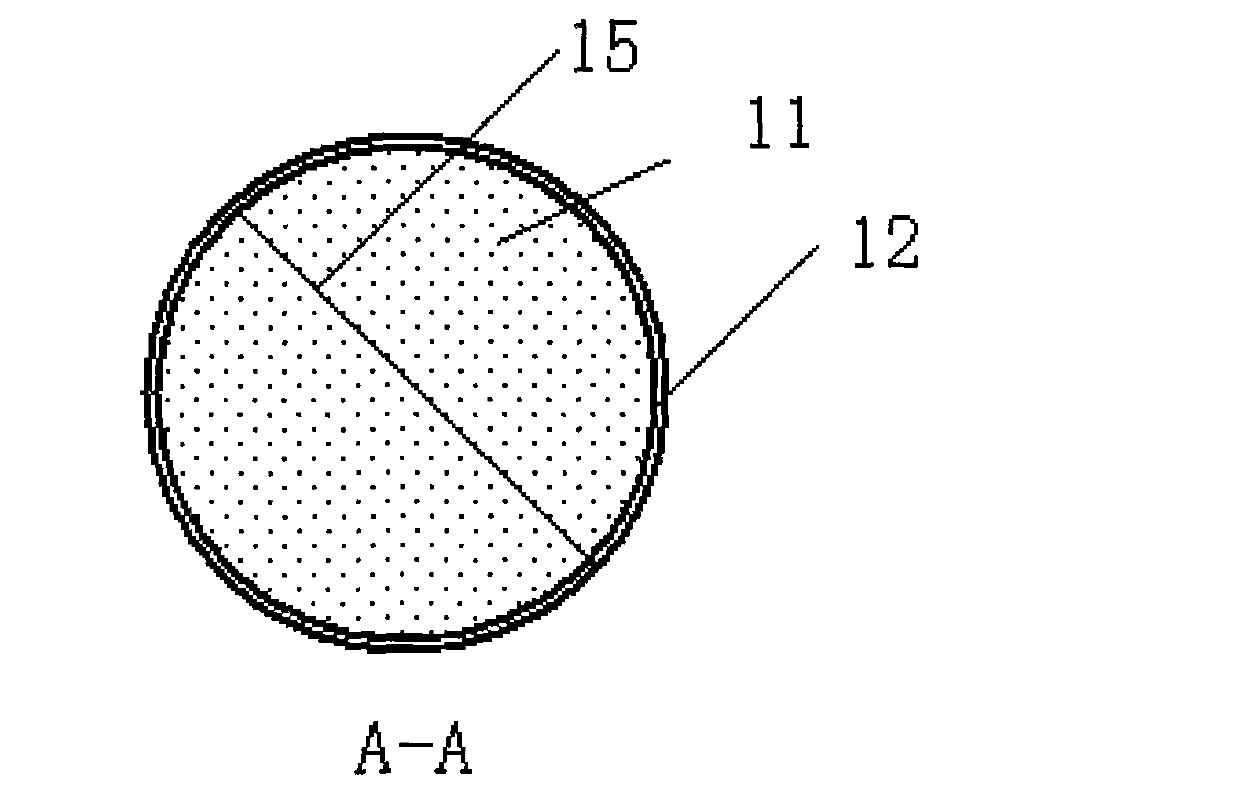

Basement deformation joint seepage prevention and treatment method

ActiveCN101705696BPrevent seepageOvercome unevennessArtificial islandsUnderwater structuresBasementAdhesive

A basement deformation joint seepage prevention and treatment method belongs to the building technology. Soft-plastic materials consisting of clay, water, oil and additive are injected into sealing bags and manufactured into soft-plastic intestine filling strips; waterproof adhesive is coated on the deformation joints and the wall surface of a place in which waterstops are embedded; and then the filing strips chock up the deformed joints and cover elastic trim strips, and finally washers are pressed and fixed by screw caps. The method can easily obtain materials, has low cost, convenient construction, simple installation, high speed, high work efficiency and obvious economic benefit and is suitable for the deformation joint seepage treatment.

Owner:ZHEJIANG HUZHOU CONSTR ENG GRP CO LTD

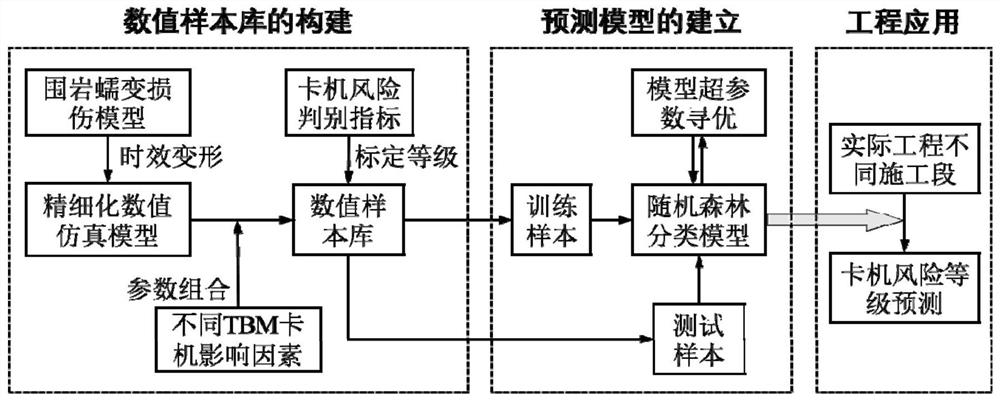

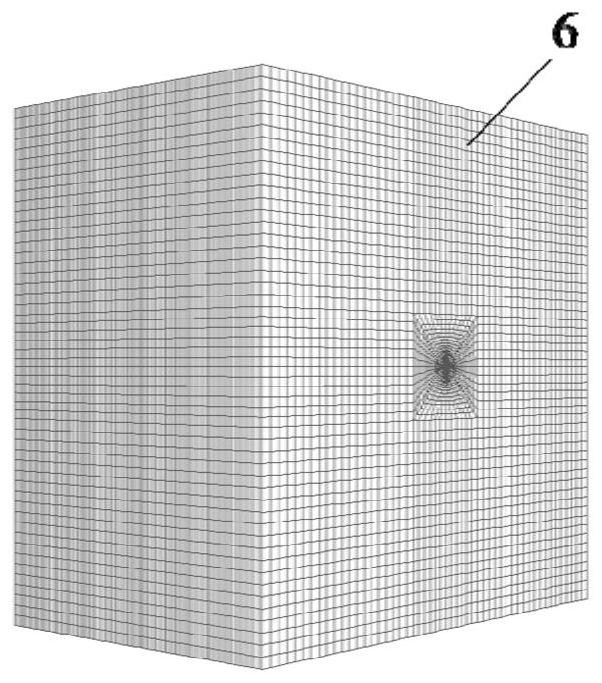

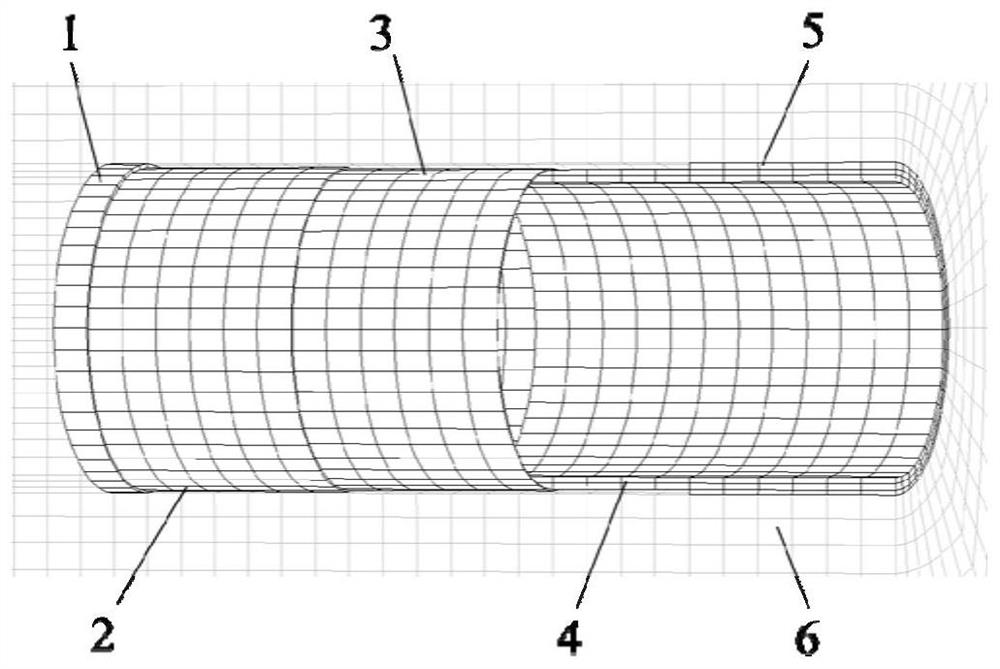

Numerical sample and random forest-based TBM jamming risk prediction method

ActiveCN112765791AOvercoming the small number of monitoring samplesOvercoming imbalancesArtificial lifeDesign optimisation/simulationRisk forecastingPrediction methods

The invention discloses a numerical sample and random forest-based TBM jamming risk prediction method. The method comprises the steps: building a refined numerical simulation model, simulating the aging deformation of surrounding rock based on a creep damage model, and achieving the simulation of a TBM construction process; setting values of different card machine influence factors in the numerical simulation model, and calculating numerical samples containing different working conditions; establishing a jamming risk discrimination index, and calibrating the jamming risk level of the sample; and establishing a random forest model, performing model training based on the numerical samples, and predicting the jamming risk level of the actual construction section by using the trained random forest model. According to the method, the jamming numerical value sample library is constructed based on refined numerical value simulation, and the problems of few monitoring samples and imbalance existing in application of machine learning in engineering are solved; by using the trained random forest model, the jamming risk level of the actual construction section can be quickly predicted, so that early prevention and control of disasters are guided, and safe and efficient construction of the TBM is ensured.

Owner:TSINGHUA UNIV

Method for cauterizing calligraphy and painting with indocalamus leaf

InactiveCN1467098AOvercome surface irregularitiesImprove yieldStampsLaser detailsEngineeringIndocalamus

A method for ironing words and drawing on reed leaf used to wrap the dumpling made of glutinous rice features that the radiated heat (laser beams controlled by computer, for example) is used to write or draw on the reed leaf to make it charred to different extents. Its advantages are non contacting mode, and high productivity and rate of finished products.

Owner:ZHEJIANG WUFANGZHAI INDAL

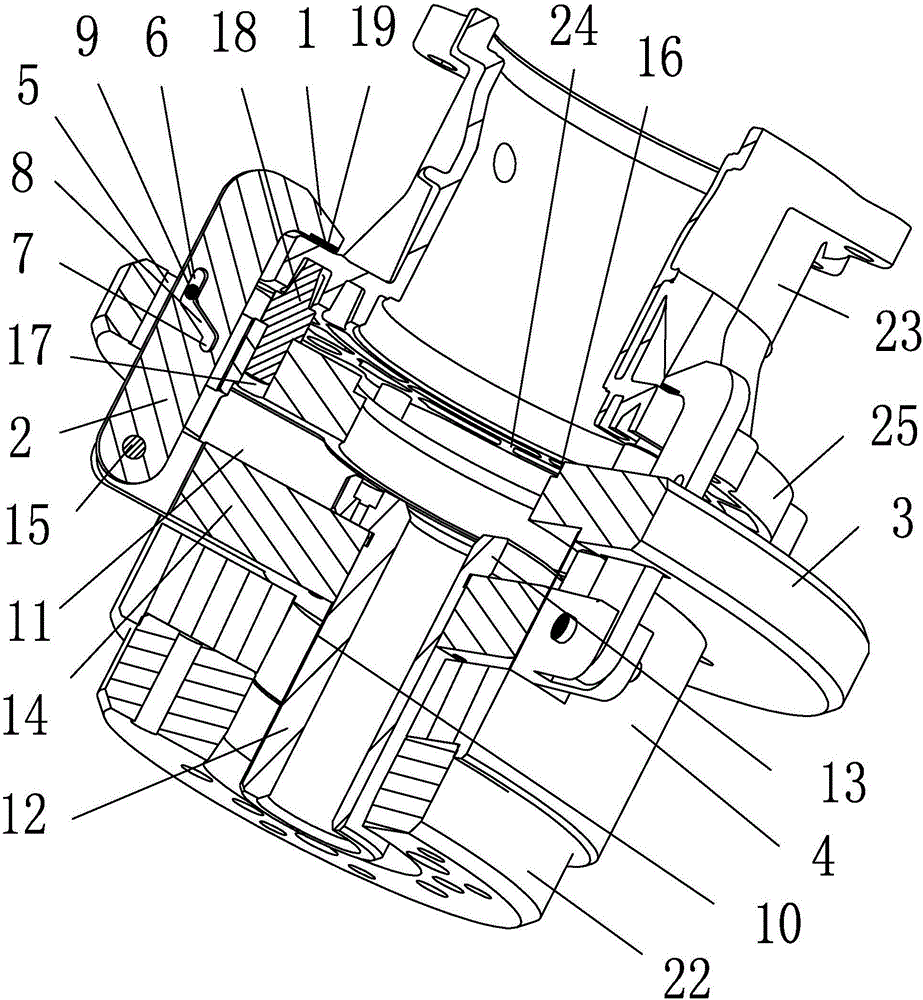

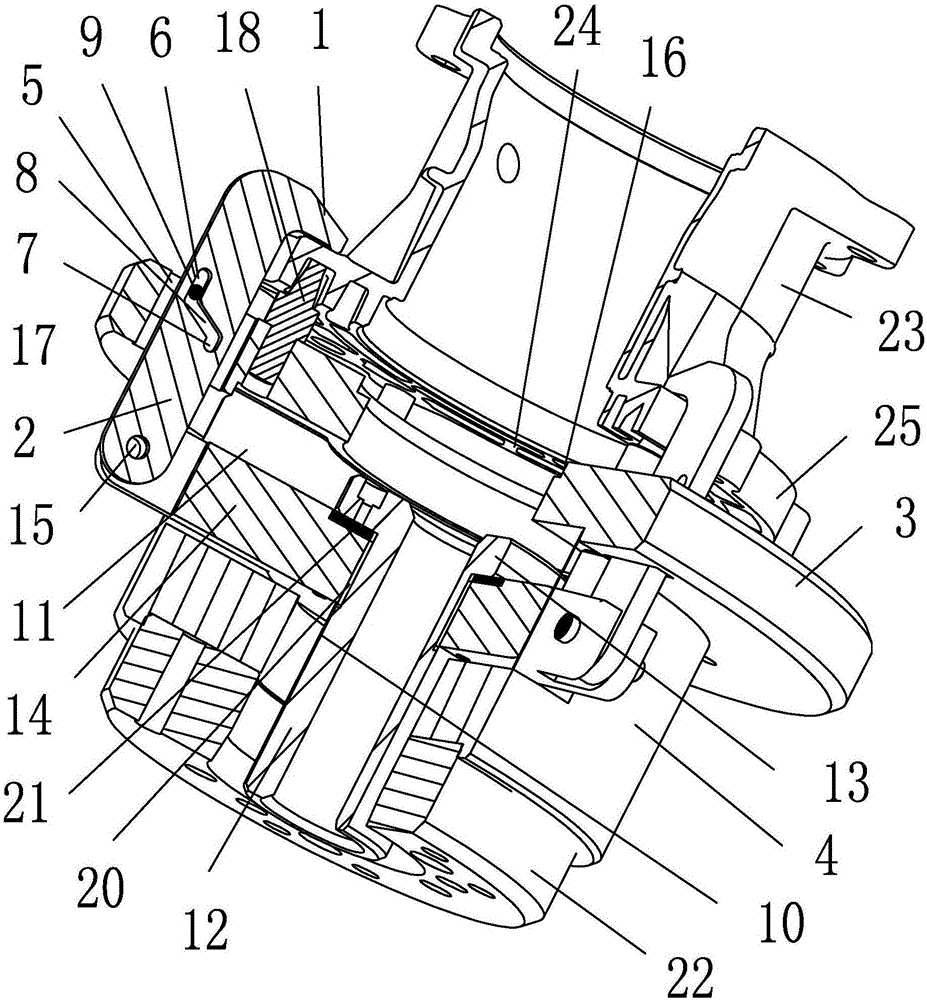

Fuel pump shell machining clamp

InactiveCN106256486AOvercome unevennessEasy loading and unloadingWork clamping meansPositioning apparatusEngineeringMachine tool

The invention relates to the field of machining clamps, and is aimed at providing a fuel pump shell machining clamp which comprises a plurality of pressing rods with claws at front ends and further comprises a positioning plate, a connecting column and a pressing rod driving device. The front end of the connecting column is connected with the rear end of the positioning plate. End through holes which are circumferentially distributed are formed in the positioning plate, and the number of the end through holes is the same as the number of the pressing rods. The pressing rods correspond to the end through holes one to one. The rear ends of the pressing rods penetrate through the end through holes and are connected with the pressing rod driving device. When the fuel pump shell machining clamp is used, the rear end of the connecting column is connected with a connecting flange of a machine tool, a fuel pump shell is placed at the front end of the positioning plate for positioning, the pressing rod driving device pulls the pressing rods to move backwards, and the claws press the front end of the flange of the fuel pump shell for clamping. The fuel pump shell machining clamp clamps the fuel pump shell for machining, and a workpiece can not deform.

Owner:宁波爱得信机械部件有限公司

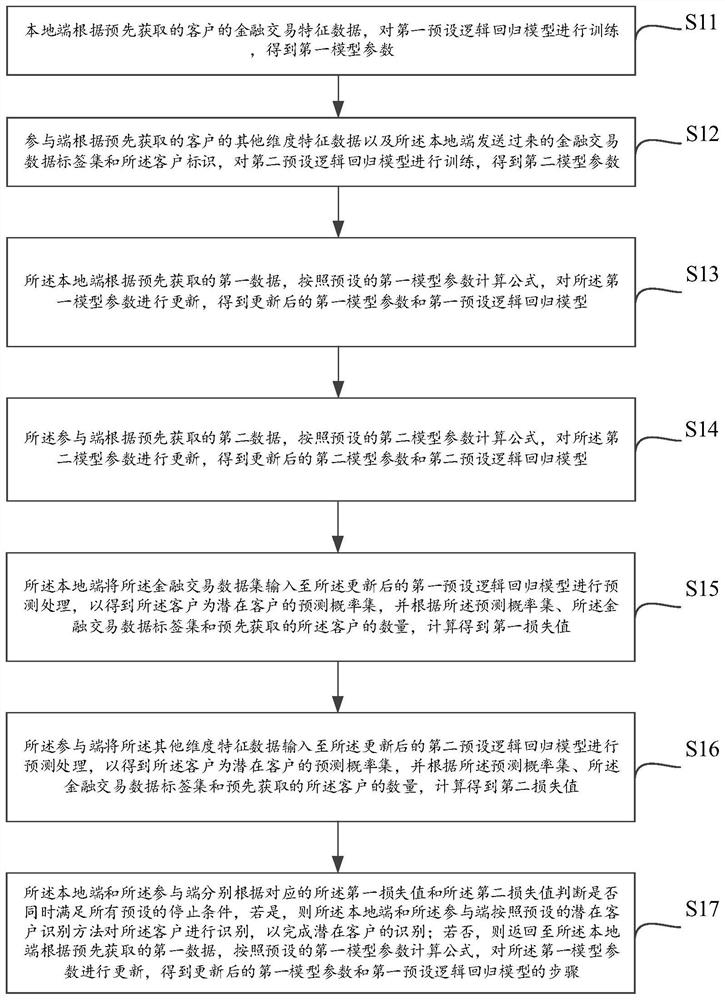

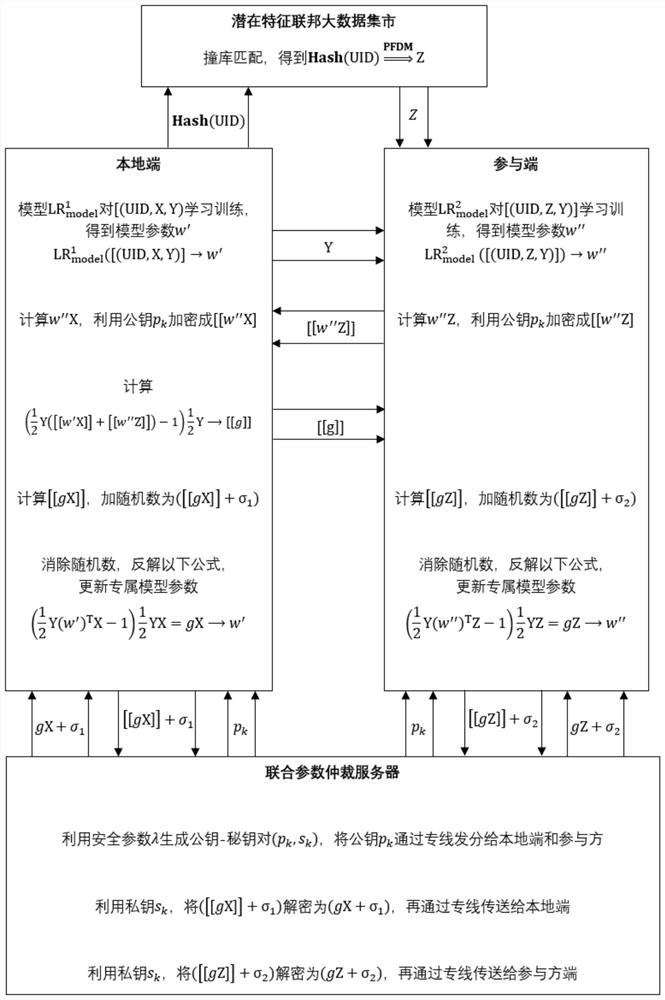

Potential customer identification method and system based on longitudinal federated learning, and medium

ActiveCN113240461AOvercome monotony and imbalanceImprove accuracyFinanceCharacter and pattern recognitionFederated learningData mining

The invention discloses a potential customer identification method and system based on longitudinal federated learning and a medium, and the method comprises the steps that a first loss value of an updated first preset logistic regression model is obtained through the calculation of a local end, and a second loss value of an updated second preset logistic regression model is obtained through the calculation of a participating end; finally, the local end and the participating end judge whether all preset stopping conditions are met at the same time or not according to the corresponding first loss value and the second loss value, and if yes, the local end and the participating end recognize the customer according to a preset potential customer recognition method so as to complete recognition of potential customers; and if not, the appointed steps are repeatedly executed, and judgment is carried out again. According to the potential customer identification method and system based on longitudinal federated learning and the medium provided by the embodiment of the invention, the accuracy of identifying potential customers is improved.

Owner:BANK OF GUANGZHOU CO LTD

Display device and method of driving the same

ActiveUS8633874B2Overcome unevennessVariation in threshold voltageCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceEngineering

Owner:JOLED INC

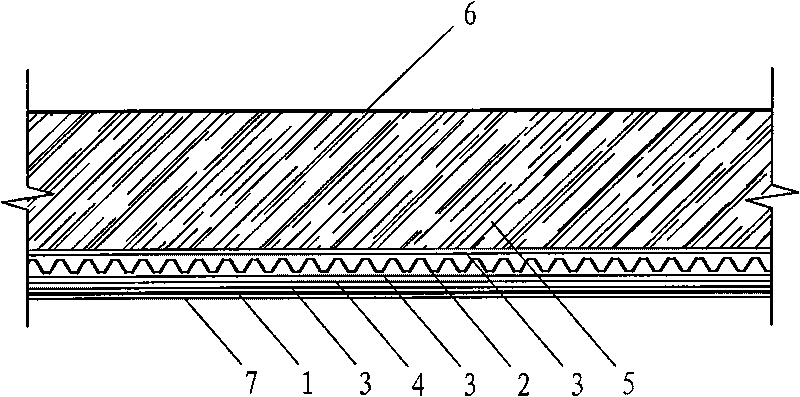

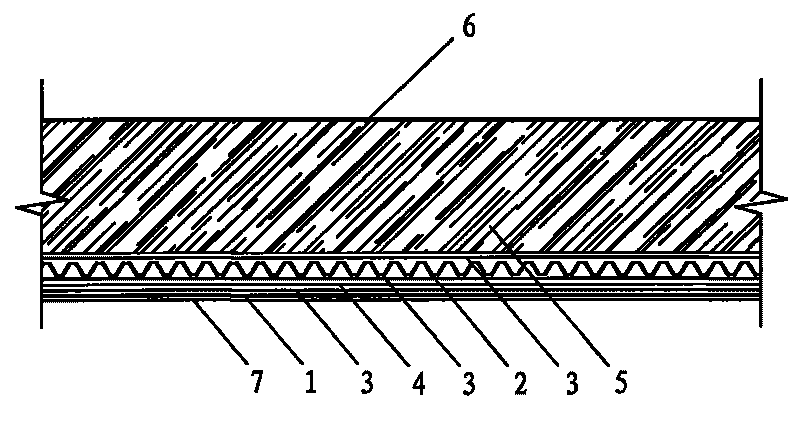

Heat insulating and sound isolating decorative corrugated composite board

The invention relates to a building board, in particular to a heat insulating and sound isolating decorative corrugated composite board which comprises a metallic board and a metallic corrugated board, wherein a resin layer is respectively attached to the lower surface of the metallic corrugated board and the back surface of the metallic board; the metallic board and the metallic corrugated board are bonded and composited together between the resin layer on the lower surface of the metallic corrugated board and the resin layer on the back surface of the metallic board through a bonding agent; a heat insulating and sound isolating layer is also bonded on the upper surface of the metallic corrugated board; the heat insulating and sound isolating layer is a heat insulating and sound isolating board or sound isolating cloth; a resin layer is also arranged between the upper surface of the metallic corrugated board and the heat insulating and sound isolating layer; and the resin layer is attached to the upper surface of the metallic corrugated board. The heat insulating and sound isolating decorative corrugated composite board has higher strength and good surface smoothness and meets the national standards.

Owner:张建卫

Corrosion-resistant glaze for pottery pot and glazing method thereof

The invention discloses a corrosion-resistant glaze material for a pottery pot. The corrosion-resistant glaze is prepared from the following raw materials in parts by weight: 20 to 50 parts of kaolin, 5 to 20 parts of limestone, 7 to 21 parts of potassium feldspar, 8 to 24 parts of lepidolite, 1 to 5 parts of zirconium oxide, 2.6 to 3.4 parts of zinc oxide, 1.3 to 2.7 parts of tin oxide, 10 to 20 parts of terpene resin and 15 to 30 parts of 1-hydroxyethylidene-1, 1-diphosphonate. The invention further discloses a glazing method of the corrosion-resistant glaze for the pottery pot, the process is simple, and raw materials are easy to obtain. The pottery pot glaze prepared by the method has the characteristic of excellent corrosion resistance.

Owner:重庆名檀陶瓷有限公司

Natural fiber reinforced polyurethane elastomer composite material and preparation method thereof

The invention discloses a natural fiber-reinforced polyurethane elastomer composite material. The natural fiber-reinforced polyurethane elastomer composite material is prepared from the following components in parts by weight: 30-70 parts of natural fibers and 70-30 parts of polyurethane elastomers, wherein the natural fibers are selected from jute, sisal, hemp, flax and ramie, and the polyurethane elastomers are selected from hard polyurethane elastomers, soft polyurethane elastomers or half-hard polyurethane elastomers. The invention further discloses a preparation method of the natural fiber-reinforced polyurethane elastomer composite material. According to the natural fiber-reinforced polyurethane elastomer composite material and the preparation method, as the degradable natural fiber is taken as the raw material, the environmental protection is benefited; and the raw materials of a component A and a component B of liquid polyurethane are mixed to soak a natural fiber felt and then the natural fiber felt is cured and formed, so that the problem of the uneven surface of a product, caused in the conventional pouring process of the glass fibers and the polyurethane elastomers, is overcome, and the prepared composite material has the characteristics that the abrasive resistance is good and the shock strength is improved and can be used for replacing the conventional glass fiber-reinforced composite material to be used in automotive interior decoration parts.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

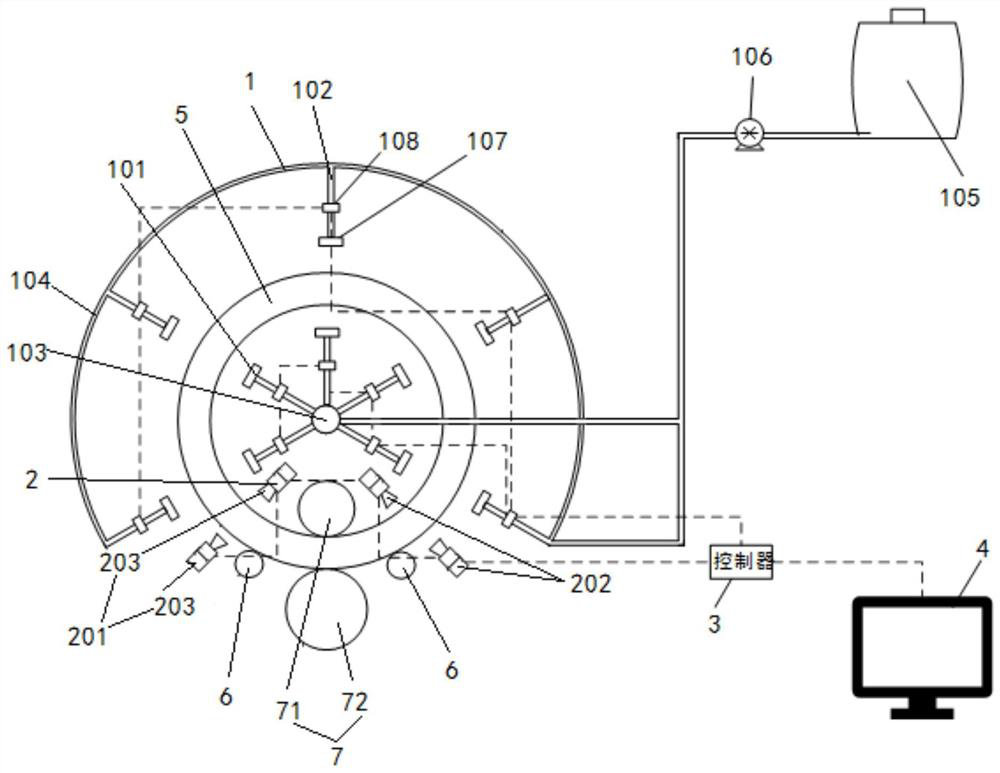

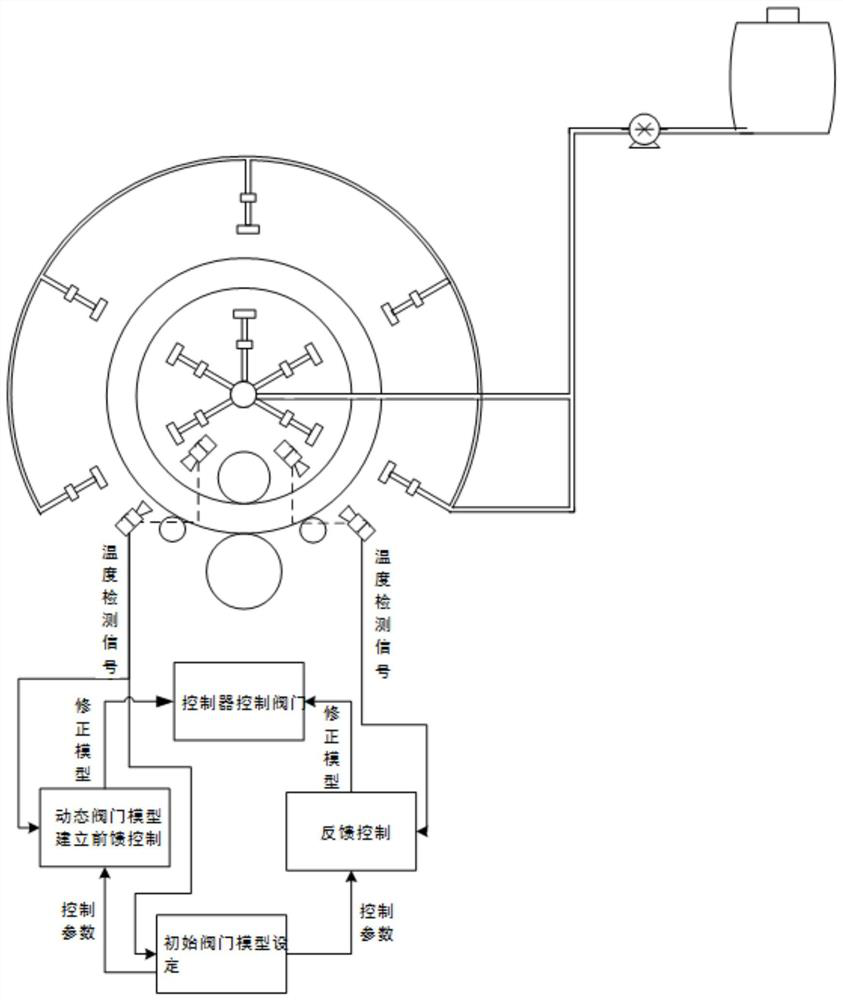

A kind of uniform cooling system and method for differential temperature rolling of large cylinder section

ActiveCN113695405BHomogeneous temperature gradientUniform internal organizationTemperature control deviceMeasuring devicesThermodynamicsJet flow

Owner:YANSHAN UNIV

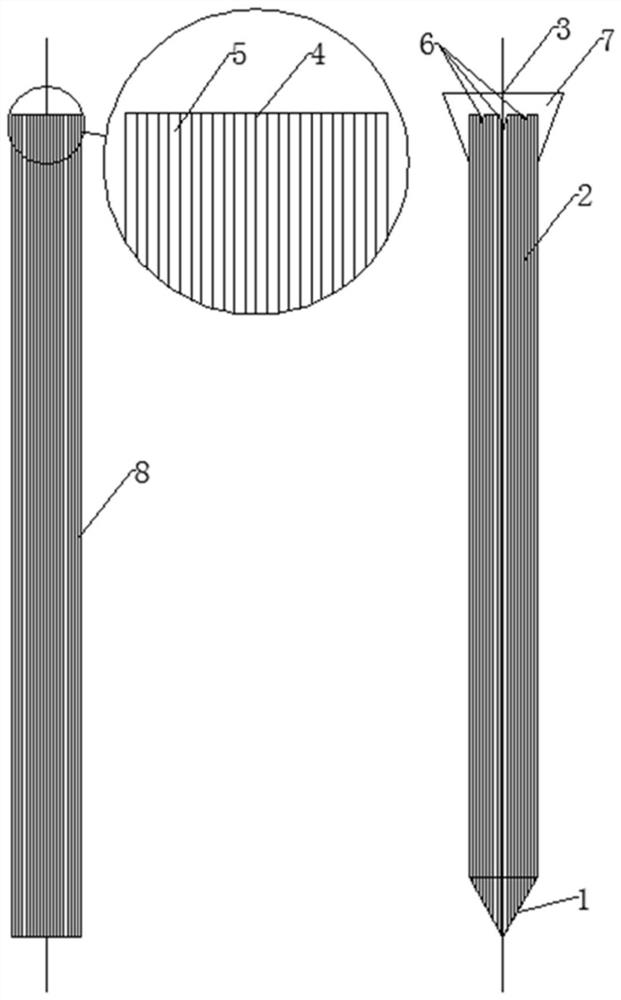

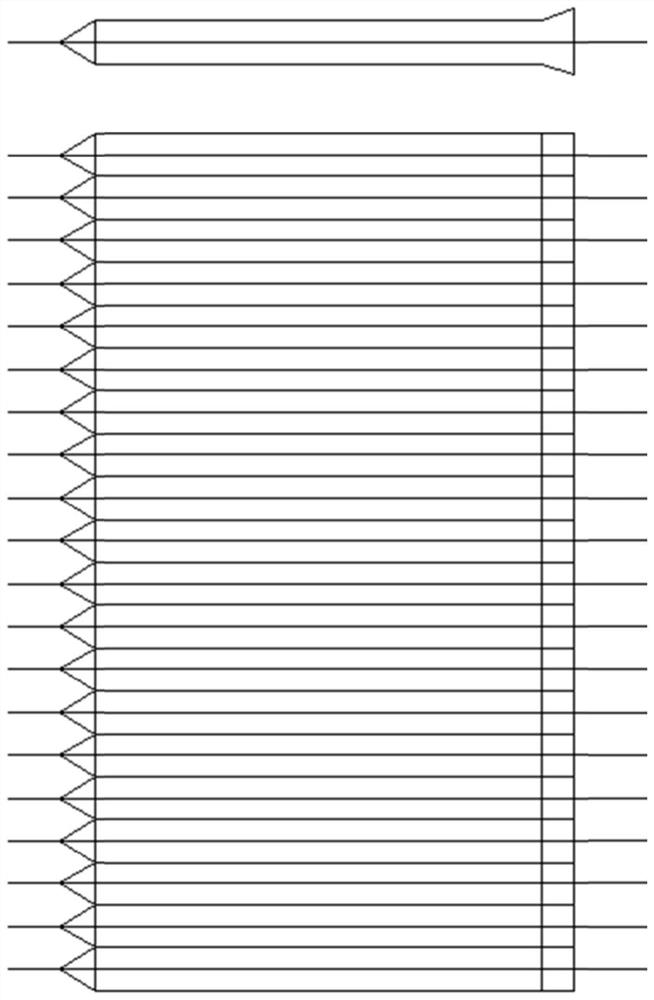

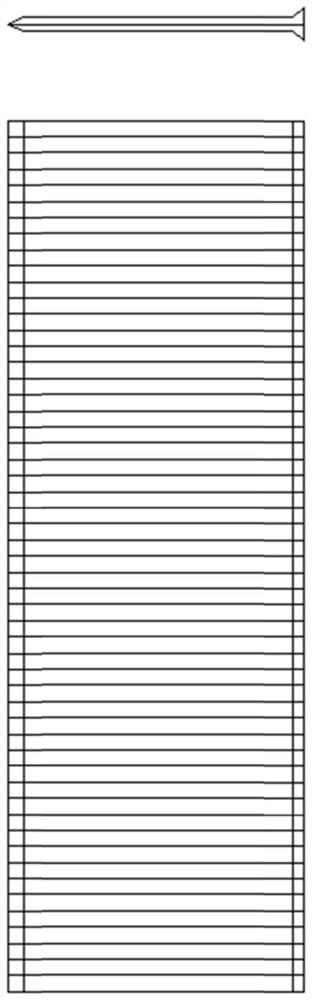

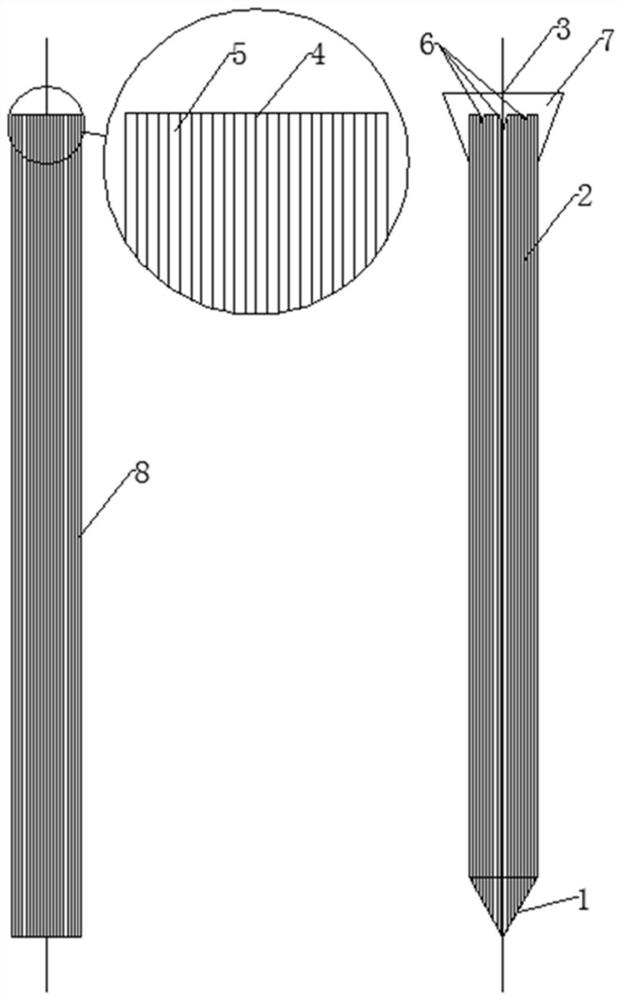

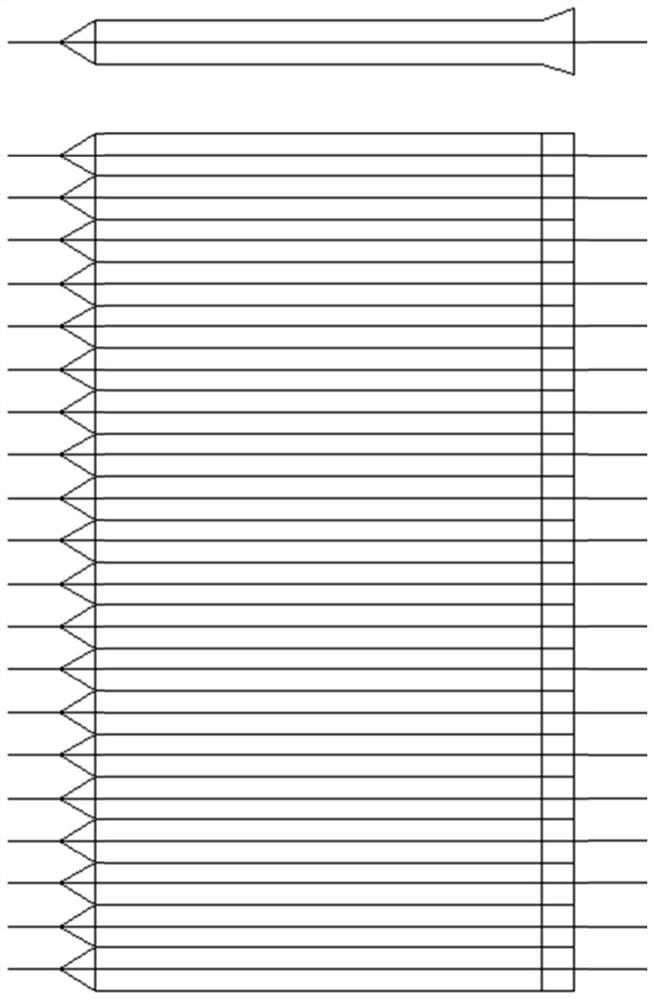

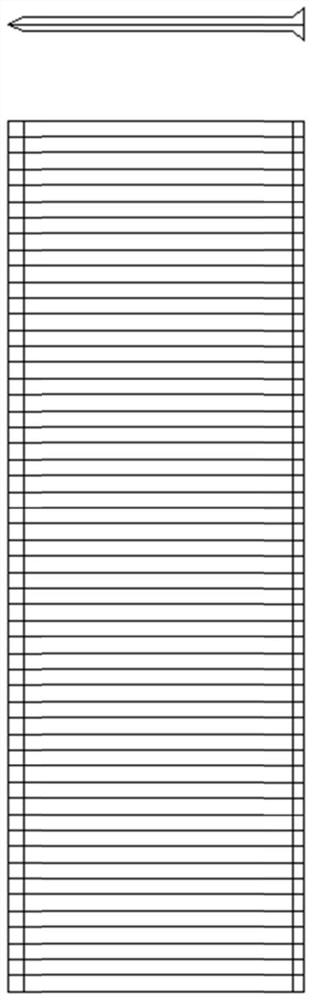

Bamboo gun nail and production method thereof

ActiveCN113681669BSolve the problem of impermeabilitySolve the problem of high requirements for milling cutter sharpeningBio-packagingWood treatment detailsAdhesiveMechanical engineering

This application discloses a bamboo gun nail and its production method. The bamboo gun nail is made of a plurality of bamboo nails with equal thickness and width bonded in parallel to form a row. The nail heads of the bamboo nails are polygonal wedge-shaped or conical. The nail body of two adjacent bamboo nails is separated by adhesive. The thickness of the nail tail of the bamboo nail is greater than the thickness of the nail body, which are respectively square or rectangular. The bamboo nail is a reinforcement layer and a thin Bamboo layer-a layered structure at intervals, with a density greater than 1200kg / m 3 .

Owner:钱一辰

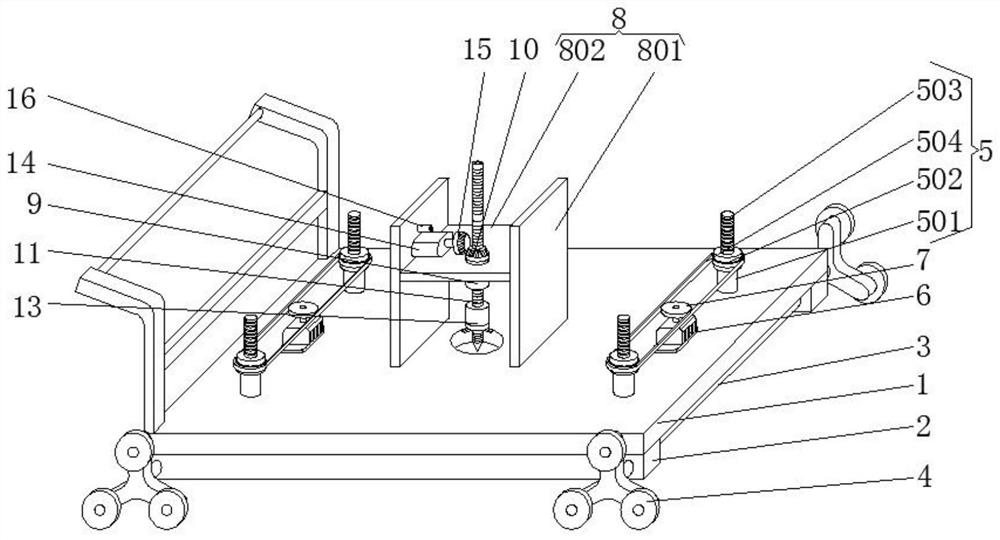

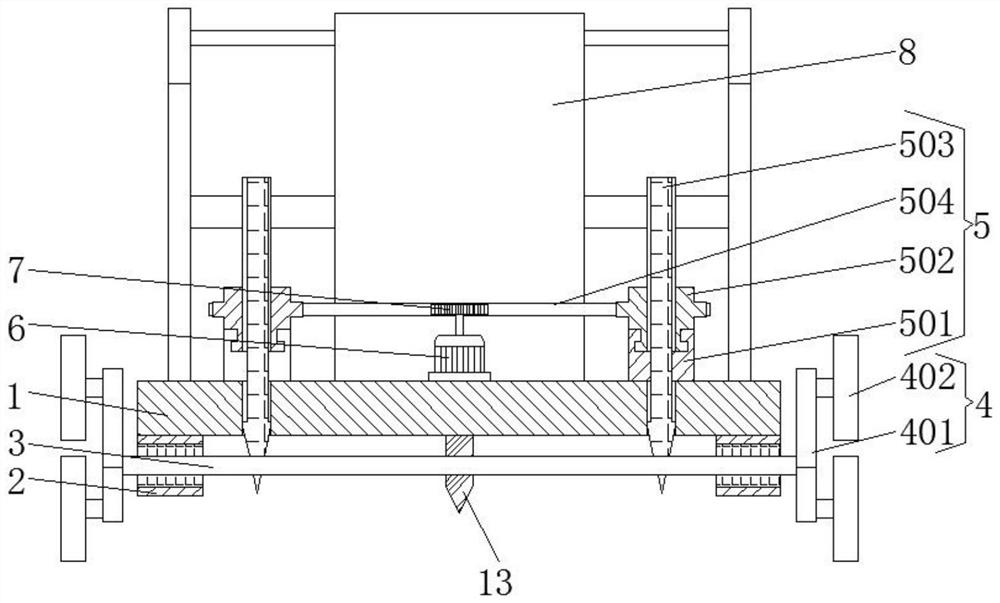

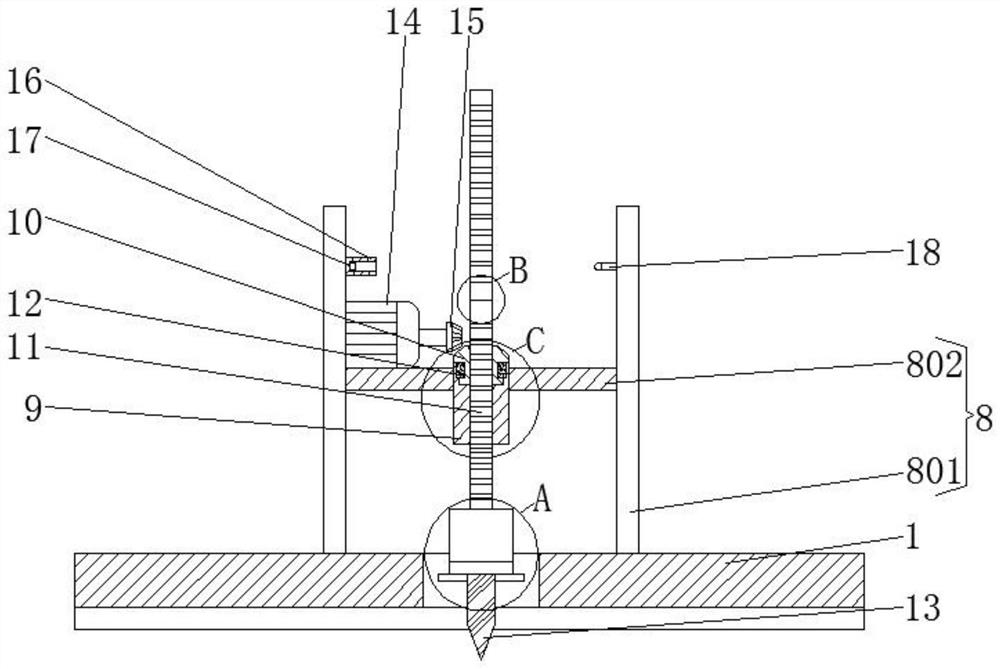

Portable shallow-water layer punching device suitable for hydrogeology

InactiveCN111794677AOvercome unevennessAvoid affecting the effect of punchingDrilling rodsConstructionsPunchingGear wheel

The invention discloses a portable shallow-water layer punching device suitable for hydrogeology. The portable shallow-water layer punching device comprises a moving base, wherein a mounting base is fixedly connected to the lower surface of the moving base, a rotary rod is inserted into the mounting base, moving mechanisms across obstacles are fixedly connected to both ends of the rotary rod, a punching positioning mechanism is connected to one side of the upper surface of the moving base, a positioning motor is connected to the upper surface of the moving base and is located on the side surface of the punching positioning mechanism, a positioning driving gear is connected to the output end of the positioning motor in a transmission mode, a punching bracket is arranged on the upper surfaceof the moving base, and a punching guide sleeve is inserted into the punching bracket. According to the portable shallow-water layer punching device suitable for hydrogeology, the punching positioning mechanism is matched with the positioning motor, so that the device can be easily and stably fixed to the ground by virtue of a positioning rod during use, the vibration generated during punching isprevented so as not to influence the punching effect, and a drilling mechanism is arranged, so that a punching drill can be conveniently and quickly replaced.

Owner:NORTHWEST UNIV

Bamboo gun nail and production method thereof

ActiveCN113681669ASolve the problem of impermeabilitySolve the problem of high requirements for milling cutter sharpeningBio-packagingWood treatment detailsAdhesiveMechanical engineering

The invention discloses a bamboo gun nail and a production method thereof. The bamboo gun nail is formed by connecting and bonding a plurality of bamboo nails with the same thickness and width in parallel into a row, the nail head of each bamboo nail is in a polygonal wedge shape or a conical shape, nail bodies of every two adjacent bamboo nails are separated through an adhesive, and the thickness of the nail tail of each bamboo nail is larger than that of the nail bodies. The bamboo nails are square or rectangular, each bamboo nail is of a layered structure with a reinforcing layer and a thin bamboo piece layer spaced one by one, and the density is larger than 1200 kg / m<3>.

Owner:钱一辰

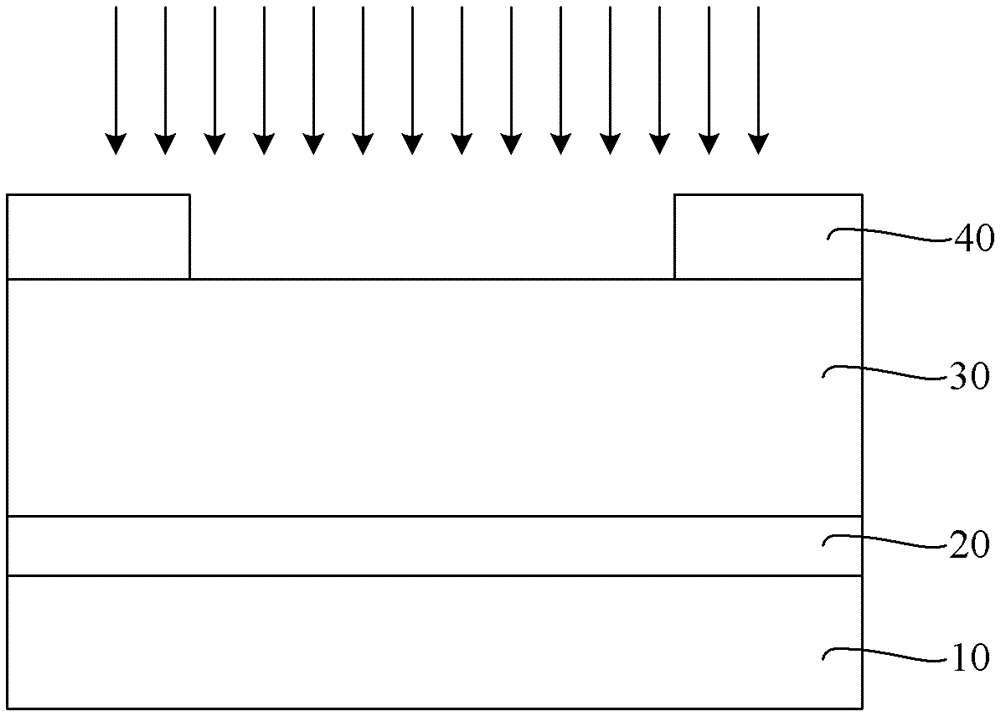

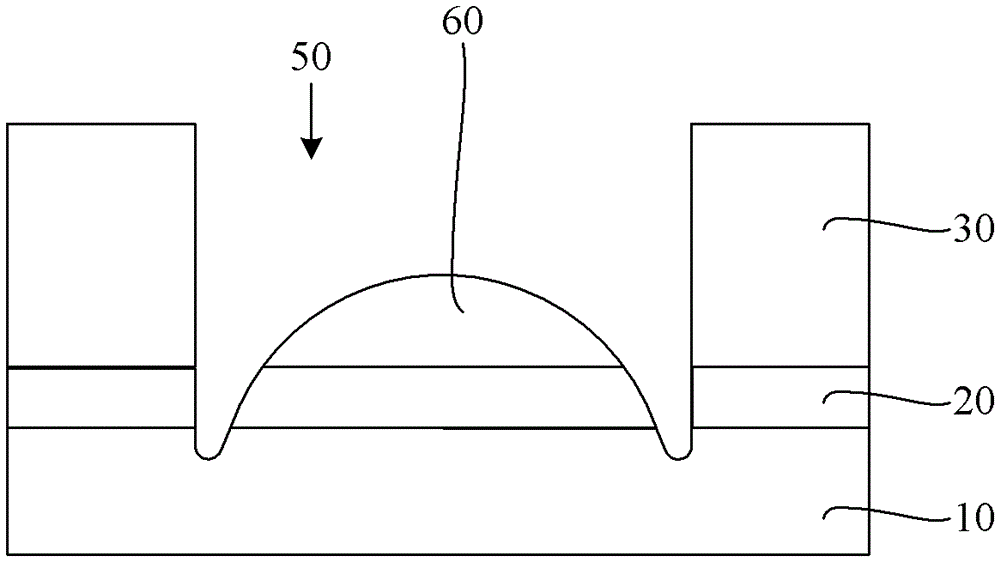

Semiconductor structure and manufacturing method thereof

ActiveCN111883520BOvercome unevennessImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDevice material

Owner:YANGTZE MEMORY TECH CO LTD

Guide rail type automatic troweling machine

PendingCN106836758ACompact structureEasy to makeBuilding constructionsReciprocating motionStructural engineering

The invention discloses a guide rail type automatic troweling machine which comprises a guide rail, a support capable of horizontally sliding on the guide rail in a reciprocating mode, and a box body capable of vertically moving in the support in a reciprocating mode. The box body is provided with a troweling device capable of coating a wall with lime in a pressing mode and a driving device for driving the troweling device to move. A power transmission mechanism for connecting the driving device with the troweling device is arranged on the outer side of the box body, and a lifting mechanism capable of driving the box body to vertically move in a reciprocating mode is arranged between the driving device and the support. The guide rail type automatic troweling machine is compact in structure and easy to manufacture, the wall can be flat and tightly coated with the lime well in the pressing mode through compound motion formed by vertical reciprocating motion of the box body and rotation of the troweling device, the guide rail type automatic troweling machine can slide on the guide rail to trowel different regions of the wall, the working speed is high, the effect is good, labor intensity is greatly reduced, and the decoration cost is effectively reduced.

Owner:WUZHOU UNIV

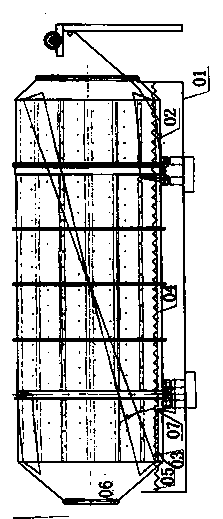

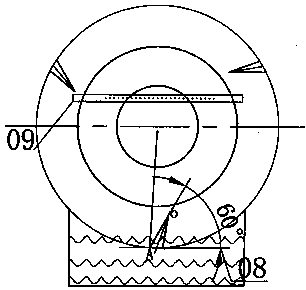

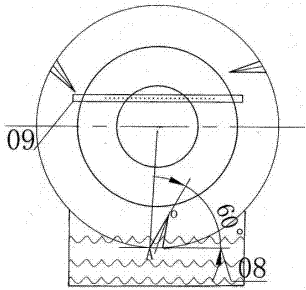

Wax-throwing machine with water groove

The invention discloses a wax-throwing machine with a water groove. The wax-throwing machine comprises an open width washing and spray device (09), a rotating wax-throwing cylinder (02), a width expanding cropping device as well as a power and driving device, and the wax-throwing machine is characterized in that the wax-throwing cylinder is a one-way rotating wax-throwing cylinder; the lower part of the wax-throwing cylinder is provided with a water supplying groove (01), and the lower part of the wax-throwing cylinder stretches 1-2.5cm into a water supplying groove inner water surface (05); the inner wall of the wax-throwing cylinder is provided with three levogyration spiral ribs (03), and the spiral ribs and the axial lead of the wax-throwing cylinder can form a 20-degree angle (07); the levogyration spiral ribs of the wax-throwing cylinder and the left side of the lowest position in the wax-throwing cylinder can form a chord tangent angle (08) which is 60 degrees, and the wall of the wax-throwing cylinder is provided with a plurality of through holes (04) the diameters of which are 2-2.5cm. The wax-throwing machine provided by the invention has the advantages that the manufactured wax stripe is distinct and fine and smooth, the consistency is good, a wax printed cloth is prevented from twisting, and the residual wax is easy to clean; the wax-throwing machine also adopts the one-way rotation, and disadvantage that the wax stripe has defects because the wax printed cloth twists is effectively solved.

Owner:南充嘉美印染有限公司

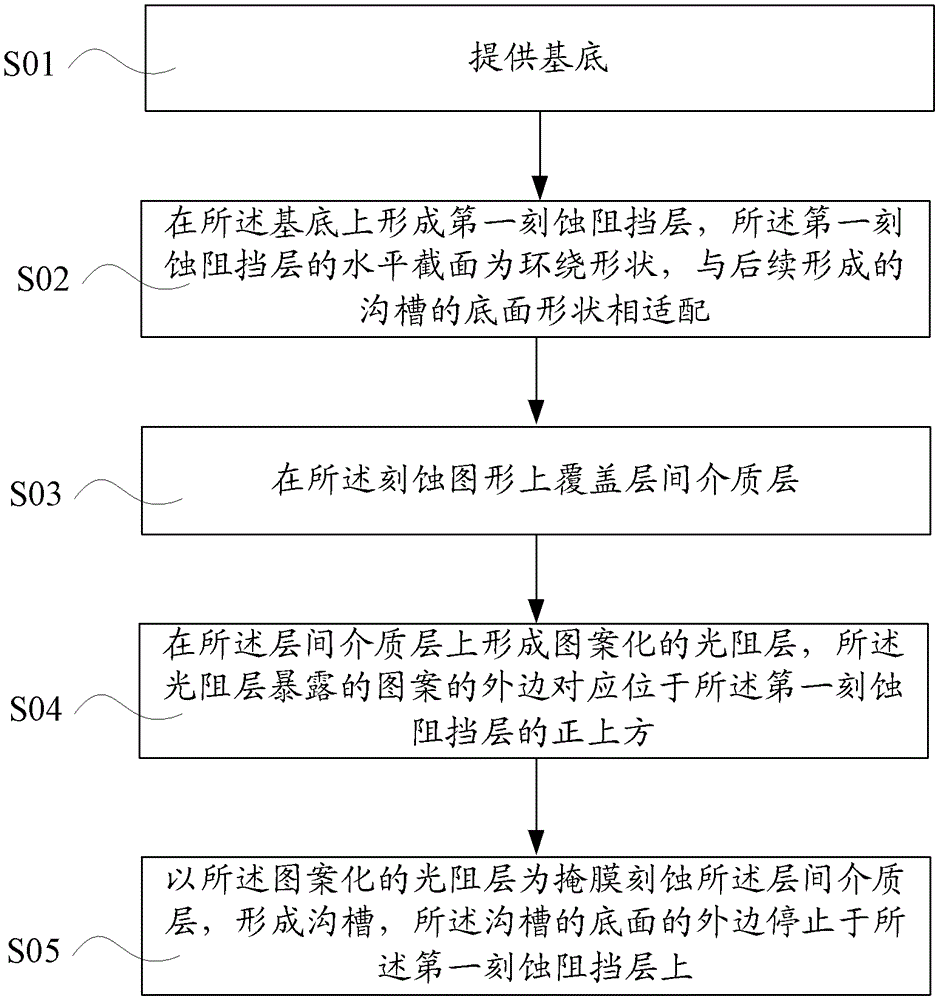

Manufacturing method of semiconductor device

ActiveCN103187265BImprove performanceProtect from etch damageSemiconductor/solid-state device manufacturingSemiconductorMetal

The invention provides a manufacturing method of a semiconductor device. A first etching barrier layer is formed on a substrate, the horizontal cross section of the first etching barrier layer is circle-shaped and matched with the shape of the bottom face of a groove formed in follow-up process, and therefore the thickness of an etching barrier pattern on the edge outside the bottom face of the groove is increased. In the process of etching to form the groove, the outer edge of the bottom face of the formed groove can stop at the first etching barrier layer, therefore the problem that the bottom face is uneven due to the fact that etching removing speed near the edge outside the groove is larger than the etching removing speed in the middle is solved, the substrate below the etching barrier layer is prevented from being damaged by etching, the phenomenon of short circuit of the device due to the fact that a super-thick metal layer enters the semiconductor substrate when the super-thick metal layer is formed in a deposition mode can be avoided, the super-thick metal layer which is good in electric connection characteristic can be formed in the follow-up process, and the performance of the semiconductor device can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Wax-throwing machine with water groove

Owner:南充嘉美印染有限公司

A cavity type bulk acoustic wave resonator and its preparation method

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com