Method for laminating multilayer printed circuit board

A core board and outer layer technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as unevenness of the PCB surface, and achieve the effect of overcoming the unevenness of the board surface and improving the production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

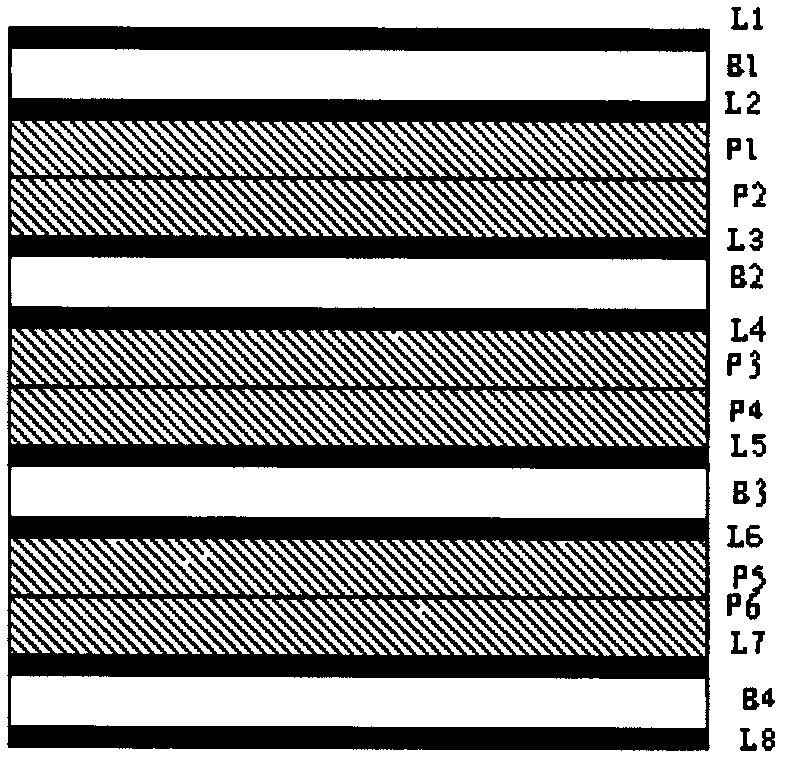

[0013] Embodiments of the present invention provide a method for laminating multilayer PCBs. A prefabricated core board is used to make the outer layer of a multilayer PCB, wherein the core boards are composed of two conductive layers and a curing sheet, and the curing sheet is located between two Between the two conductive layers, the two conductive layers respectively constitute the outer layer and the sub-outer layer of the multilayer PCB.

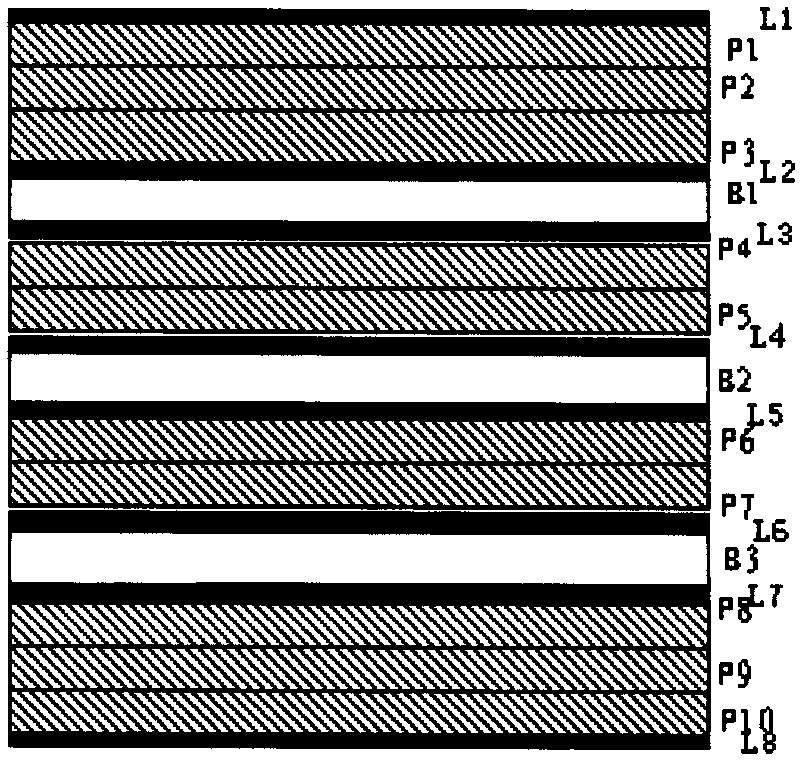

[0014] in such as figure 1 In the related technology shown, the outermost conductive layers L1 and L8 use separate copper foils for temporary thermocompression bonding, and P1, P2 and P3, and P8, P9 and P10 are in a flowing state during the lamination process, so Both the conductive layer L1 and the conductive layer L8 are affected by other internal conductive layers L2, L3, L4, L5, L6 and L7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com