Outer wall plate connecting piece and construction method

A technology for exterior wall panels and connectors, which is applied in covering/lining, construction, building construction, etc., which can solve the problems of inaccurate positioning and low precision of exterior wall panels, and achieve improved comprehensive installation efficiency, convenient processing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

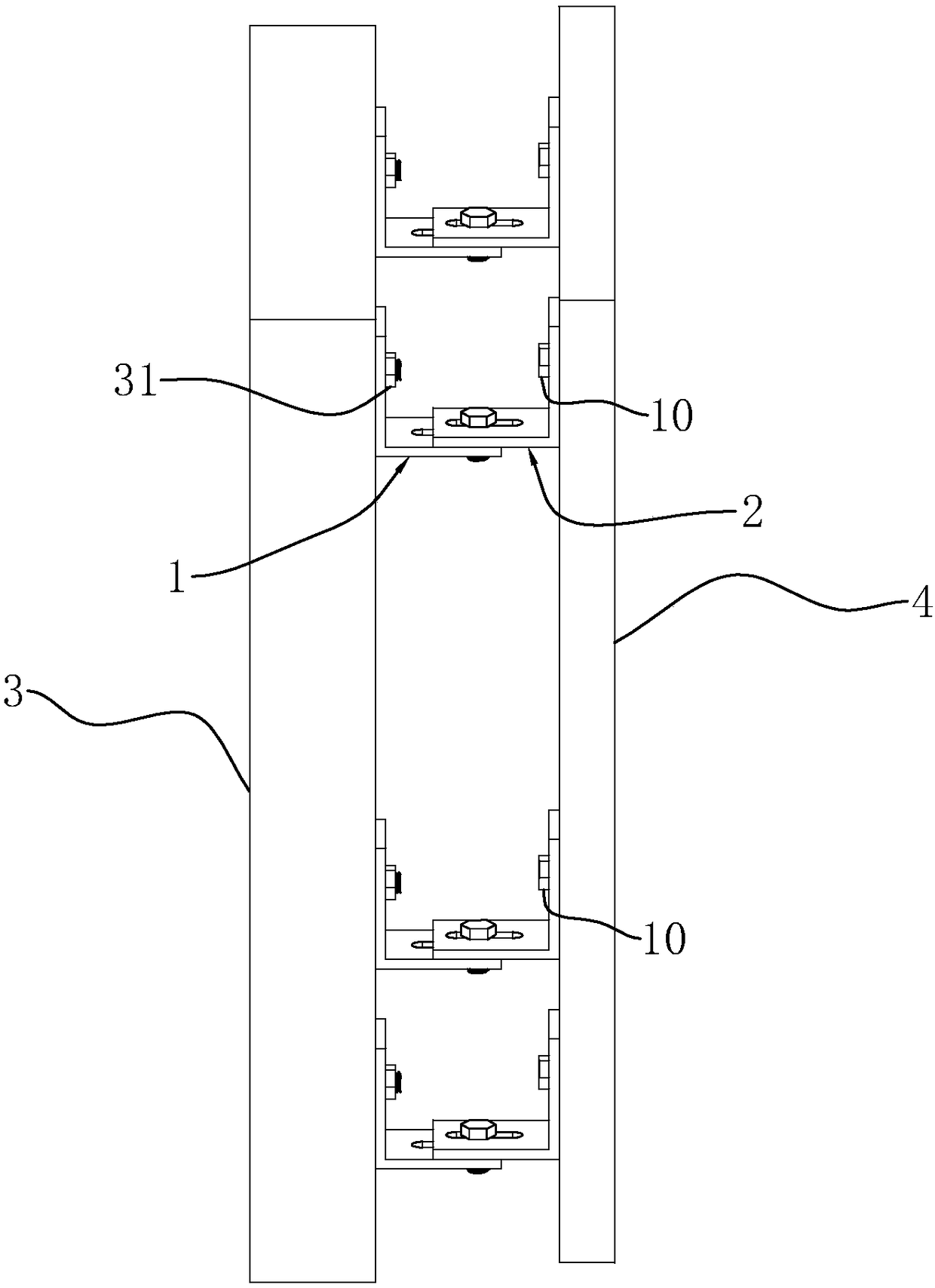

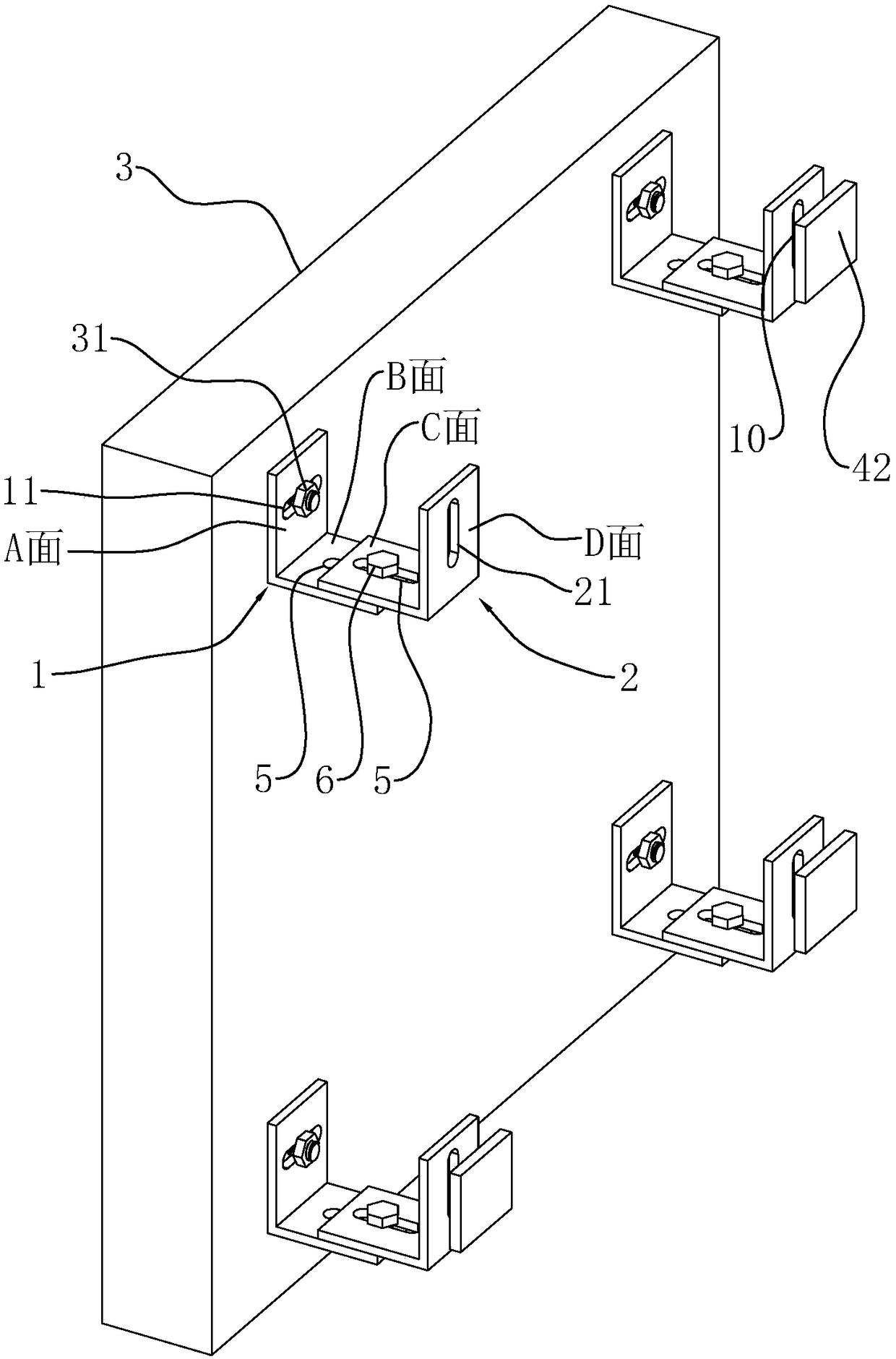

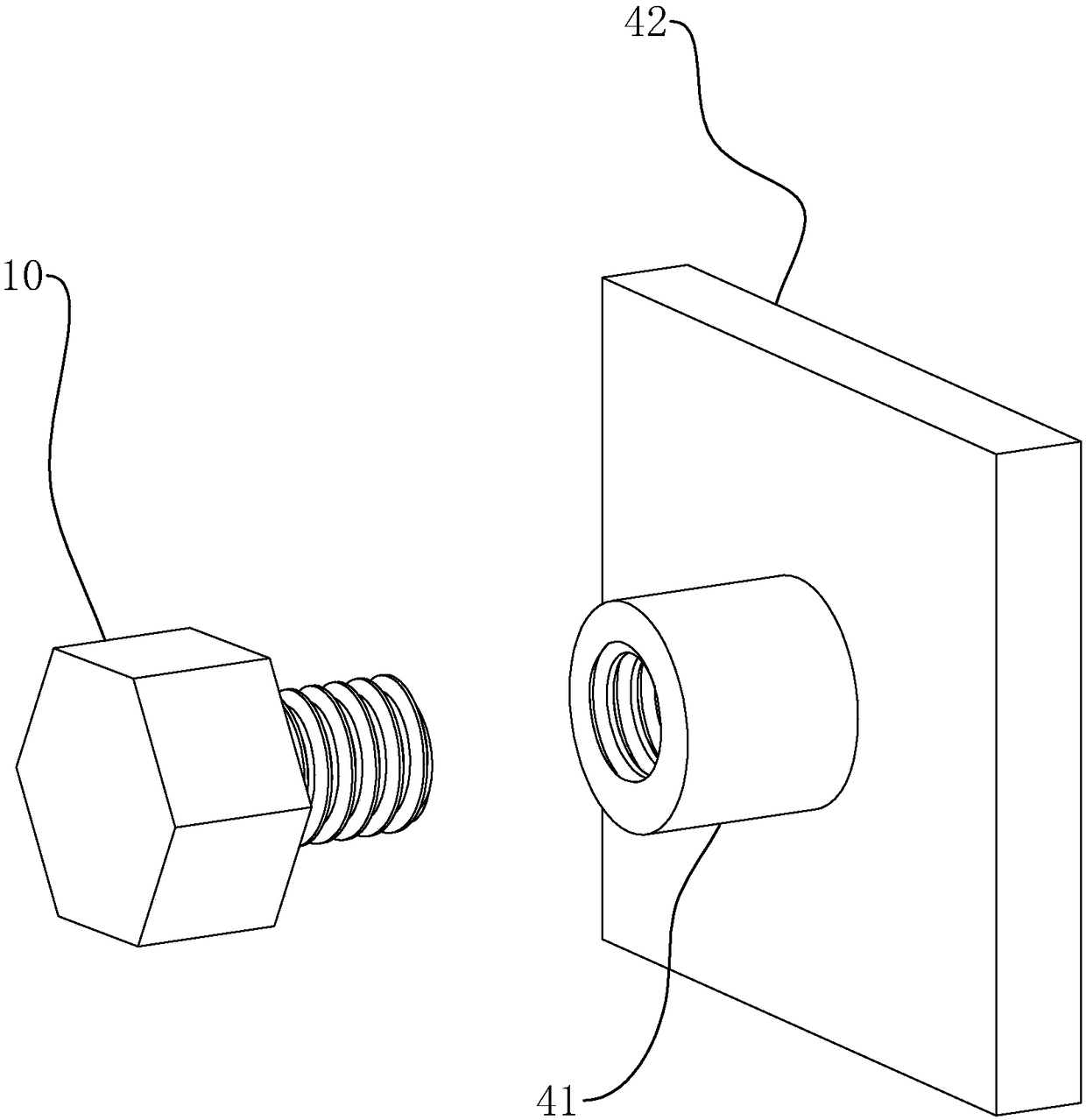

[0043] Such as figure 1 and figure 2 As shown, a connector is provided near the four corners of each exterior wall panel 4, and embedded bolts 31 ( figure 2 The exterior wall panel 4) is not shown in . The external wall panel connector includes a first angle steel 1 , a second angle steel 2 , a first bolt 6 and a second bolt 10 . The first angle steel 1 includes a surface A and a B surface, and the second angle steel 2 includes a C surface and a D surface. The lower U-shaped groove structure (the opening is facing upwards in the figure); the horizontal direction of the A surface is provided with strip-shaped horizontal adjustment bolt holes 11, and the pre-embedded bolts 31 pre-buried on the building exterior wall 3 pass through. The first angle steel 1 is fixed through the horizontal adjustment bolt hole 11; the B surface and the C surface are provided with a strip-shaped distance adjustment hole 5 perpendicular to the outer wall panel 4, and the first bolt 6 passes thro...

Embodiment 2

[0048] Such as Figure 4 As shown, the difference from Embodiment 1 lies in the following:

[0049] In order to make the fixing of the outer wall panel 4 more firm, the first bolt 6 includes two bolts, and a rubber backing plate 7 is provided between the B surface and the C surface. The rubber backing plate 7 can not only increase the frictional force between the B surface of the first angle steel 1 and the C surface of the second angle steel 2, but also when the height deviation value of the embedded bolt 31 exceeds the adjustment range of the vertical adjustment bolt hole 21 , the up and down position of the exterior wall panel 4 can be further adjusted by selecting rubber backing plates 7 of different thicknesses.

[0050] In order to prevent the second bolt 10 from loosening, the outer wall panel 4 slides downward, that is, the second bolt 10 moves downward along the vertical adjustment bolt hole 21, so the second bolt 10 and the C surface of the second angle steel 2 are ...

Embodiment 3

[0052] Since in the first embodiment, the arrangement of the connectors is to arrange one at each of the four corners of the exterior wall panel 4, correspondingly, four embedded bolts 31 also need to be arranged on the exterior wall 3 of the building. In order to reduce the number of embedded bolts 31 in the horizontal direction, as Figure 5 and Figure 6 As shown, the first angle steel 1 is set as two distance adjustment holes 5 in its length direction, and the distance between the two distance adjustment holes 5 is equal to two adjacent second bolts 10 on two adjacent exterior wall panels 4 The pre-embedded bolts 31 on the building exterior walls 3 are basically located at the joints 43 in the vertical direction of two adjacent exterior wall panels 4 . That is to say, instead of the original scheme that one embedded bolt 31 corresponds to one first angle steel 1 and one second angle steel 2, one embedded bolt 31 corresponds to one first angle steel 1 and two second angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com