Guide rail type automatic troweling machine

A plastering machine and rail-type technology, which is applied in the direction of construction and building structure, can solve the problems that the consistency of the plastering surface cannot be guaranteed, the safety of the operators cannot be guaranteed, and the artificial plastering environment is harsh. The effect of reducing decoration cost, overcoming the unstable center of gravity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

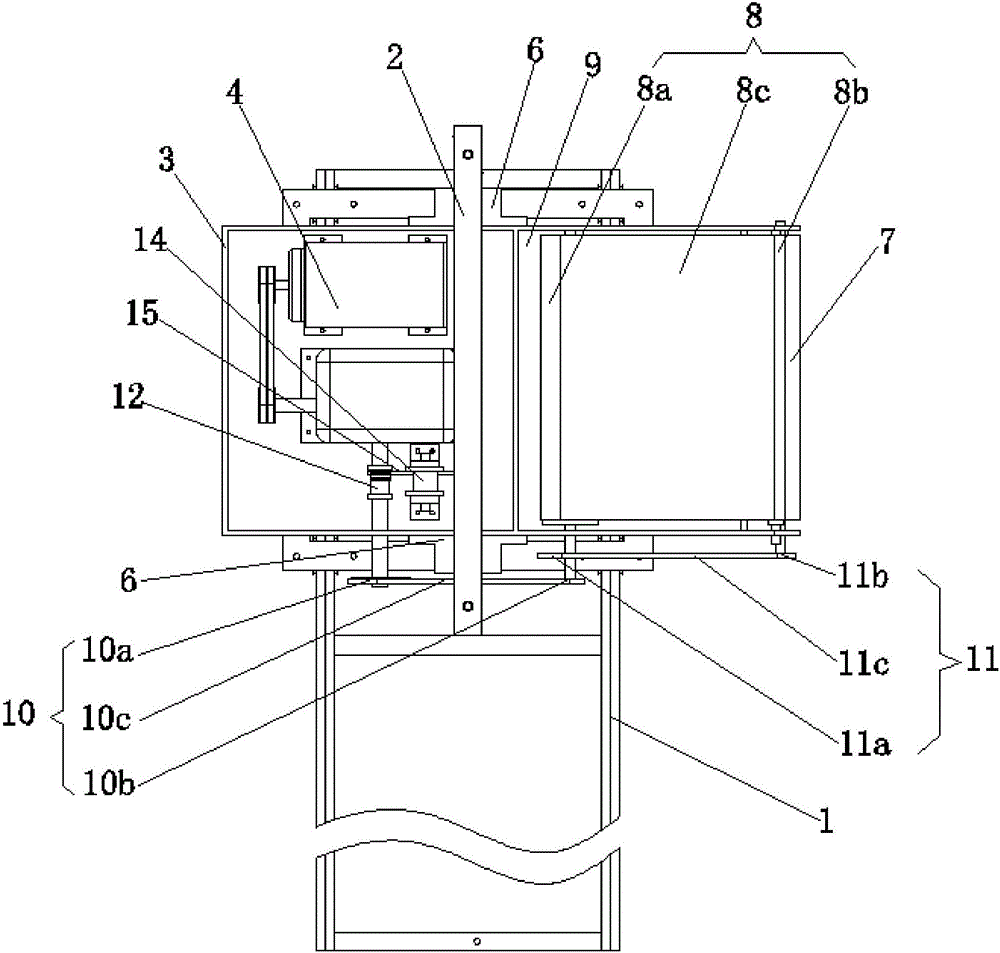

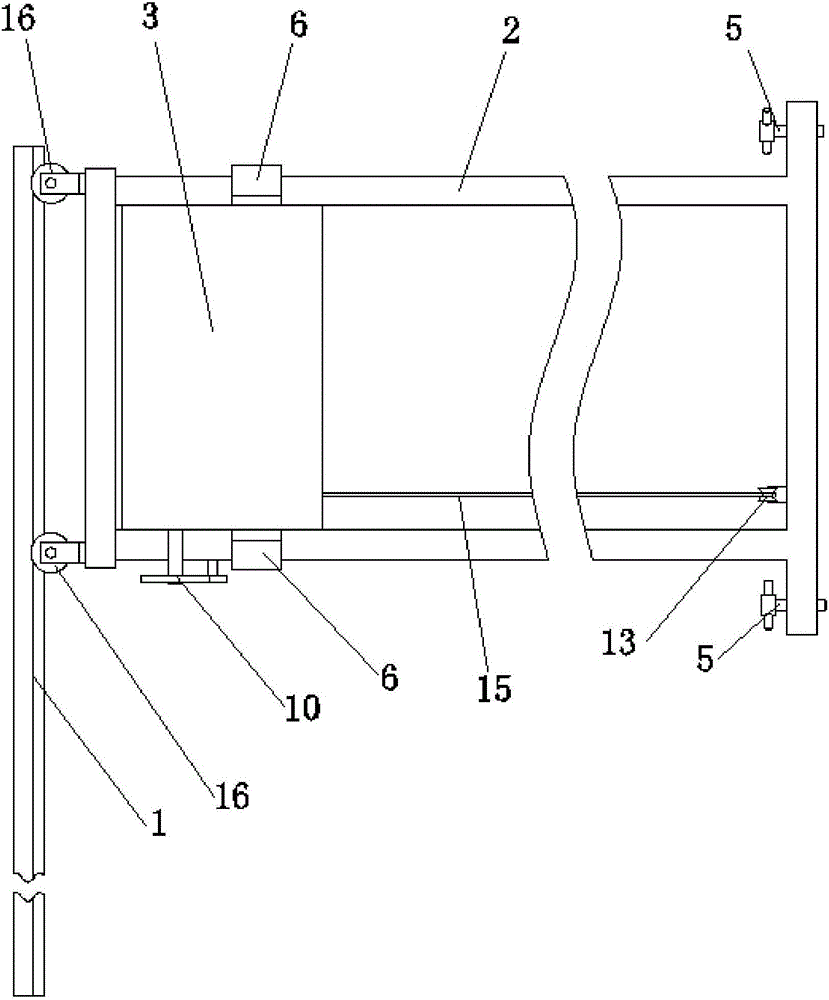

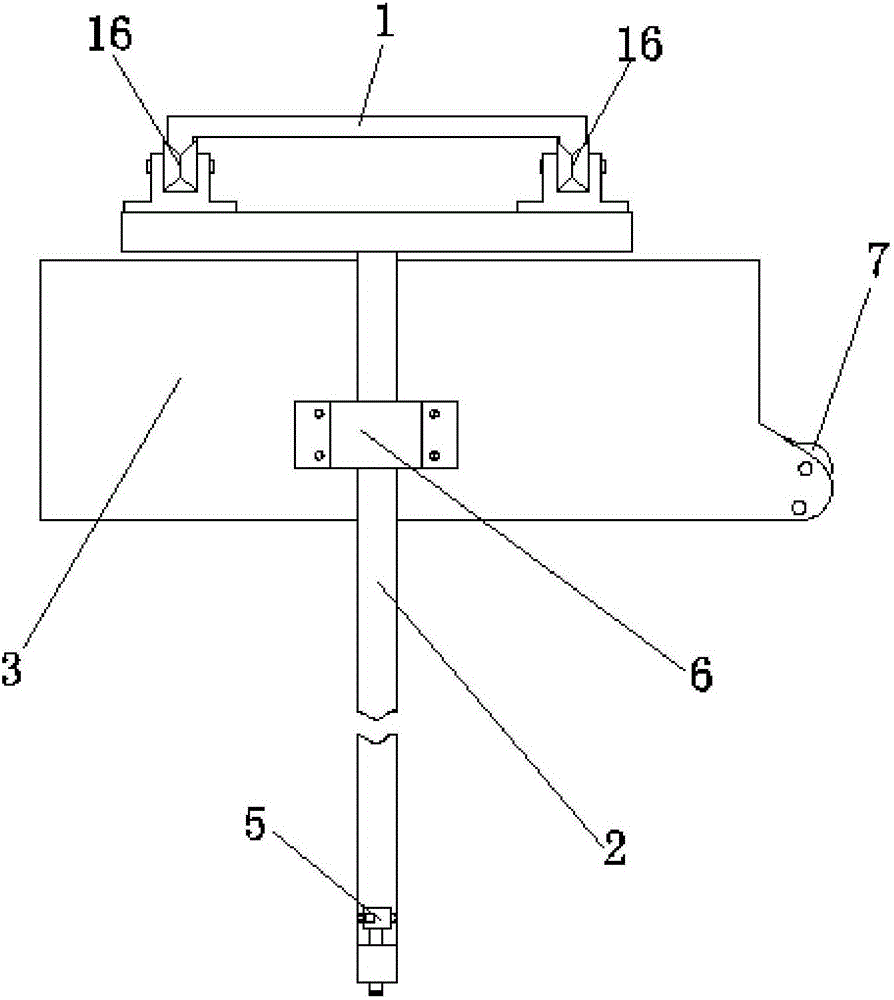

[0030] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0031] refer to Figure 1-9 , a guide rail type automatic plastering machine of the present invention, comprising a guide rail 1, a bracket 2 capable of horizontally reciprocating sliding on the guide rail 1 and a box body 3 capable of reciprocating up and down in the bracket 2, on the box body 3 respectively There is a plastering device that can press and cover the gray material on the wall surface and a driving device 4 that drives the movement of the plastering device. Both the plastering device and the driving device 4 reciprocate up and down with the box body 3, wherein the driving device 4 includes The drive motor and the reduction box transmit power to the outside through the output shaft; a power transmission mechanism connecting the drive device 4 with the plastering device is provided on the outside of the box body 3, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com