Wax-throwing machine with water groove

A technology of wax throwing and sinking, which is applied in the direction of textiles and papermaking, fabric surface trimming, etc., to achieve the effect of solving the defects of wax pattern flakes and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

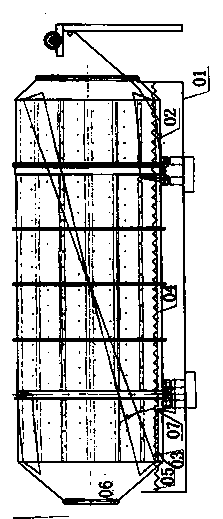

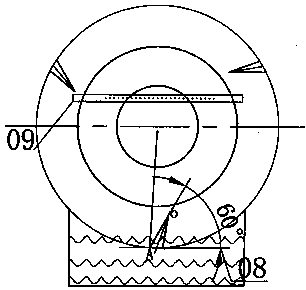

[0007] Such as figure 1 , 2 As shown, the present invention includes an open-width water washing and spraying device 09, a rotating wax removal cylinder 02, a spreading device, a power and a transmission device, and is characterized in that the wax removal cylinder is a one-way rotating wax removal cylinder, and the wax removal The cylinder is provided with a cloth outlet 06, the lower part of the wax throwing cylinder is provided with a water supply tank 01, the lower part of the wax throwing cylinder extends into the water supply tank 05 below the water surface 1-2.5 cm, and the inner wall of the wax throwing cylinder is provided with three left-handed spiral ribs 03, the said The spiral rib 03 is a triangle, O is its top, the spiral rib and the axis of the wax throwing cylinder form an angle of 20 degrees 07, and the chord angle 08 formed by the left-handed spiral rib of the wax throwing cylinder and the left side of the lowest point A in the wax throwing cylinder is 60 deg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com