Lead salt film structure for infrared photoelectricity and preparation method thereof

A lead-salt and thin-film technology, used in circuits, electrical components, final product manufacturing, etc., to improve the specific detection rate, reduce low-frequency noise, and achieve high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 composite structure lead salt film structure

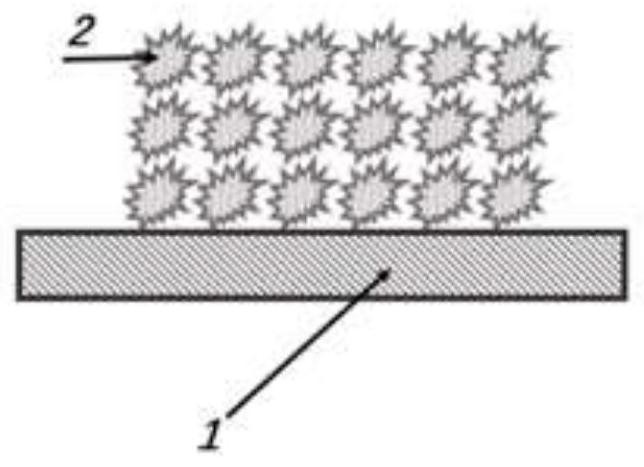

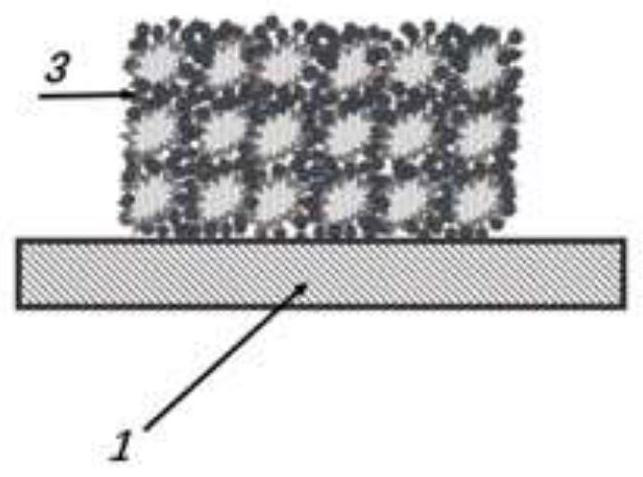

[0046] refer to figure 1 and figure 2 , the present invention provides a kind of compound structure lead salt thin film, 1 is substrate, 2 is the lead salt grain layer of loose structure prepared by physical vapor deposition method, 3 is the small grain lead salt of chemical method growth;

[0047] Wherein, the lead salt grain layer is covered on the substrate, and there are gaps between the lead salt grains;

[0048] Wherein, the small grain lead salt is embedded in the gap between the lead salt grains of the lead salt grain layer;

[0049] Wherein, the lead salt is lead sulfide or lead selenide;

[0050] Wherein, the substrate is a quartz substrate or a sapphire substrate or a silicon wafer containing an oxide layer.

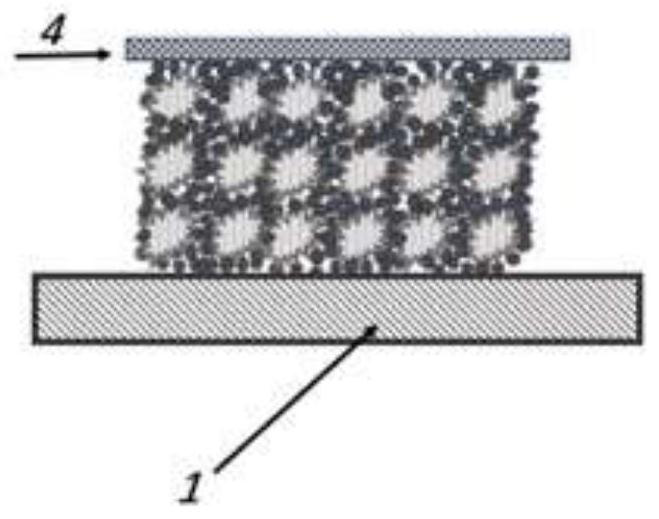

[0051] refer to image 3 , 4 is the passivation layer, after annealing the lead salt thin film of the composite structure, a passivation layer is added, and the passivation layer is bonde...

Embodiment 2

[0052] The preparation of embodiment 2 composite structure lead selenide film

[0053] (1) physical vapor deposition

[0054] The quartz substrate is cut into a regular size (such as 4*2.5cm2), cleaned, and multiple pieces of quartz are placed in a fixture and placed in a vapor deposition furnace;

[0055] Add polycrystalline lead selenide into the crucible, close the furnace hall, and evacuate to 10-4Pa level;

[0056] Heating the crucible to melt the lead selenide to volatilize it;

[0057] According to the thickness parameters of the film thickness meter, the thickness of the lead selenide film is 0.9-1.1um;

[0058] Turn off the heating power supply, fill with nitrogen gas to normal pressure, open the furnace, and take out the quartz plate with lead selenide film.

[0059] (2) Chemical water bath

[0060] Adopt 99.99% pure selenium powder (5g) and 99% pure sodium sulfite (7.98g) and high-purity water 600mL to configure sodium selenosulfate solution, stir for 24 hours, ...

Embodiment 3

[0072] Embodiment 3 product test

[0073] The chip formed through the step-by-step processing of the embodiment 2 can be used for spot welding packaging to form a lead selenide detector with excellent performance.

[0074] Noise test and photoelectric response test were carried out on the lead selenide detector. The noise test results are as follows: Figure 4 As shown; and using a 500K black body light source, the photoelectric response test results are as follows Figure 5 shown.

[0075] The result shows that the noise of the device is extremely low. Compared with existing market products, the noise of the lead-salt detector of the present invention is 1-2 orders of magnitude lower, and the specific detection rate reaches 5.5*10 10 Jones, compared with similar foreign products Laser Components lead selenide detector (1.8*10 10 Jones) is about 200% higher than that of Sorebo's similar lead selenide products (2.5*10 9 Jones) more than 10 times higher. In particular, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com