Heat insulating and sound isolating decorative corrugated composite board

A thermal insulation and sound insulation, composite board technology, applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of lack of reinforcement, safety hazards, damage to the flatness of the panel and surface paint, etc., to achieve high thermal insulation , Increase the adhesion and meet the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

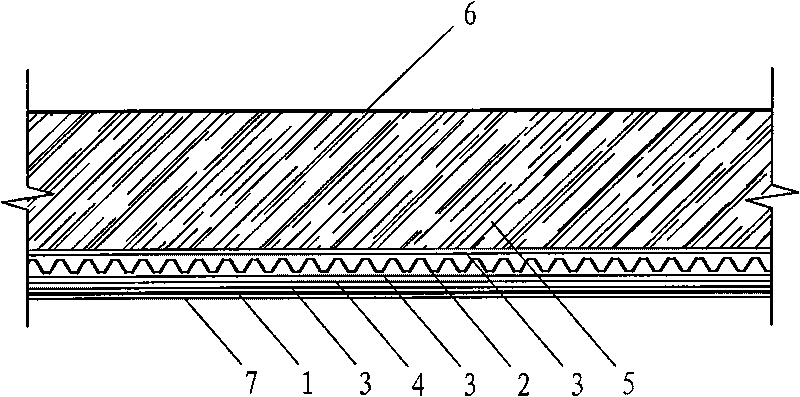

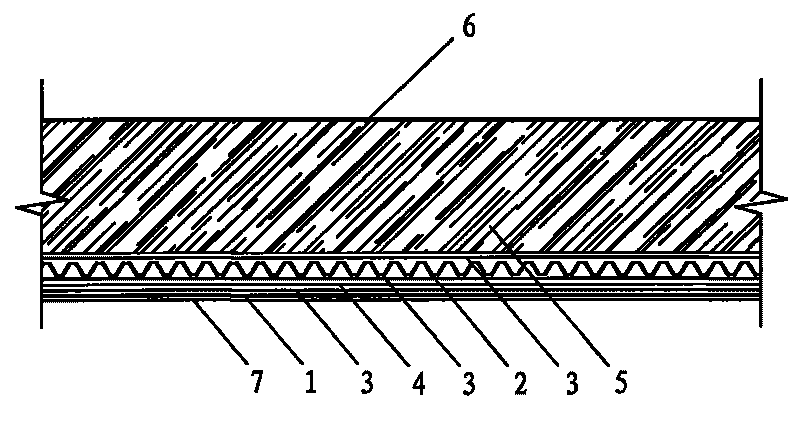

[0016] see figure 1 , is a structural schematic diagram of the thermal insulation and sound insulation decorative corrugated composite board of the present invention. A thermal insulation and sound insulation decorative corrugated composite board, comprising a metal plate 1 and a metal corrugated board 2, the metal corrugated board has a thickness of 0.1-0.3mm and a height of 3-10mm. A resin layer 3 is attached to the lower surface of the metal corrugated board 2 and the back of the metal plate 1, and the resin layer 3 is made of epoxy resin or polyurethane, and its thickness is 5-10um. The lower surface of the metal corrugated board 2 and the resin layer 3 on the back side of the metal board 1 are bonded and compounded together by an adhesive 4, and there is also a joint between the upper surface of the metal corrugated board 2 and the thermal insulation layer 5, which is the same as the above. The resin layer 3 is attached to the upper surface of the metal corrugated board ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com