Protection cover manufacturing method capable of preventing electromagnetic wave interference

A manufacturing method and technology of protective cover, which are applied in electrical components, magnetic field/electric field shielding, ion implantation plating, etc., can solve the problems of high material cost, scrapping, and cumbersome combined structure, achieve lightweight processing and molding, overcome end face The effect of smoothing and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0036] The protective cover for preventing electromagnetic wave interference produced by the present invention mainly includes a casing 1 and a metal coating layer 20 , wherein the casing 1 is made of plastic material.

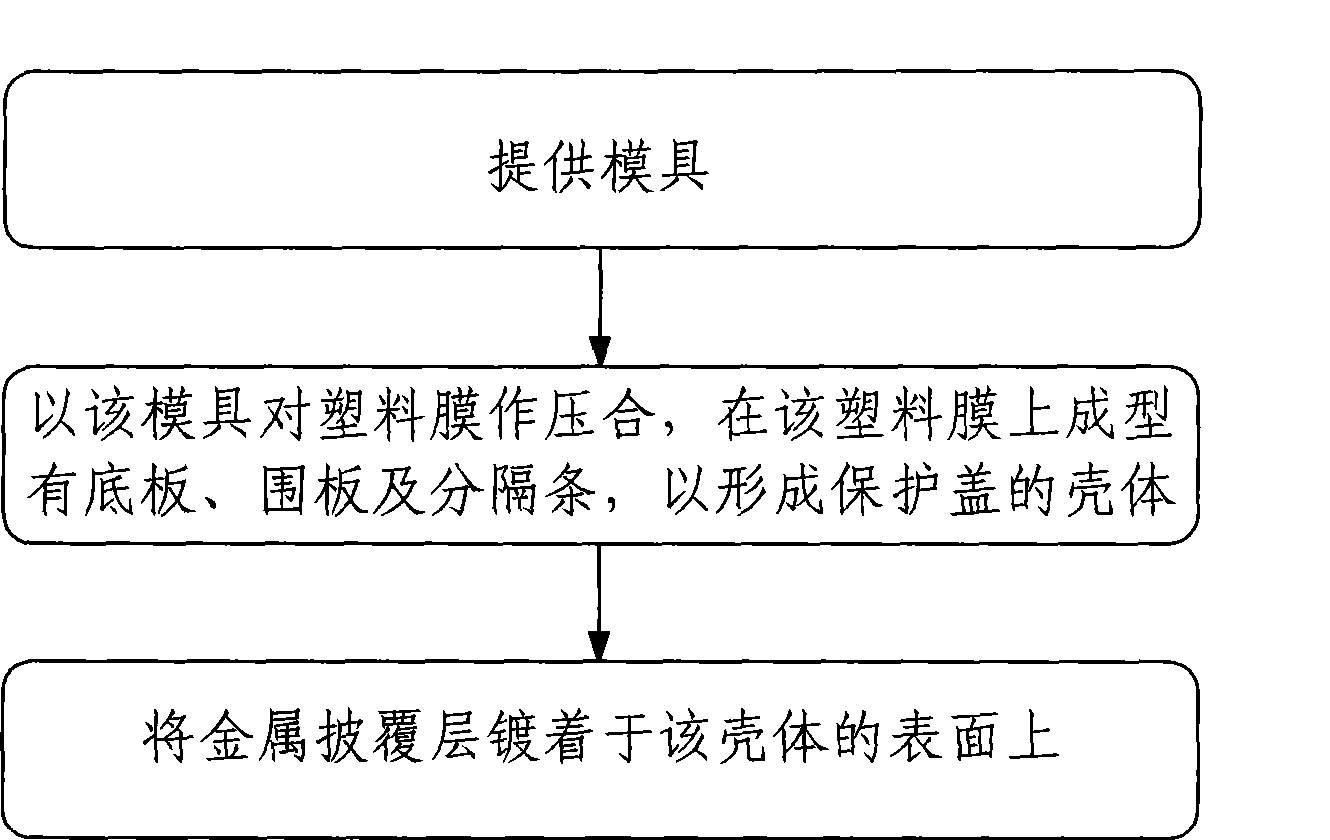

[0037] Please refer to Figure 1 to Figure 6 As shown, the present invention provides a method for manufacturing a protective cover capable of preventing electromagnetic wave interference, the steps of which include:

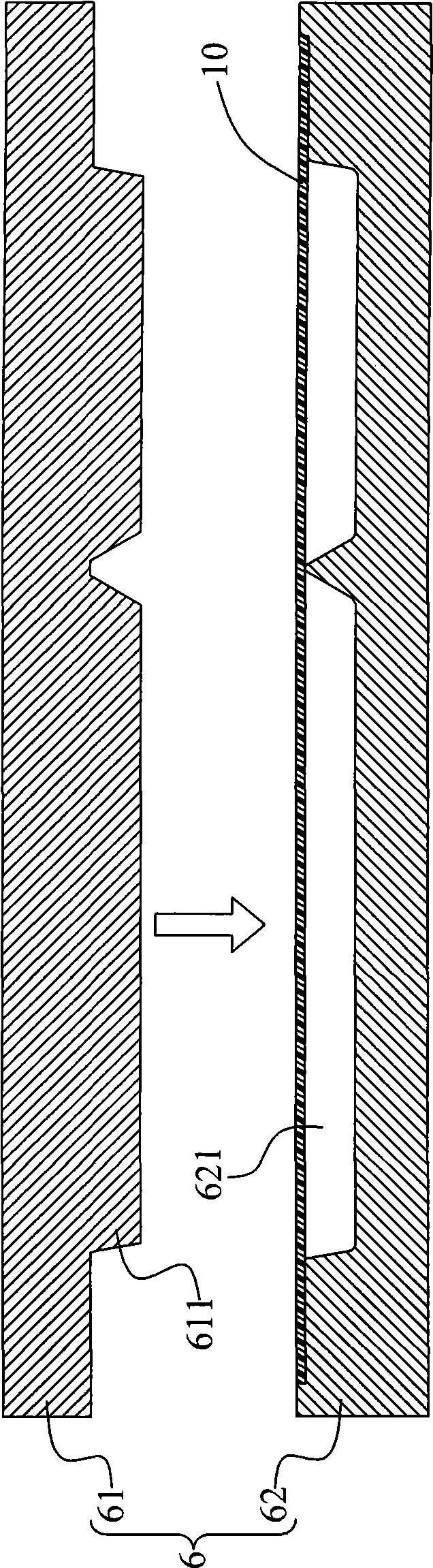

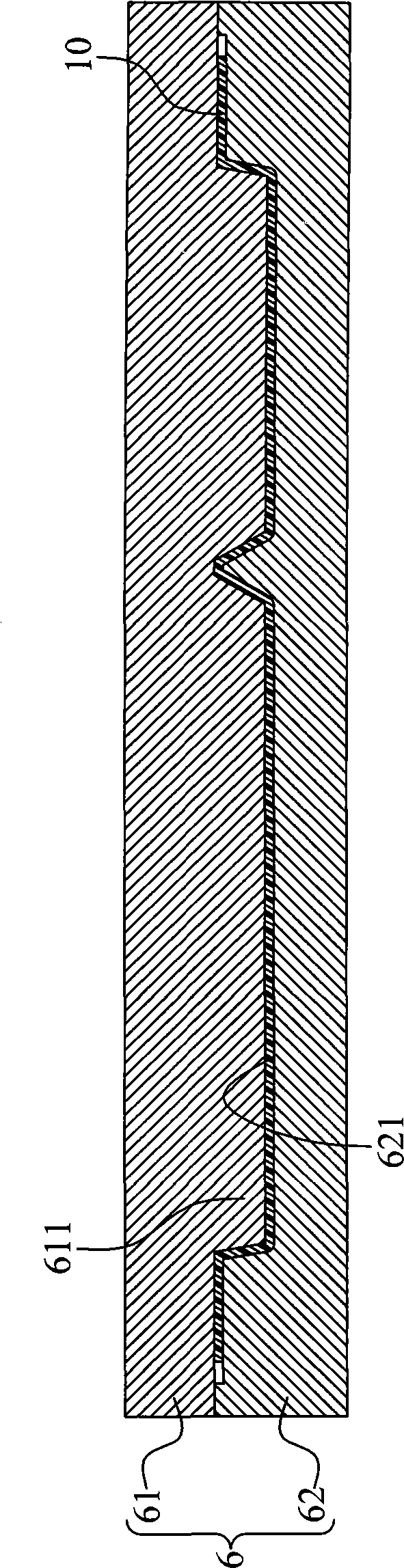

[0038] a), provide mold 6 (such as figure 2 shown); in this step, the mold 6 is made up of an upper module 61 and a lower module 62, and a recessed groove 621 in the shape of a protective cover is processed inside the lower module 62; The grooves 621 correspond to the convex parts 611...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com