Patents

Literature

33results about How to "Made low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

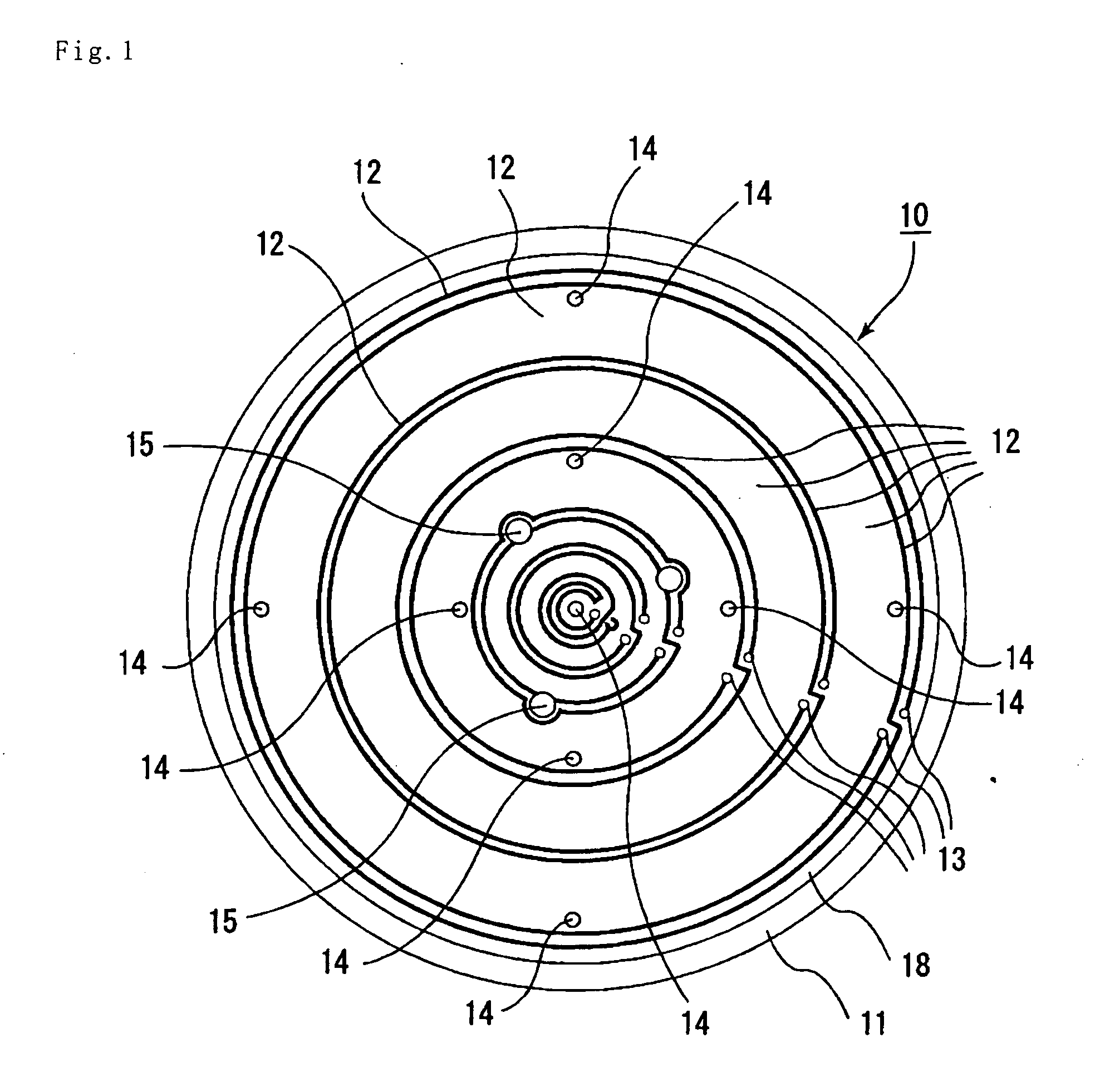

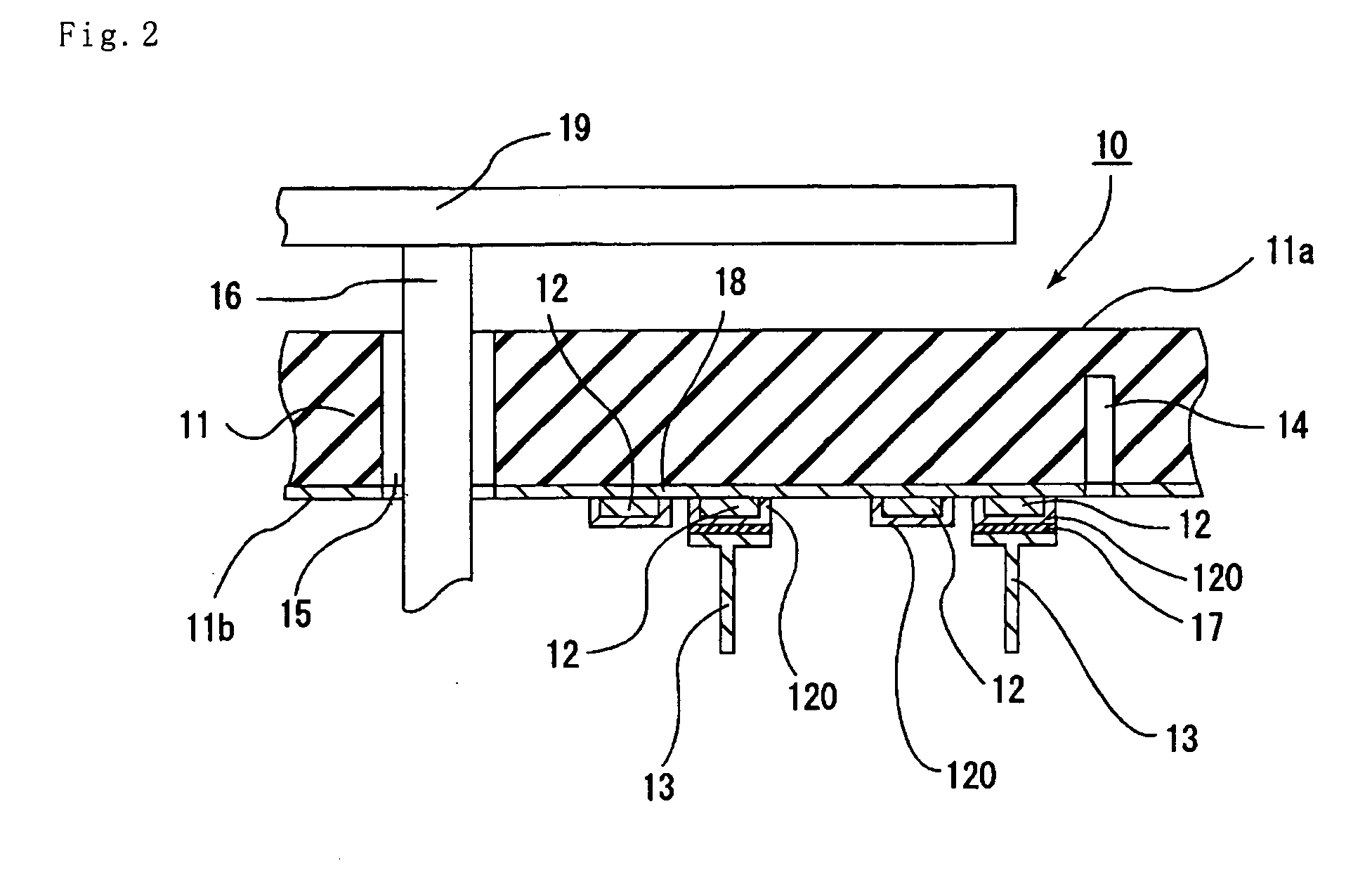

Ceramic heater

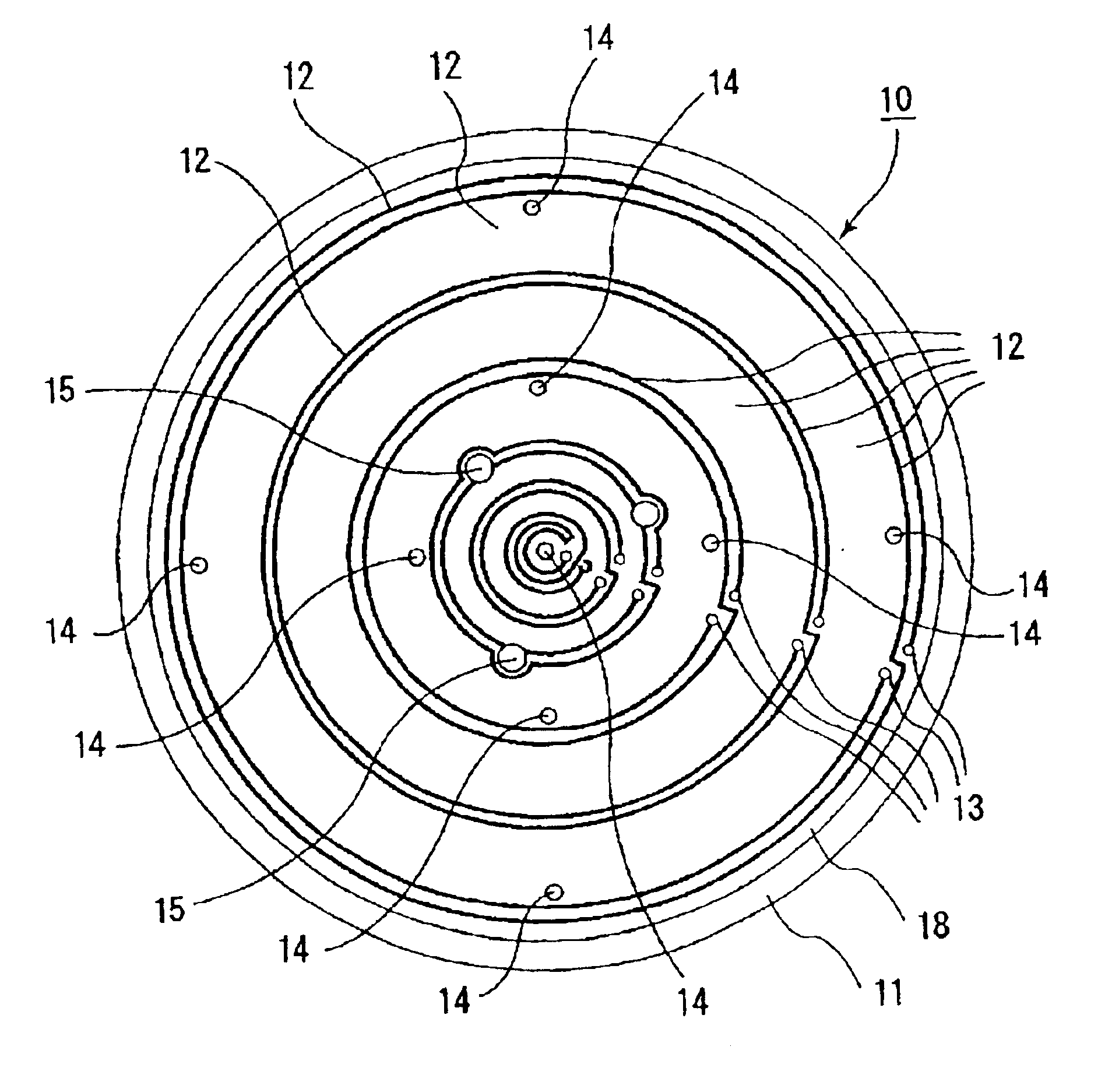

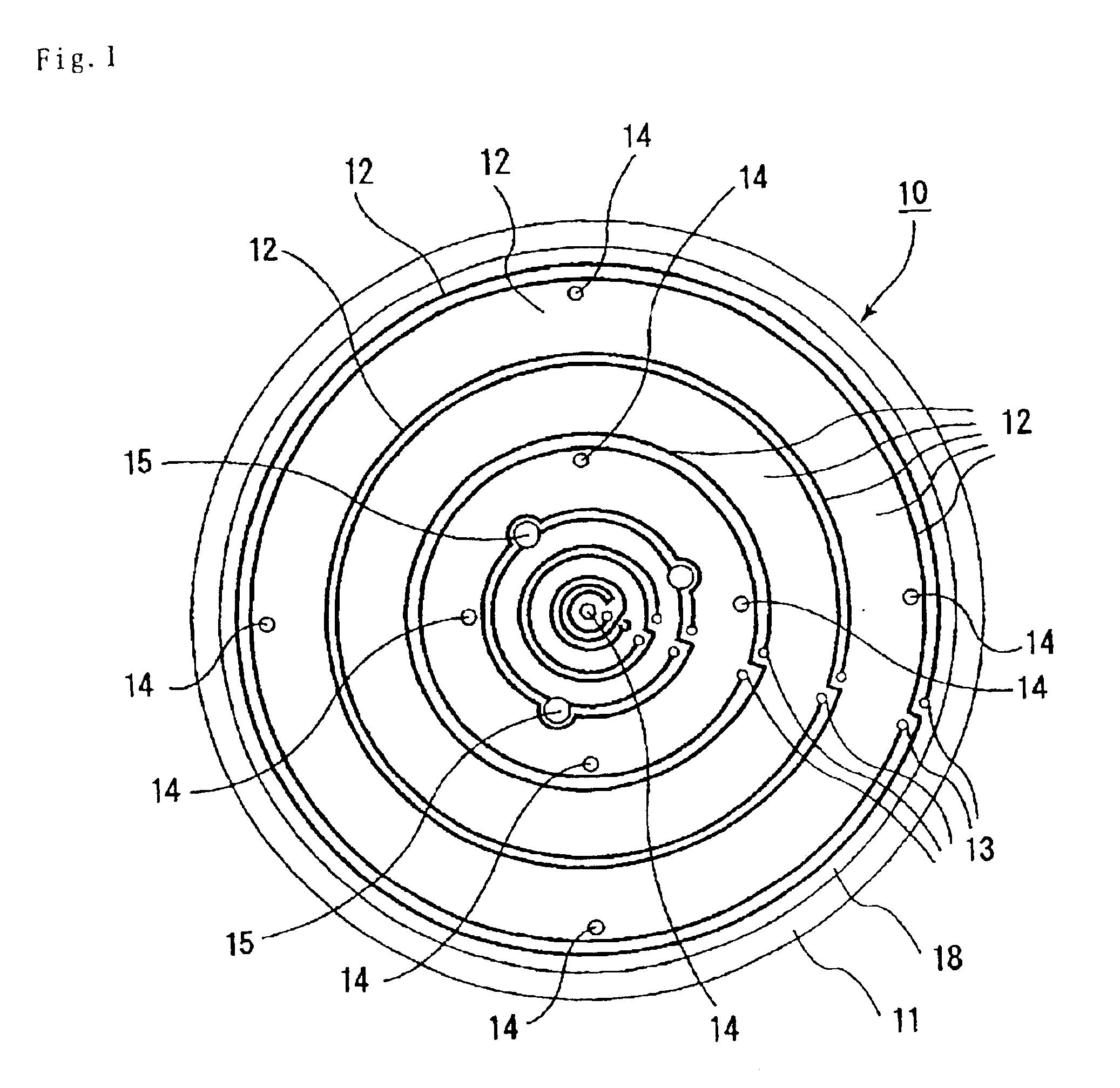

InactiveUS6888106B2Overcome unevennessOvercome imbalanceSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgySemiconductor

A ceramic heater making it possible to prevent a short circuit in its resistance heating element and heat a semiconductor wafer evenly. The ceramic beater includes a ceramic substrate, an insulating layer having volume resistivity higher than that of the ceramic substrate, being formed on at least a part of the ceramic substrate, and a resistance heating element formed on the insulating layer.

Owner:IBIDEN CO LTD

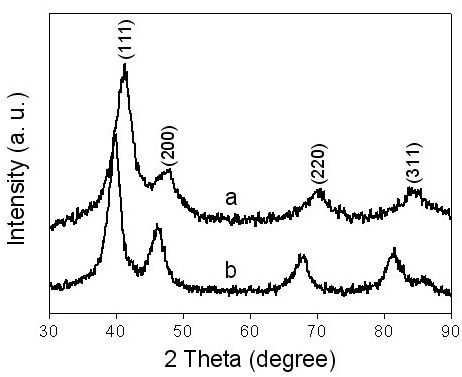

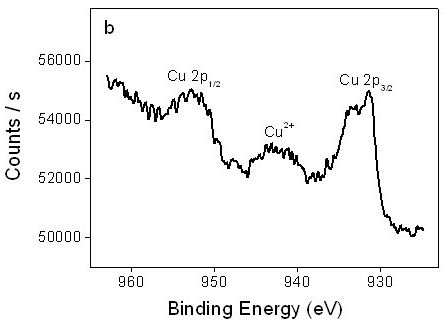

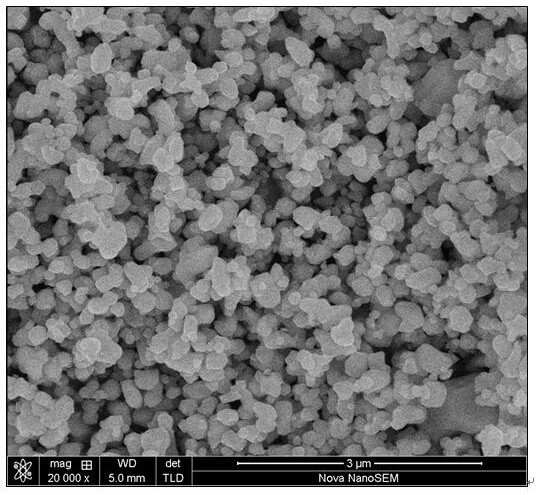

Preparation method of direct methanol fuel cell anode catalyst

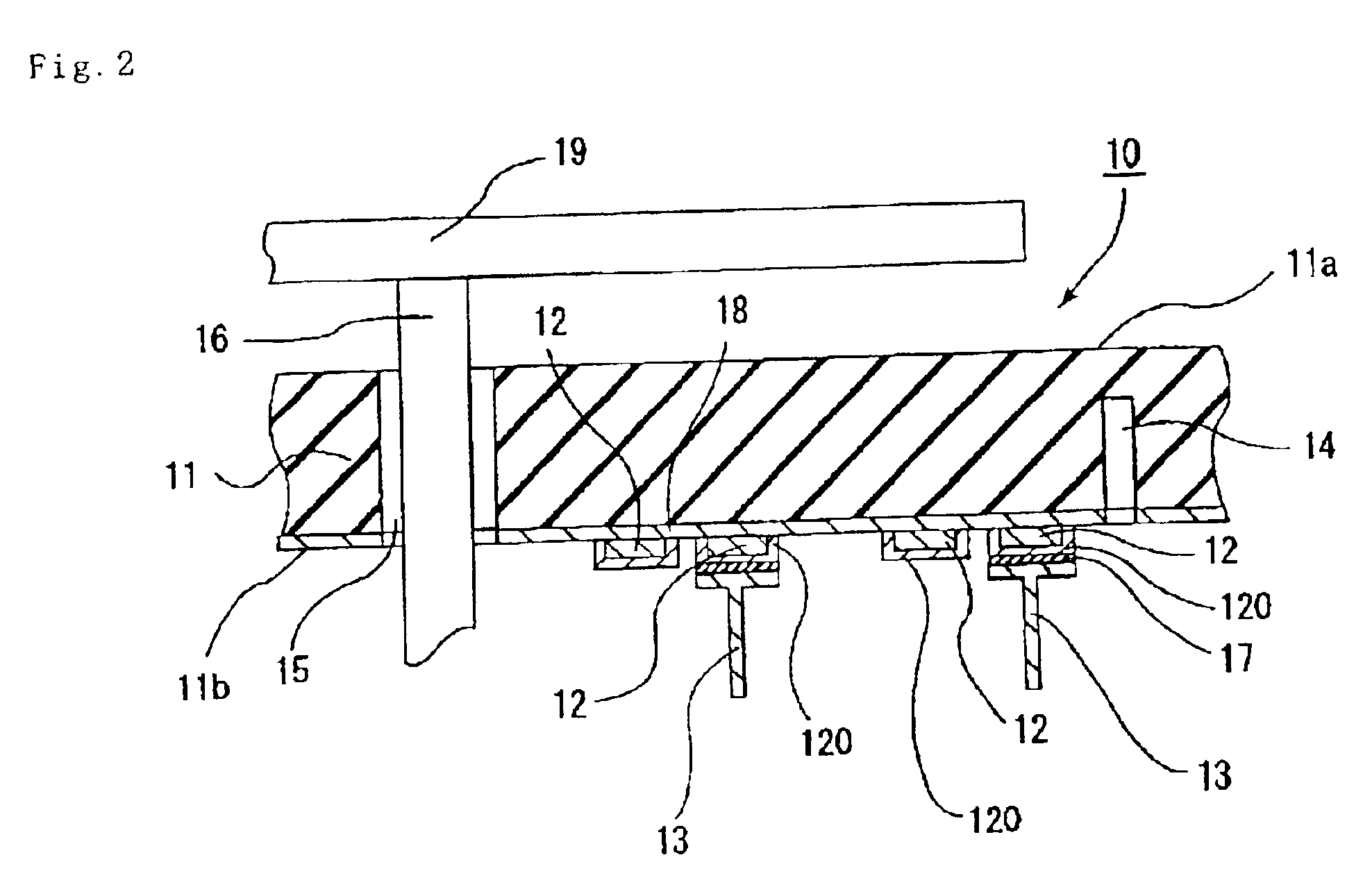

InactiveCN102380371AHigh load rateUniform particle sizeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFunctionalized graphenePoly ethylene

The invention discloses a preparation method of a direct methanol fuel cell anode catalyst, and belongs to the technical field of electrocatalysis and energy. The method comprises the following steps: firstly preparing polyethyleneimine (PEI) functionalized graphene, then mixing H2PtCl6, CuCl2 and PEI functionalized graphene according to a certain mass ratio, dispersing in secondary water by ultrasonic, performing in-situ reduction of H2PtCl6 and CuCl2 by sodium borohydride under a room temperature condition so as to prepare a PtCu two-component nanoparticle / graphene catalyst (PtCu / graphene). The PtCu two-component nanoparticles (PtCuNPs) prepared by the method of the invention are uniformly dispersed on PEI functionalized graphene, and the particle size of the PtCu alloy nanoparticles is about 4-6 nm. Electrochemical experiment results show that the PtCu / graphene catalyst has excellent electrocatalytic activity for methanol oxidation; and the method is simple in operation, is mild and controllable in experiment conditions, and has extensive application prospects.

Owner:NANCHANG UNIV

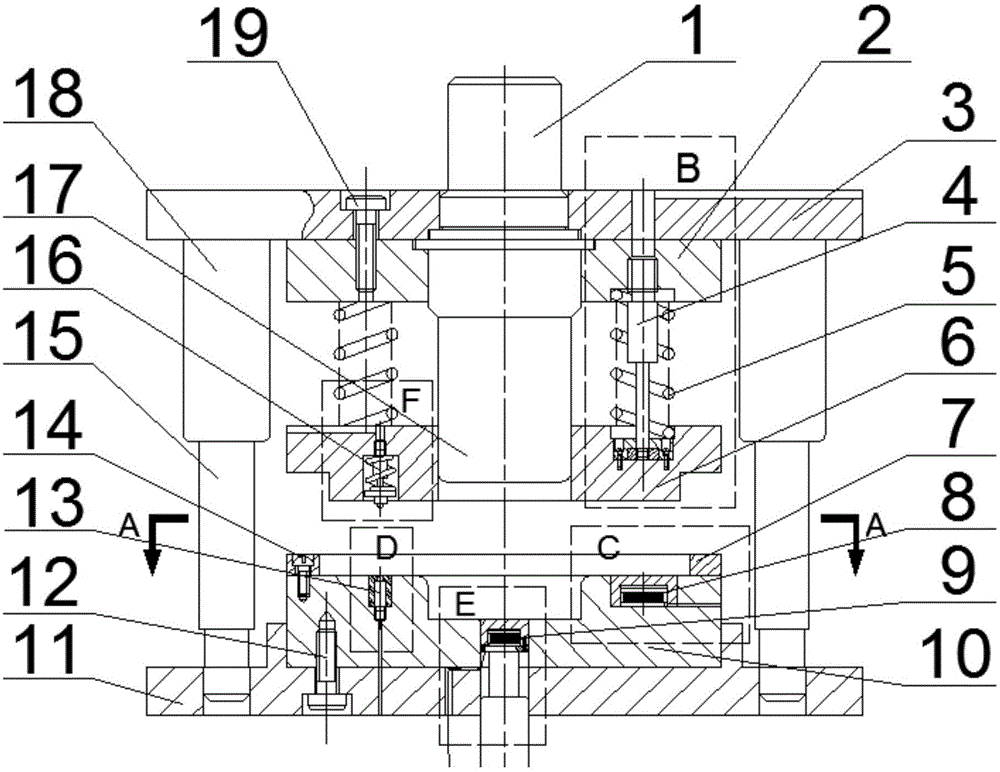

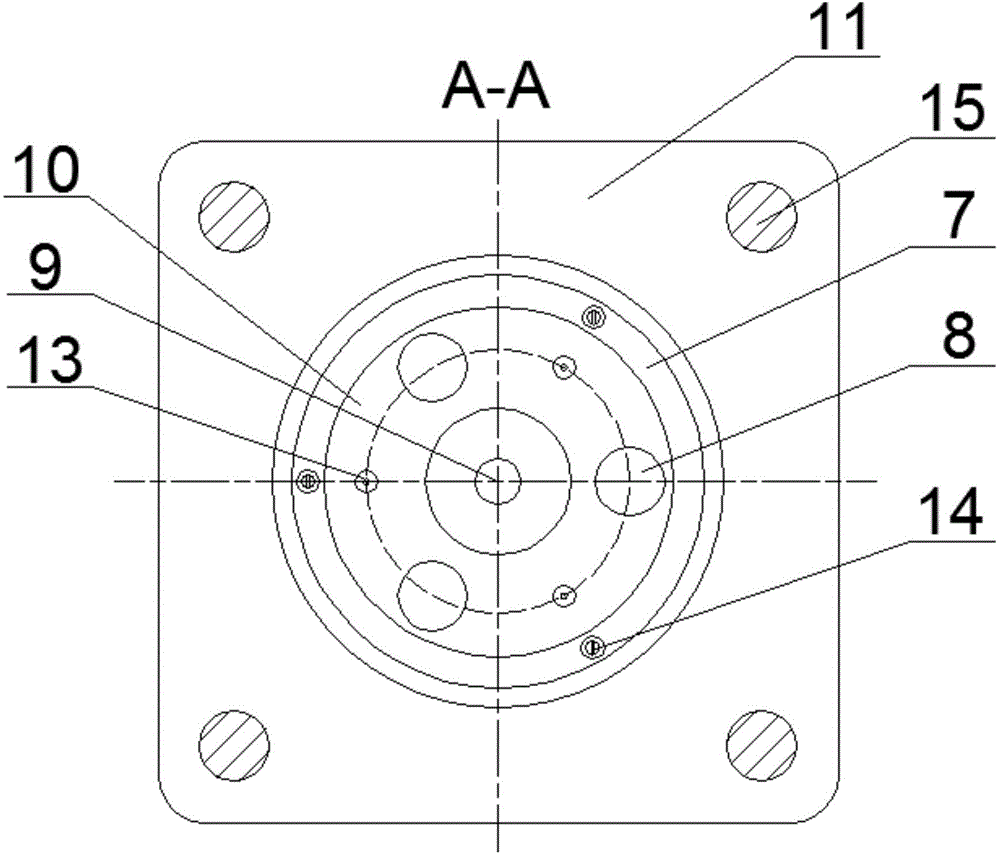

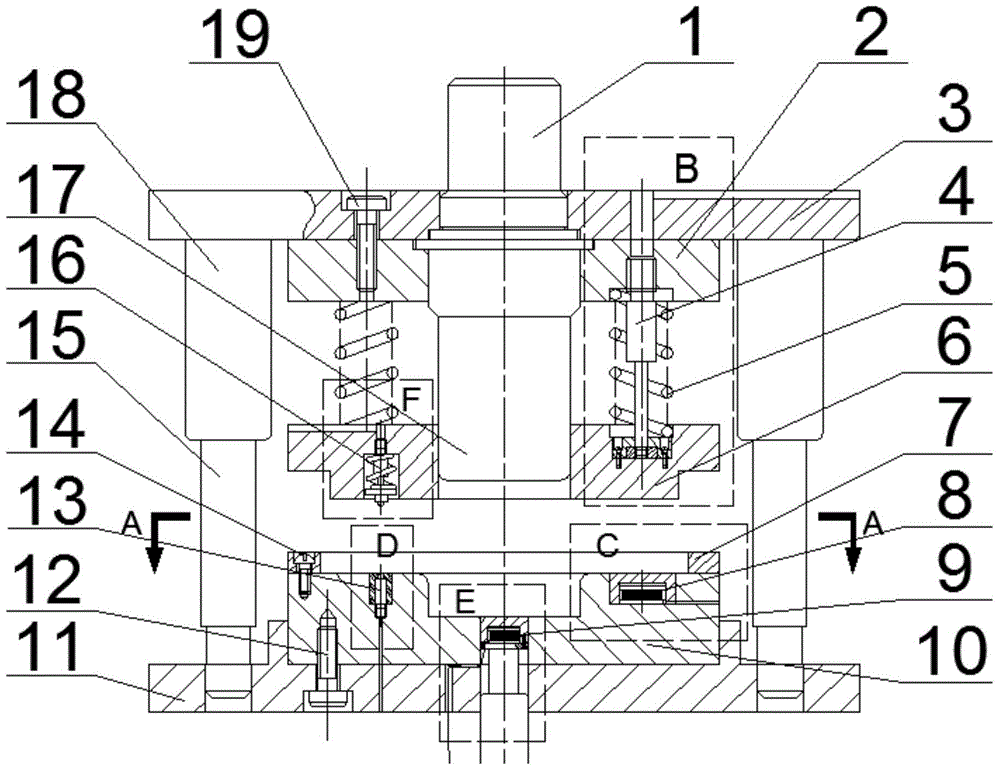

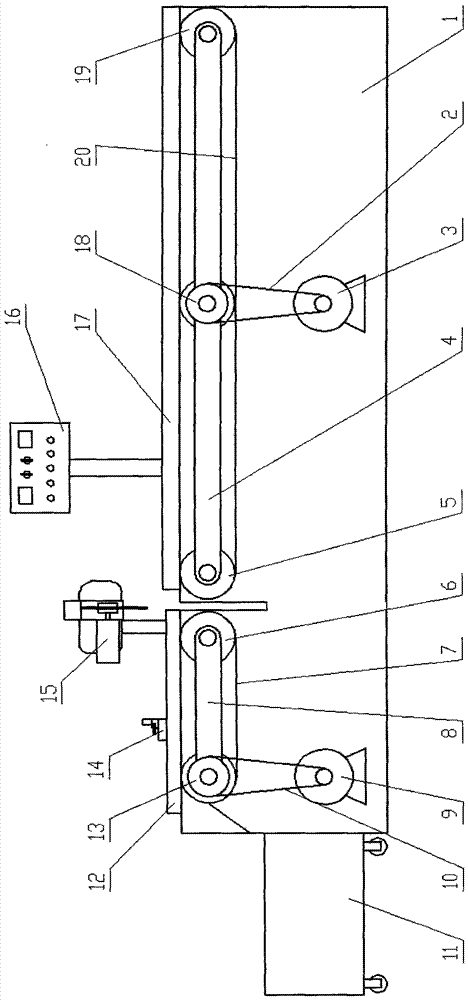

Sheet part stamping/welding integrated manufacturing device

ActiveCN104889736AIncrease productivityReduce production energy consumptionShaping toolsMetal-working feeding devicesEngineeringSpot welding

The invention provides a sheet part stamping / welding integrated manufacturing device. The sheet part stamping / welding integrated manufacturing device comprises a concave die and a convex die; the concave die is fixed on a lower plate; the convex die is connected to an upper plate; the lower plate and the upper plate are connected together by use of a guide column and a guide sleeve; a plurality of first magnetorheological dampers are connected to the lower surface of a convex die fixed plate; a blank holder is connected to the lower ends of the first magnetorheological dampers; a plurality of second magnetorheological dampers are mounted on the lower part of the blank holder; the lower ends of the second magnetorheological dampers are connected with a spot-welding upper electrode; a plurality of stop-welding lower electrodes are mounted at the outer edge of the concave die; a first electromagnet is mounted in the central position of the concave die; more than two second electromagnets are mounted at the outer edge of the concave die; the mounting positions of the second electromagnets are all located in a circle determined on the basis of the center of the spot-welding lower electrode, and distributed alternately with the stop-welding lower electrodes. The sheet part stamping / welding integrated manufacturing device is integrated with stamping and welding; sheet parts machined by use of the device are low in resilience, low in consumed energy source and high in machining efficiency.

Owner:XI AN JIAOTONG UNIV

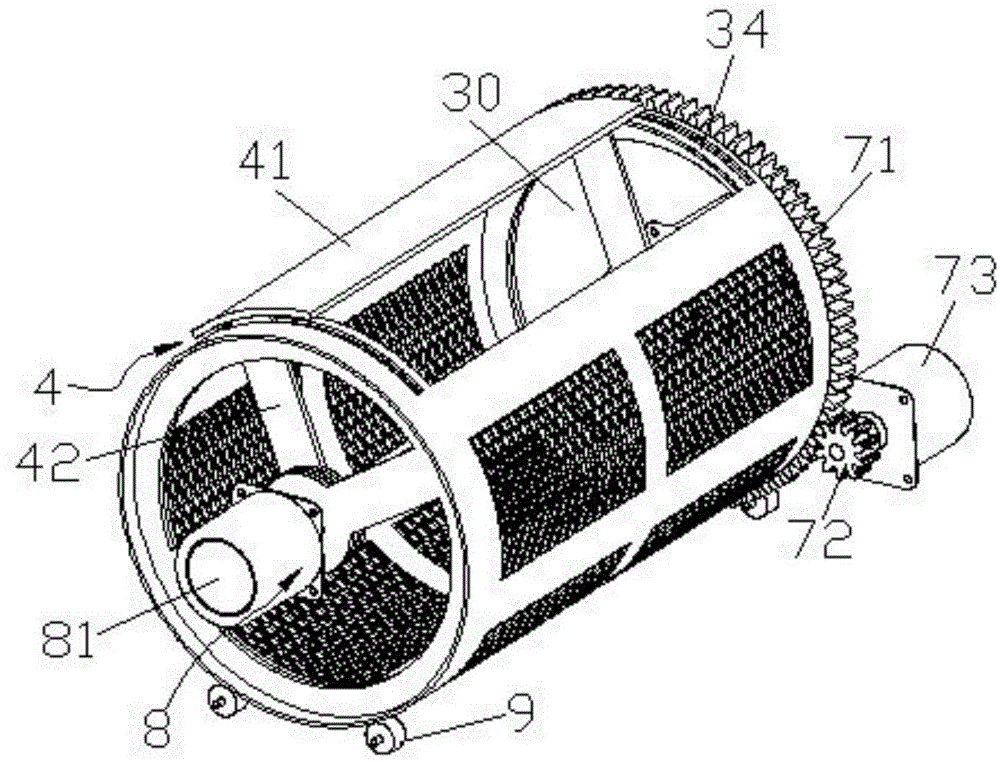

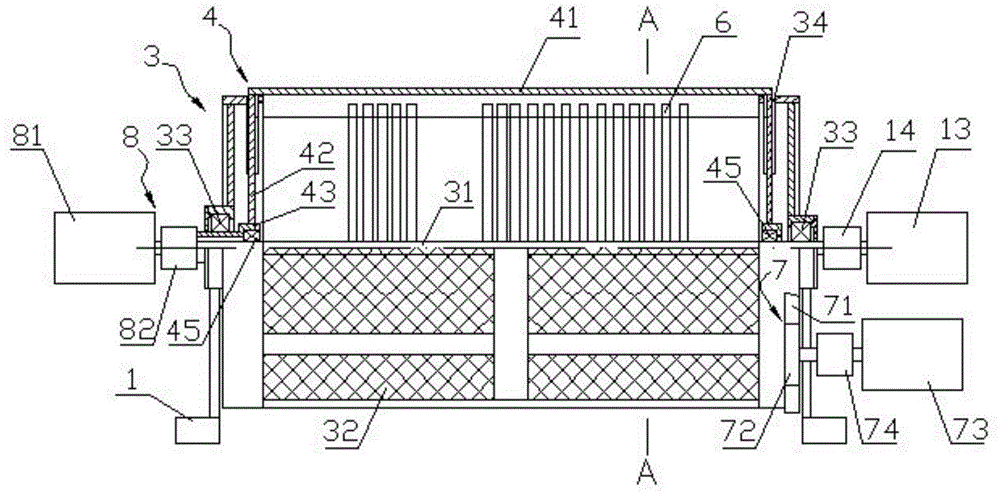

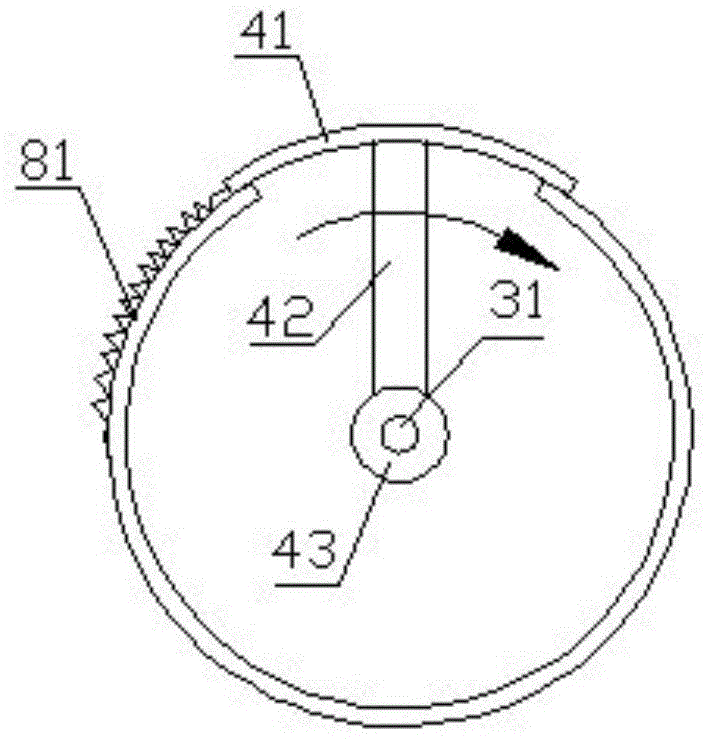

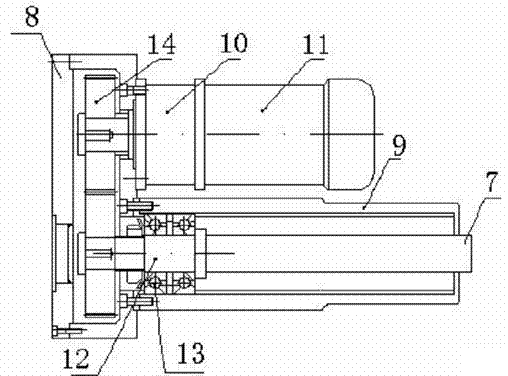

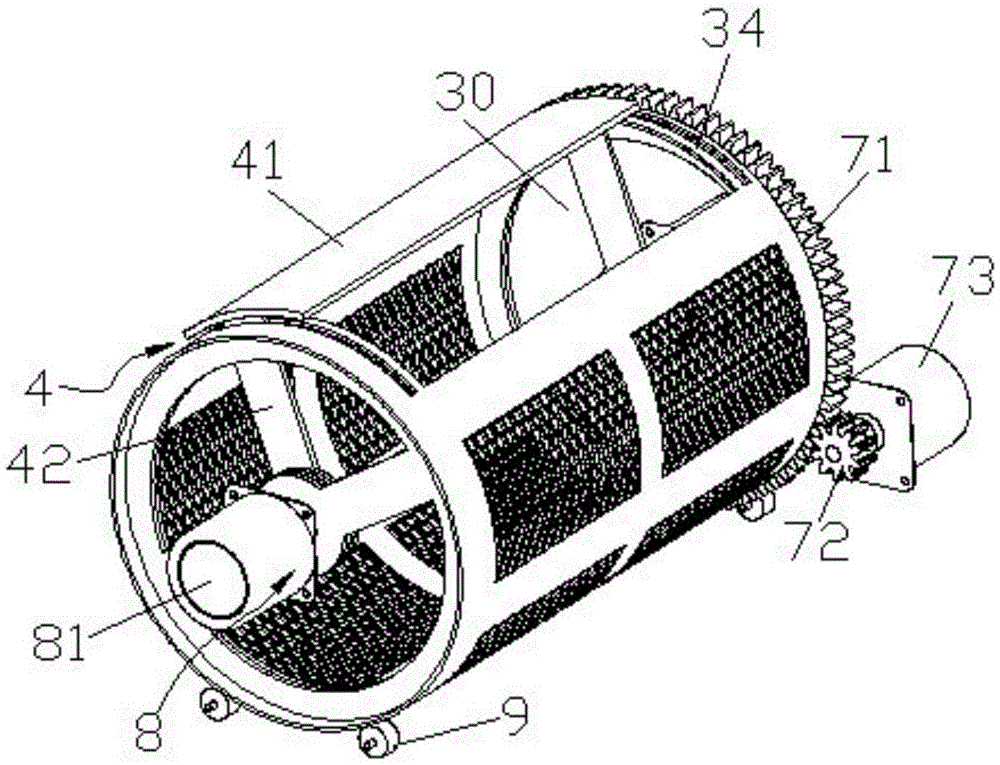

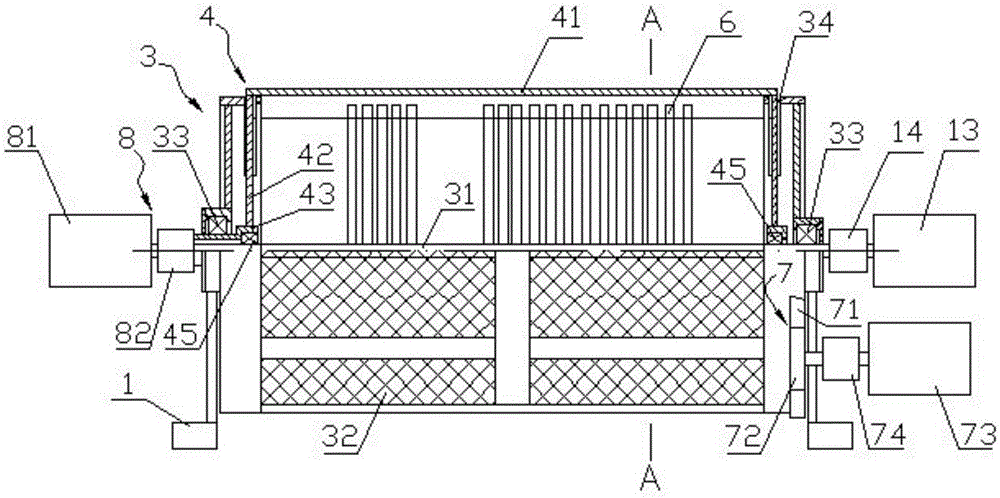

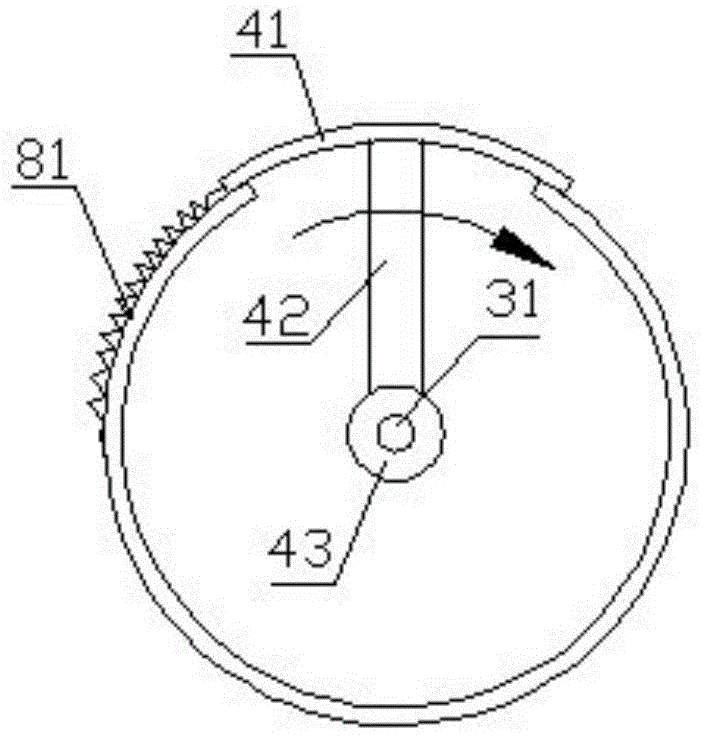

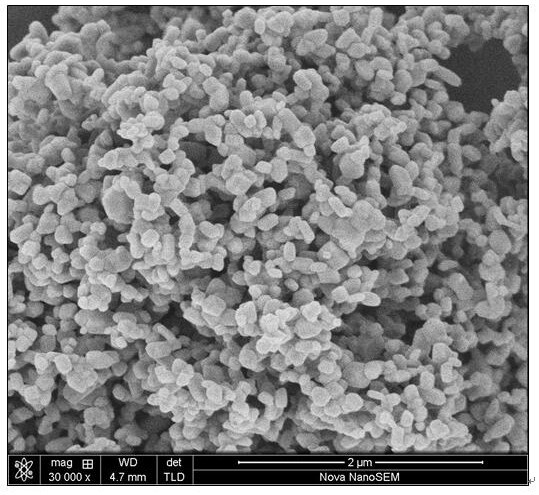

Mahjong tile cleaning machine

ActiveCN104084399AEasy to put inClean up thoroughlyCleaning using toolsCleaning using liquidsGear driveWater spray

The invention relates to a mahjong tile cleaning machine which comprises a frame, a casing, a rotary drum, a drum door, a water spraying pipe, a brush, a gear driving mechanism and a drum door driving mechanism. The rotary drum is supported on the frame rotatably and driven by the gear driving mechanism, a tile feeding and discharging port is formed in the circumference of the rotary drum, the drum door is arranged on the rotary drum rotatably and driven by the drum door driving mechanism, and the tile feeding and discharging port in the rotary drum is opened or closed by means of the rotation of the drum door relative to the rotary drum. The brush is arranged in the center of the rotary drum, the water spraying pipe is arranged on one side outside the rotary drum, the casing is arranged on the frame, and the rotary drum is covered with the casing. The mahjong tile cleaning machine has the advantages that tiles can go in and out of the rotary drum easily, the tile feeding and discharging port can be opened and closed automatically, dirt on the tiles can be cleaned away completely due to double action of friction of the brush and jet of the water spraying pipe, and the mahjong tile cleaning machine has an automatic drying function and is high in automation degree and efficiency and capable of saving time and labor.

Owner:徐州华锌际新材料科技有限公司

Electric control device of small-sized loader

InactiveCN103088855AImprove efficiencyDoes not consume energyMechanical machines/dredgersElectricityElectric control

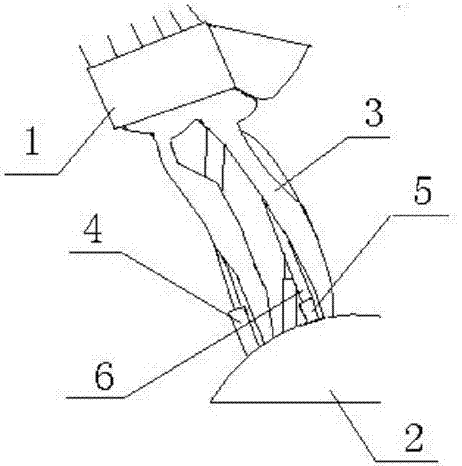

The invention discloses an electric control device of a small-sized loader. The electric control device of the small-sized loader at least comprises a bucket, a loader body, an operating mechanism and a lifting mechanism of the small-sized loader, wherein the bucket is connected with the loader body through lifting arms, the lifting arms comprise a left arm, a middle arm and a right arm, and movable joints are arranged on the left arm, the middle arm and the right arm. The electric control device of the small-sized loader is characterized in that the left arm, the middle arm and the right arm are respectively connected with an electric cylinder telescopic arm, an electric cylinder is fixed with the loader body, and the electric cylinder is electrically connected with the operating mechanism. The electric control device of the small-sized loader solves the technical problems that an existing loader driving system is inconvenient to install, low in transmission efficiency, short in service life, large in running noise, and low in reliability.

Owner:QINGDAO LUDA PROJECT MACHINE MFR

Graphene modified antistatic TPU film

The invention discloses a graphene modified antistatic TPU film, which is prepared from the following raw materials by mass: 60-80 parts of polyether TPU resin, 1-3 parts of modified graphene, 2-4 parts of a heat stabilizer, 1-3 parts of a lubricant, 1-2 parts of a plasticizer, and 0.5-2 parts of nano-alumina. After modification by a silane coupling agent and reduction by ammonia water, the treated graphene oxide is uniformly dispersed in TPU resin, and does not polymerize in itself, thus enhancing the electrical conductivity and impact resistance of the TPU film. After modification treatment,the nano-alumina has strengthened mechanical properties and affinity to resin materials; at the same time, the dosages of nano-alumina and graphene are low, thus lowering the making cost.

Owner:安徽嘉明新材料科技有限公司 +1

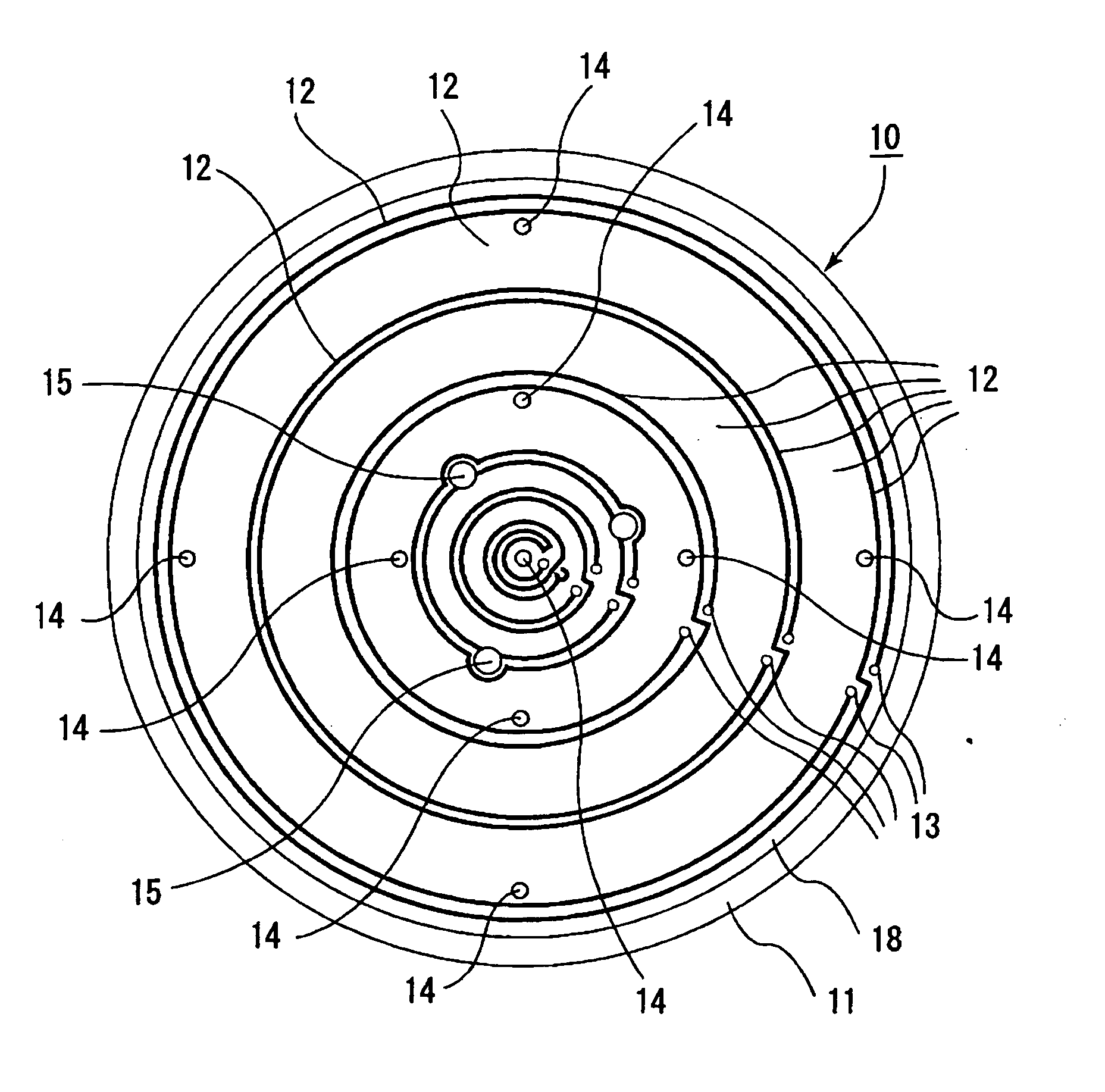

Ceramic heater

InactiveUS20050016987A1Easy to masterOvercome unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgySemiconductor

An objective of the present invention is to provide a ceramic heater making it possible to prevent a short circuit in its resistance heating element and heat a semiconductor wafer evenly. The ceramic heater of the present invention is a ceramic heater comprising: a ceramic substrate; an insulating layer having volume resistivity higher than that of said ceramic substrate, being formed on at least a part of said ceramic substrate; and a resistance heating element formed on said insulating layer.

Owner:IBIDEN CO LTD

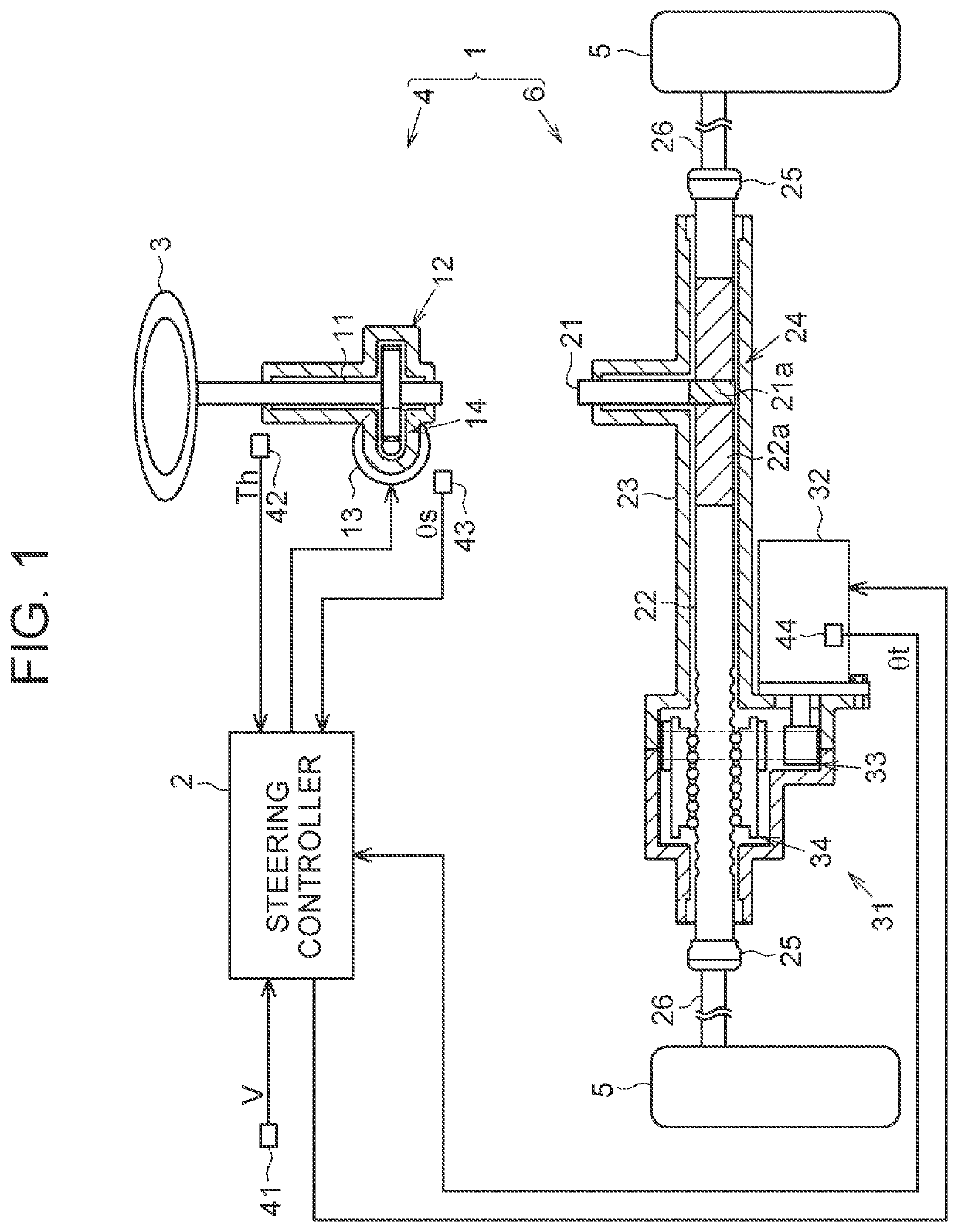

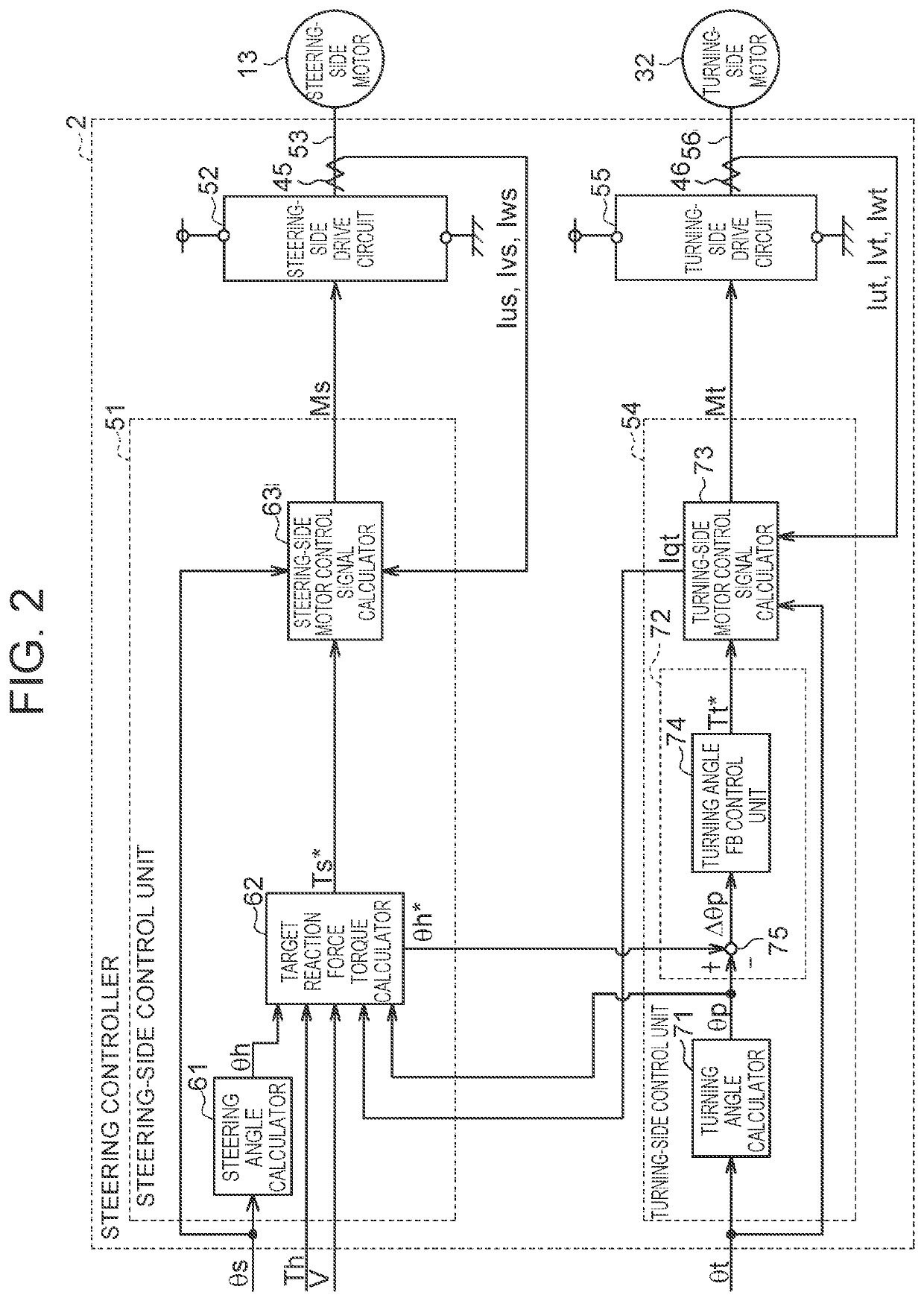

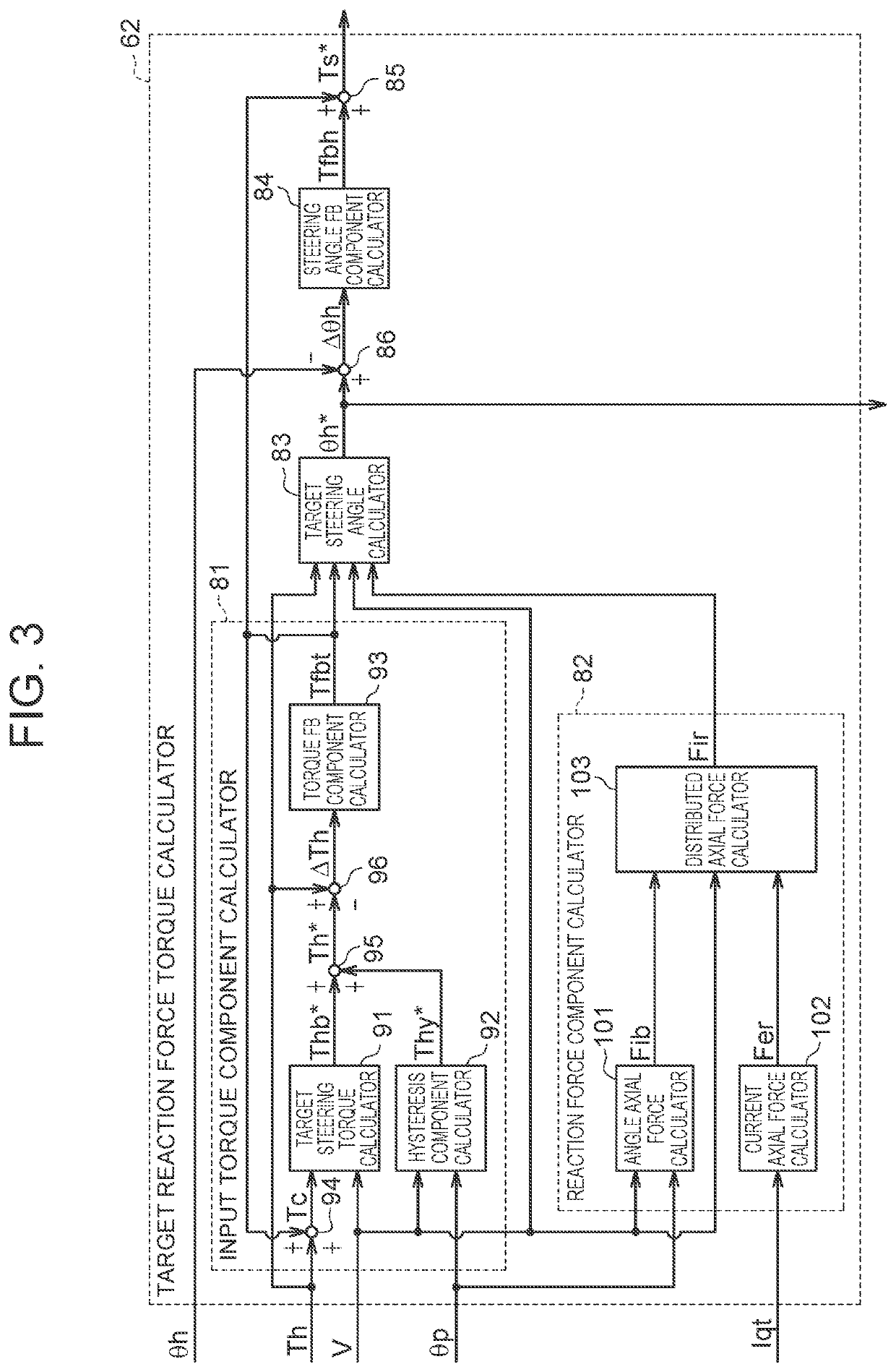

Steering controller

PendingUS20210284226A1Steering feeling can be improvedAvoiding characteristicSteering linkagesAutomatic steering controlEngineeringSteering control

A steering controller includes a torque command value calculator configured to calculate a torque command value used as a target value of the motor torque. The torque command value calculator has a hysteresis component calculator configured to calculate a hysteresis component added such that the command value component has hysteresis characteristics and changes accordingly with respect to change of a state quantity that changes in accordance with operation of the steering device. The hysteresis component calculator is configured to calculate the hysteresis component by adding the hysteresis differential component to the hysteresis basic component.

Owner:JTEKT CORP

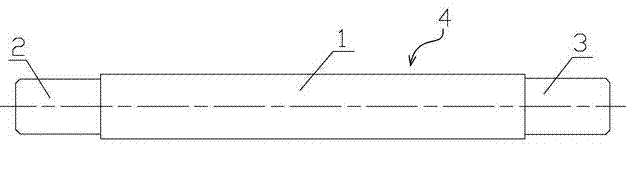

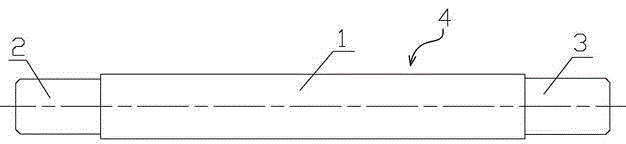

Preparation method of fiber pipe with pattern or letter on surface

ActiveCN103331918ANot easy to break awayNot easy to damageDuplicating/marking methodsTubular articlesFiberEpoxy

The invention relates to a preparation method of a fiber pipe with a pattern or a letter on the surface. The preparation method comprises the following steps of: 1) winding fiber prepreg on a core mold to form a pipe blank, 2) printing reverse pattern or letter ink on one side of a plastic film, 3) winding the plastic film on the pipe blank to replace a release belt to size the pipe blank, or winding in an incomplete covering or partial overlying manner, then winding the release belt for sizing, 4) placing the wound pipe blank in a curing oven for baking for 1-3h at 110-175 DEG C to allow the pattern or letter ink on the plastic film and phenolic resin or epoxy resin of the pipe blank to be immersed mutually, solidified and formed, and 5) removing the mold, and stripping the plastic film to obtain the finish product. The preparation method has the advantages that the pattern is not easy to separate and damage, paint polishing or paint spraying is not required during preparation, the preparation technology is simple, the time, labor and raw materials are saved, and the manufacturing cost is low.

Owner:威海六高橡塑科技有限公司

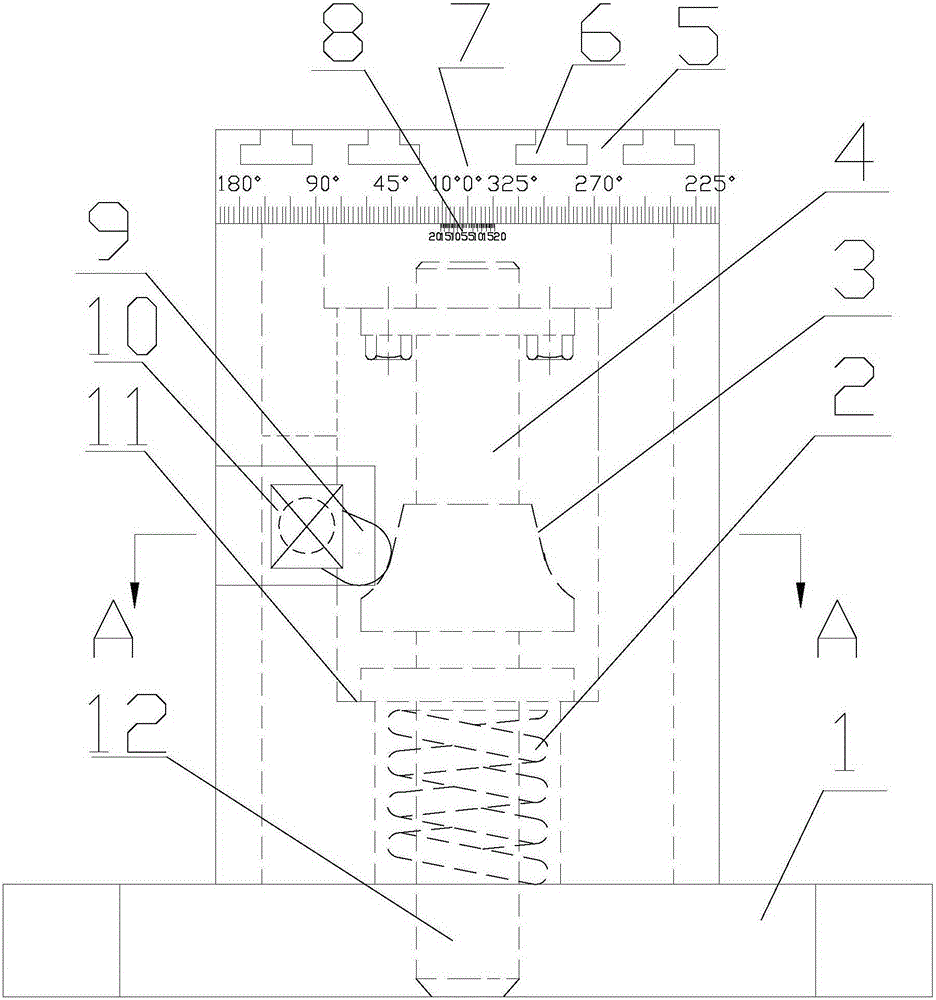

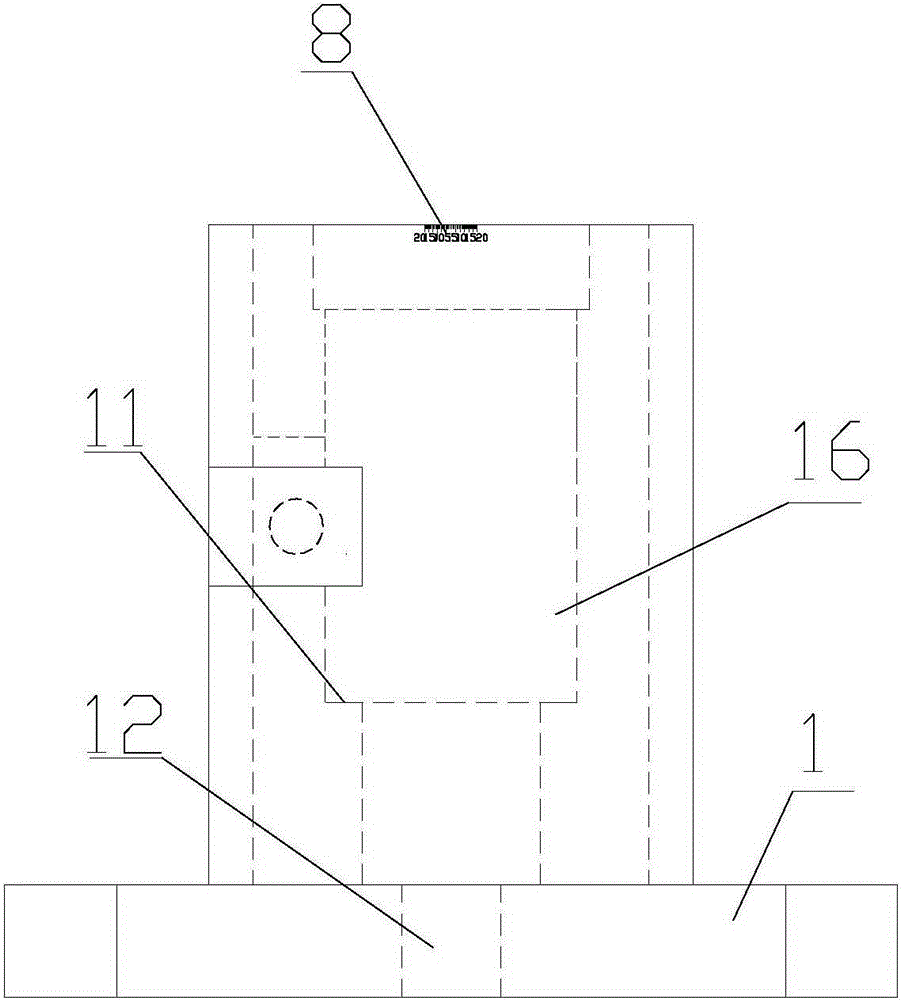

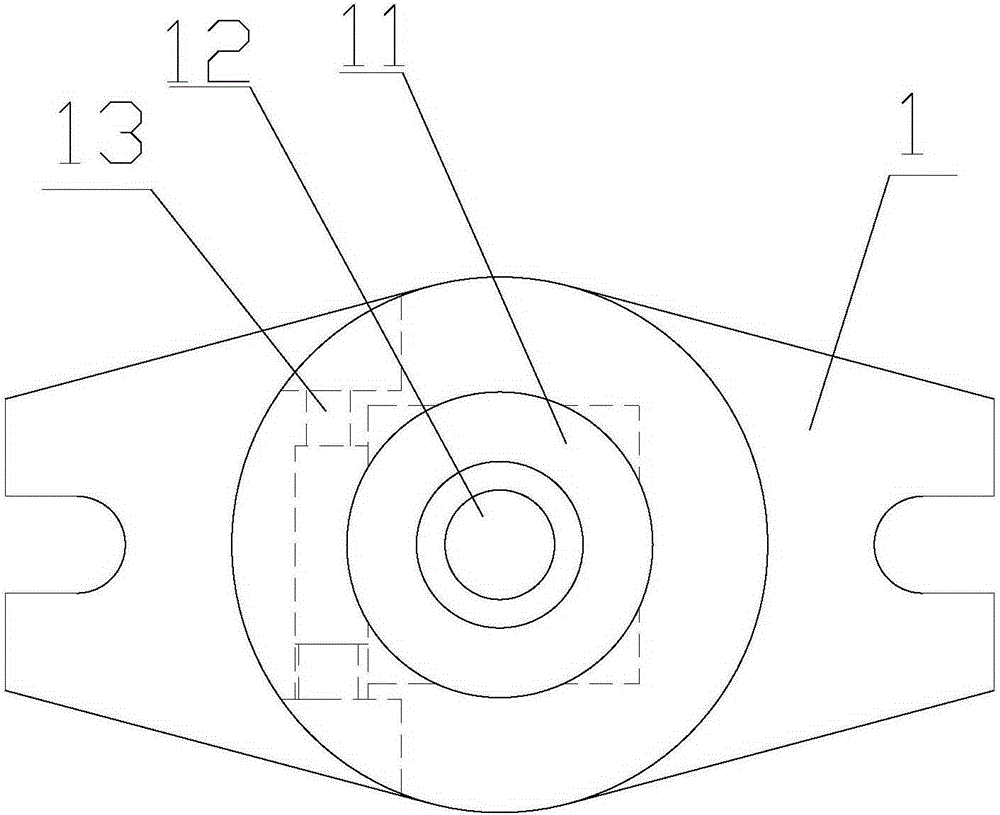

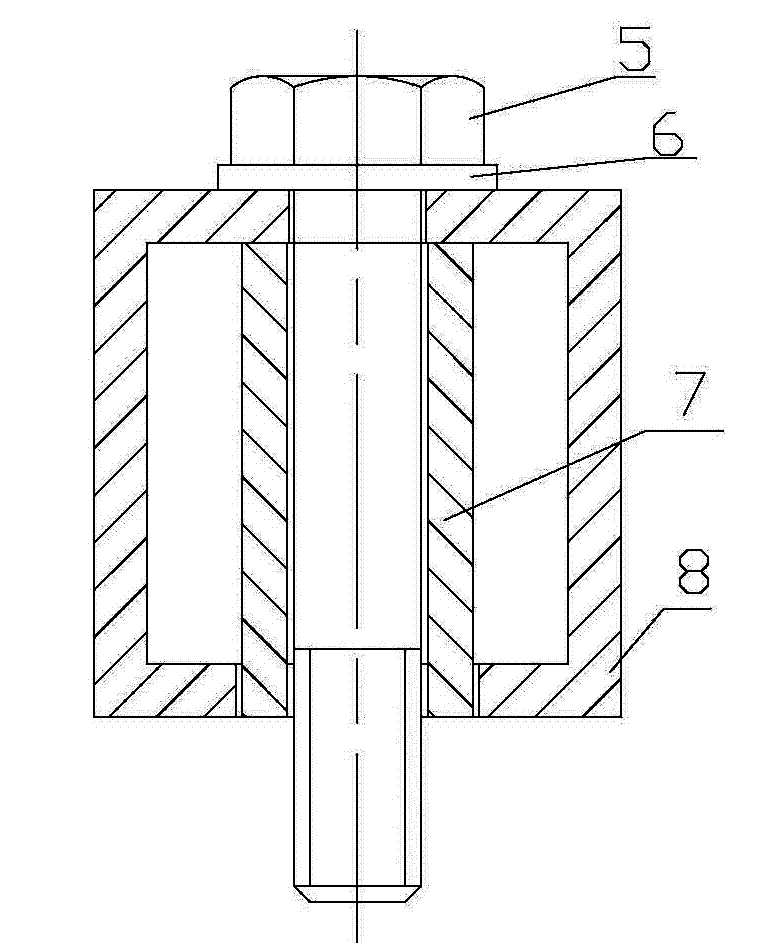

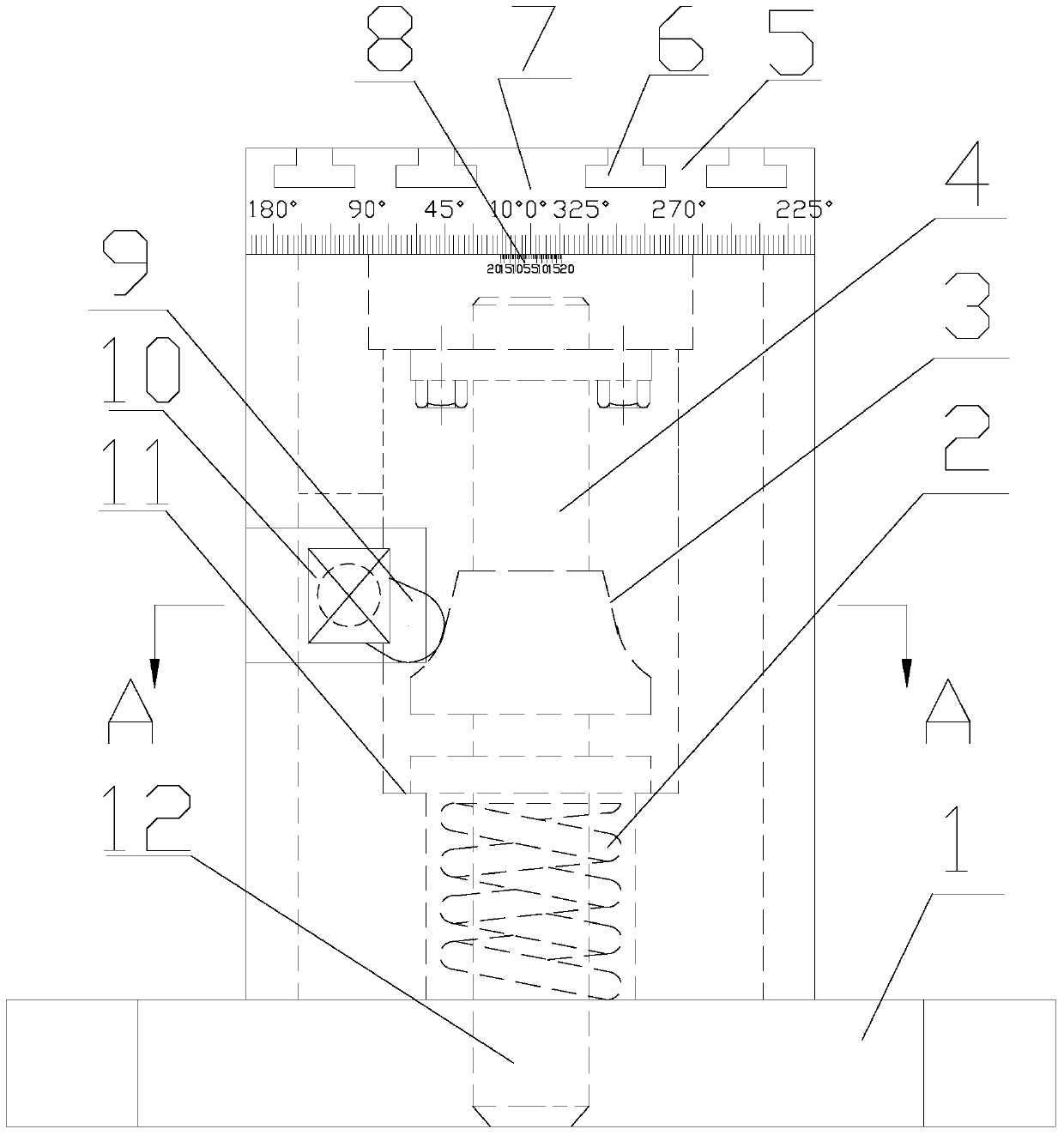

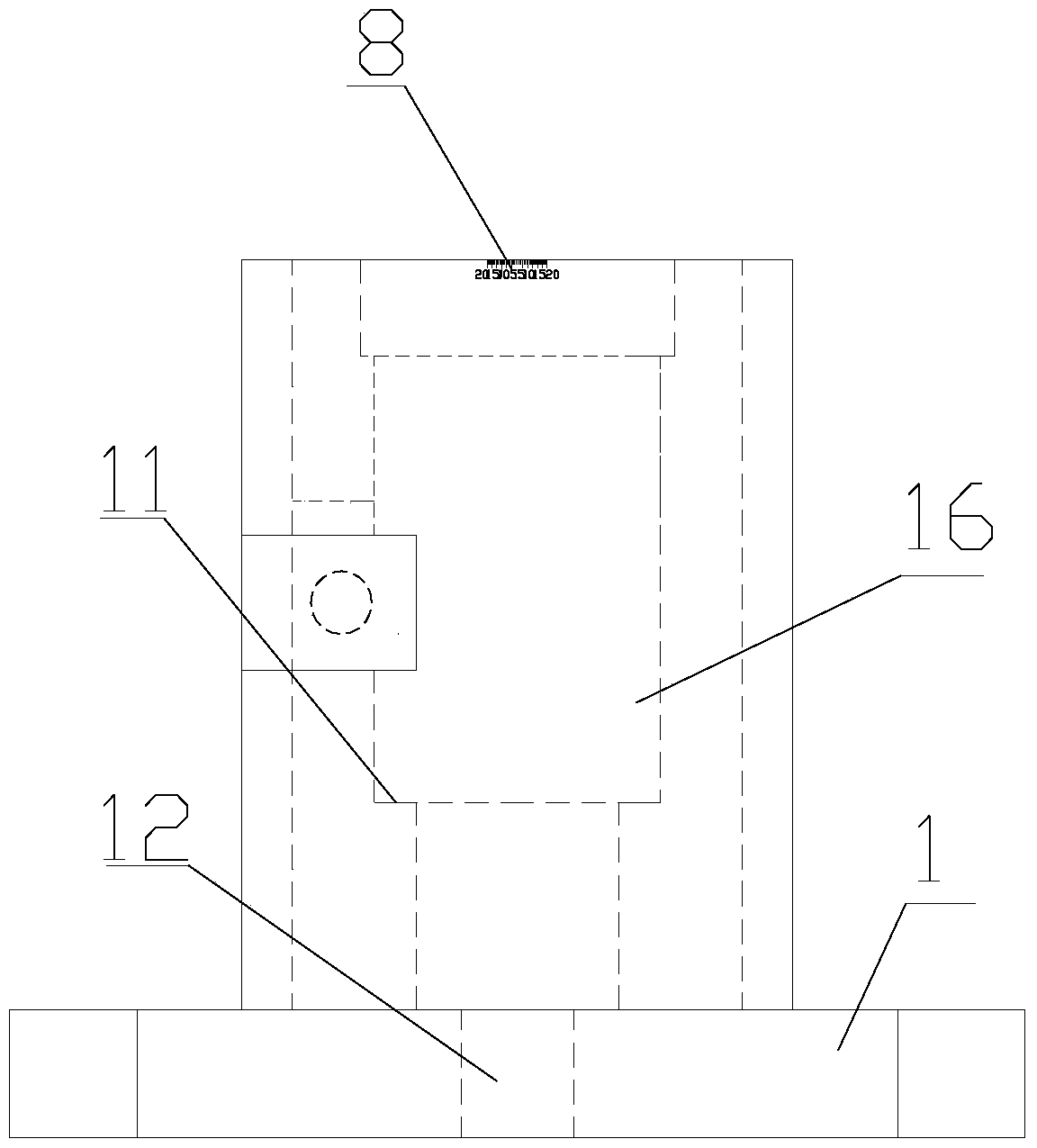

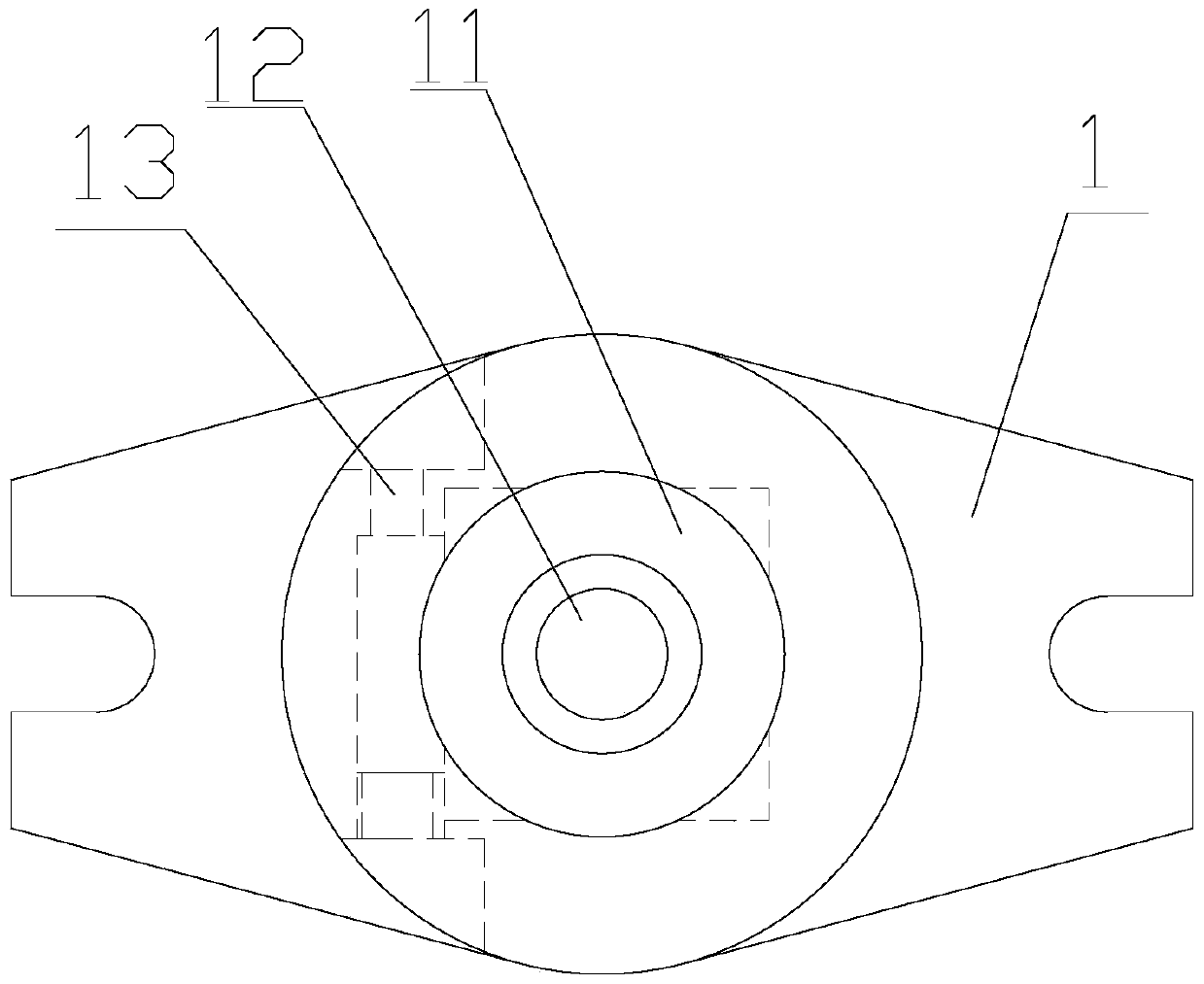

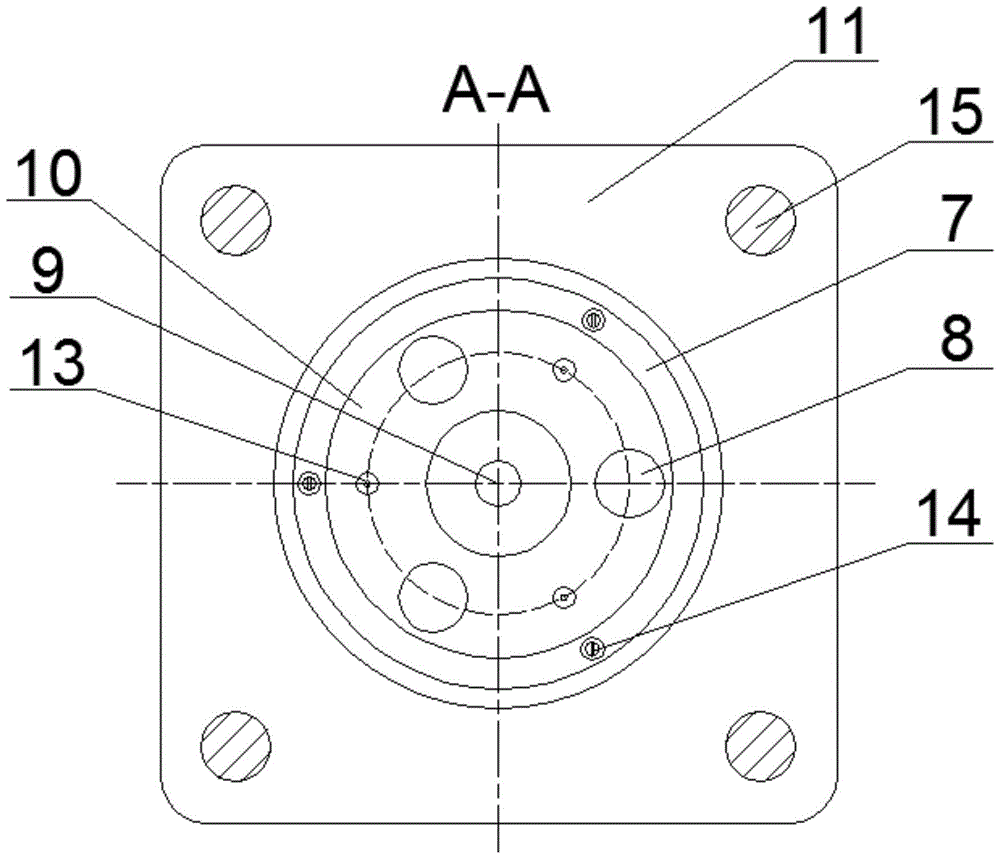

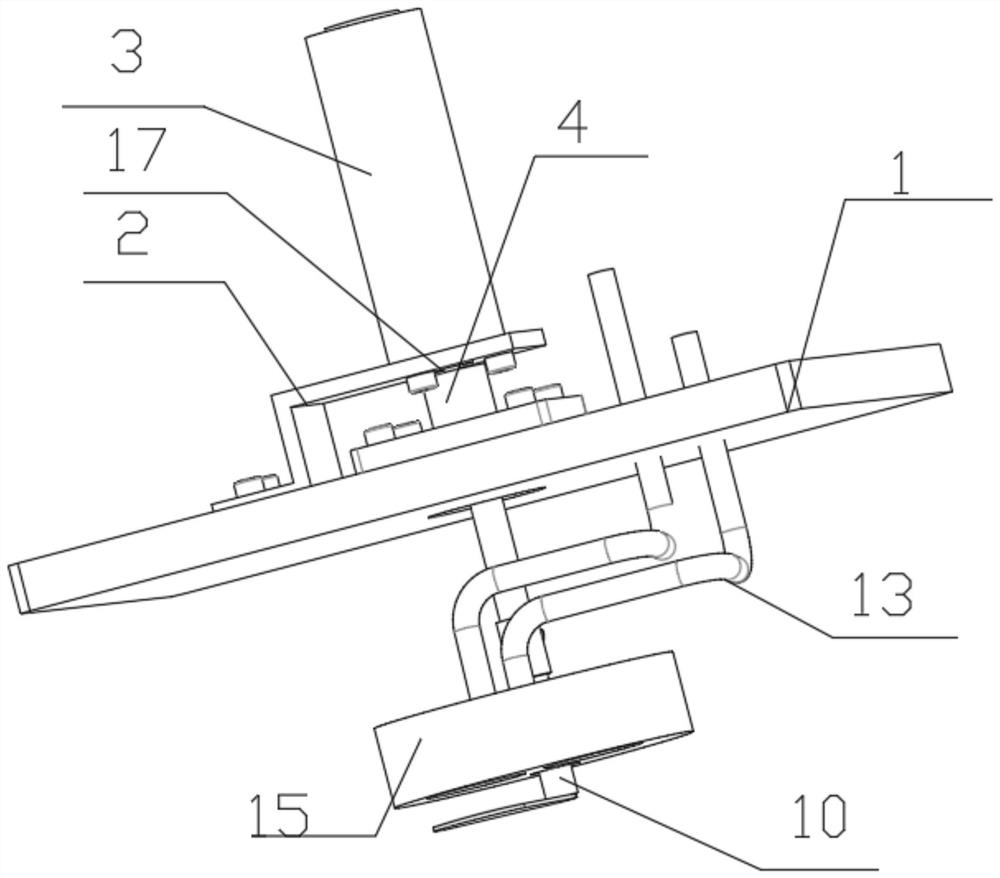

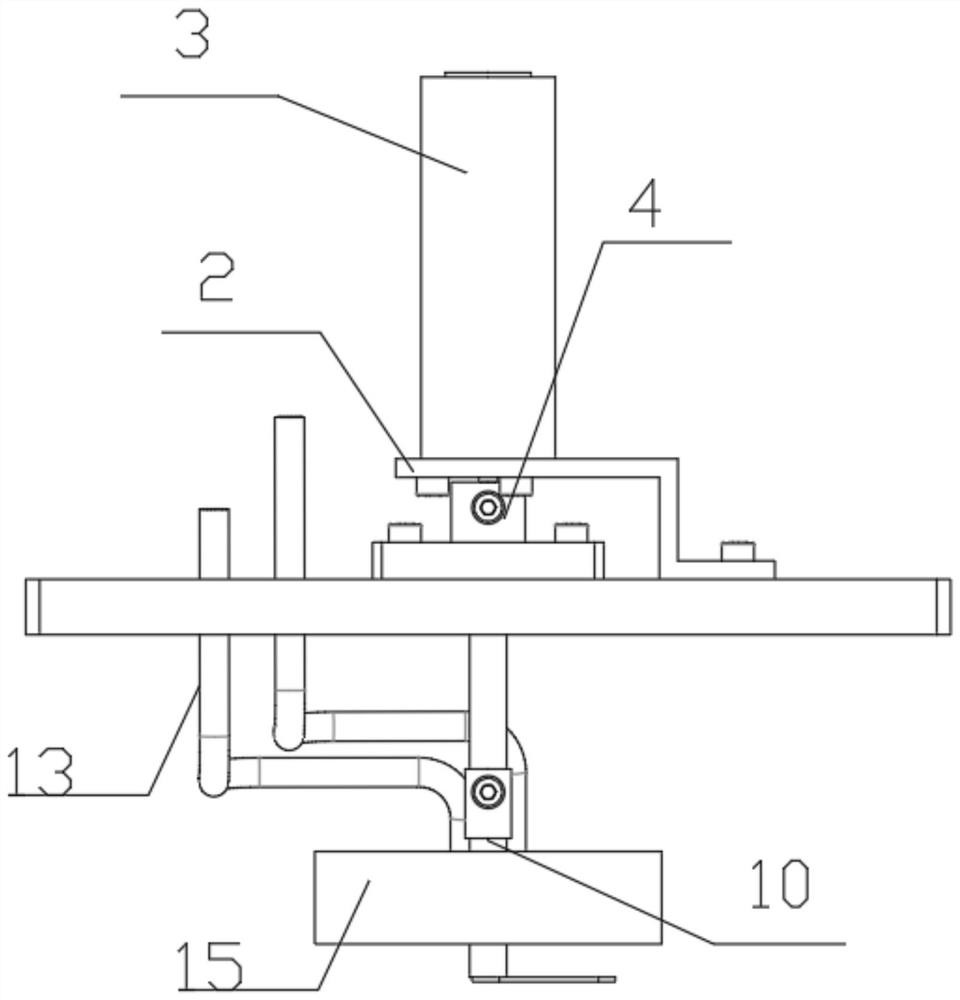

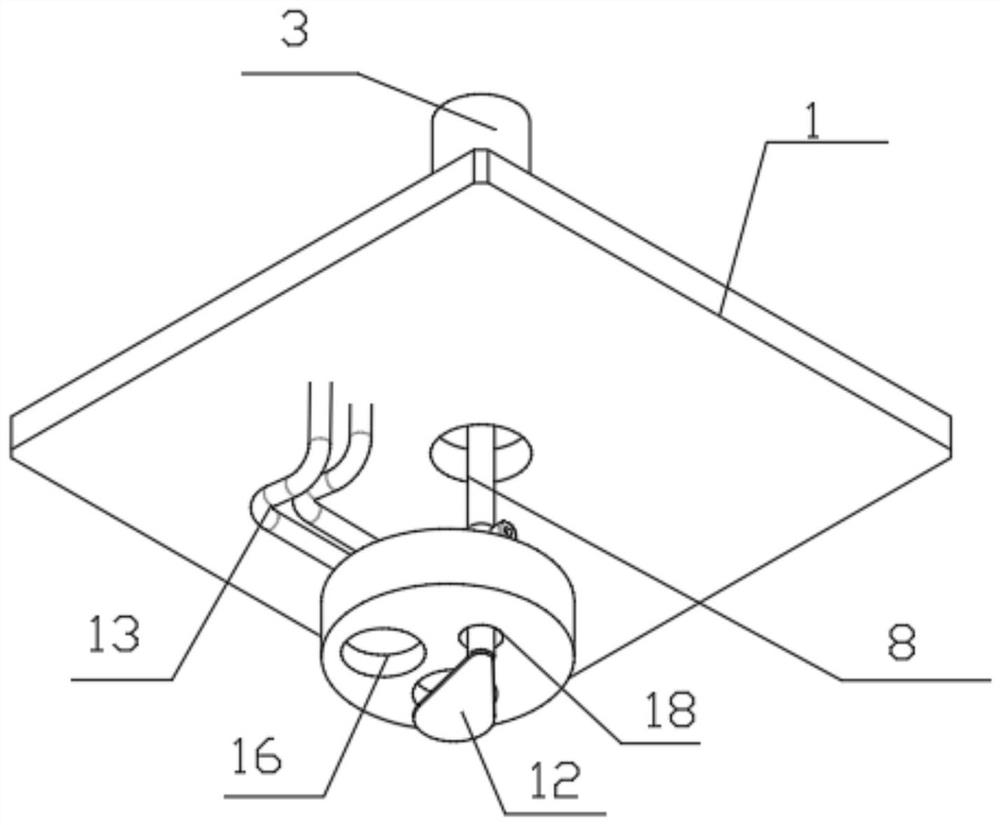

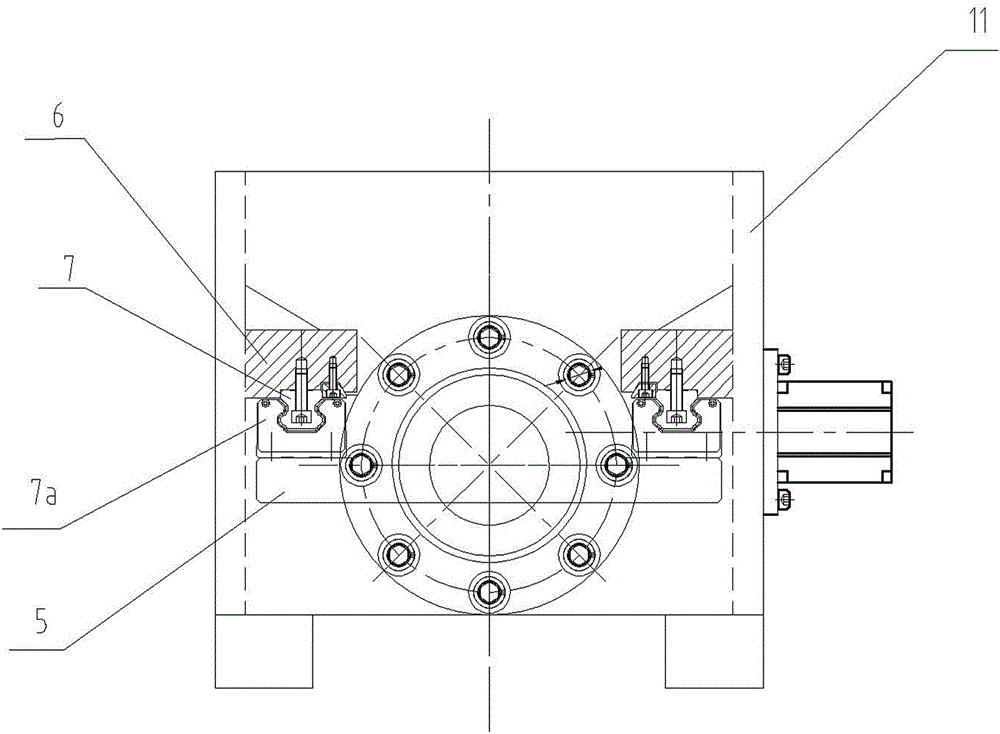

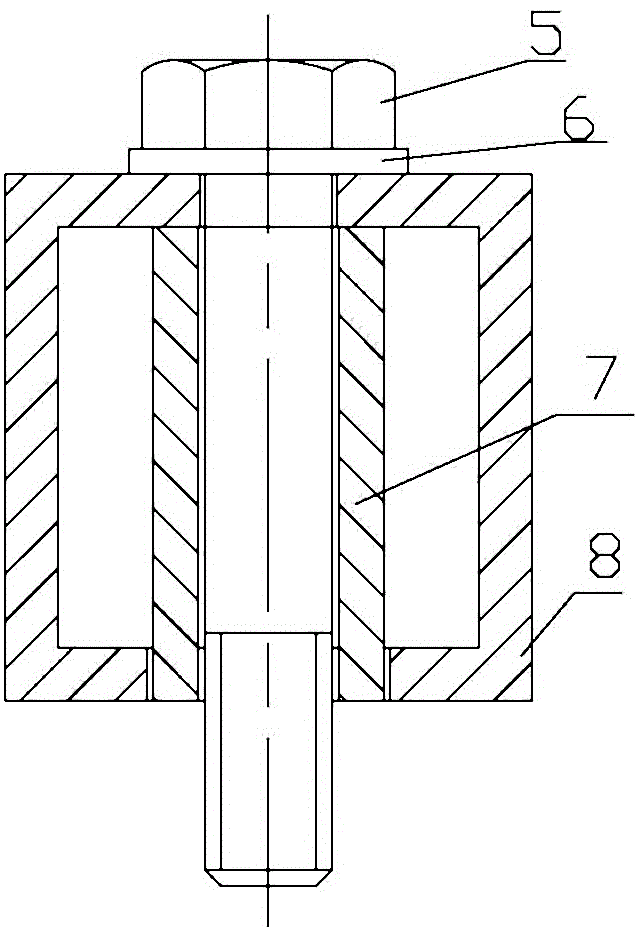

Scale division positioning tool rotary table

InactiveCN105215787ASimple structureReduce weightPrecision positioning equipmentRotational axisCircular cone

The invention discloses a scale division positioning tool rotary table and aims to provide a working table which is convenient to mount and move, high in working efficiency and capable of saving efforts during operation and machining and rotating scale division workpieces. The scale division positioning tool rotary table is achieved according to the technical scheme that a rotary shaft (4) is connected with a reset spring (2) through upright barrel stepped holes and a flange plate at the lower end of a circular cone rotating body (3); the flange plate at the lower end of the circular cone rotating body is positioned on a positioning stepped surface (11) of the upright barrel stepped holes; stepped grooves which are symmetrical relative to the axis in the diameter direction is formed in an upright barrel; a handle shaft with a locking cam (9) positions the locking cam on an inclined conical surface of the circular cone rotating body through assembling holes in the straight walls of the stepped grooves; a rotary plate (5) rotates division numbers to align the division numbers to division numbers on a machine base; the handle shaft (10) is rotated clockwise through a handle head so that the locking cam can make contact with the inclined conical surface of the circular cone rotating body, and the circular cone rotating body is locked and fixed so as to machine a workpiece.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

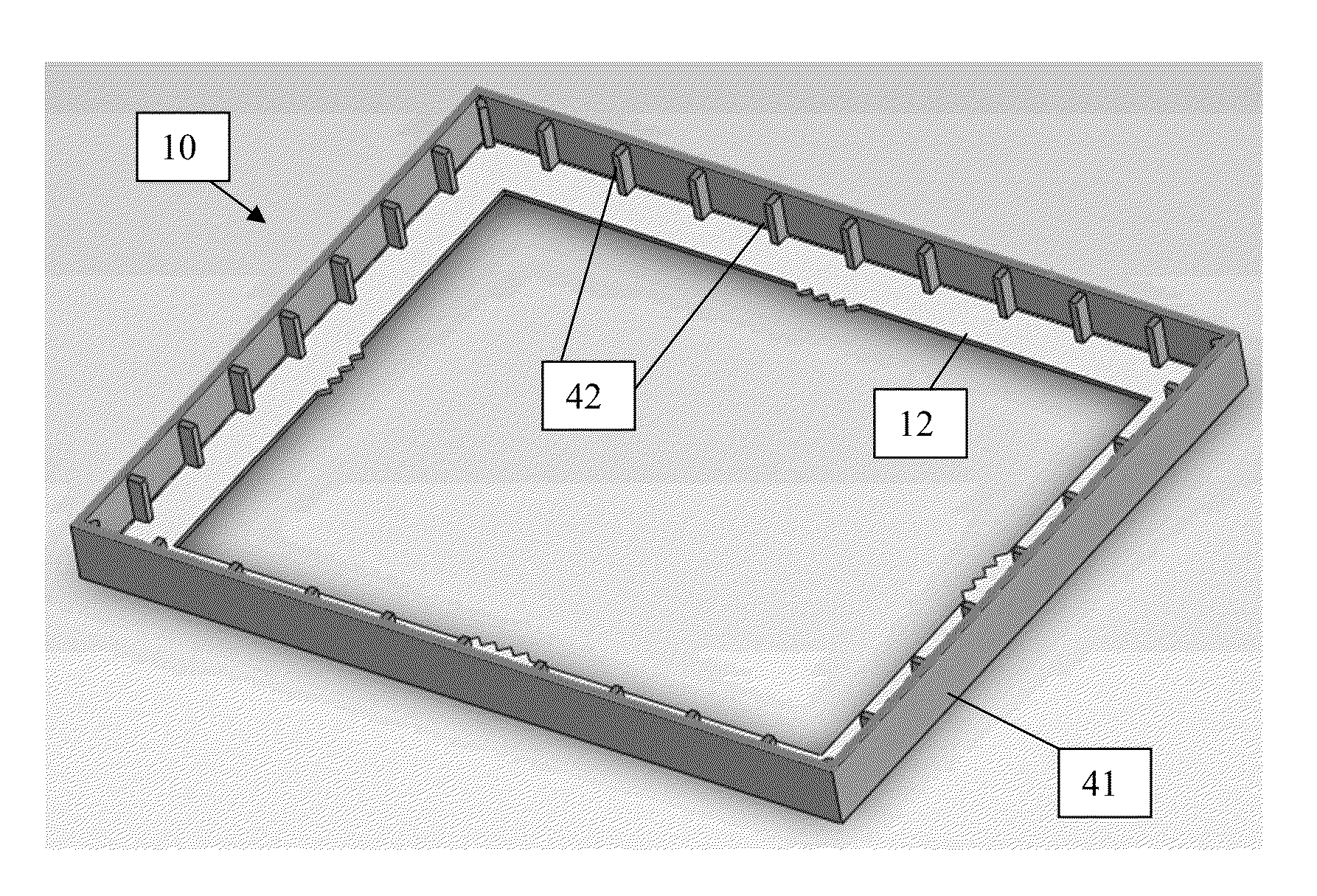

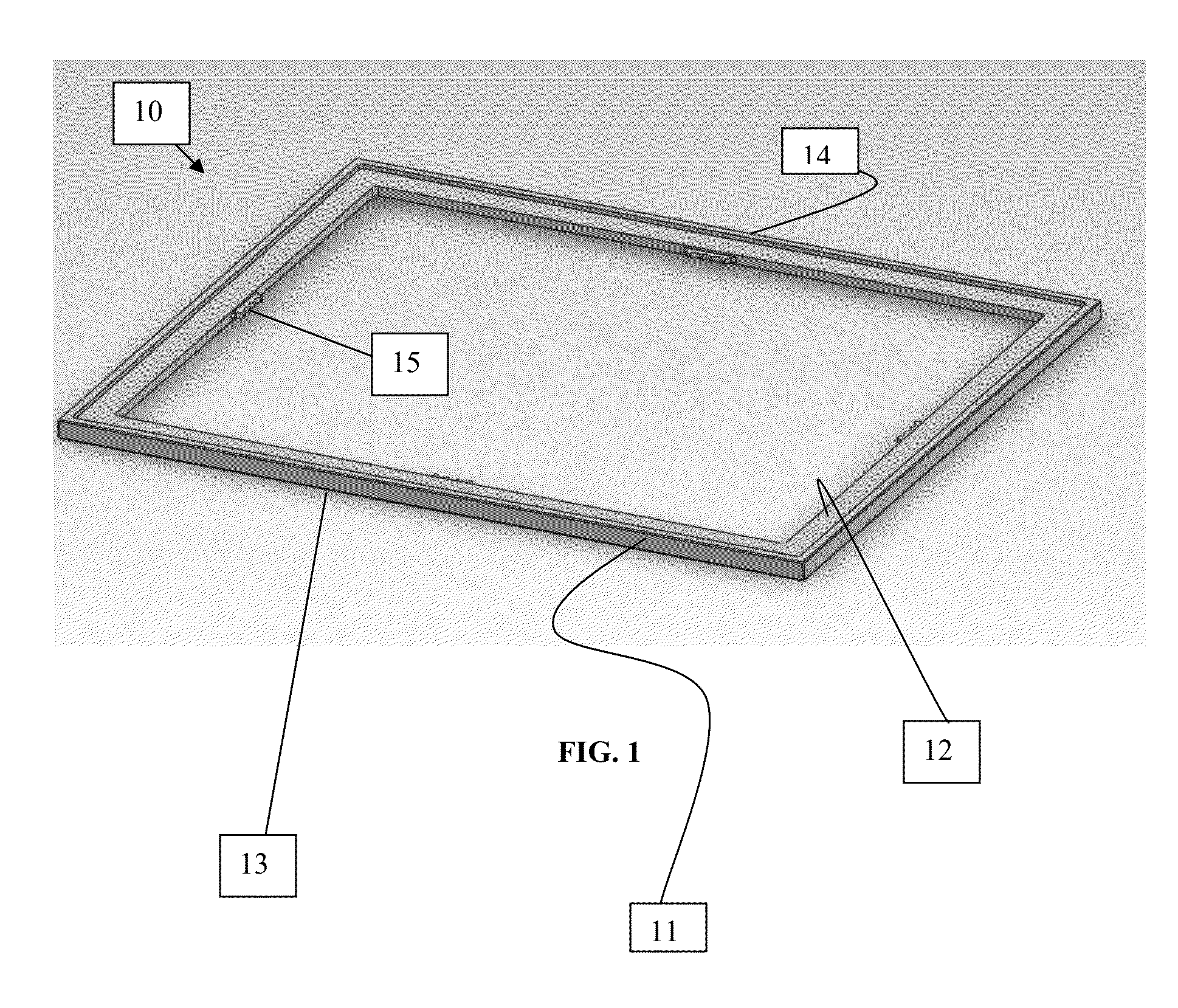

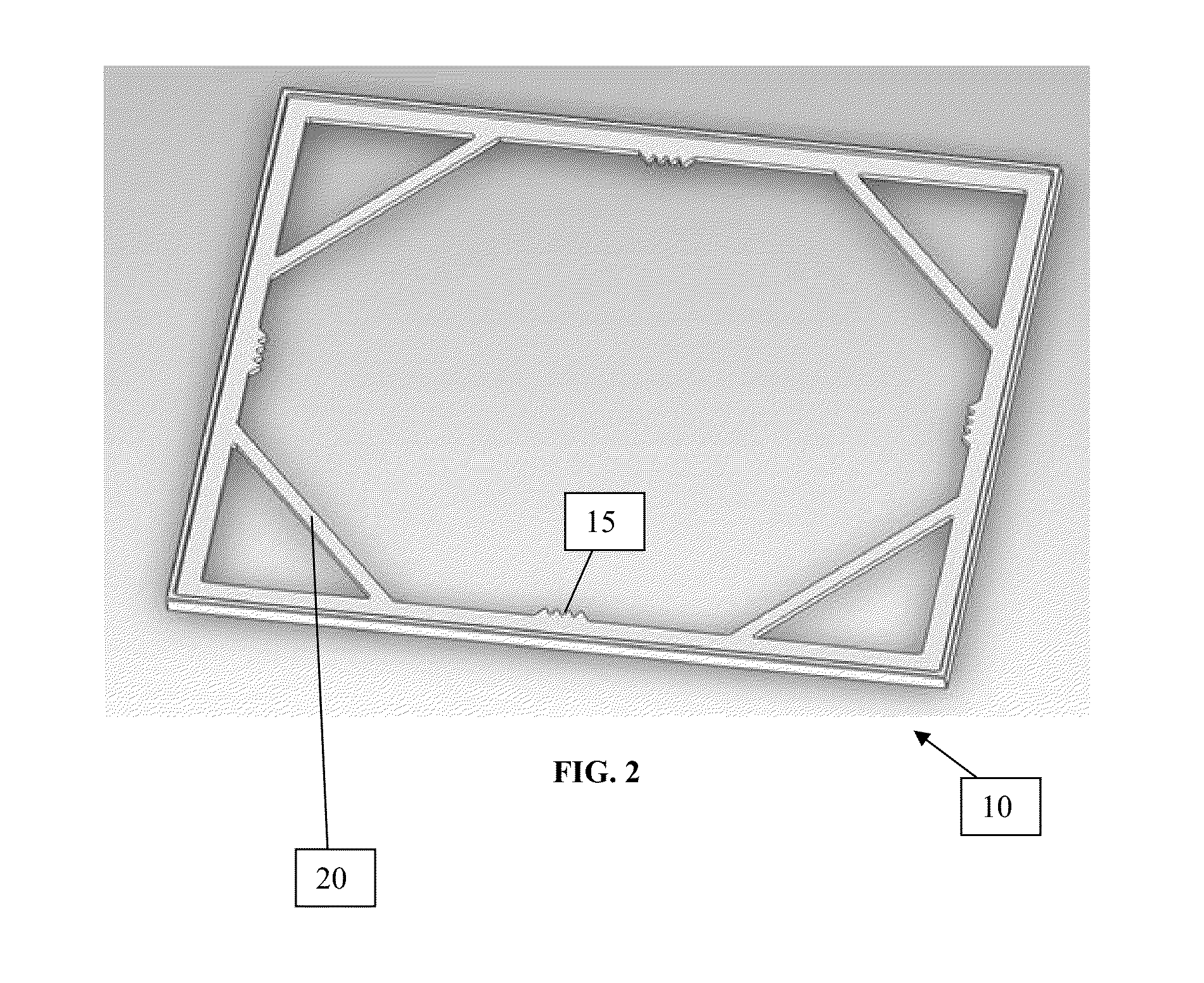

Display Frames and Methods For Display

InactiveUS20130160339A1Increased durabilityImprove wear resistancePicture framesDomestic mirrorsEngineering

Owner:GLENNON MICHAEL

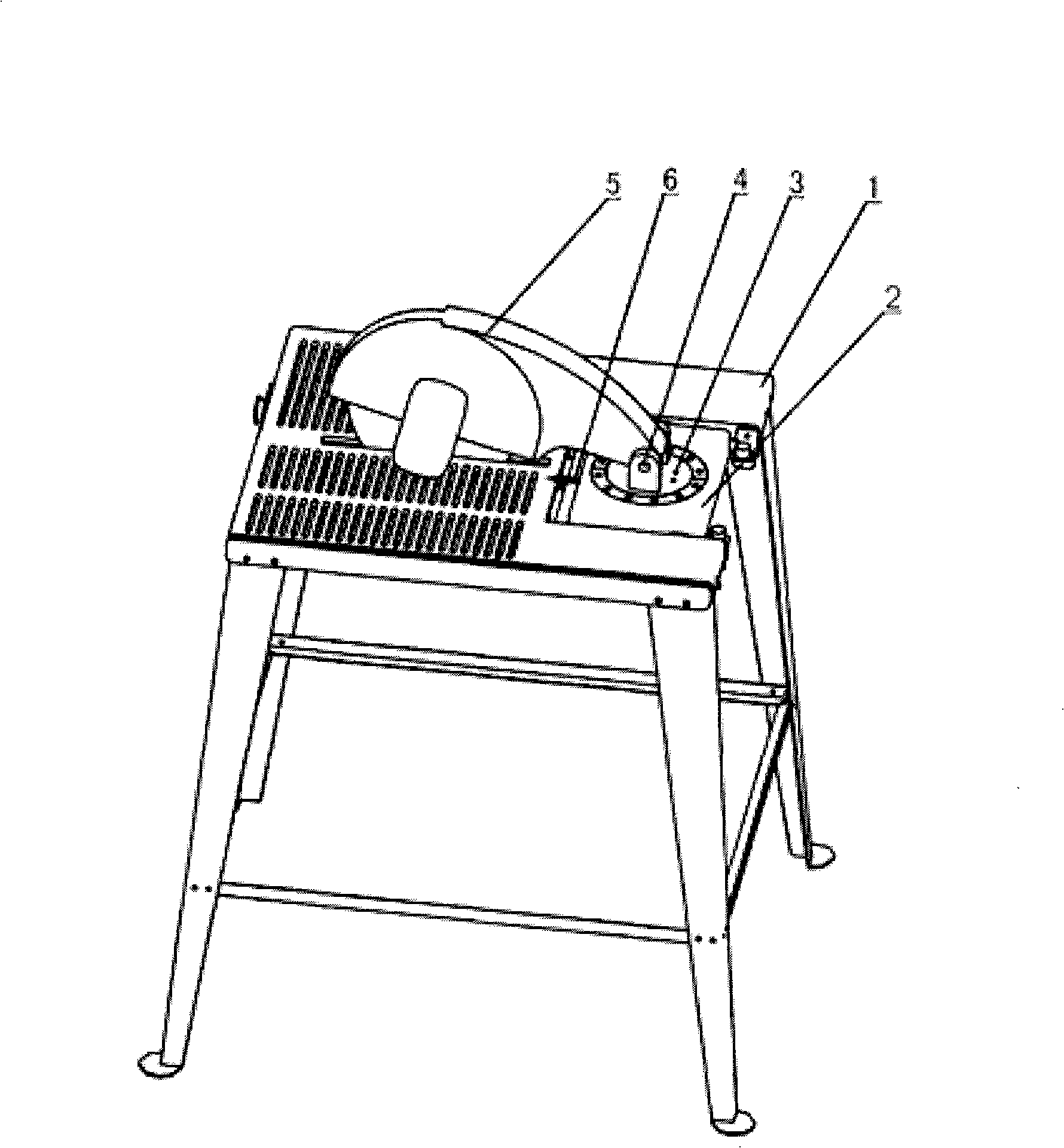

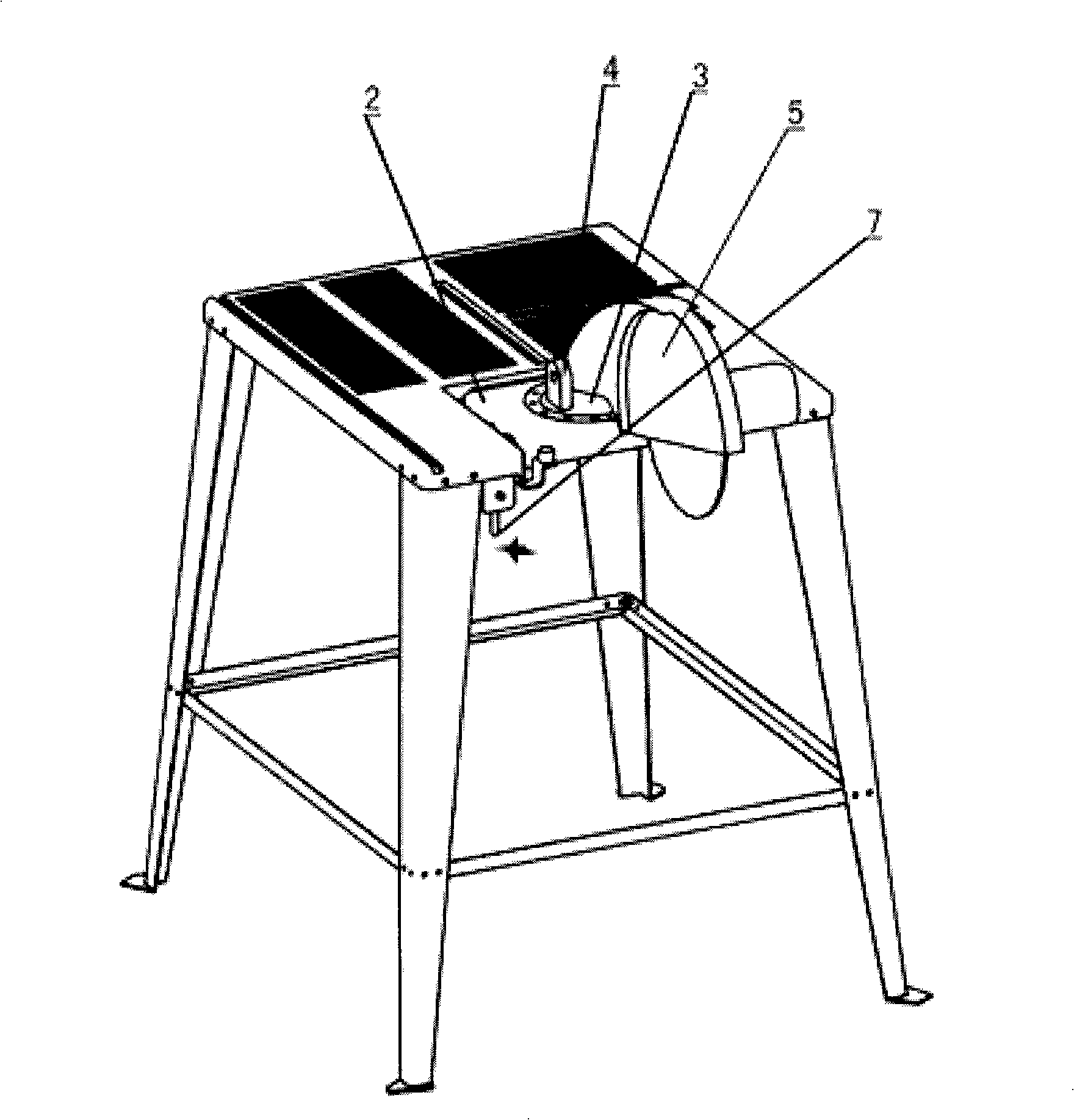

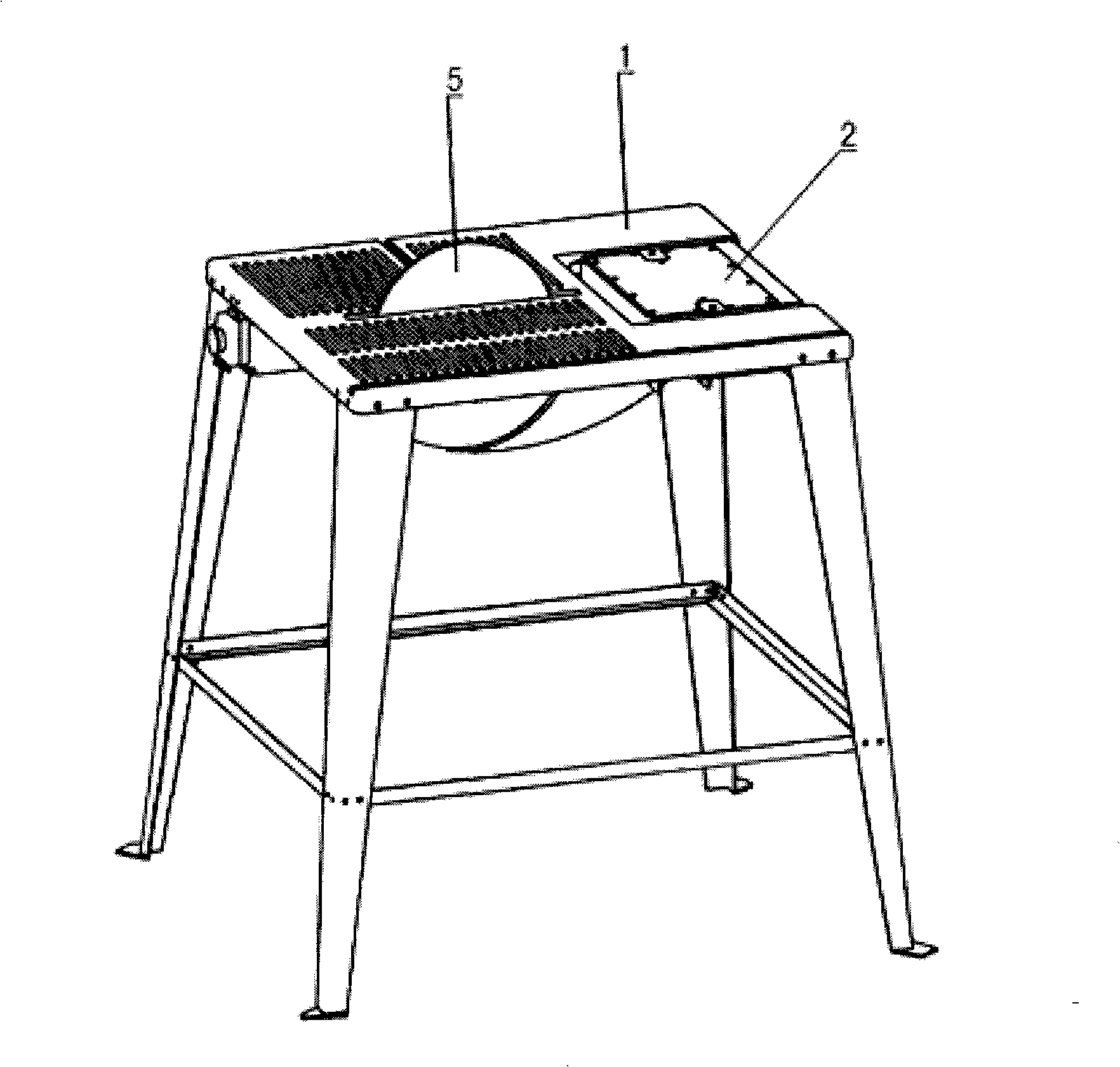

Combination bench saw head overturn structure

InactiveCN101284318AReduce thicknessSave resourcesMetal sawing devicesLarge fixed membersEngineeringWorkbench

A combined breast bench head overturning structure comprises an overturning table and a rotating seat arranged on the overturning table, wherein a fitting seat is installed on the rotating seat and used for mounting the combined breast beach head; the overturning table is connected on a workbench surface through a rotating shaft parallel with the workbench surface; a first positioning mechanism is arranged between the overturning table and the workbench surface and locates the overturning table in a position where the front of the overturning table faces the workbench surface or the back of the overturning table faces the workbench surface; the rotating seat is connected on the overturning table in such a manner that the rotating seat can rotate inside the overturning table surface; and a second positioning mechanism is installed between the rotating seat and the overturning table.

Owner:张建江

Detection method of self-trapping threaded sleeve drilling bottom hole and anti-stretching and anti-twist values

ActiveCN103090764AImprove the qualified rate of one installationImprove versatilityMachine part testingMechanical diameter measurementsMeasurement deviceTrapping

The invention discloses a detection method of a self-trapping threaded sleeve drilling bottom hole and anti-stretching and anti-twist values and aims to solve the problems that the prior self-trapping threaded sleeve drilling bottom hole detection method is tedious, stretching resistance is not detected, and potential safety hazards exist. The detection method of the self-trapping threaded sleeve drilling bottom hole and the anti-stretching and anti-twist values comprises the following steps: 1) drilling a bottom hole; 2) detecting the bottom hole by adopting a hole diameter detection device; 3) detecting verticality; and 4) detecting anti-stretching and anti-twist values of the a self-trapping threaded sleeve by adopting an anti-stretching and anti-twist value measurement device. The detection method of the self-trapping threaded sleeve drilling bottom hole and the anti-stretching and anti-twist values improves the percent of once installment pass of the self-trapping threaded sleeve, eliminates potential quality hazard, and reduces reworking and production cost.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Indexing and positioning tooling turntable

InactiveCN105215787BSimple structureReduce weightPrecision positioning equipmentCircular coneEngineering

The invention discloses a scale division positioning tool rotary table and aims to provide a working table which is convenient to mount and move, high in working efficiency and capable of saving efforts during operation and machining and rotating scale division workpieces. The scale division positioning tool rotary table is achieved according to the technical scheme that a rotary shaft (4) is connected with a reset spring (2) through upright barrel stepped holes and a flange plate at the lower end of a circular cone rotating body (3); the flange plate at the lower end of the circular cone rotating body is positioned on a positioning stepped surface (11) of the upright barrel stepped holes; stepped grooves which are symmetrical relative to the axis in the diameter direction is formed in an upright barrel; a handle shaft with a locking cam (9) positions the locking cam on an inclined conical surface of the circular cone rotating body through assembling holes in the straight walls of the stepped grooves; a rotary plate (5) rotates division numbers to align the division numbers to division numbers on a machine base; the handle shaft (10) is rotated clockwise through a handle head so that the locking cam can make contact with the inclined conical surface of the circular cone rotating body, and the circular cone rotating body is locked and fixed so as to machine a workpiece.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

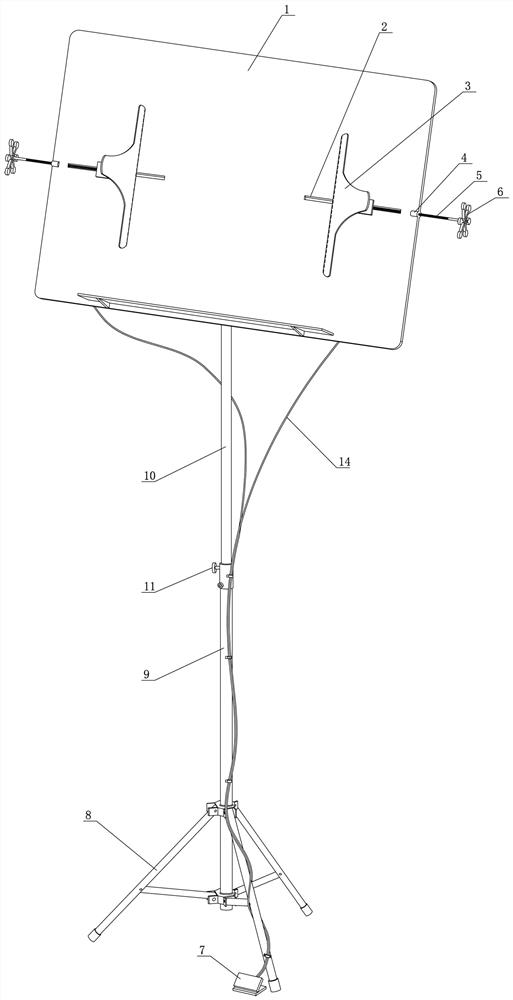

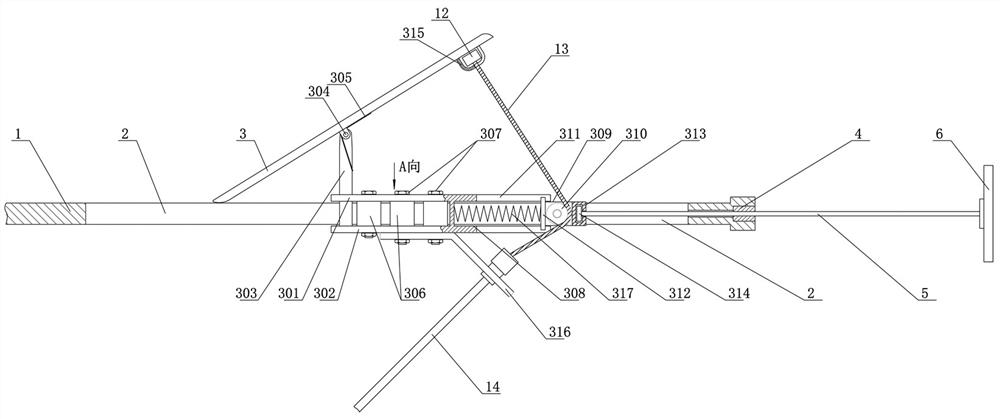

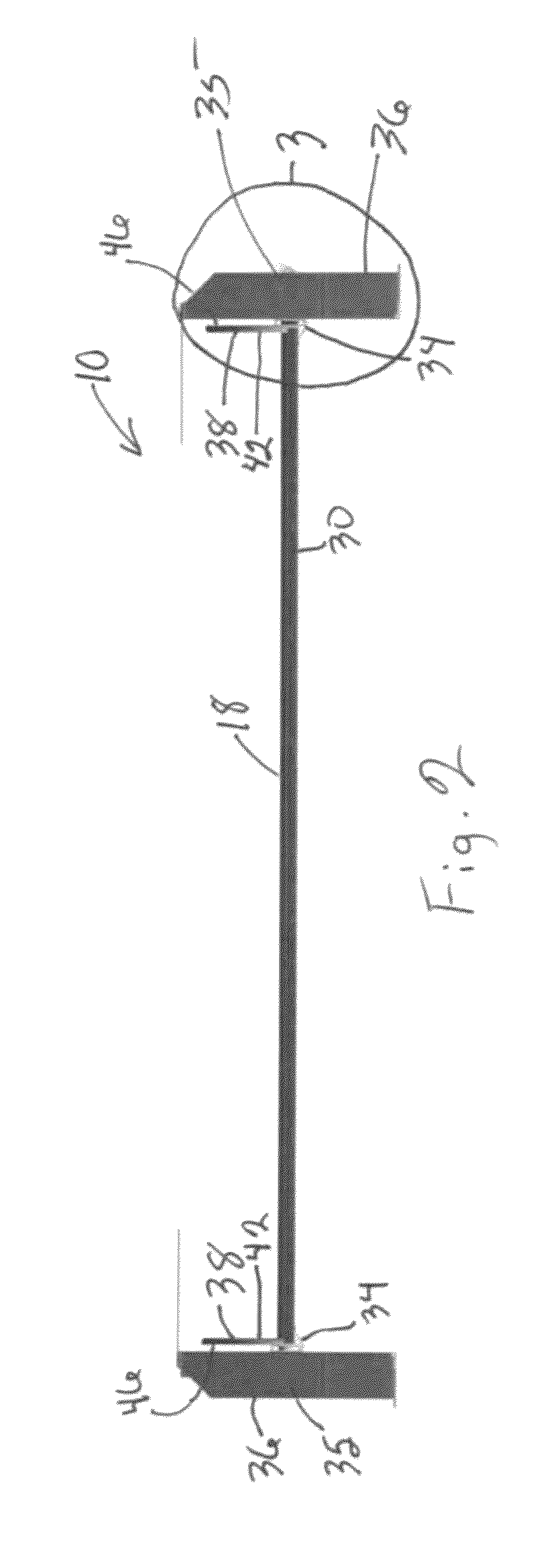

sheet music stand

Owner:HENAN POLYTECHNIC

A kind of graphene modified antistatic tpu film

The invention discloses a graphene-modified antistatic TPU film, which is prepared from the following raw materials in parts by mass: 60-80 parts of polyether-type TPU resin, 1-3 parts of modified graphene, and 2-4 parts of thermal stabilizer , 1-3 parts of lubricant, 1-2 parts of plasticizer, and 0.5-2 parts of nano-alumina; after graphene oxide is modified by silane coupling agent and reduced by ammonia water, it is uniformly dispersed in TPU resin, and at the same time It does not polymerize itself, which enhances the electrical conductivity and impact resistance of the TPU film; after the nano-alumina is modified, the mechanical properties of the nano-alumina and the affinity for the resin material are enhanced; at the same time, the nano-alumina, graphite The amount of alkene is less, which reduces the production.

Owner:安徽嘉明新材料科技有限公司 +1

A punching/welding integrated manufacturing device for plate parts

ActiveCN104889736BIncrease productivityReduce production energy consumptionShaping toolsMetal-working feeding devicesEngineeringSpot welding

An integrated stamping / welding manufacturing device for plate parts, including a die and a punch, the die is fixed on the lower die, the punch is connected to the upper die, the lower die and the upper die are connected together through guide posts and guide sleeves, the punch A plurality of first magnetorheological dampers are connected to the lower surface of the mold fixing plate, and the lower end of the first magnetorheological dampers is connected to a binder ring, and the lower part of the binder ring is equipped with a plurality of second magnetorheological dampers. The lower end of the variable damper is connected to the spot welding upper electrode; the outer edge of the die is equipped with a plurality of spot welding lower electrodes, the center of the die is equipped with a first electromagnet, and more than two electromagnets are installed on the outer edge of the die. The second electromagnet, the installation position of the second electromagnet is all on the circle determined on the basis of the center of the spot welding lower electrode, and forms a phase distribution with the spot welding lower electrode. The present invention integrates punching / welding. The plate parts processed by the device have small springback, less energy consumption and high processing efficiency.

Owner:XI AN JIAOTONG UNIV

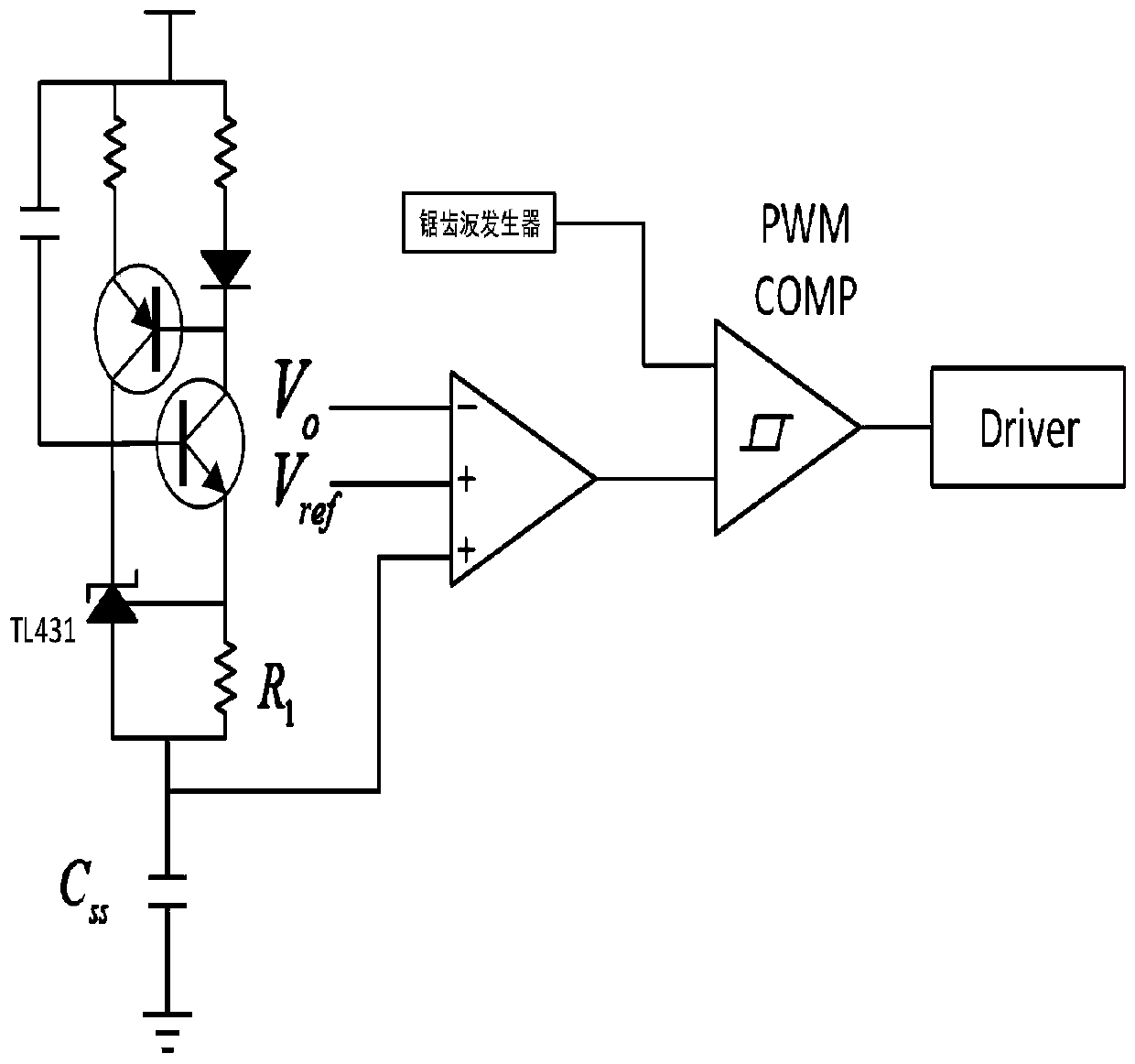

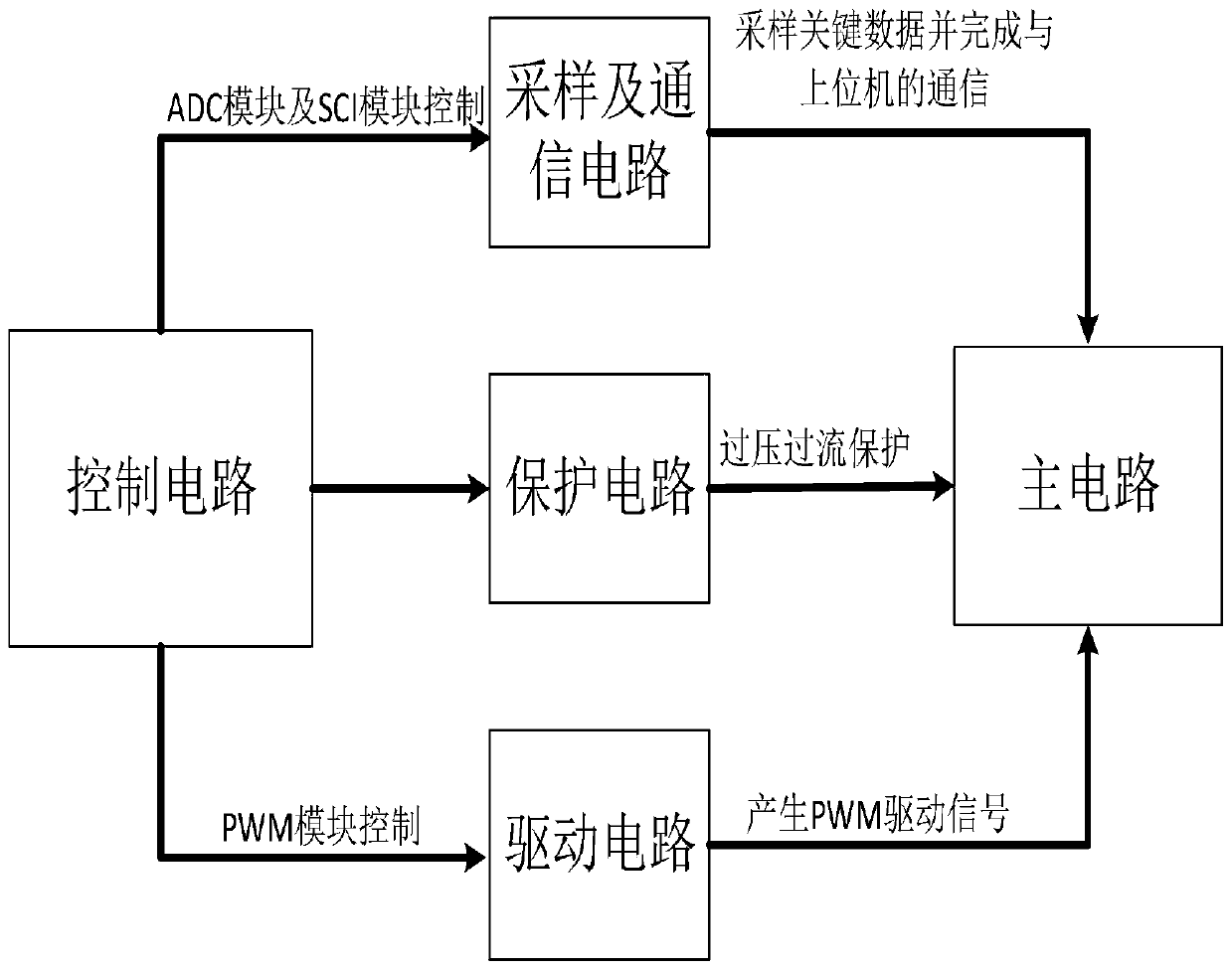

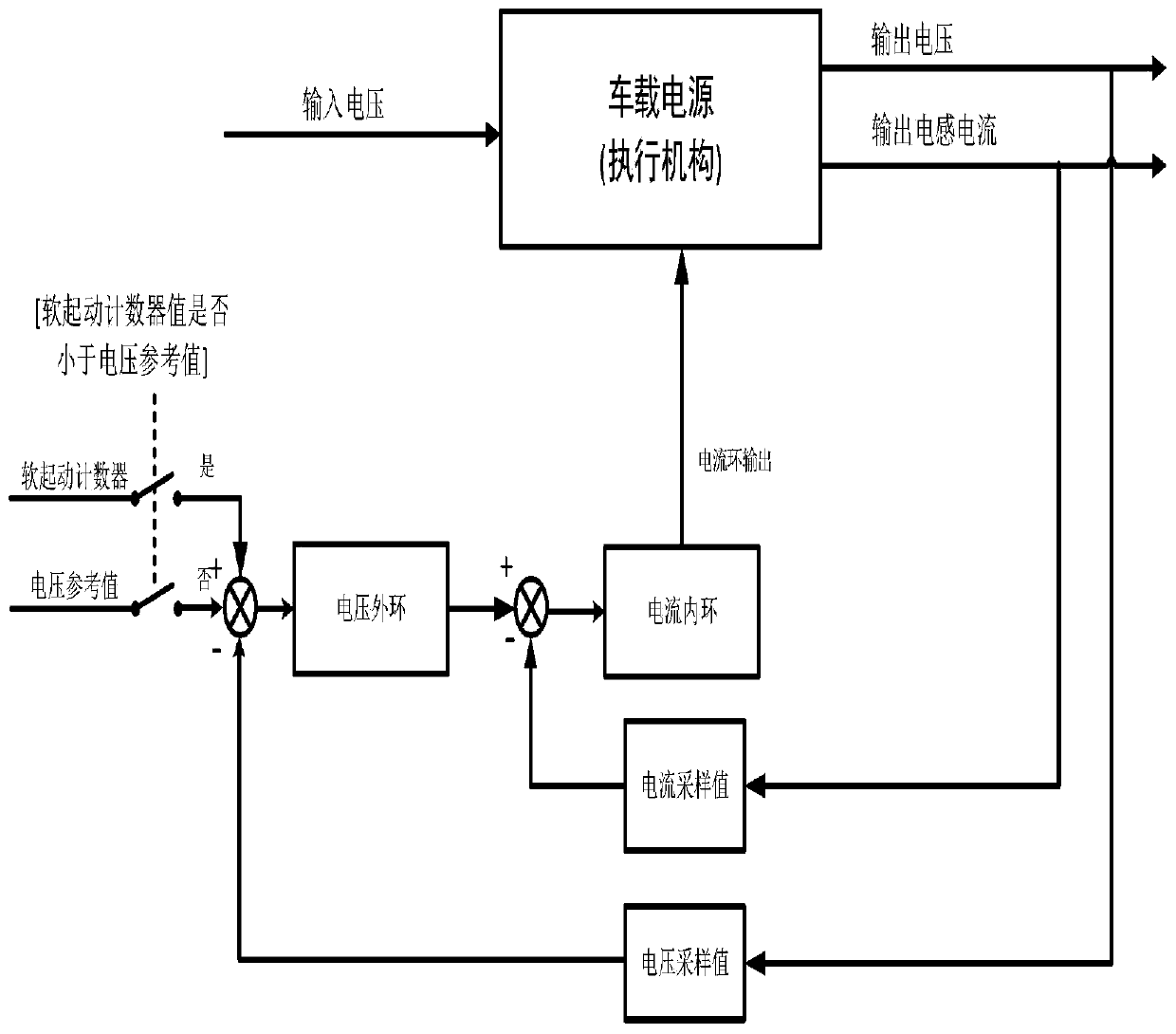

A digital vehicle power supply output soft start method

ActiveCN110336457BSolve the technical problems of soft startReduce volumePower conversion systemsCapacitancePerformance function

The invention discloses a digital onboard power supply output soft start method and belongs to the field of onboard electronic technology. The method comprises establishing an onboard power supply main circuit and an onboard power supply control unit, initializing a configuration function, completing a performance function, comparing a soft start counter with a set voltage reference value in orderto select either of the soft start counter and the set voltage reference value as a voltage external-loop voltage reference to be substituted into the voltage outer-loop PID calculation, thereby realizing the soft start of the onboard power supply, solving the technical problem of the soft start of the onboard power supply, and eliminating the defect that the onboard power supply, which is a switching power supply, has over-high and sharply increased output-end voltage so as to cause an output-end capacitor to be unable to sustain the excessive surge current. The method avoids the use of a soft start circuit, thereby reducing the volume of the onboard power supply and the manufacturing cost, avoiding the power consumption of the soft start circuit, improving the operating efficiency of the onboard power supply and realizing the controllable soft start time.

Owner:南京桐润新能源有限公司

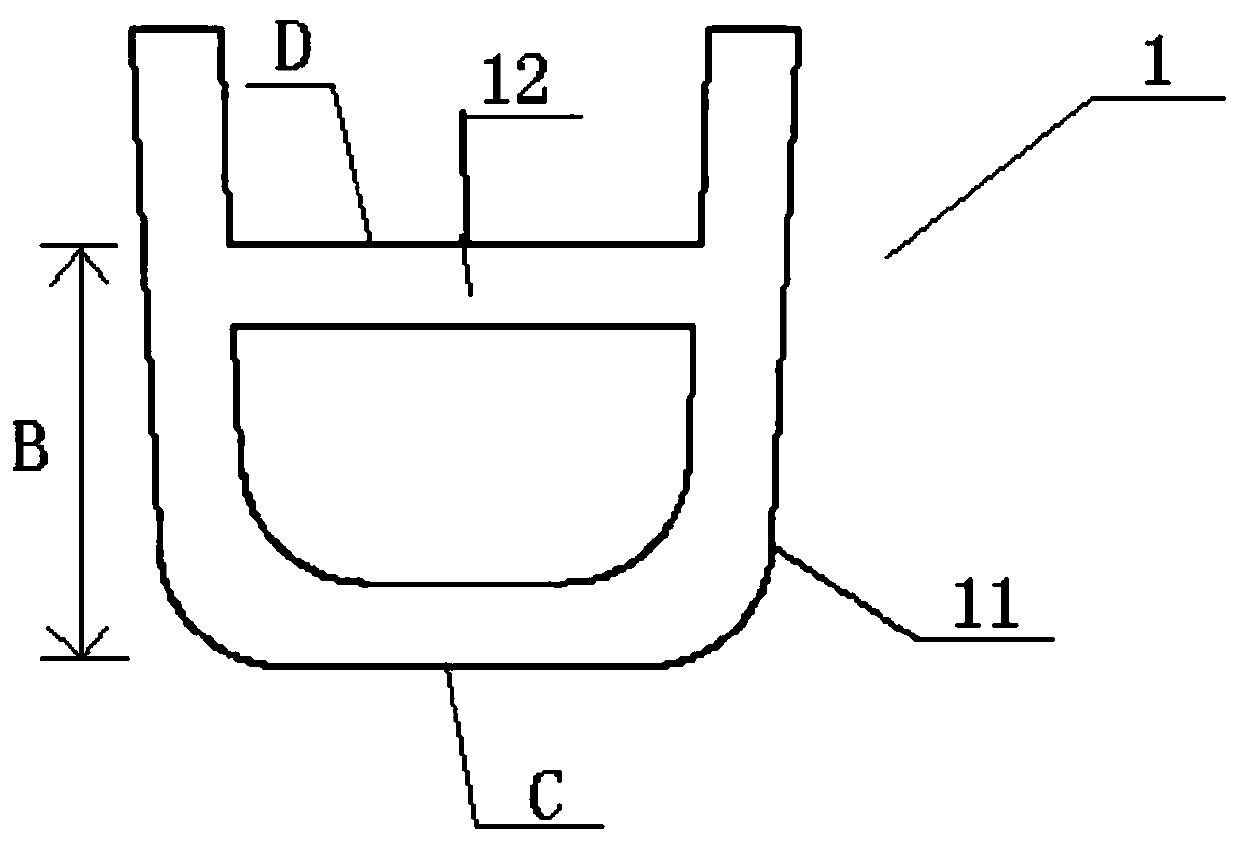

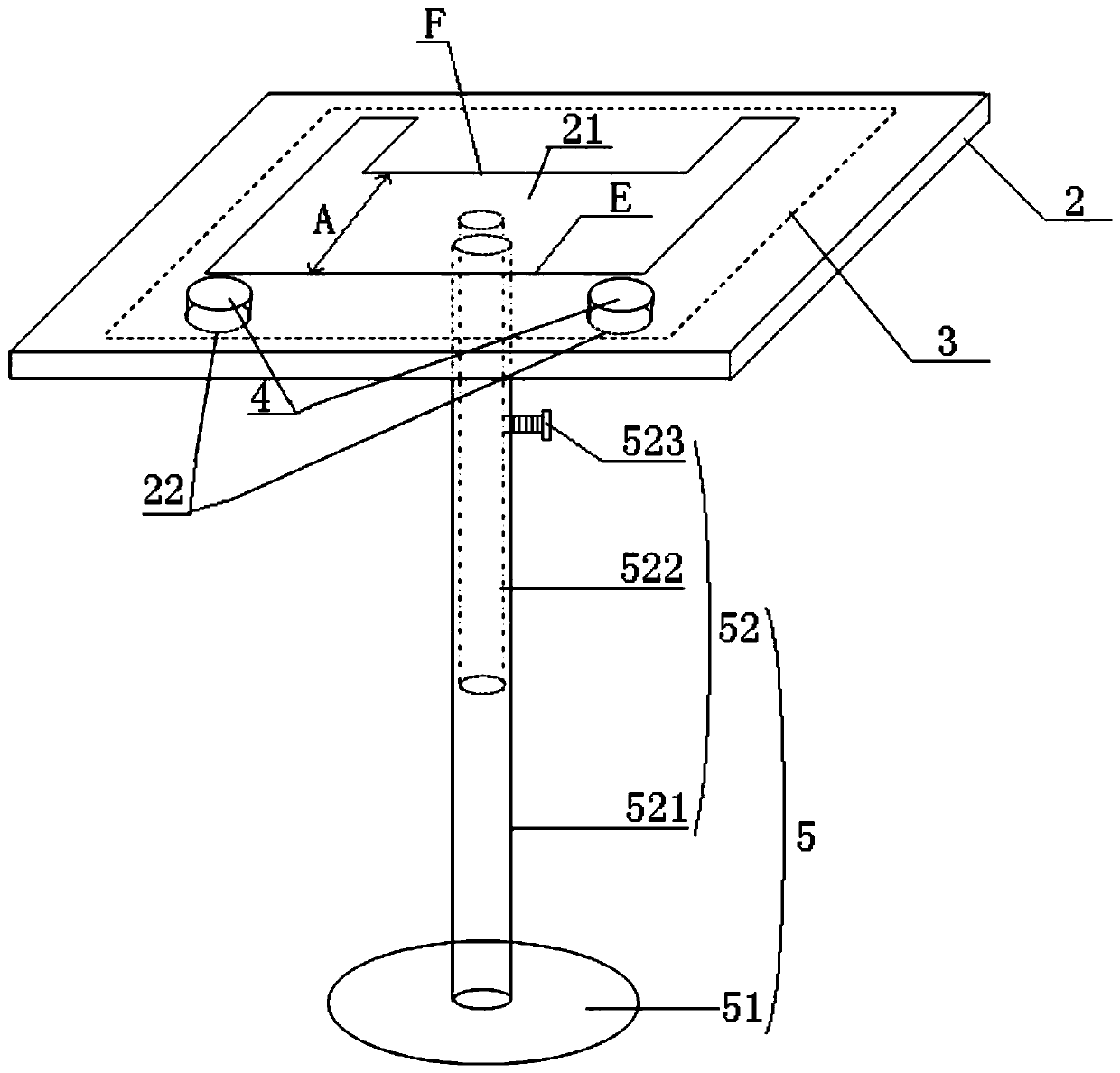

Assembling-welding auxiliary jig for L2-S type part and welding method thereof

PendingCN110142557ASimplify the soldering processEnsure high precision assemblyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses an assembling-welding auxiliary jig for an L2-S type part and a welding method thereof. The assembling-welding auxiliary jig comprises a substrate (2), a base plate (3) and twolimiting steel pipes (4); the substrate (2) is provided with an assembling hole (21) and two installing holes (22), the assembling hole (21) is in a U shape, and the distance between the two installing holes (22) is equal to the distance between the two ends of a U-shaped opening of a U-shaped part (11); the base plate (3) is fixedly installed on the lower surface of the substrate (2), and the lower end of the assembling hole (21) and the lower ends of the two installing holes (22) are blocked; and the two limiting steel pipes (4) are installed in the two installing holes (22) correspondingly. The installing welding method is suitable for the assembling-welding auxiliary jig. The assembling-welding auxiliary jig has the advantages of being simple in structure, reasonable in design, convenient to use, low in manufacturing cost, good in assembling-welding precision, high in working efficiency and the like.

Owner:DALIAN COSCO KHI SHIP ENG

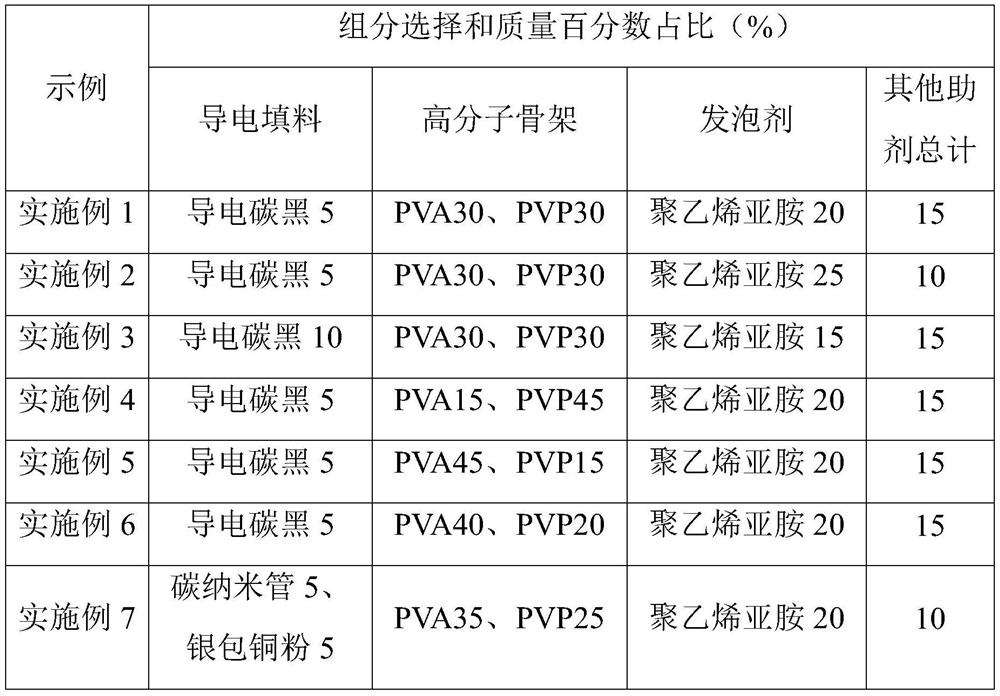

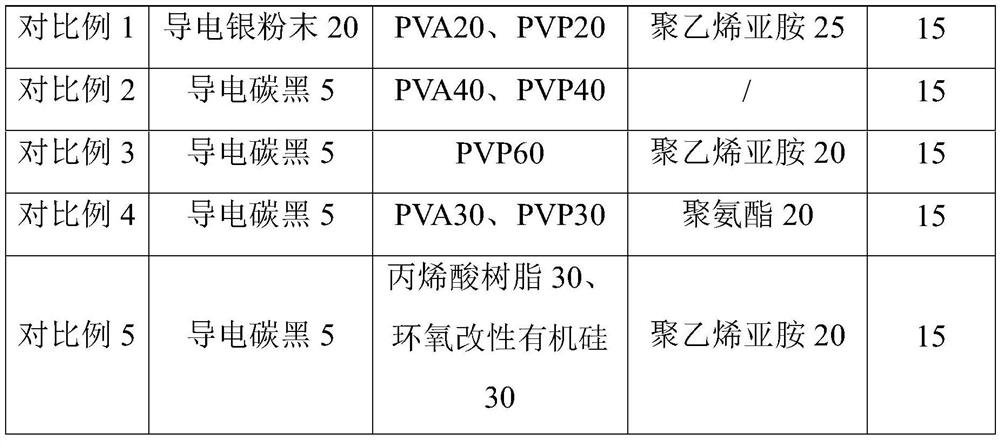

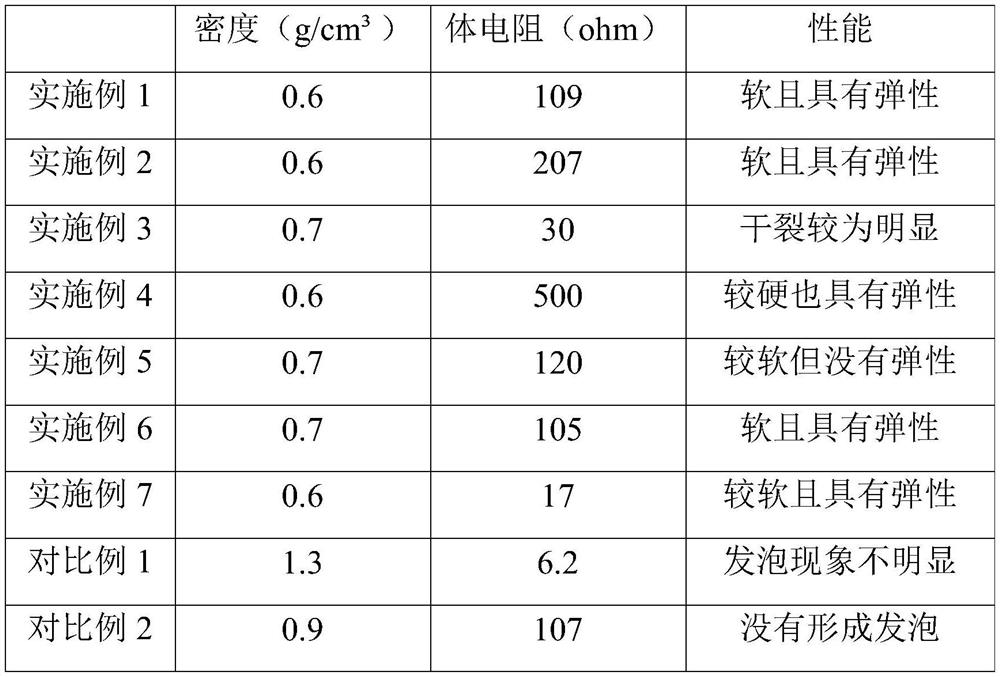

Foam type conductive colloidal skin-friendly dressing as well as preparation method and application thereof

PendingCN114774067AImprove economyLow densityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyvinyl alcoholPyrrolidinones

The invention discloses a foam type conductive colloidal skin-friendly dressing as well as a preparation method and application thereof, and relates to the technical field of conductive materials. The foam type conductive colloidal skin-friendly dressing is prepared from the following raw materials in parts by weight: 1 to 10 parts of polyvinyl alcohol, 1 to 10 parts of polyvinylpyrrolidone, 15 to 25 parts of polyethyleneimine, 1 to 5 parts of cross-linking agent, 1 to 5 parts of softener, 1 to 5 parts of stabilizer, 10 to 90 parts of water and 5 to 10 parts of conductive filler. Effective crosslinking is completed through reasonable proportion regulation and control, the skin-friendly foam type conductive adhesive with a pore channel structure is formed, the formed conductive adhesive is small in density and small in resistance, can meet the application requirement of a human body sensor electrode, and is non-toxic to skin, biodegradable and good in biocompatibility. The traditional Chinese medicine composition is free of irritation to skin, low in manufacturing cost and safe to use, and has a good economic effect. The method can be widely applied to preparation of a pipeline sealing anti-leakage agent, flexible medical electronic equipment, a sensor electrode or an auxiliary buffer electrode.

Owner:深圳市哈深智材科技有限公司

A kind of preparation method of fiber pipe material with pattern or characters on the surface

ActiveCN103331918BNot easy to break awayNot easy to damageDuplicating/marking methodsTubular articlesEpoxyFiber

The invention relates to a preparation method of a fiber pipe with a pattern or a letter on the surface. The preparation method comprises the following steps of: 1) winding fiber prepreg on a core mold to form a pipe blank, 2) printing reverse pattern or letter ink on one side of a plastic film, 3) winding the plastic film on the pipe blank to replace a release belt to size the pipe blank, or winding in an incomplete covering or partial overlying manner, then winding the release belt for sizing, 4) placing the wound pipe blank in a curing oven for baking for 1-3h at 110-175 DEG C to allow the pattern or letter ink on the plastic film and phenolic resin or epoxy resin of the pipe blank to be immersed mutually, solidified and formed, and 5) removing the mold, and stripping the plastic film to obtain the finish product. The preparation method has the advantages that the pattern is not easy to separate and damage, paint polishing or paint spraying is not required during preparation, the preparation technology is simple, the time, labor and raw materials are saved, and the manufacturing cost is low.

Owner:威海六高橡塑科技有限公司

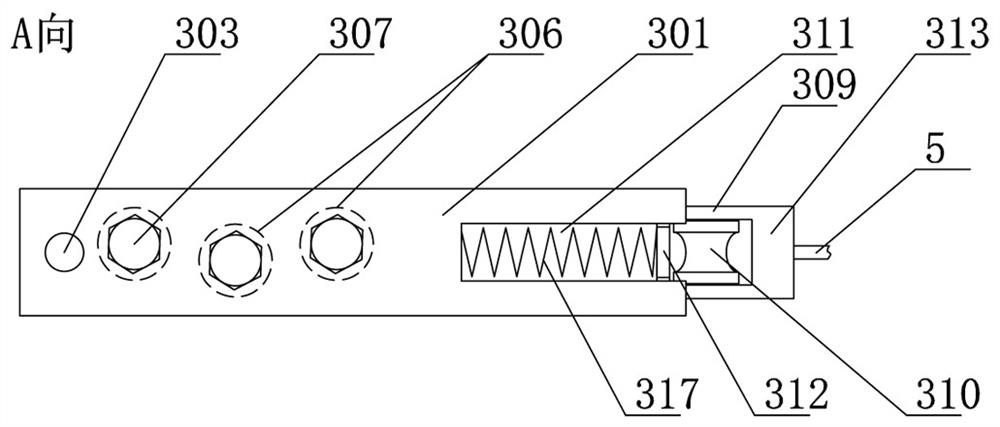

Magnetofluid integrated crystal oscillator baffle switching mechanism

PendingCN112634980AReduce the number of re-pollutionReduce replacement efficiencyScreening apparatusWeighing apparatus detailsMechanical engineeringCrystal oscillator

In order to solve the problems that a crystal oscillator piece in a crystal oscillator probe is repeatedly polluted, the crystal oscillator frequency is likely to be unstable, consequently the evaporation capacity of target materials cannot be accurately detected by the crystal oscillator probe, and the coating thickness of a substrate is not uniform, the invention provides a magnetofluid integrated crystal oscillator baffle switching mechanism. Magnetofluid is driven by an air cylinder to rotate, and the magnetofluid is rotated to drive a shielding plate to rotate, so that a shielding piece on the shielding plate is located under a detection hole of one unused crystal oscillator piece, and the frequency of repeated contamination of the crystal oscillator piece is reduced; the shielding piece is rotatably located at the lower end of the detection hole of the polluted crystal oscillator piece, and the unpolluted detection hole is used; the replacement efficiency of the crystal oscillator piece is reduced, and meanwhile the shielding plate is detachably connected with the magnetofluid after being polluted, thereby facilitating replacement; the sealing performance of an evaporator cavity is improved through use of the magnetofluid, and the structure is simple; and the operation is convenient, and the manufacturing cost is low.

Owner:苏州佑伦真空设备科技有限公司

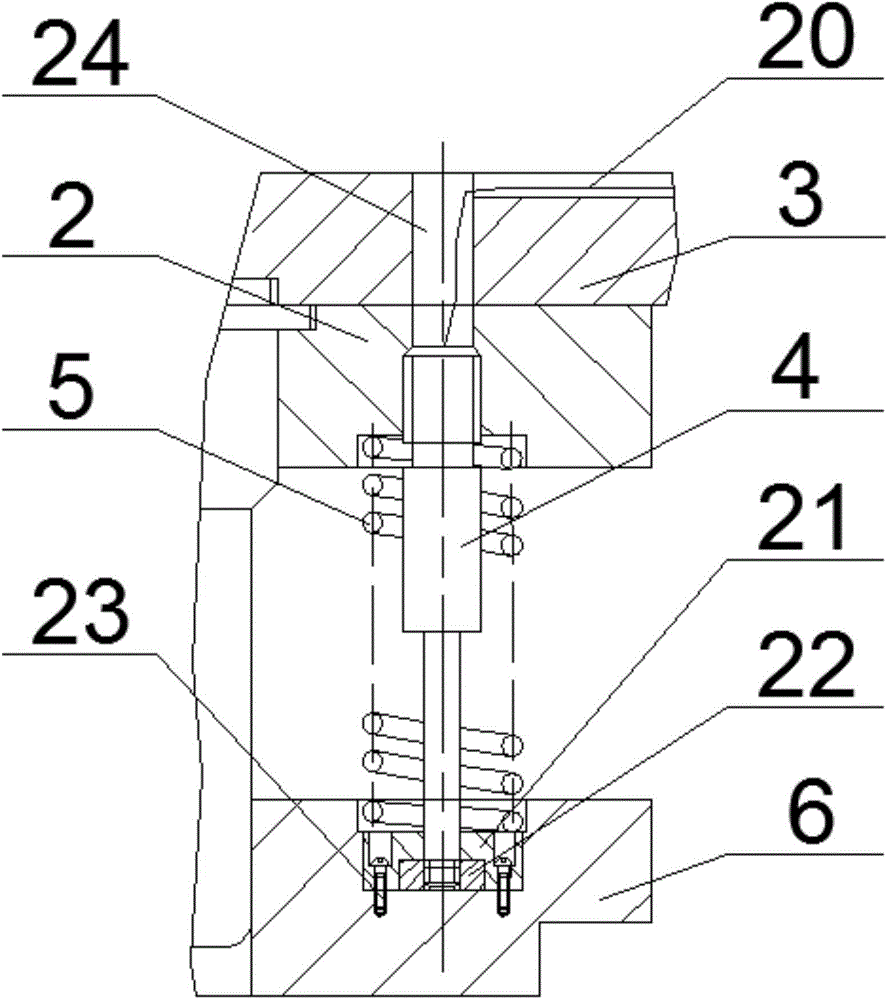

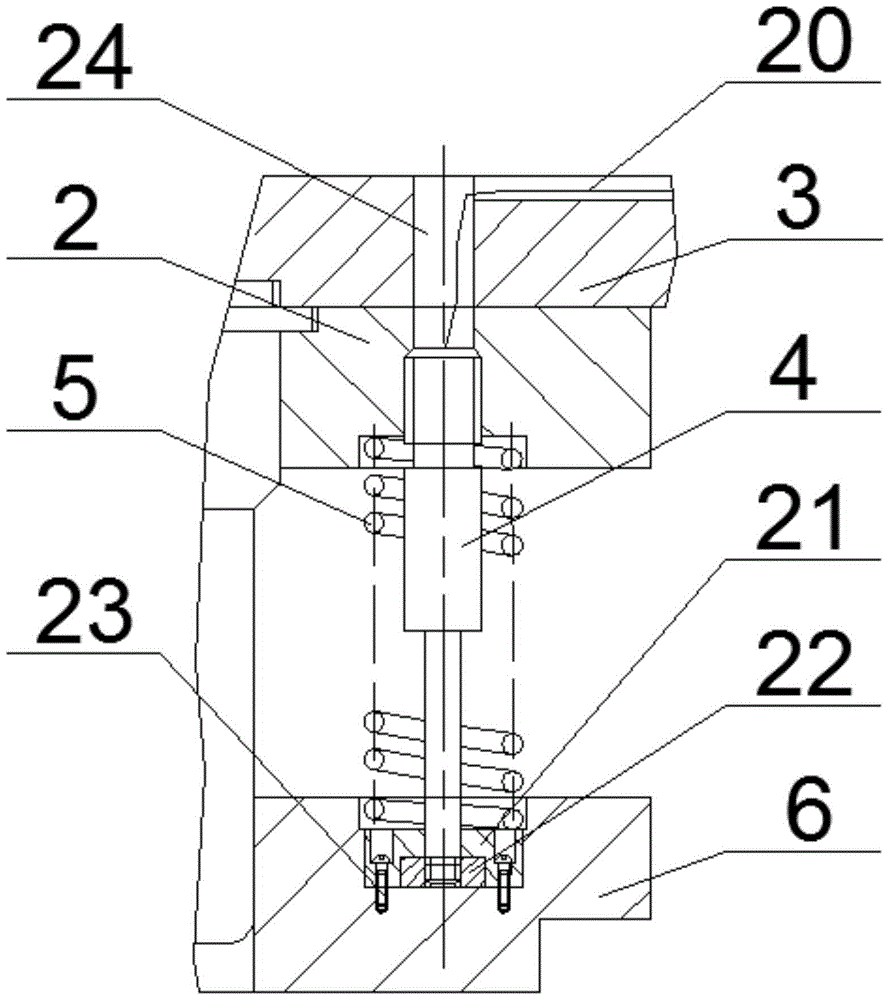

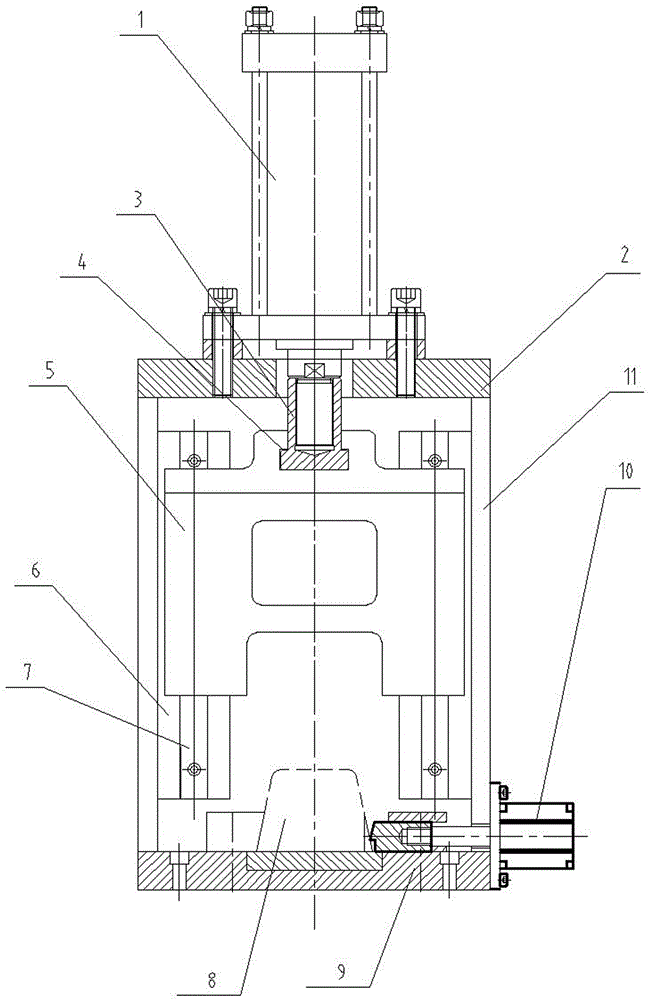

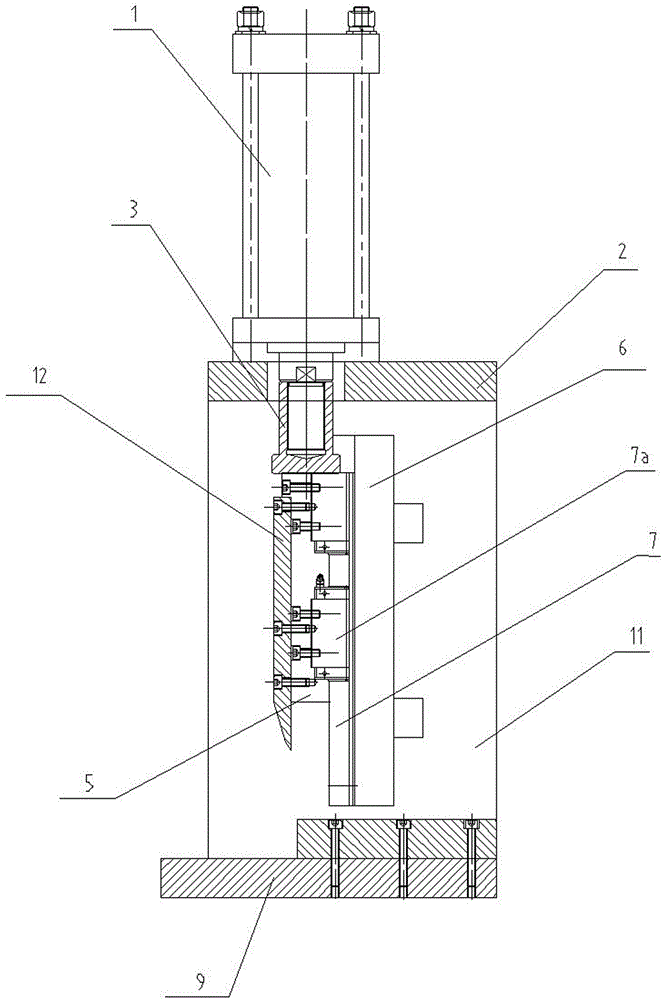

Lead ingot slicer

The invention relates to a lead ingot slicer used in a lead ingot granulation device. The lead ingot slicer comprises a rack composed of an upper plate (2), a lower plate (9) and stand plates (11) connected to the two sides. An oil cylinder (1) is arranged on the upper plate (2). A piston rod of the oil cylinder (1) is connected with a T-shaped connector (3). The T-shaped connector (3) is connected and matched with a T-shaped hole in the upper end of a cutter rest (5). A cutter (12) is connected to the cutter rest. The stand plates on the two sides of the rack are each connected with a guide rail base (6). A linear guide rail (7) and a sliding base (7a) of the linear guide rail (7) are arranged on each guide rail base (6). Each sliding base (7a) is connected with the cutter rest (5). The lead ingot slicer has the beneficial effects that due to the fact that the standard linear guide rails capable of being purchased on the market are adopted, manufacturing cost is obviously reduced, and abrasion to the linear guide rails is small; and production efficiency is improved, the service life of the cutter is prolonged, and cost is reduced.

Owner:ANHUI AULY MACHINERY TECH

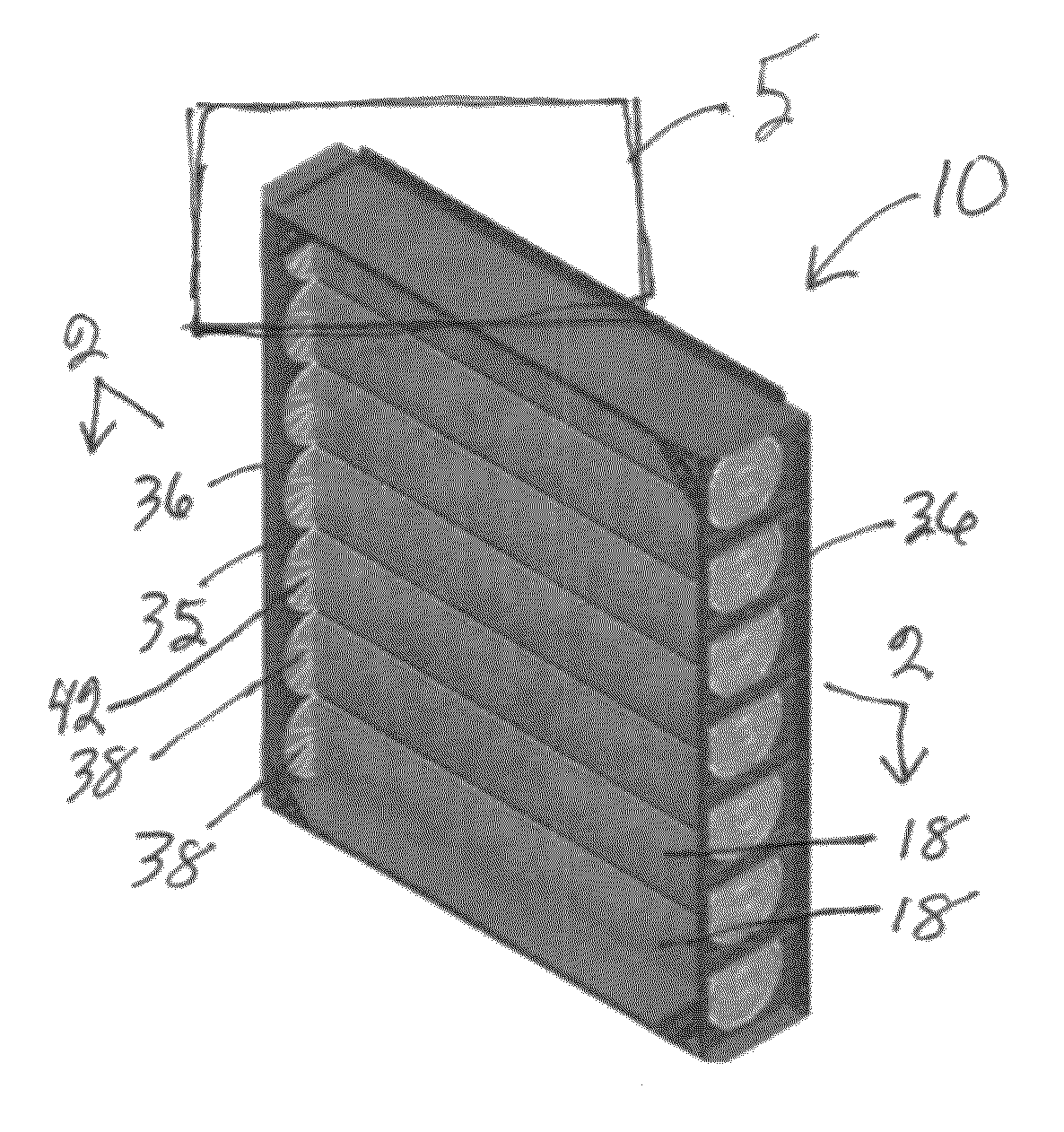

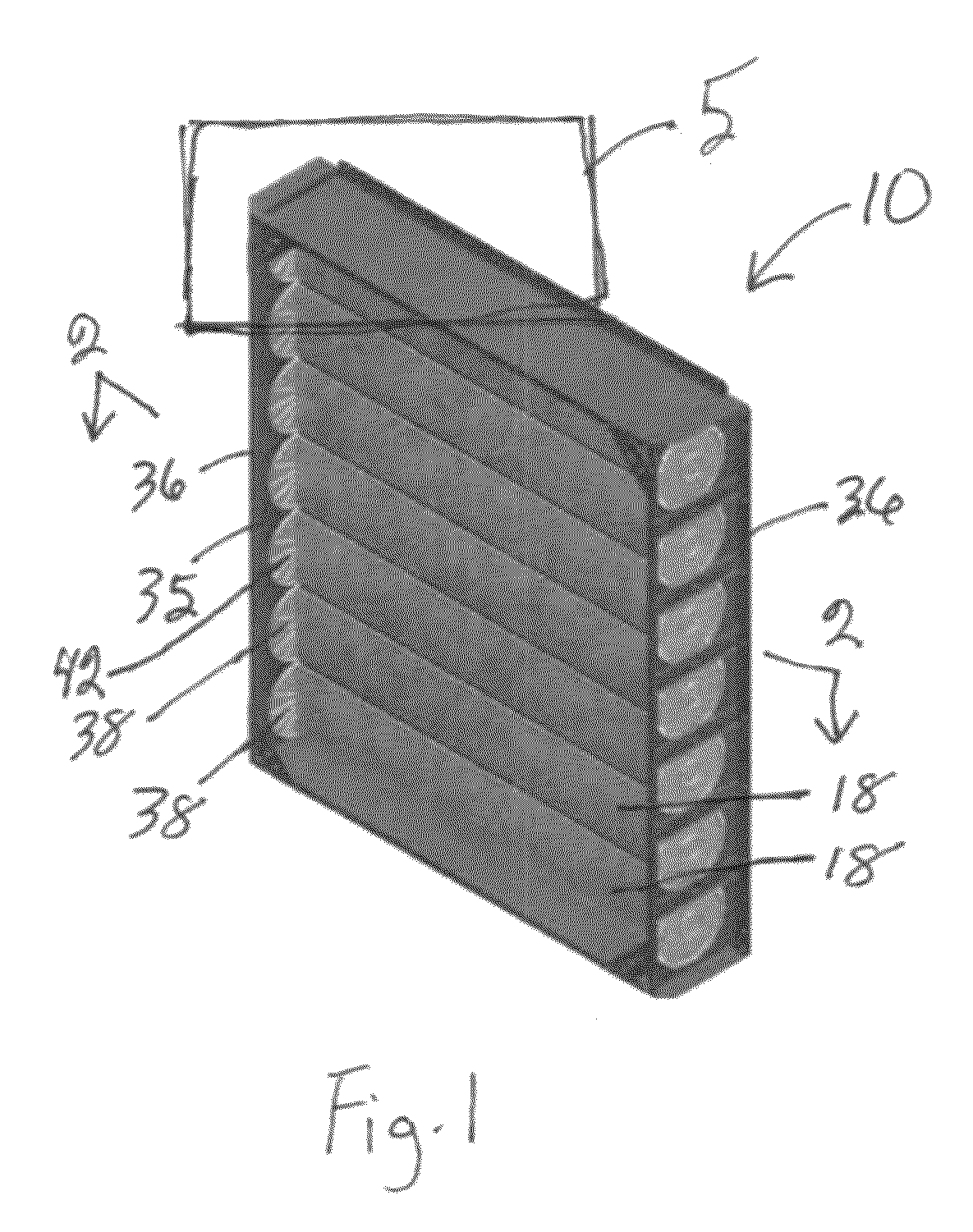

Air damper

ActiveUS9234603B1Improve sealingReduce frictionLighting and heating apparatusSpace heating and ventilation detailsEngineeringLow friction

A low cost air damper that provides a good seal with low torque requirements. Blade seals of square cross sectional configuration are provided on each damper blade so that the blade seals engage adjacent blades before the blades are fully closed. L-shaped side seals and multiple discs that receive the ends of the blades serve collectively to seal between sides of the damper frame and the blades when the blades are closed even when the blades are not cut precisely. One edge of the L-shaped side seals engages and seals against the discs and the other edge of the side seals laps over and seals against a flat side of the blades and against the square blade seals. A low friction coating is applied to the side seals to further reduce friction.

Detection method of self-trapping threaded sleeve drilling bottom hole and anti-stretching and anti-twist values

ActiveCN103090764BImprove the qualified rate of one installationImprove versatilityMachine part testingMechanical diameter measurementsMeasurement deviceTrapping

The invention discloses a detection method of a self-trapping threaded sleeve drilling bottom hole and anti-stretching and anti-twist values and aims to solve the problems that the prior self-trapping threaded sleeve drilling bottom hole detection method is tedious, stretching resistance is not detected, and potential safety hazards exist. The detection method of the self-trapping threaded sleeve drilling bottom hole and the anti-stretching and anti-twist values comprises the following steps: 1) drilling a bottom hole; 2) detecting the bottom hole by adopting a hole diameter detection device; 3) detecting verticality; and 4) detecting anti-stretching and anti-twist values of the a self-trapping threaded sleeve by adopting an anti-stretching and anti-twist value measurement device. The detection method of the self-trapping threaded sleeve drilling bottom hole and the anti-stretching and anti-twist values improves the percent of once installment pass of the self-trapping threaded sleeve, eliminates potential quality hazard, and reduces reworking and production cost.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

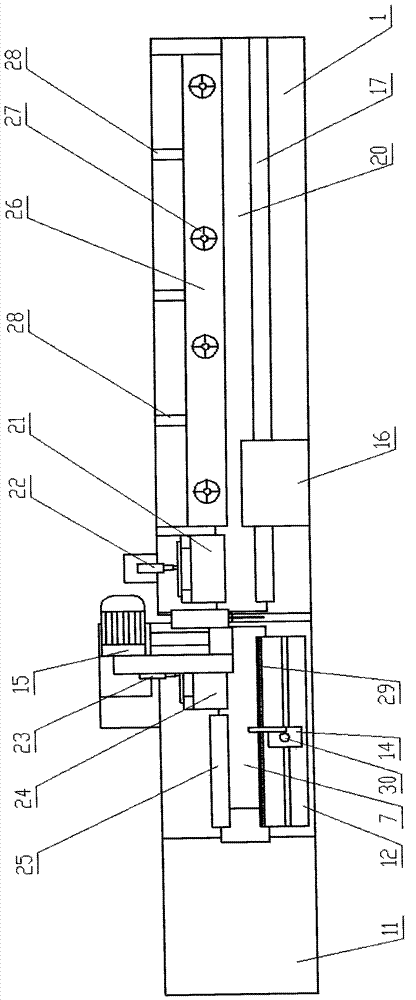

a cutting machine

The invention discloses an automatic cut-off machine comprising a main unit base, a feed mechanism, a discharge mechanism, a length limiting mechanism, a cutting mechanism, a compressing mechanism, a loading vehicle and an operating box. The feeding mechanism delivers an aluminum alloy profile to the discharge mechanism; after the aluminum alloy profile is in contact with a detection switch of the length limiting mechanism, discharging and feeding stop; the compressing mechanism pushes a pressure plate through a cylinder so as to fix and compress the profile; the cutting mechanism cuts the profile; after cutting, the length limiting mechanism pops up; the discharge mechanism delivers the cut profile to the loading vehicle; the length limiting mechanism pops down, and the feed mechanism moves to perform feeding. The automatic cut-off machine is simple in structure and low in manufacturing cost, has a wide cutting range, allows accurate cutting and has an automatic cutting mode and a manual step cutting mode.

Owner:TONGXIANG GUANGYU PLASTIC PROD

Mahjong tile cleaning cylinder

ActiveCN104084398BEasy to put inClean up thoroughlyCleaning using toolsCleaning using liquidsGear driveDual action

The invention relates to a mahjong tile cleaning cylinder, which includes a frame, a casing, a drum, a cylinder door, a water spray pipe, a brush, a gear transmission mechanism and a cylinder door transmission mechanism. The drum is rotatably supported on the frame and is driven by a gear. Transmission mechanism transmission; the drum is provided with an entrance and exit port on the circumferential surface, and the drum door is rotatably arranged on the drum and driven by the drum door transmission mechanism. The drum door rotates relative to the drum to control the entry and exit of the drum. The sign mouth is closed or opened; the brush is set in the center of the drum, the water spray pipe is set on the outer side of the drum, and the shell is placed on the frame and contains the drum. Its advantages are: the cards are easy to enter and exit the drum, and the opening and closing of the card inlet and outlet are performed automatically. The dual effects of brush friction and water spray pipe spray can more thoroughly remove dirt on the cards, and it has an automatic drying function and a high degree of automation. High, efficient, saving time and effort.

Owner:ZONGYANG COUNTY ZHONGBANG TECH INFORMATION CONSULTING CO LTD

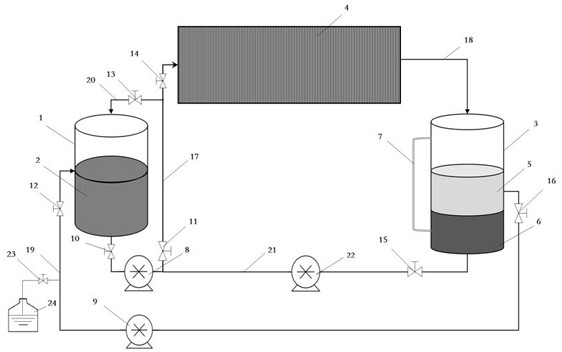

Method and device for washing ultrafine powder material for ceramic capacitor

PendingCN112266243ASolve the function of removing and purifying functional powder materialsAvoid pollutionFiltration circuitsCeramic capacitorSlurry

The invention relates to a device and a method for washing an ultrafine powder material for a ceramic capacitor. The method is characterized by comprising the following steps of: (1) adding the ultrafine powder material into a pre-washing storage tank (1), adding high-purity water, and circulating the material in the tank body to prepare 10 to 50 percent washing slurry; (2) pumping the slurry intoa filtering device (4), controlling the pressure to be 0.1 to 2.0 MPa, and feeding filtrate into a collecting storage tank (3); (3) collecting the storage tank, standing for layering, and pumping thelower-layer ultrafine precipitate into the filtering device (4) again; (4) adding high-purity water into the raw material storage tank (1), and pumping into the filtering device (4) for filter pressing and washing until the total impurity content in filtrate at an outlet of the filtering device is less than 500ppm; and (5) carrying out pressure maintaining concentration on the ultrafine powder material in the filtering device (4), and controlling the water content to be 10 to 30%. The method has the advantages that the equipment investment cost is low, the operation is simple, no dispersing agent or flocculating agent is added, the yield is high, and the method has good universality in the aspect of washing the ultrafine powder material for the ceramic capacitor and is suitable for industrial production.

Owner:安徽凯盛应用材料有限公司 +1

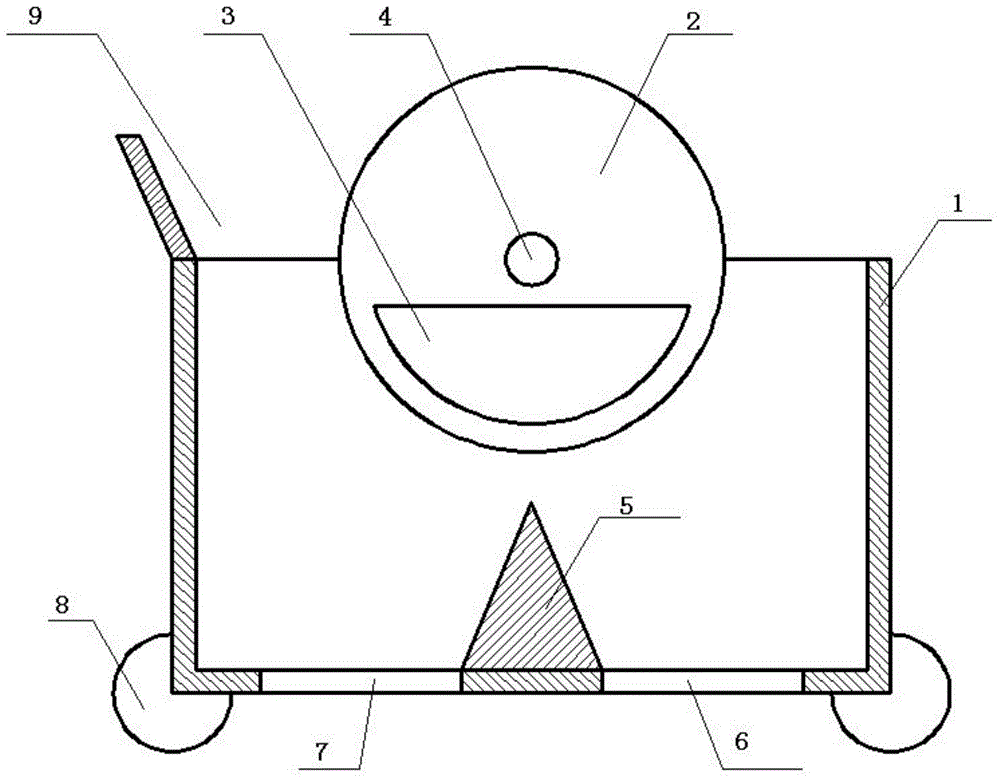

Magnetic separator

InactiveCN104084299ASimple preparation processMade lowMagnetic separationMagnetic separatorEngineering

The invention relates to a magnetic separator, comprising a case, a roller, a rotating shaft and universal wheels, wherein the roller is installed at a middle position of the upper part of the case through the rotating shaft; the roller is in a hollow cylindrical structure; the lower half in the roller is fixedly provided with the magnet; a feeding opening is disposed on the upper part of the case at the side of the roller; and one side of the lower part of the case is provided with a tailings discharging opening; the other side of the lower part of the case is provided with a concentrate discharging opening; and the universal wheels are fixedly connected to the bottom of the case. The magnetic separator provided by the invention is in no need of arranging a special demineralization structure, and can discharge materials automatically through the rotation of the roller. A manufacturing process is simple; manufacturing cost is reduced; and the service life is prolonged.

Owner:潘纪鸿

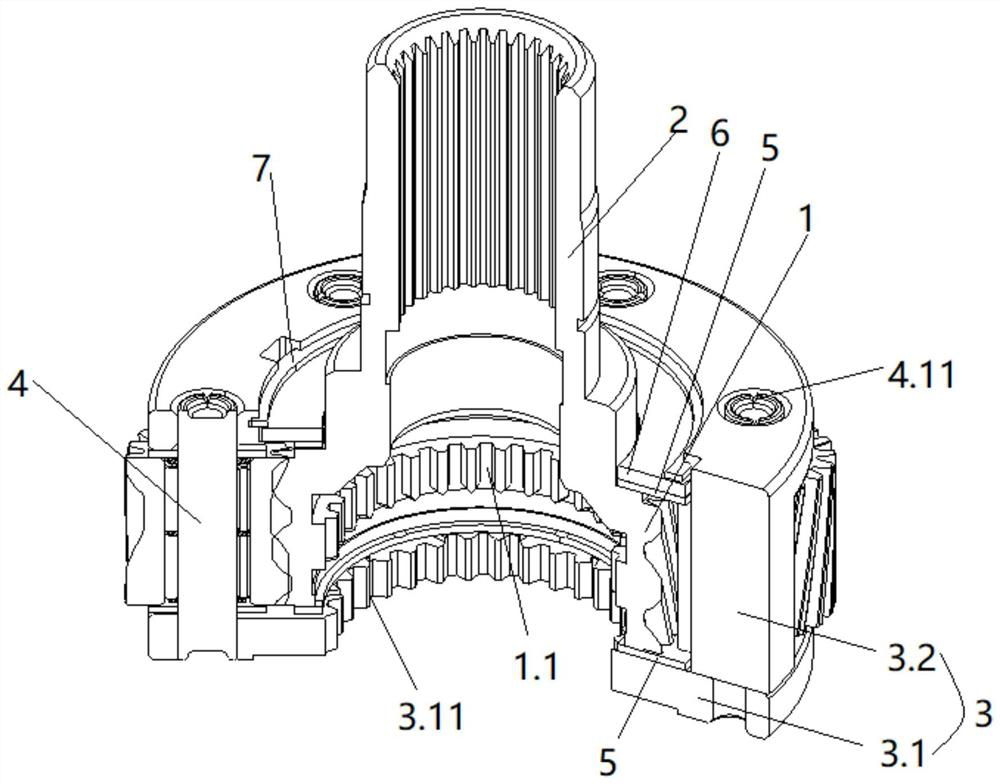

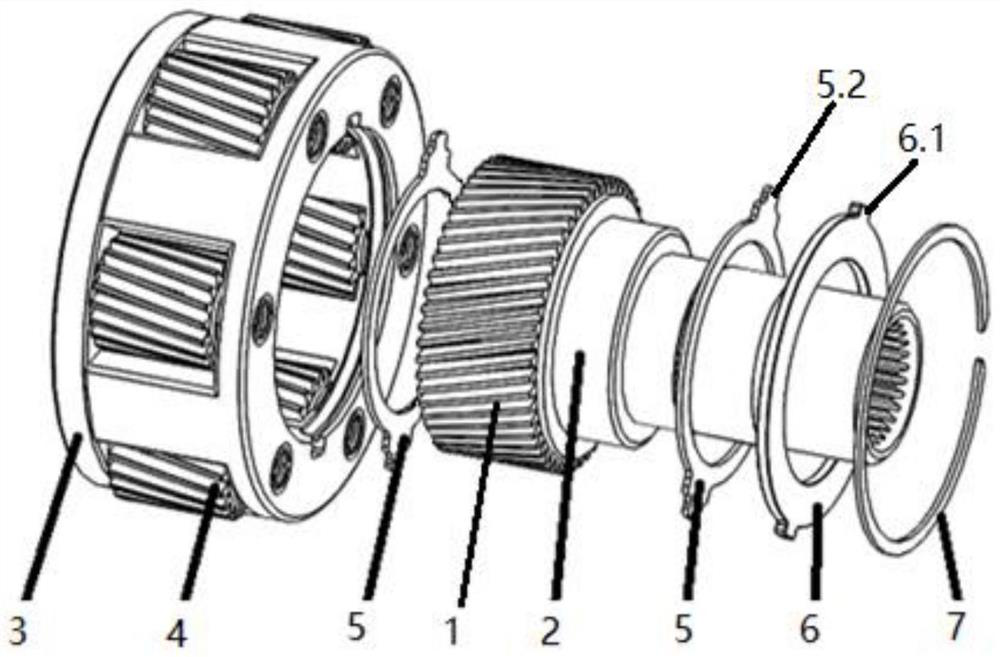

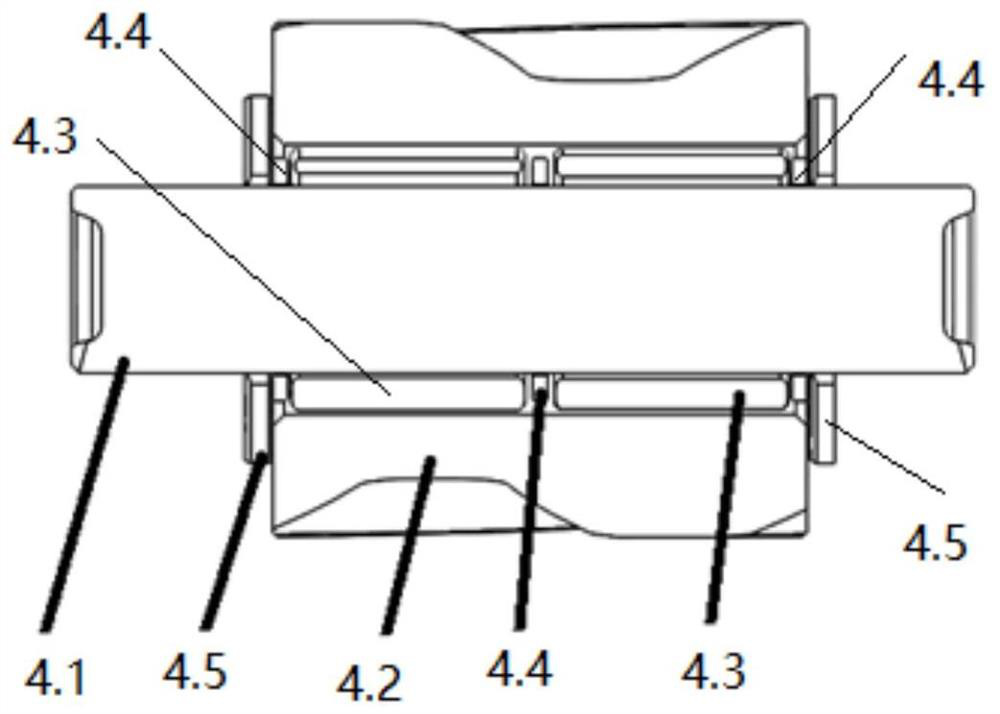

Planetary reducer

The invention discloses a planetary reducer which comprises a sun gear connected with an output shaft of a gearbox through a sun gear shaft. The planetary gear carrier is coaxial with the sun gear, the sun gear is contained in the planetary gear carrier, and one end of a sun gear shaft extends out of the planetary gear carrier; the planetary gear assembly is meshed with the sun gear and rotationally connected to the planetary gear carrier; at a high gear, power is output through an internal spline on the sun gear; and at the low gear, the power passes through the planetary gear assembly and then is output through an internal spline on the planetary gear carrier. The method has the advantages of good manufacturability, low cost and the like.

Owner:东风汽车零部件集团有限公司刃量具分公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com