Ceramic heater

a ceramic heater and heater body technology, applied in the field of ceramic heaters, can solve the problems of short circuit, inability to use ceramics, and inability to control the temperature of ceramics,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

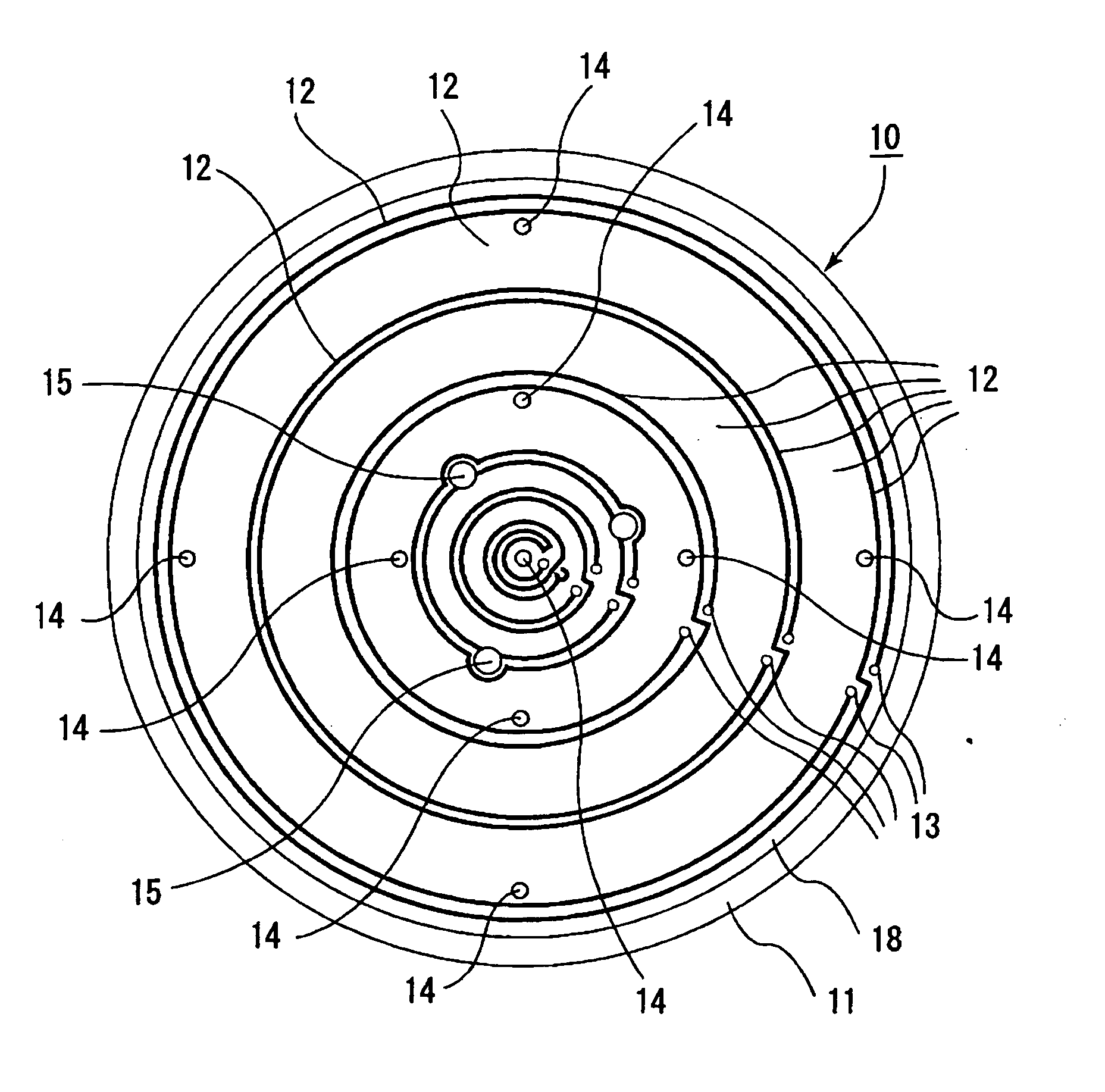

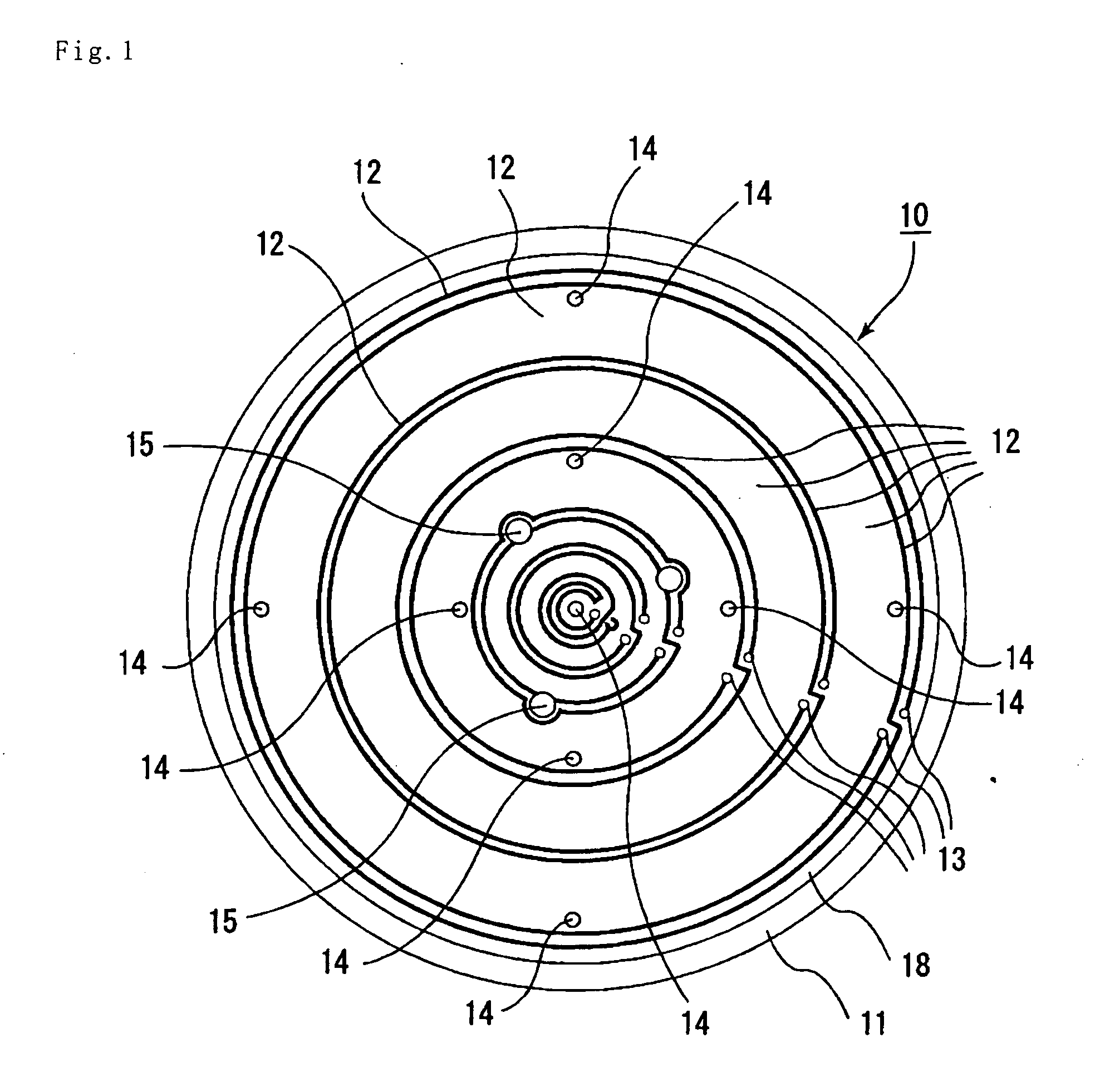

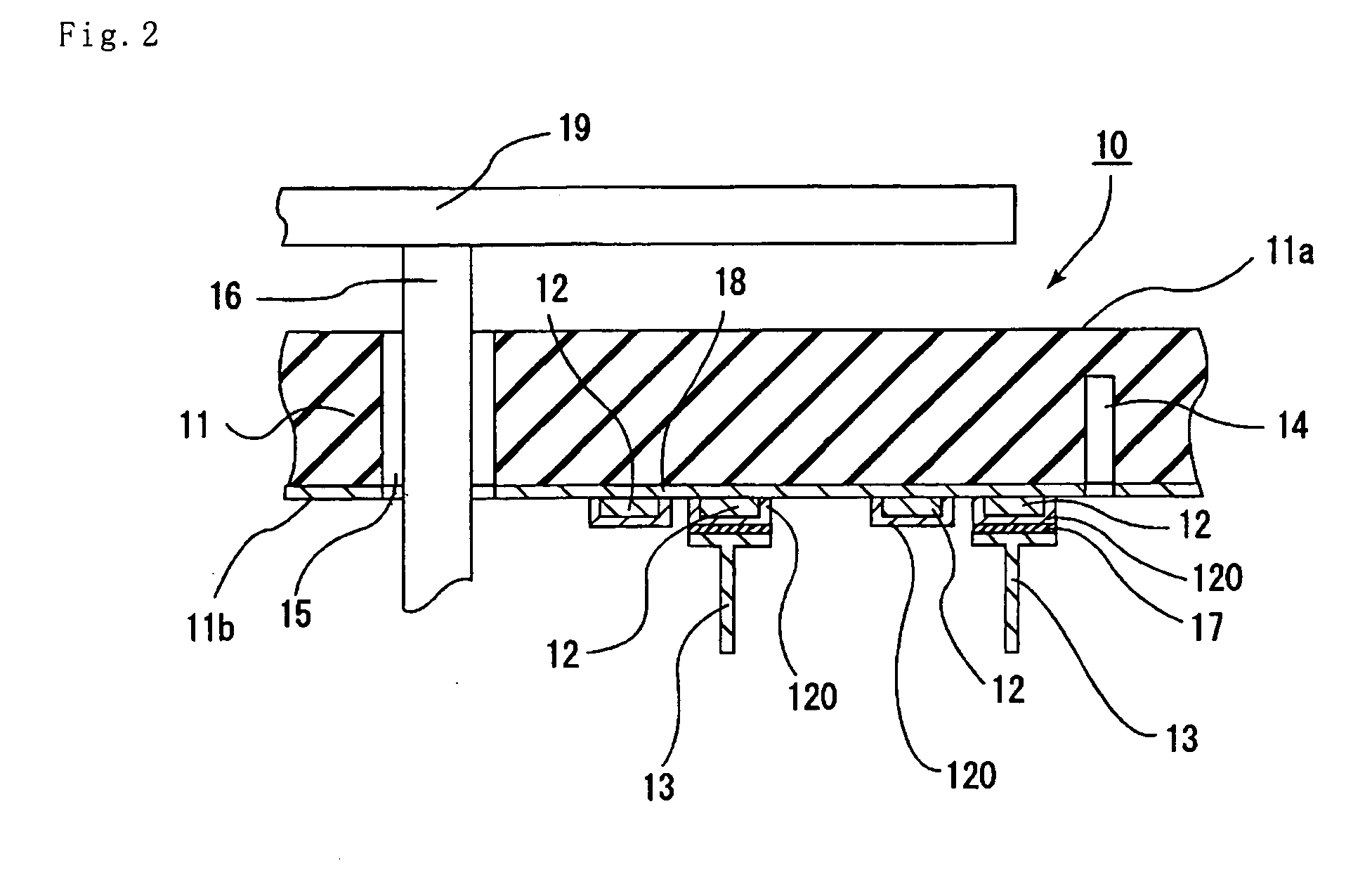

Image

Examples

example 1

Production of a Ceramic Heater Made of Silicon Carbide

[0135] (1) The following were mixed: 100 parts by weight of silicon carbide powder (average particle diameter: 0.3 μm), 4 parts by weight of B4C (average particle diameter: 0.5 μm) as a sintering aid, 0.5 part by weight of C (Mitsubishi Diablack, made by Mitsubishi Chemical Corp.), 12 parts by weight of an acrylic binder, 0.5 part by weight of a dispersant and an alcohol. Thereafter, the mixture was subjected to spray-drying to make granular powder.

[0136] (2) Next, this granular powder was put into a mold and formed into a flat plate form to obtain a raw formed body (green).

[0137] (3) The raw formed body subjected to the above-mentioned processing treatment was hot-pressed at 2100° C. and a pressure of 17.6 (180 kg / cm2) MPa to obtain a silicon carbide ceramic substrate having a thickness of 3 mm.

[0138] Next, this plate was cut out into a disk having a diameter of 210 mm to prepare a ceramic substrate 11.

[0139] (4) Next, a so...

example 2

Production of a Ceramic Heater Made of Silicon Carbide

[0148] A ceramic heater made of silicon carbide was produced in the same manner as in Example 1 except that powder of silicon carbide having an average particle diameter of 1.0 μm was used, the sintering temperature was set to 1900° C., and further the surface of the resultant ceramic substrate was fired at 1500° C. for 2 hours to form an insulating layer having a thickness of 1 μm and comprising SiO2.

example 3

Production of a Ceramic Heater Made of Aluminum Nitride

[0149] (1) A composition made of 100 parts by weight of aluminum nitride powder (average particle diameter: 0.6 μm), 4 parts by weight of yttria (Y2O3, average particle diameter: 0.4 μm), 12 parts by weight of an acrylic resin binder, and an alcohol was subjected to spray-drying , so as to make granular powder.

[0150] (2) Next, this granular powder was put into a mold and formed into a flat plate form to obtain a raw formed body (green).

[0151] (3) The raw formed body subjected to the above-mentioned processing treatment was hot-pressed at 1800° C. and a pressure of 200 kg / cm2 to obtain an aluminum nitride sintered body having a thickness of 3 mm.

[0152] Next, this plate was cut out into a disk having a diameter of 210 mm to prepare a ceramic substrate 11. In the same way as in Example 1, the sol solution used in Example 1 was applied onto the bottom face of this ceramic substrate, and the resultant product was dried and fired,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com