Method and device for washing ultrafine powder material for ceramic capacitor

A technology of ceramic capacitors and ultrafine powders, applied in chemical instruments and methods, separation methods, filtration circuits, etc., can solve problems such as difficult solid-liquid separation, low separation efficiency, and environmental pollution by ultrafine powders, and achieve manufacturing costs Low cost, simple operation, good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

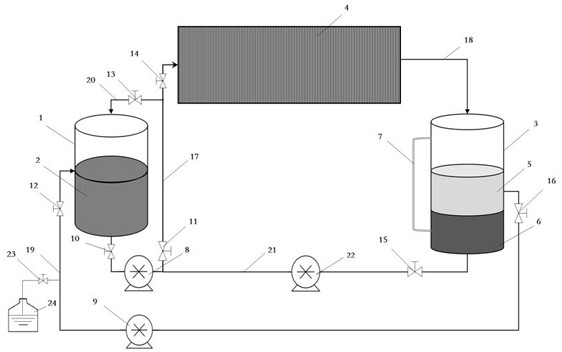

[0050] 1. Add the superfine barium titanate powder material for ceramic capacitors into the pre-washing storage tank 1, add high-purity water, open valves 10, 11 and 13, and close all other valves, then open the circulating pump 8 and circulate twice, each For 20 minutes each time, fully mix the barium titanate ultrafine powder material with high-purity water to make a washing slurry with a concentration of 15%;

[0051] 2. After the pre-washing storage tank 1 circulates and disperses evenly, open the valve 14, close the valves 15, 16 and valve 13 in turn, and pump the washing slurry into the filter device 4 through the pipeline 17 through the pump 8 to control the internal pressure of the filter device 0.3MPa, the filtered filtrate enters the collection storage tank 3 through the pipeline 18;

[0052] 3. Continuously feed the washing slurry into the filter device 4 until the washing slurry completely enters the filter device 4, stop feeding, and close the delivery pump 8 and ...

Embodiment 2

[0059] According to steps 1-8 in Example 1, the barium titanate ultrafine powder material for ceramic capacitors is dispersed in the pre-washing storage tank 1 in batches for 3 times, and the barium titanate ultrafine powder for each batch of ceramic capacitors is controlled. The error range of bulk slurry concentration is within ±5%, and the material content of barium titanate ultrafine nanopowder for ceramic capacitors after washing is 99.89%.

Embodiment 3

[0061] 1. Add the titanium dioxide ultrafine powder material for ceramic capacitors into the pre-washing storage tank 1, add high-purity water, open valves 10, 11 and 13, and close all other valves, then open the circulation pump 8, and circulate 3 times, each time 30 Minutes, fully mix the titanium dioxide ultrafine powder material with high-purity water to make a washing slurry with a concentration of 25%;

[0062] 2. After the storage tank 1 circulates and disperses evenly, open the valve 14, close the valves 15, 16 and valve 13 in turn, pump the slurry 2 to be washed into the filter device 4 through the pipeline 17 through the pump 8, and control the internal pressure of the filter device to 0.3 MPa, filtered water enters the collection storage tank 3 through the pipeline 18;

[0063] 3. Continuously feed the washing slurry into the filter device 4 until the washing slurry completely enters the filter device 4, stop feeding, and close the delivery pump 8 and the valve 10; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com