A punching/welding integrated manufacturing device for plate parts

A technology for manufacturing devices and parts, which is applied in the field of high-strength plate forming and connecting devices, can solve the problems of increasing the difficulty of springback control and difficult control of plate springback, and achieve fast and efficient production, saving production space and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

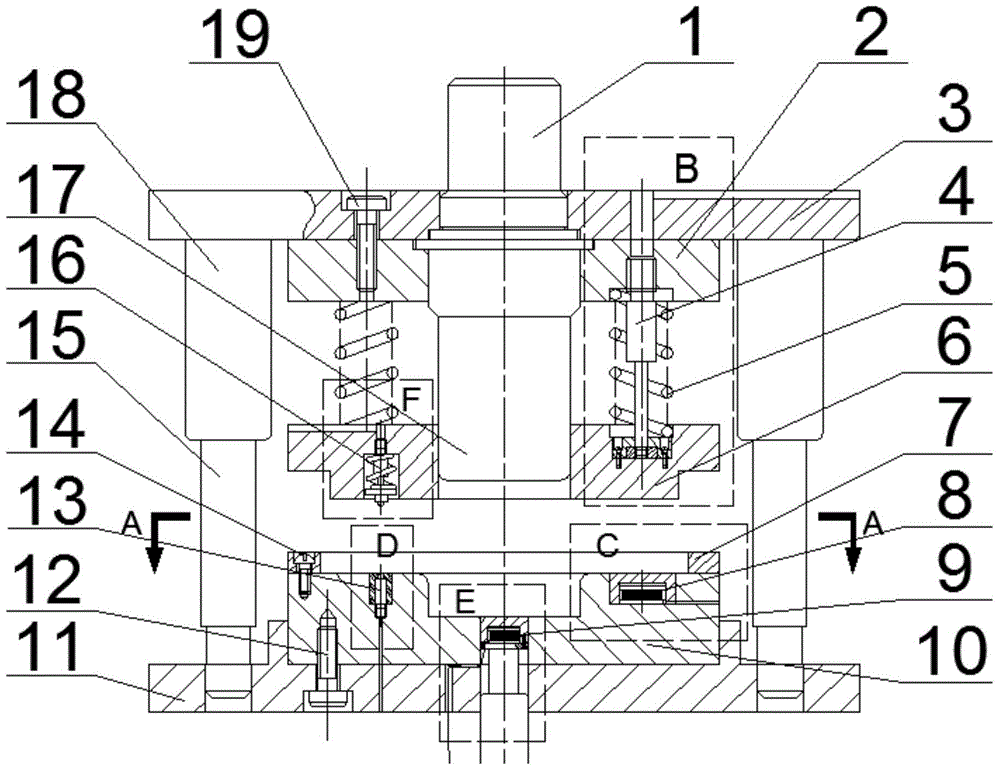

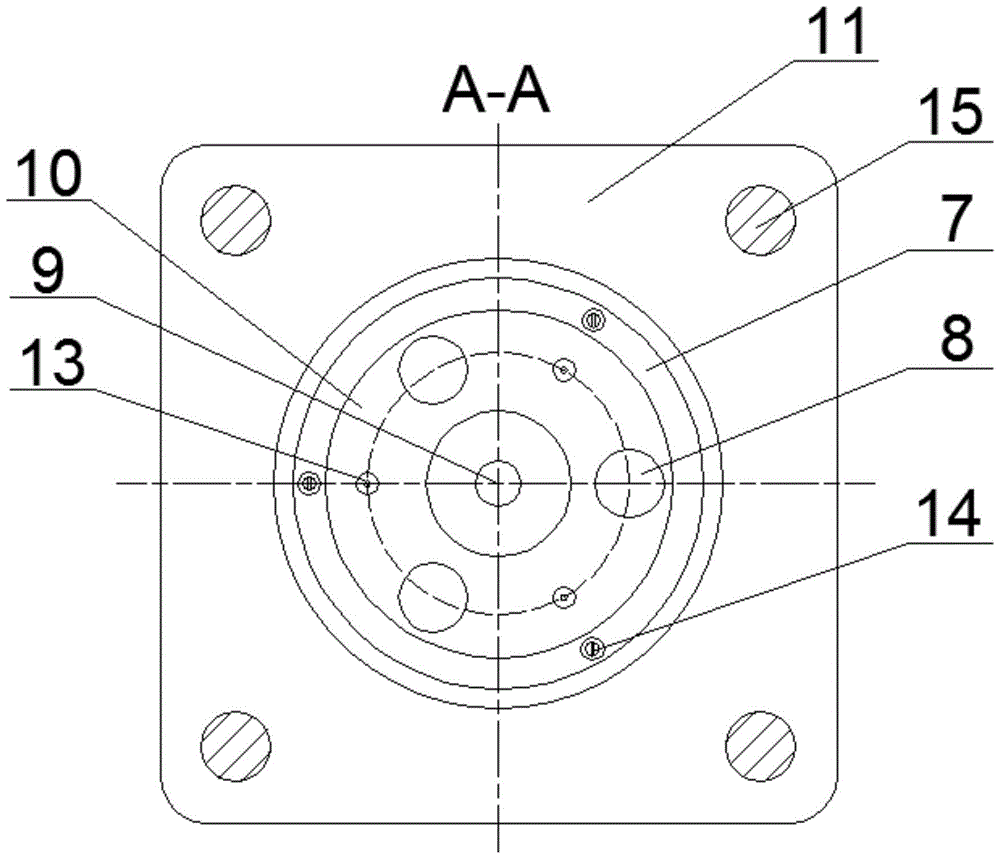

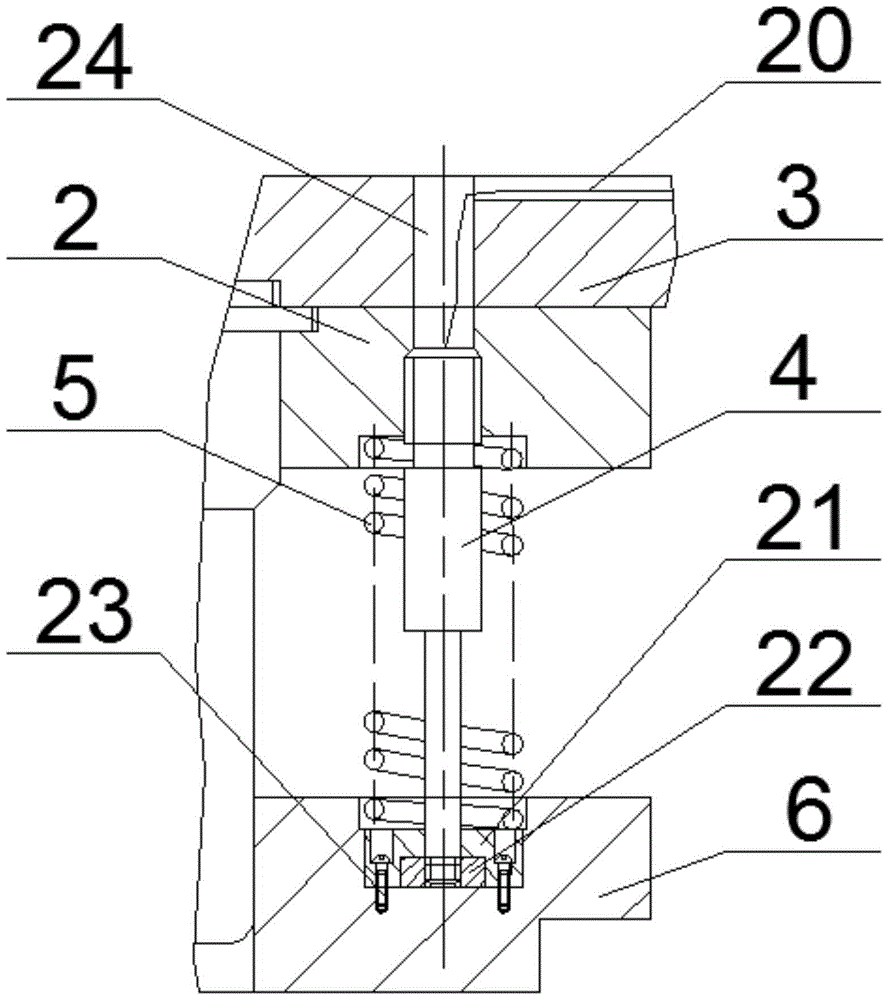

[0033] refer to figure 1 , a punching / welding integrated manufacturing device for plate parts, including a die 10 and a punch 17, the die 10 is fixed on the lower template 11 by a third screw 12, the punch 17 and its handle 1 are a whole, the punch 17 has a circular cross-sectional shape in the direction perpendicular to its own axis, and the upper template 3 is set on the mold handle 1, and the transition fit between the mold handle 1 and the upper template 3, and the upper template 3 passes through the first screw 19 and the punch The fixed plate 2 is connected, the punch fixed plate 2 is set on the punch 17 to form a transition fit with the punch 17, the lower template 11 and the upper template 3 are connected together through the guide post 15 and the guide sleeve 18, and the punch fixed plate 2 is connected under There are four first magnetorheo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com