Indexing and positioning tooling turntable

An indexing positioning and tooling technology, which is applied to precision positioning equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as delay in production cycle, slow indexing time, inconvenient maintenance, etc., to improve work efficiency, direct positioning, and Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

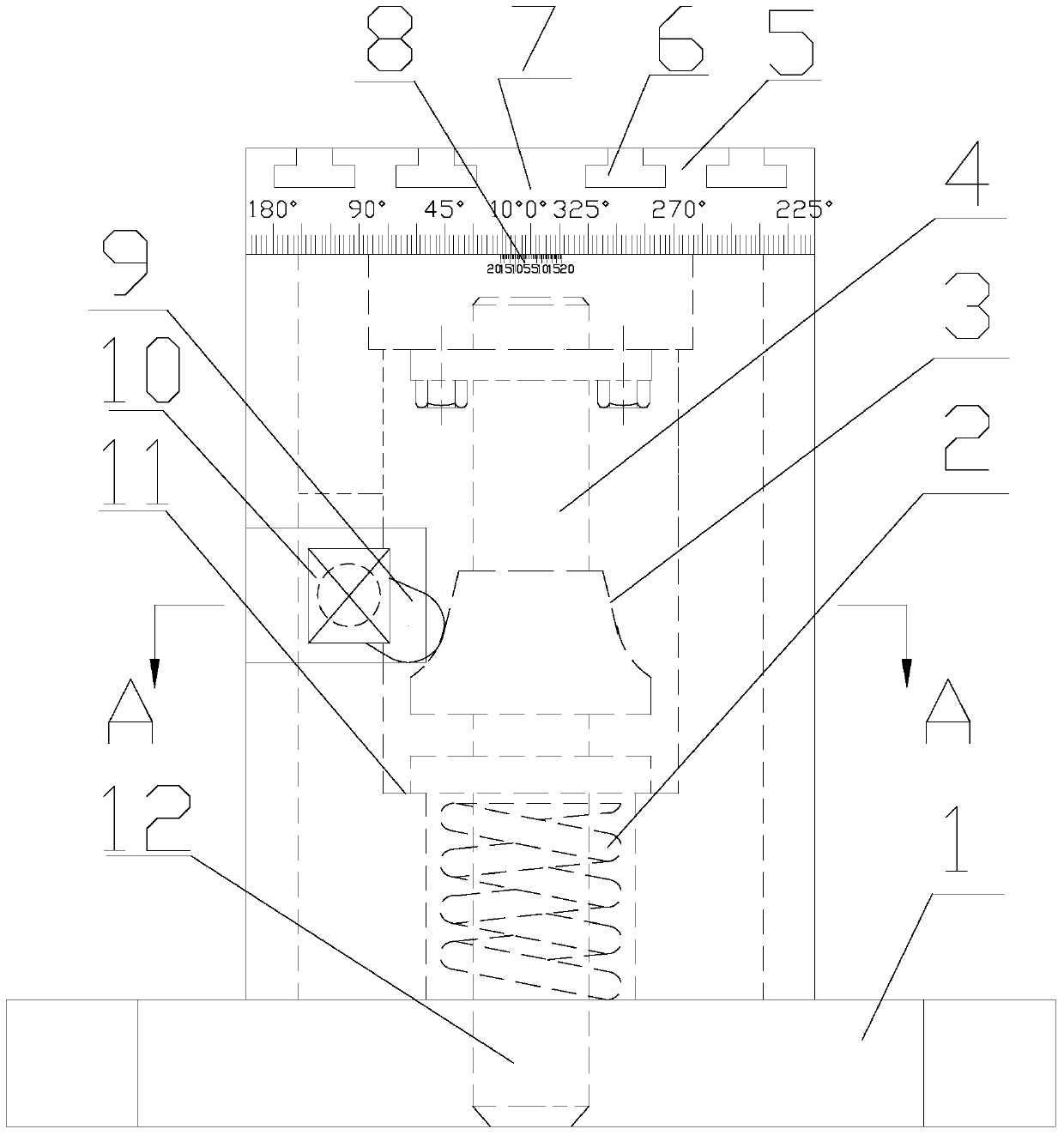

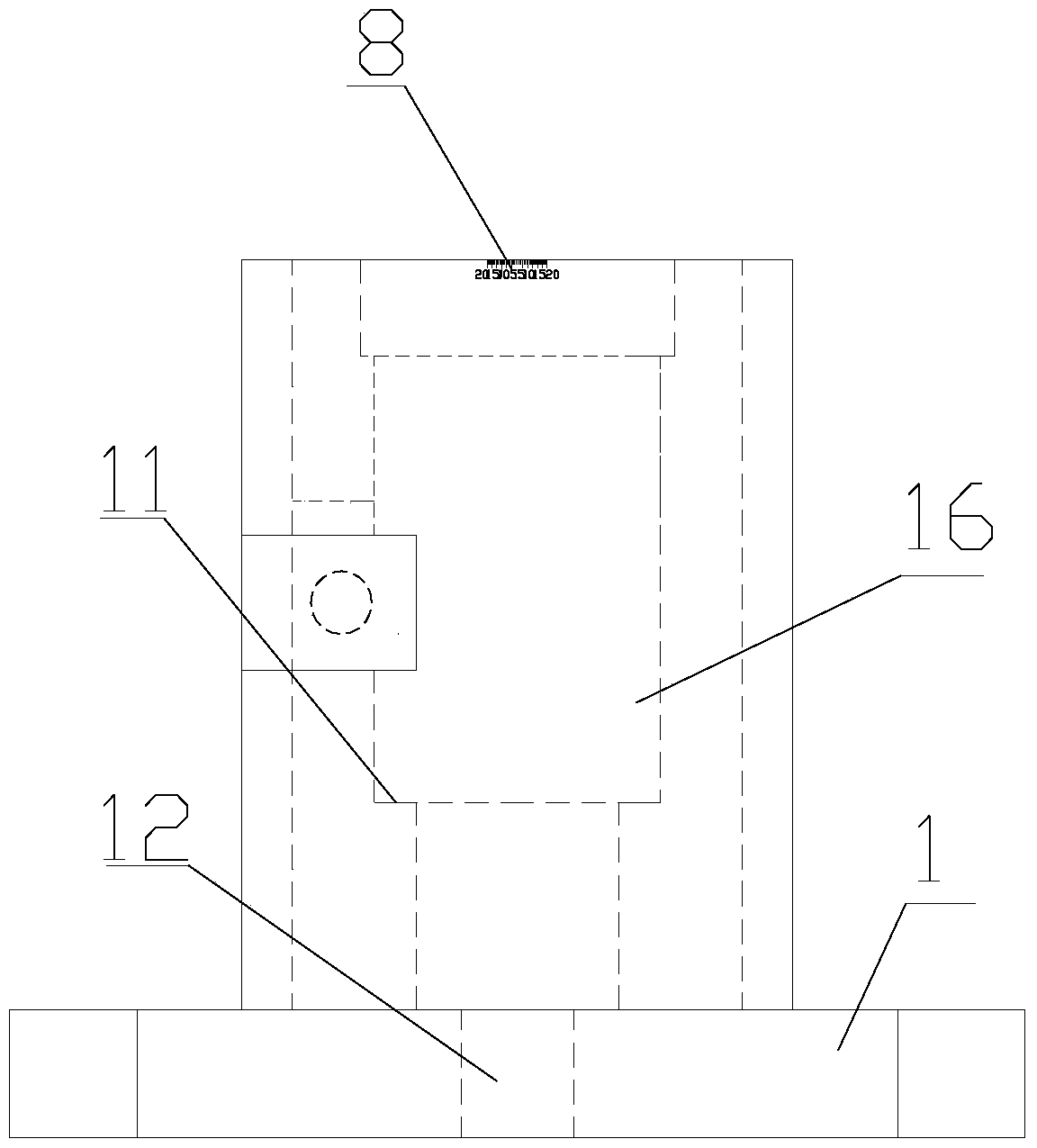

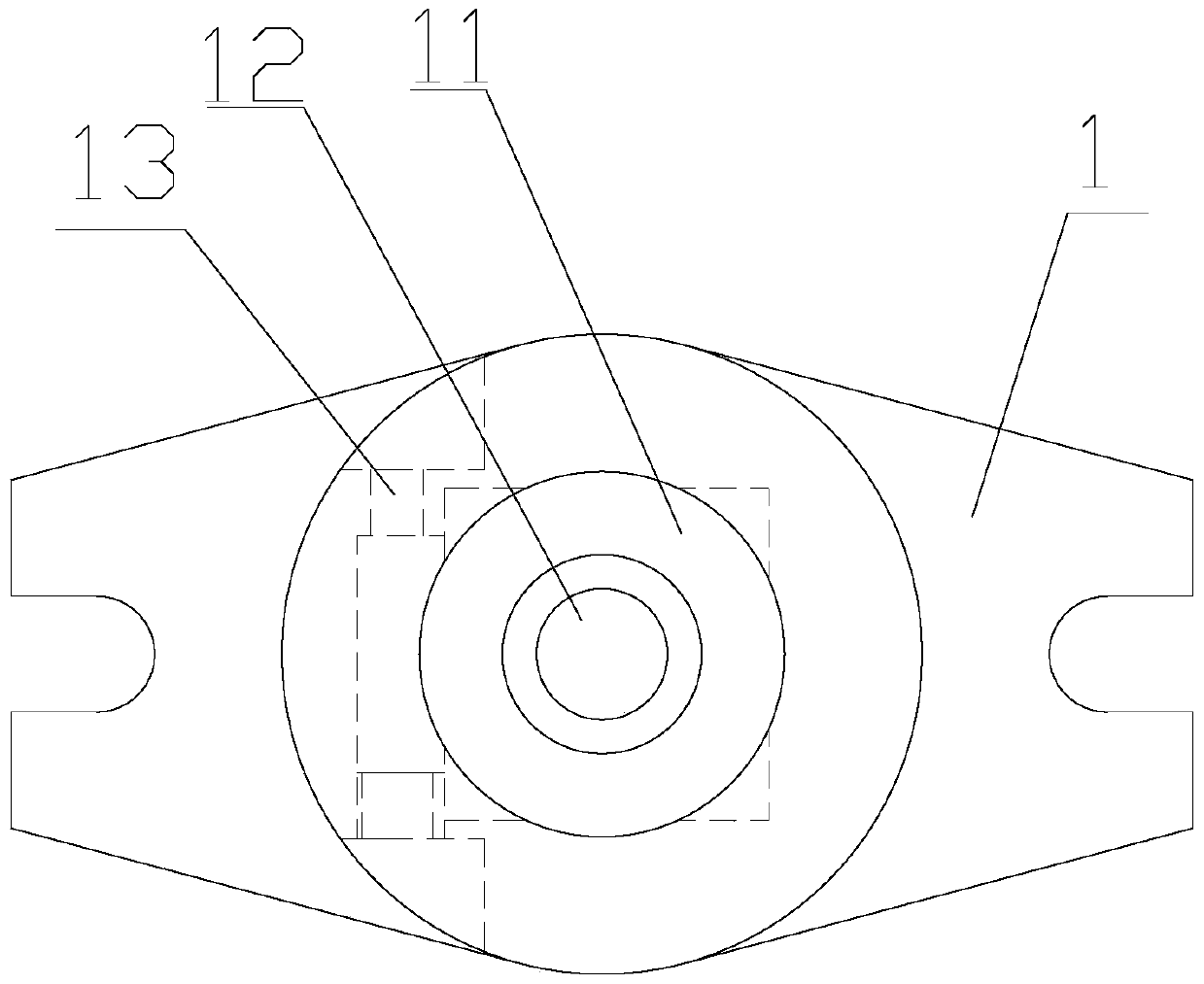

[0015] refer to Figure 1-Figure 4 . In the embodiments described below, the indexing and positioning tool turntable mainly includes: a machine base 1 with mounting notches formed at both ends and a vertical cylinder fixedly connected to the base of the machine base 1 . Among them, the outer circular wall of the upper end surface of the vertical cylinder body of the machine base 1 is engraved with a scale mark of 0'~20', and the upper end of the vertical cylinder body has a step hole for installing and positioning the rotating disk 5, and the rotating disk 5 passes through the Bolts are fixedly connected to the shaft end flange of the rotating shaft 4, and the port lightening hole connects the step rotation positioning hole 12 to the positioning step surface 11. Back-moving spring 2 is assembled on the base rotation positioning hole 12 steps. The rotating disk 5 assembled on the end of the vertical cylinder is the main rotating device. There are scales from 0° to 360° along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com