Detection method of self-trapping threaded sleeve drilling bottom hole and anti-stretching and anti-twist values

A detection method and self-tapping screw technology, which are applied in the direction of measuring device, mechanical measuring device, mechanical diameter measurement, etc., can solve the problems of hidden safety hazards, cumbersome detection methods, and no detection of tensile force, etc., and achieve low production cost and detection. The method is quick and simple, and the effect of eliminating hidden dangers of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

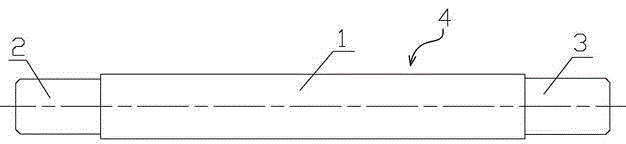

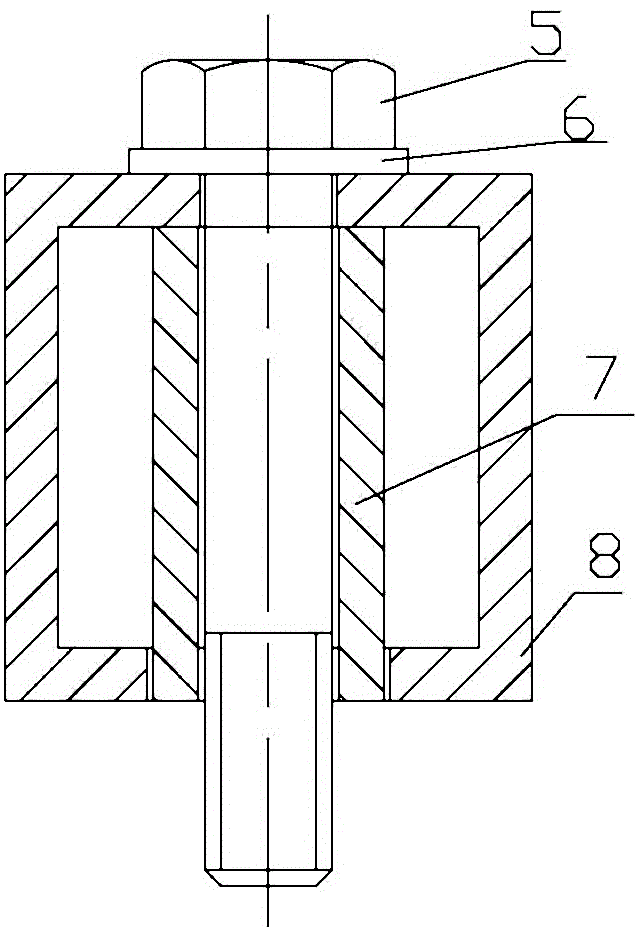

[0032] A self-tapping screw sleeve drilling bottom hole and tensile and torsion value detection method, when drilling, select a drill flower 0.1mm~0.2mm smaller than the theoretical diameter, so that the drilled hole diameter reaches the theoretical diameter. For example, the diameter of the bottom hole of the M12×12 self-tapping screw sleeve is required to be 15mm. According to the working environment, choose a drill bottom hole of 14.8mm or 14.9mm. The reduced 0.1-0.2mm is used to offset the hole diameter caused by equipment vibration and operator shaking. Compensation for deviations. A large number of experiments have proved that the compensation parameter value of 0.1㎜~0.2㎜ is generally used for drilling bottom holes before installation of other specifications and models of self-tapping screw inserts.

[0033] Before installing the self-tapping screw insert, there is a technical range for the diameter of the bottom hole, that is, the maximum and minimum values of the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com