a cutting machine

A technology of machinery and main engine, applied in the field of cutting machinery, can solve the problems of electric spark damage, low cutting accuracy, time-consuming and labor-intensive, etc., and achieve the effect of improving production efficiency, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

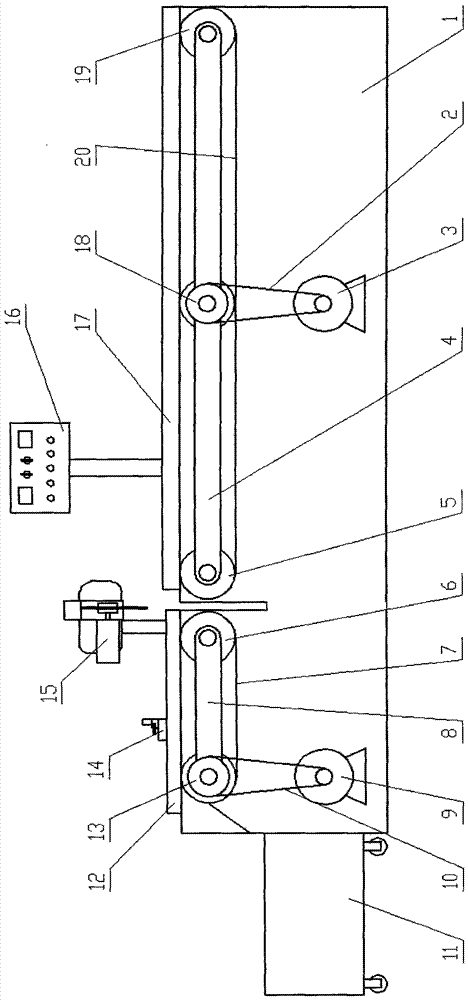

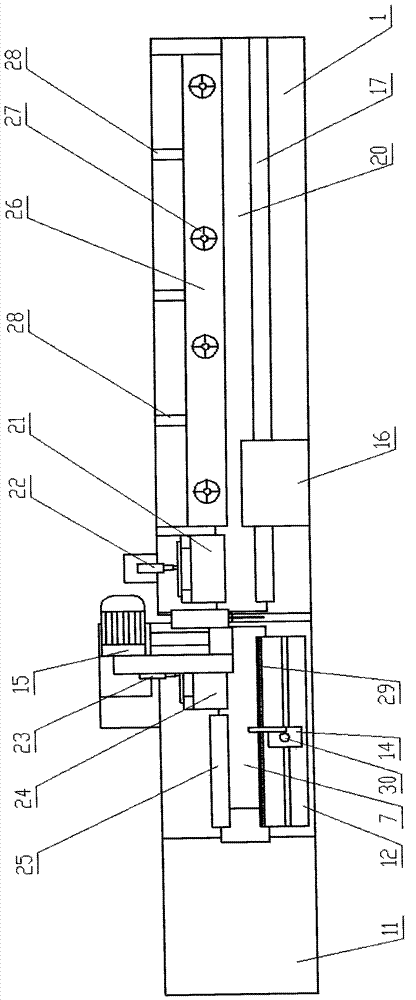

[0016] see figure 1 , figure 2 A kind of cutting machine of the present invention shown, comprises main engine base 1, feeding mechanism, unloading mechanism, length limiting mechanism 14, cutting mechanism 15, pressing mechanism, charging cart 11 and operation box 16; Described main engine base 1 is The foundation of the whole machine, the right part of the main engine base 1 is the feeding mechanism, including the feeding motor 3, the feeding motor belt 2, the feeding driving wheel 18, the feeding conveyor belt 20, the feeding driving belt bracket 4, the feeding roller 5, the feeding roller 19 and the feeding fixing plate 17 , wherein the feed motor belt 2 is connected to the feed motor 3 and the feed drive wheel 18, the feed drive wheel 18, the first feed roller 5 and the second feed roller 19 are all fixed on the feed drive belt bracket 4, and the feed drive wheel 18 is driven by the feed conveyor belt 20 The first feeding roller 5 and the second feeding roller 19 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com