Lead ingot slicer

A slicer and lead ingot technology, which is applied in the field of lead ingot slicers, can solve the problems of low service life and high production cost, and achieve the effects of small wear, improved production efficiency, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

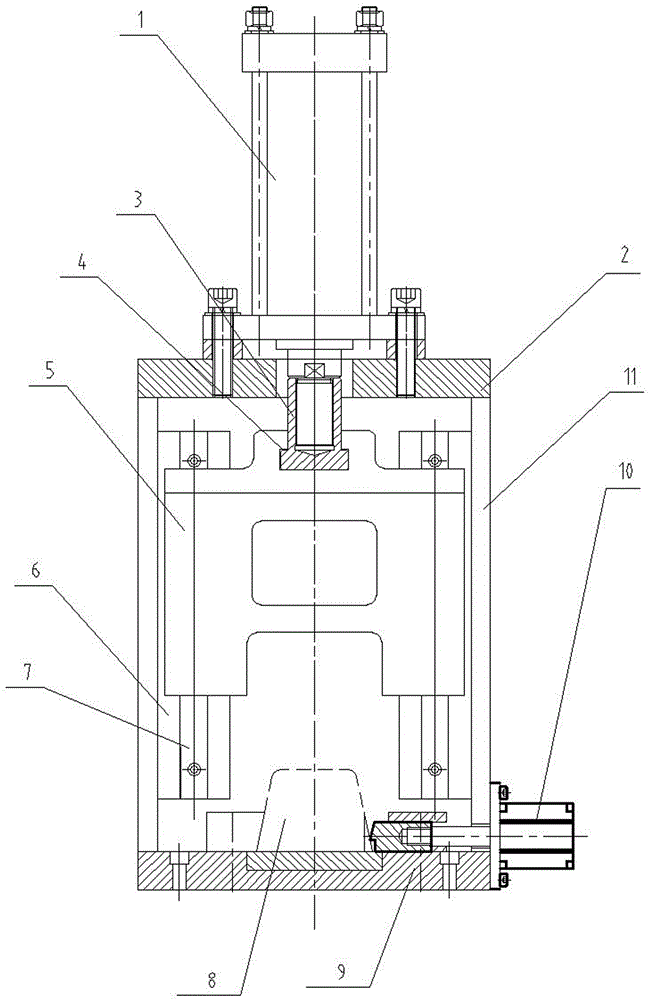

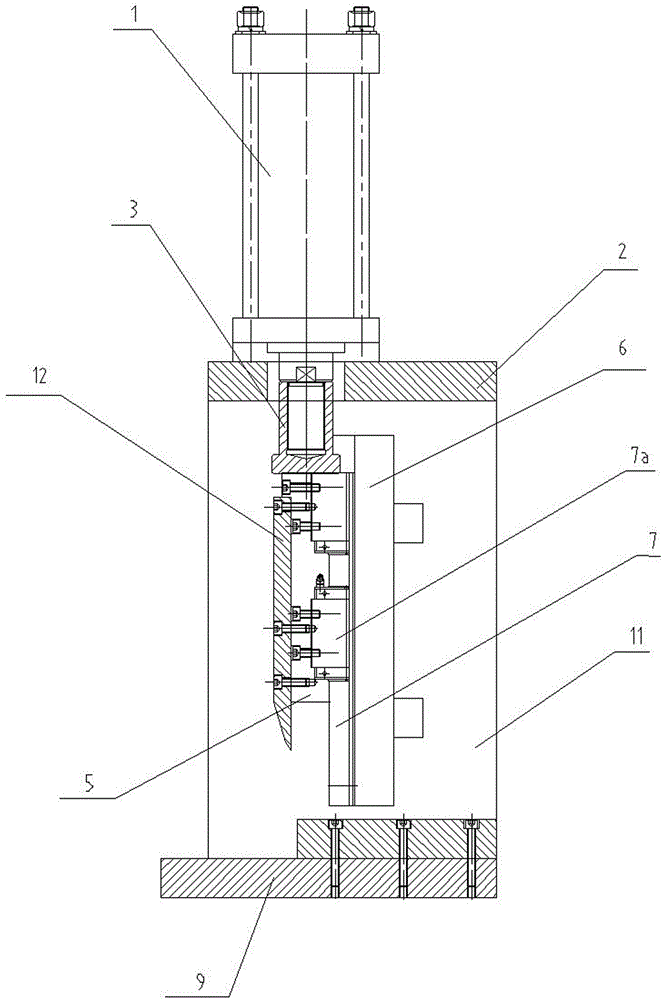

[0012] like figure 1 As shown, the lead ingot slicing machine provided by the present invention comprises a frame made up of an upper plate 2, a lower plate 9 and vertical plates 11 connected on both sides, an oil cylinder 1 is arranged on the upper plate 2, and the piston rod of the oil cylinder 1 is connected A T-shaped connector 3, the T-shaped connector 3 is connected with the T-shaped hole 4 on the cutter frame 5 upper end. like image 3 As shown, the cutter 12 is connected to the cutter frame 5. This connection makes the cutter frame and the piston rod of the oil cylinder have the advantages of simple structure and high connection strength, which plays a great role in improving the service life.

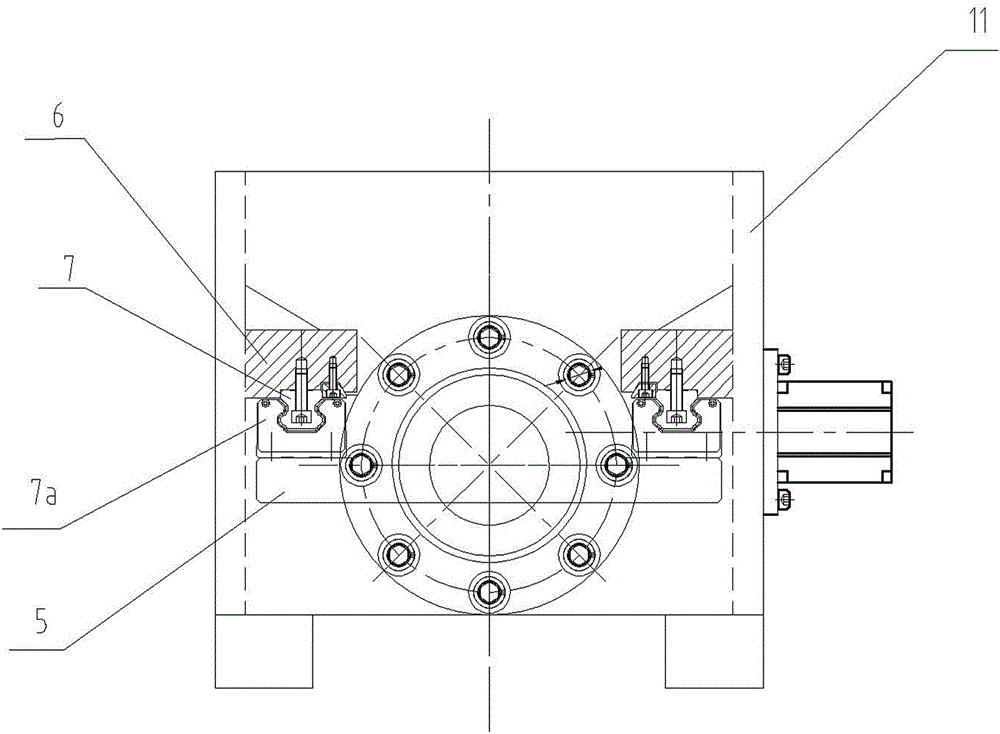

[0013] like figure 1 , figure 2 and image 3 As shown, a guide rail base 6 is respectively connected to the inner side of the vertical plate on both sides of the frame, and each guide rail base 6 is provided with a linear guide rail 7, and the linear guide rail 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com