Basement deformation joint seepage prevention and treatment method

A technology for deformation joints and basements, applied in the field of building leakage prevention and construction, can solve the problems of poor concrete vibrating, loose concrete wrapping, and inability to adapt to structural deformation, and achieves remarkable treatment effect, simple installation, and mildew prevention effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

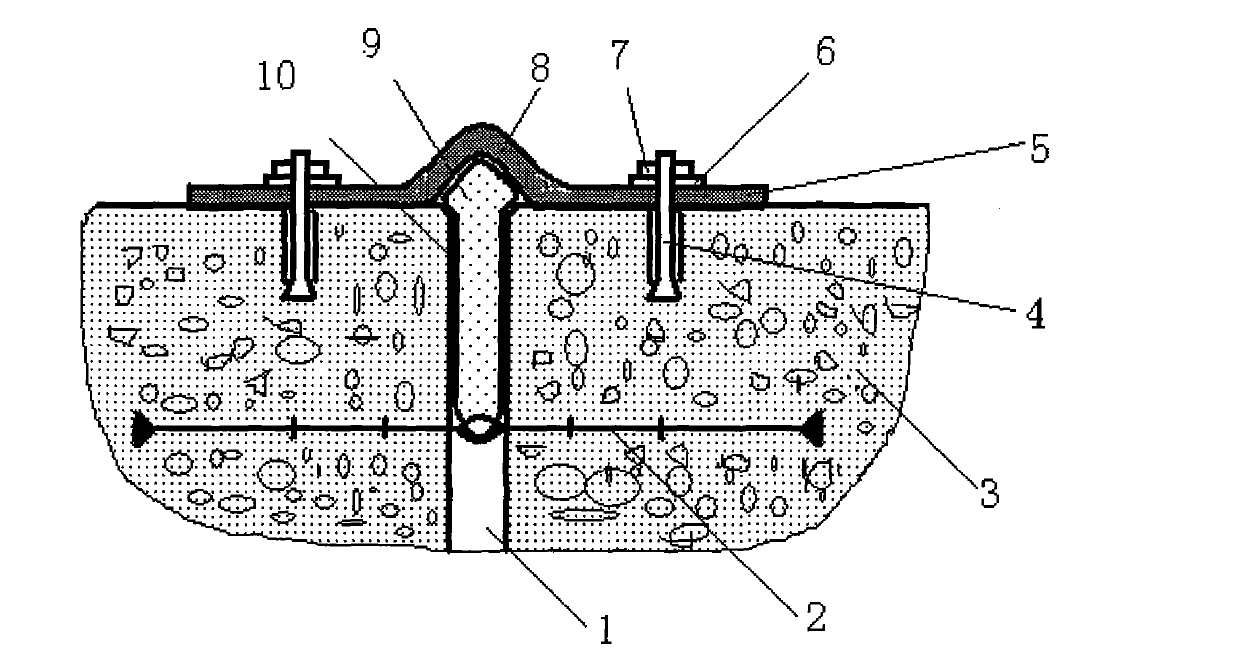

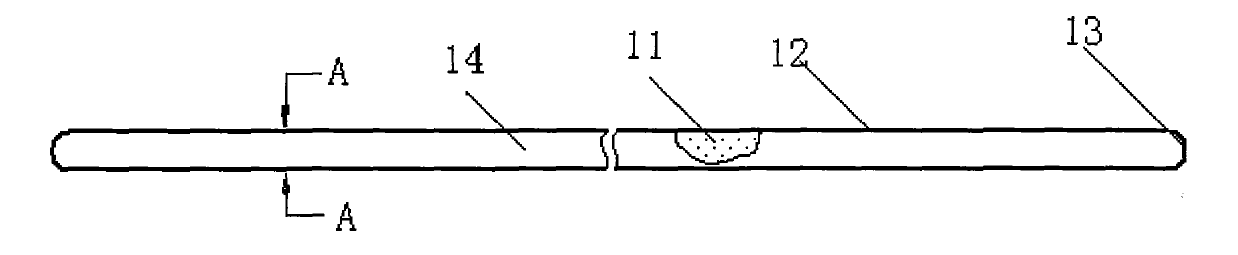

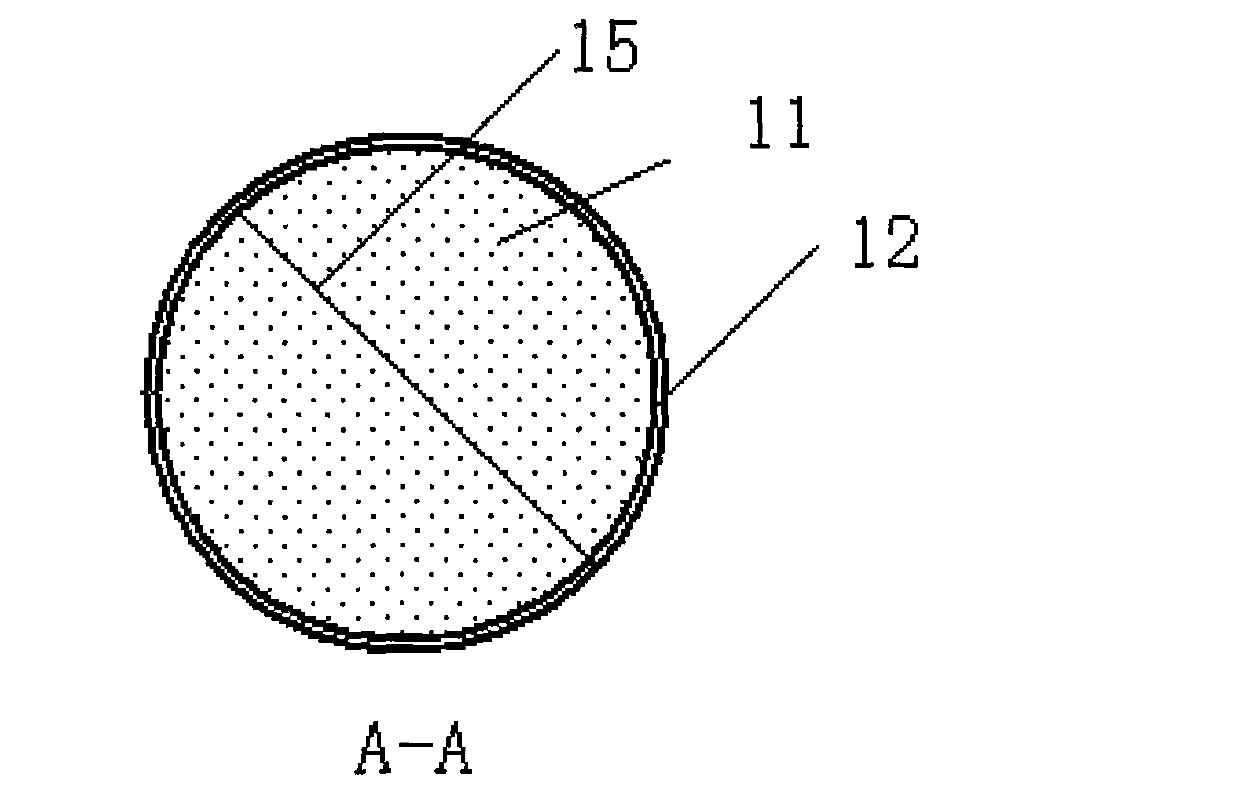

[0022] Embodiment 1 Rubber bag mud sausage stuffing strip controls leakage method: the soft sticky material (9) in the soft plastic sausage stuffing strip (15) is made of (weight percentage) clay 25%, water 55%, waste oil 19.5%, twelve Sodium alkylbenzene sulfonate 0.35%, sodium carboxymethyl cellulose 0.15%, a little sodium hydroxide, fully mixed and stirred evenly. Pour into the rubber film bag (8) with a thickness of 0.03~0.08 mm and then tightly seal the two ends (13), such as figure 2 shown.

[0023] The clay is kaolin, the main component of which is kaolin (Al 2 o 3 2SiO2 2 2H 2 O) and microcrystalline kaolinite (Al 2 o 3 4SiO2 2 2H 2 O) mainly, microcrystalline kaolinite is also called bentonite, which is an ideal filler with fine particles, significant swelling when exposed to water, high viscosity and plasticity. Water adopts tap water. The oil is waste oil from urban sewers. Additives are emulsifier sodium dodecylbenzene sulfonate and tackifier sodium car...

Embodiment 2

[0026]Embodiment 2 The plastic film bag slime sausage filling method for controlling leakage is basically the same as that of Example 1, except that: 1. The film bag (8) adopts a polyethylene film bag (12) with a thickness of 0.015 to 0.045 mm. 2. The soft sticky material in the soft plastic sausage filling strip (15) adopts oil clay (11), and the formula (percentage by weight) of oil clay (11): muddy clay 30%, No. 10 waste engine oil 14.5%, water 55%, Sodium dodecylbenzenesulfonate 0.35%, sodium carboxymethylcellulose 0.15%. 3. The waterproof adhesive (10) adopts vinylidene chloride copolymer latex, and its mixing ratio is: solid content 50% vinylidene chloride copolymer emulsion 68%, 10% trisodium phosphate solution 7%, 5% polyvinyl alcohol solution 13% , 60% titanium dioxide slurry 12%. Preparation method: Put 10% trisodium phosphate into water and stir until completely dissolved, then add 50% vinylidene chloride copolymer emulsion. Put 5% polyvinyl alcohol into water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com