Bamboo gun nail and production method thereof

A production method and technology of bamboo gun nails, which are applied in the directions of nails, staples, biological packaging, etc., can solve the problems of insufficient stability of bamboo nails, low yield, fluffing of nail tails, etc., so as to improve the stability of bamboo nails, improve the Water content gradient, the effect of increasing the amount of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

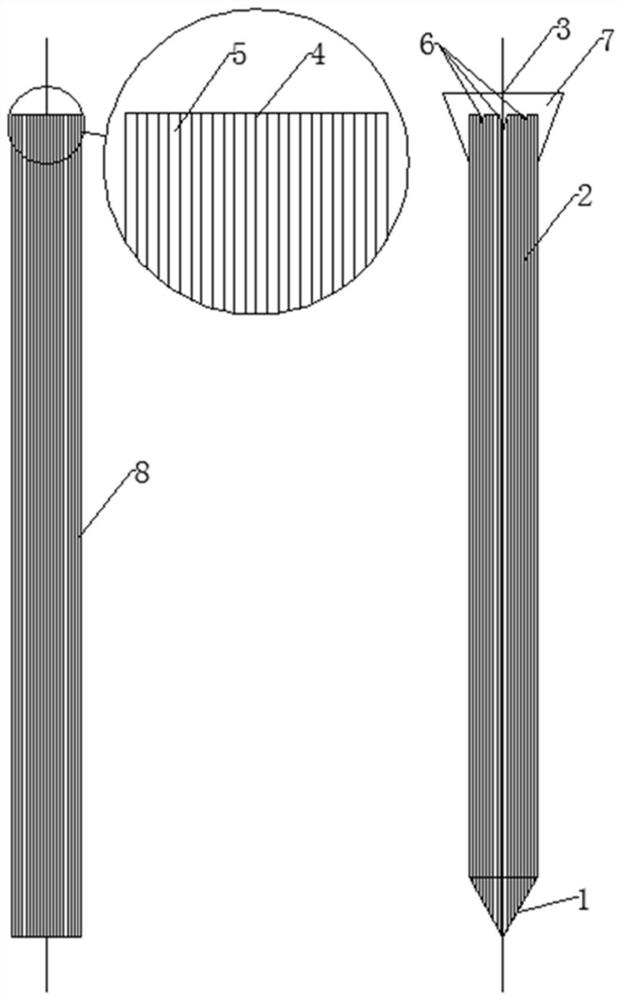

[0035] refer to figure 1 with figure 2 , the present embodiment provides a kind of bamboo gun nail, described bamboo gun nail is made of a plurality of bamboo nails with equal thickness and width bonded in parallel and formed in a row, and the nail head 1 of the bamboo nail is wedge-shaped or conical, corresponding to Adhesive is separated between the nail bodies 2 of two adjacent bamboo nails, and the nail tail 3 thickness of the bamboo nails is exactly 1.5 times the thickness of the nail body 2, which is square, and the bamboo nails are the reinforcing layer 4 and Thin bamboo sheet layer 5 one-to-one layered structure with a density of 1310kg / m 3 .

[0036] The production method of above-mentioned bamboo gun nail, this method may comprise:

[0037] (1) Unit processing: the bamboo section that is 7-8 years old is rotary-cut into bamboo flakes with a thickness of 0.13mm, and the bamboo flakes are within 1 / 3 of the inner bamboo wall thickness close to the green bamboo.

[...

Embodiment 2

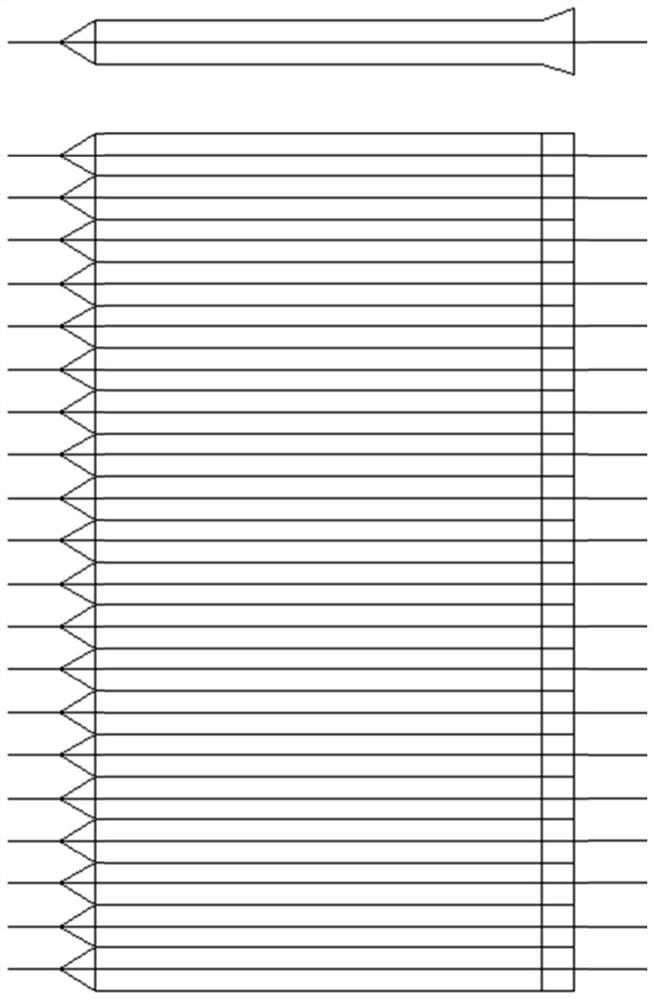

[0048] refer to image 3 , the present embodiment provides a kind of bamboo gun nail, described bamboo gun nail is made of a plurality of bamboo nails with equal thickness and width bonded in parallel and formed in a row, the nail head 1 of the bamboo nail is polygonal wedge shape, adjacent two Adhesive is separated between the nail bodies 2 of the said bamboo nails, the nail tail 3 thickness of said bamboo nails is greater than the thickness of said nail body 2, and they are rectangular respectively, and said bamboo nails are reinforced layer 4 and thin bamboo sheet layer 5 One by one layered structure with a density greater than 1280kg / m 3 .

[0049] The production method of above-mentioned bamboo gun nail is characterized in that, comprises:

[0050] (1) Unit processing: the bamboo section that is 5-6 years old is rotary-cut into bamboo flakes with a thickness of 0.18mm, and the bamboo flakes are within 1 / 4 of the inner bamboo wall thickness close to the green bamboo.

...

Embodiment 3

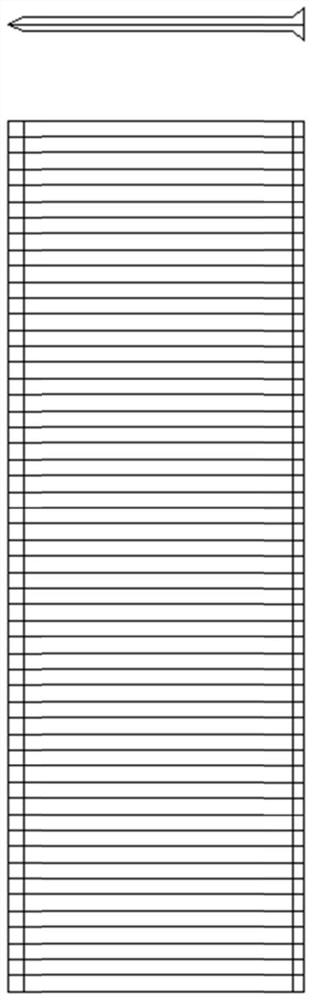

[0061] refer to Figure 4 , the present embodiment provides a bamboo gun nail, the bamboo gun nail is made up of a plurality of bamboo nails with the same thickness and width bonded in parallel to form a row, the nail heads 1 of the bamboo nails are wedge-shaped, and two adjacent The nail bodies 2 of the bamboo nails are separated by an adhesive, the nail tails 3 of the bamboo nails are thicker than the nail bodies 2, and are respectively square, and the bamboo nails are reinforced layer 4 and thin bamboo sheet layer 5. One by one layered structure with a density of 1210kg / m 3 .

[0062] The production method of above-mentioned bamboo gun nail is characterized in that, comprises:

[0063] (1) unit processing: the bamboo section that the bamboo age is 6-7 years is rotary-cut to a thickness of 0.22mm bamboo flakes, and the bamboo flakes are within 1 / 3 of the inner bamboo wall thickness close to the green bamboo.

[0064] (2) drying: the bamboo flakes of (1) are dried to a moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com