Antireflection film cleaning and reusing device and cleaning method

A technology for multiplexing devices and anti-reflection coatings, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of optical performance and anti-laser damage performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

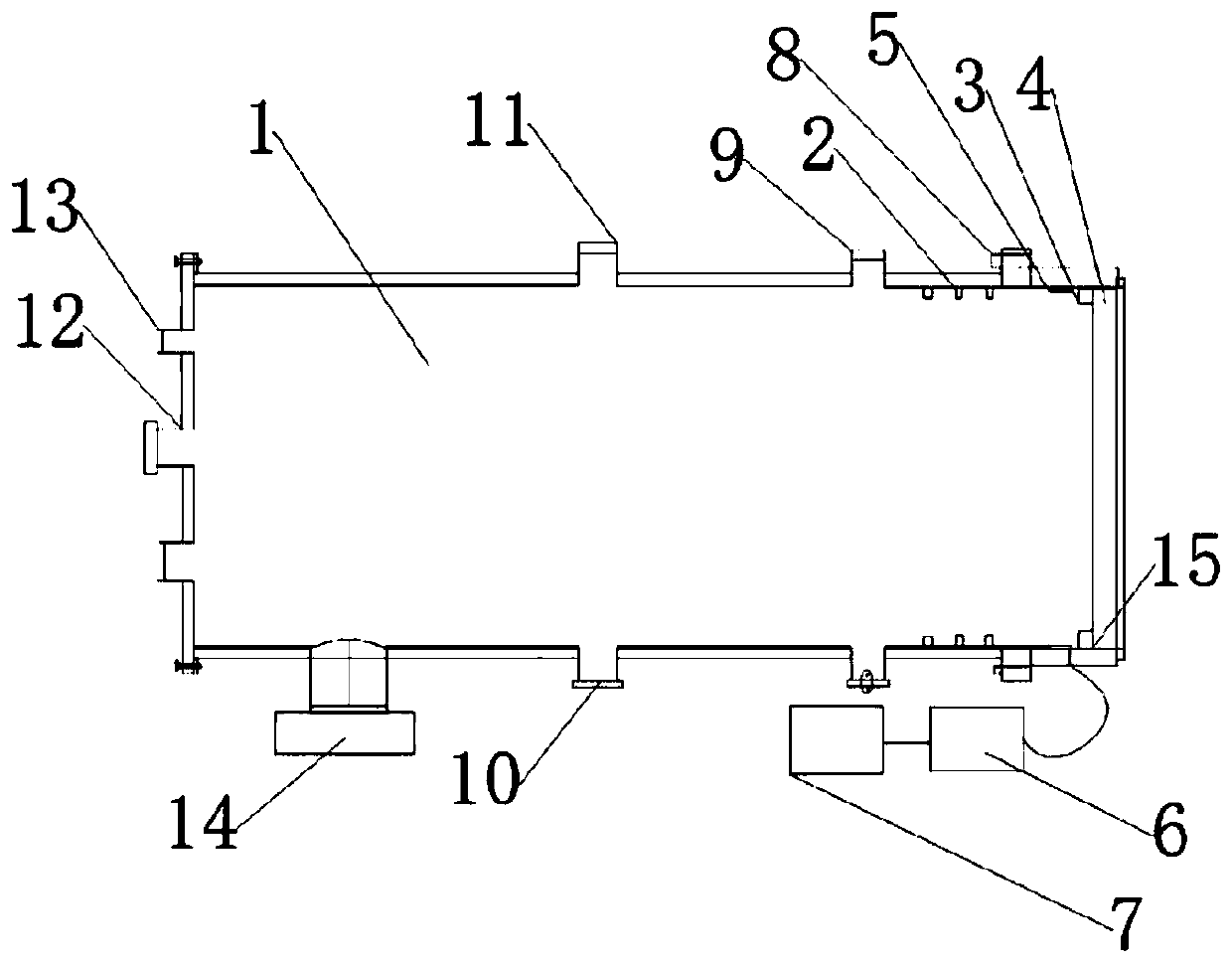

[0022] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0023] like figure 1 As shown, an anti-reflection film cleaning multiplexing device includes a vacuum chamber 1, a vacuum unit 14, a plasma control assembly 7, a vacuum sealing assembly 15 and an element fixture 2, and the element fixture 2 is installed in the vacuum chamber 1 on the top side of the inner wall, the vacuum unit 14 is installed on the bottom side of the vacuum chamber 1, and the vacuum sealing assembly 15 is installed on the outer surface of the vacuum chamber 1 and communicates with the vacuum chamber 1 , the plasma control component 7 controls the plasma reaction in the vacuum chamber 1 .

[0024] Further, the vacuum sealing assembly 15 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com