Method for preparing double-acid ferro-aluminum flocculating agent

A bis-acid aluminum iron and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, strong corrosion, strong acidity, etc. in water treatment, and achieve strong adaptability, good effect, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

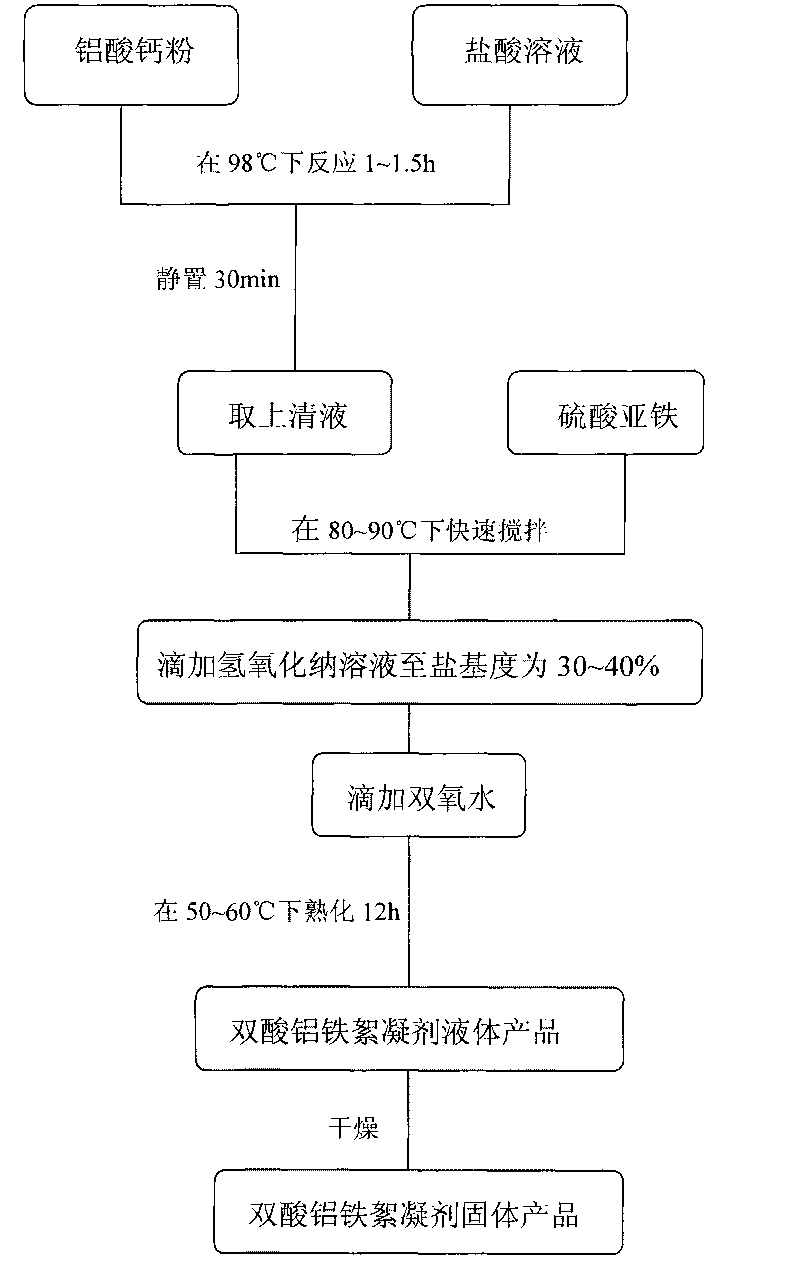

[0021] Prepare bis-acid aluminum iron flocculant, the steps are as follows:

[0022] 1. Crushing commercially available industrial-grade calcium aluminate and sieving with a 60-mesh sieve, the under-sieve is calcium aluminate powder with a particle size less than 60 mesh, wherein the aluminum content of calcium aluminate is greater than or equal to 50% (mass percentage) ;

[0023] 2. Prepare a hydrochloric acid solution with a volume percentage of 20%, and weigh 20 g of calcium aluminate powder and 80 g of hydrochloric acid in a mass ratio of 4:1 (hydrochloric acid solution: calcium aluminate powder). Mix and stir hydrochloric acid and calcium aluminate powder, react at 98°C for 1 to 1.5 hours, dissolve the aluminum in the calcium aluminate powder, and take the supernatant after standing for 30 minutes to obtain AlCl 3 of liquid.

[0024] 3. In AlCl 3 Add 2g of commercially available industrial-grade ferrous sulfate to the liquid, stir rapidly at 80-90°C, and add 40ml of so...

Embodiment 3

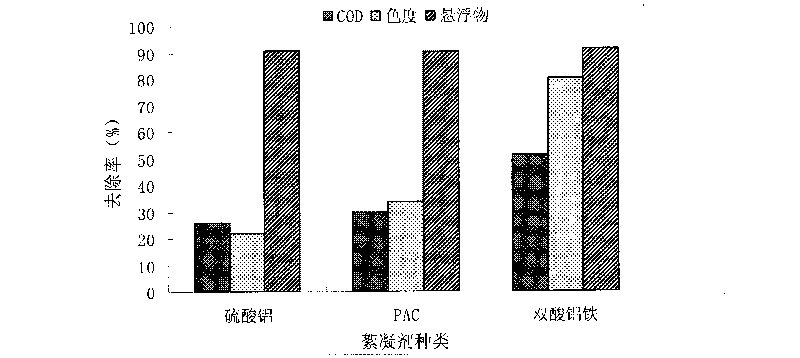

[0032] The coking waste water was treated with the bis-acid aluminum iron flocculant prepared in Example 1, and the experimental water was taken from the biochemical effluent of a coking plant. Compare the bis-acid aluminum iron flocculant of the present invention with other three flocculants, see image 3 shown.

[0033] The water quality of the biochemical effluent of the coking plant is: COD is 200mg / L, suspended matter is 80mg / L, and the chromaticity is 100. Enhanced coagulation is used for advanced treatment, and the dosage of flocculant is 200mg / L, and an additional 1mg is added / L polyacrylamide coagulant. The results are compared as follows:

[0034] The bis-acid aluminum-iron flocculant is better than other flocculants in removing COD, suspended solids and chroma in the biochemical effluent of the coking plant, and the removal rates are about 51% for COD, 85% for SS, and 80% for chroma.

Embodiment 4

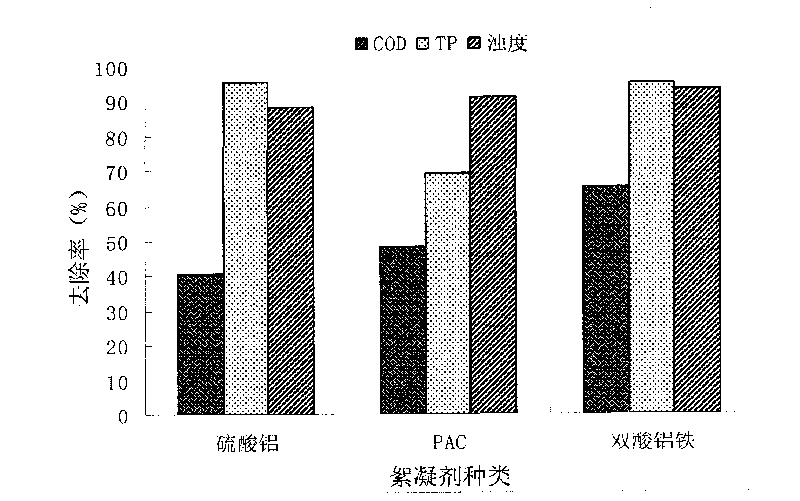

[0036] The micro-polluted water was treated with the bis-acid aluminum iron flocculant prepared in Example 1, and the experimental water was taken from the Huangpu River. The bis-acid aluminum iron flocculant prepared by the present invention is compared with other three kinds, see Figure 4 shown.

[0037] The water quality of Huangpu River is: COD Mn It is 6mg / L, and the turbidity is 48mg / L. It is treated with enhanced coagulation, and the dosage of flocculant is 30mg / L. The results are compared as follows:

[0038] COD of Huangpu River Water by Bis-Aluminum-Fe Flocculants Mn , the turbidity removal effect is better than other flocculants, and the removal rate is COD M n62%, turbidity 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com