Patents

Literature

38results about How to "Does not affect flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

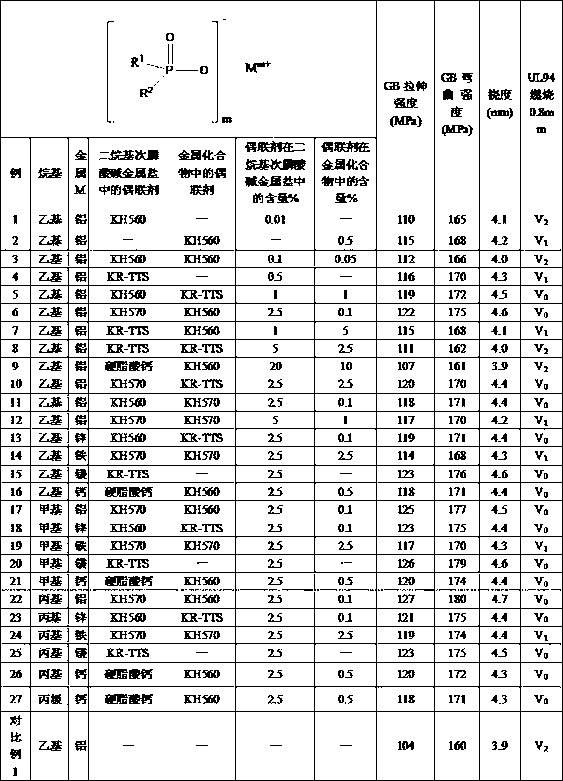

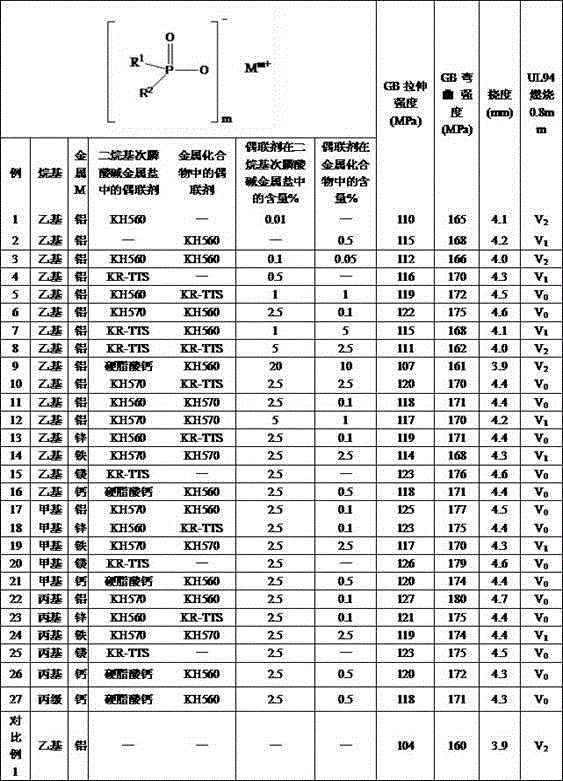

Preparation method of dialkylphosphinate metal salt

InactiveCN103172663ASmall particle sizeImprove fluidityGroup 5/15 element organic compoundsPhosphinic AcidsPhosphinidene

The invention discloses a preparation method of a dialkylphosphinate metal salt. The preparation method comprises the following steps: a) adding a coupling agent into a water solution of dialkyl phosphinic acid and / or a dialkylphosphinate alkali metal salt to get the water solution of dialkyl phosphinic acid and / or the dialkylphosphinate alkali metal salt containing the coupling agent; and b) adding the coupling agent or not adding the coupling agent into a mixture of a metal compound and water, and further reacting with the water solution of dialkyl phosphinic acid and / or the dialkylphosphinate alkali metal salt containing the coupling agent to generate the dialkylphosphinate metal salt. The dialkylphosphinate metal salt obtained by the preparation method disclosed by the invention has small particle size and good flowability; and furthermore, when the particle size is less than 90 mu m, in particular to 40 mu m, the tap density can still above 600g / L, and the problems that such flame retardants are easy to raise dust during the feeding process and less prone to uniformly mixing with resin can be well solved. The preparation method disclosed by the invention has the advantages of simple process and convenience in operation, and the coupling agent is low in price and easy to obtain; and simultaneously, production equipment is simplified and production cost is reduced.

Owner:ZHUHAI WANTONG CHEM

Method for printing multi-component intrinsic flame-retardant fabric

ActiveCN104313924AColor point clearFull colorSucessive textile treatmentsLiquid/gas/vapor treatment of propelled fabricsFiberTextile printer

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a method for printing multi-component intrinsic flame-retardant fabric. The method comprises the following steps: selecting and matching cloth, pretreating the fabric, performing rotary screen printing, steaming at high temperature, rapidly performing wet steaming, oxidizing, soaping, performing softening and color fixing, and performing steam sanforizing. The invention provides the printing technology and method which can realize clear colorizing points, full color and high printing fastness of multi-component intrinsic flame-retardant printed fabric, do not influence the flame retardance, do not damage flame-retardant fibers, and do not influence the strength; the industrial production and application of the multi-component intrinsic flame-retardant printed fabric are realized; indeed, the multi-component intrinsic flame-retardant printed fabric is popularized and applied.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

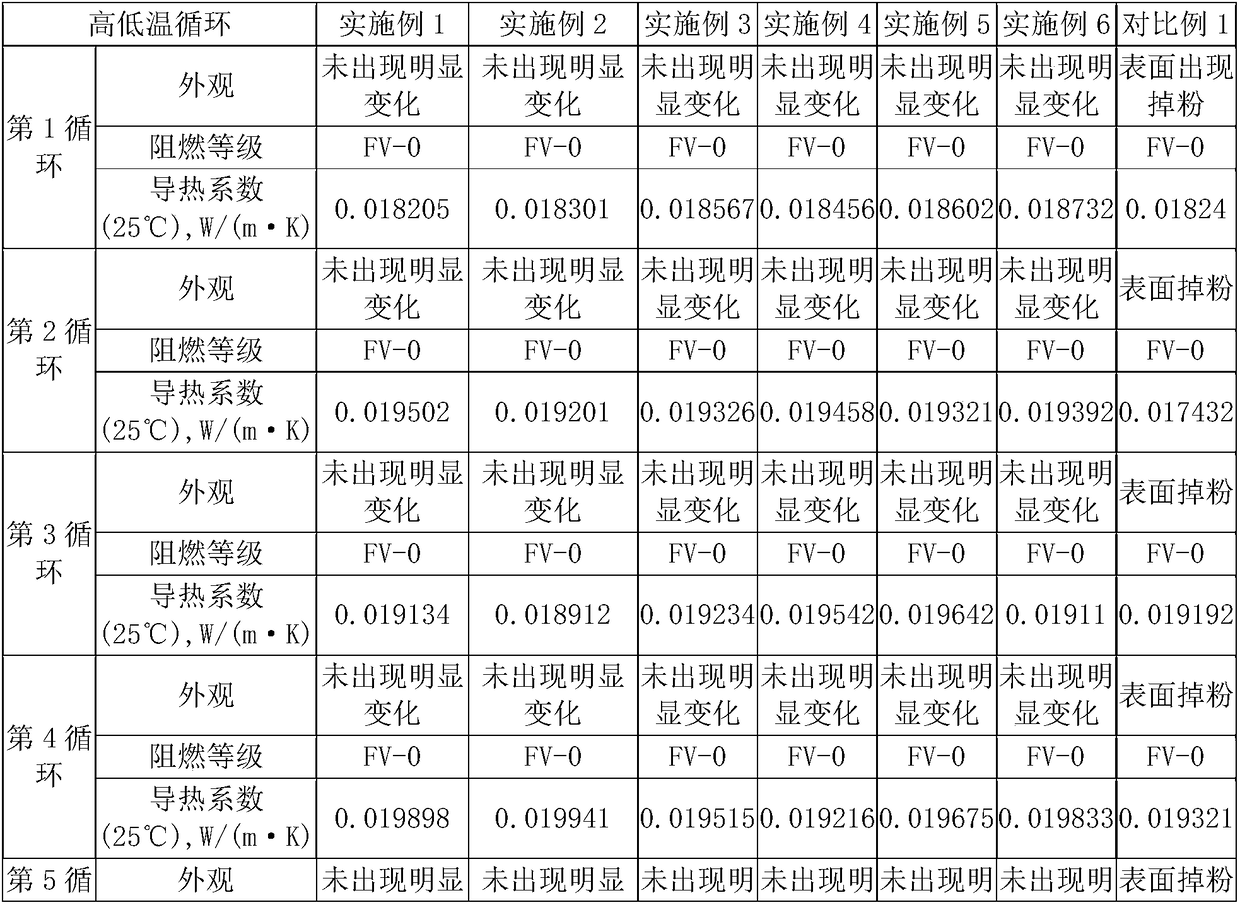

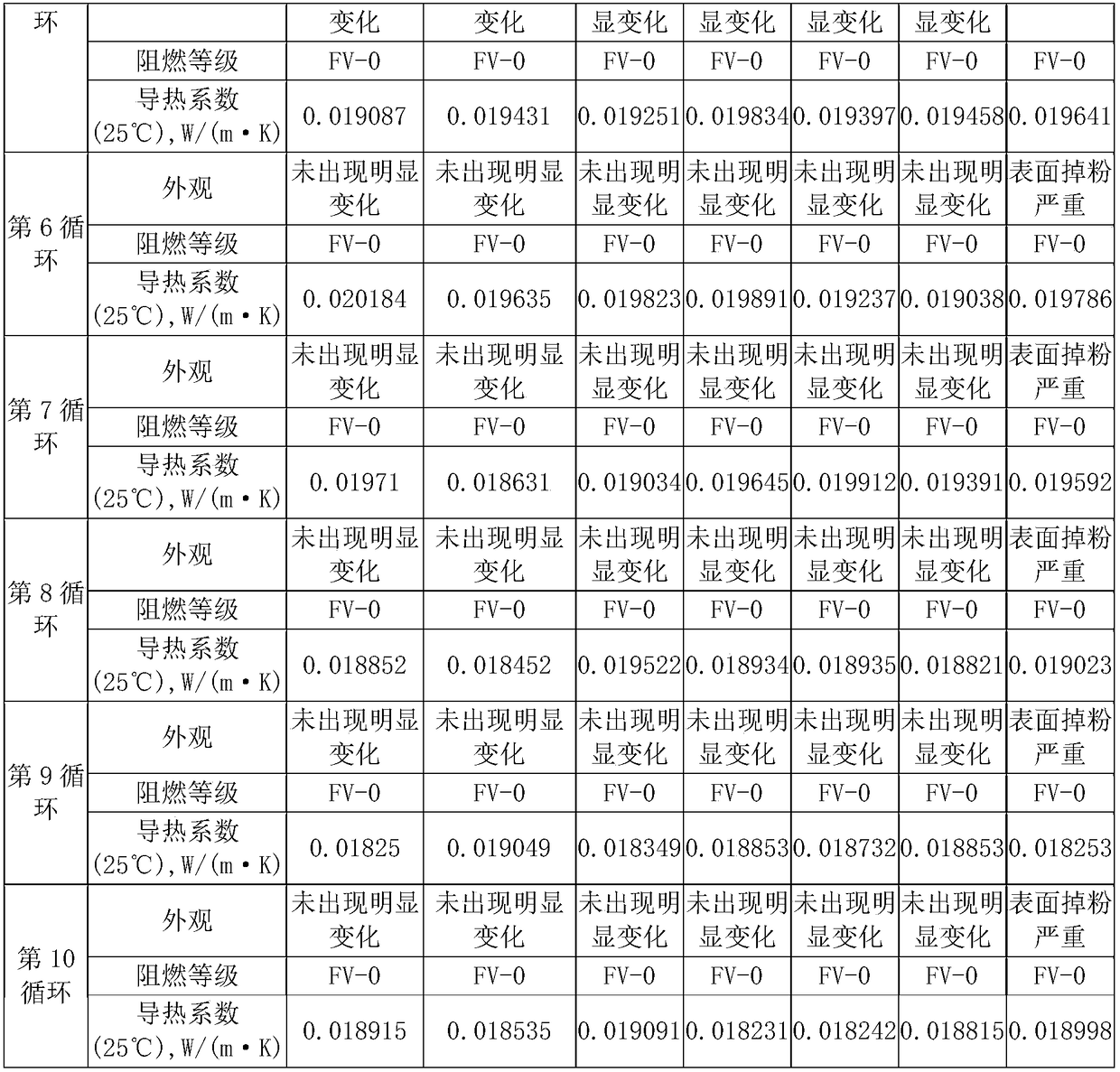

Modified phenolic aldehyde insulation foamed material preparation method

The invention discloses a modified phenolic aldehyde insulation foamed material preparation method, which belongs to the foamed material field. According to the invention, an organic-inorganic nanocomposite is taken as a modifier, the modifier, a surfactant, a foaming agent and an acidic curing agent are added in phenolic resin, the resulting mixture is dumped in a die, mechanically stirred, and foamed at certain temperature to obtain the modified phenolic aldehyde insulation foamed material. According to the invention, agglomeration problem of the inorganic nano modifier can be effectively overcome, the compatibility of the inorganic nano particle and organic resin can be increased, the mechanical strength of phenolic aldehyde cystosepiment is effectively enhanced, and the technical problems of high toughness and efflorescence degree of the traditional phenolic aldehyde cystosepiment can be solved, the density of prepared phenolic aldehyde foamed material is moderate, and the phenolic aldehyde foamed material has characteristics of good flame resistance and toughness, and low efflorescence degree.

Owner:东北大学秦皇岛分校

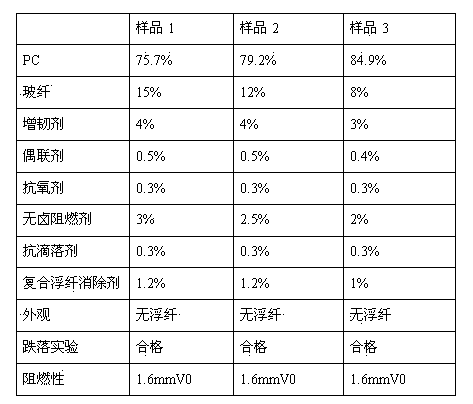

Halogen-free flame-retardant PC (polycarbonate)/GF (glass fiber) composite material for housing of electric meter and preparation method thereof

The invention belongs to the technical field of plastic modification and particularly relates to a halogen-free flame-retardant PC (polycarbonate) / GF (glass fiber) composite material for a housing of an electric meter and a preparation method thereof. The material comprises the following components in percentage by weight: 75-90% of PC, 8%-15% of glass fiber, 2%-4% of toughening agent, 0.3%-0.5% of coupling agent, 0.1%-0.3% of antioxidant, 1%-3% of halogen-free flame retardant, 0.1%-0.4% of anti-dropping agent and 0.8%-1.2% of composite floating fiber removing agent. The preparation method comprises the steps of mixing, extruding and granulating. The material provided by the invention can improve the performance-price ratio and safety of a product, and can be widely used on housings of electric meters.

Owner:QINGDAO DADU NEW MATERIAL TECH

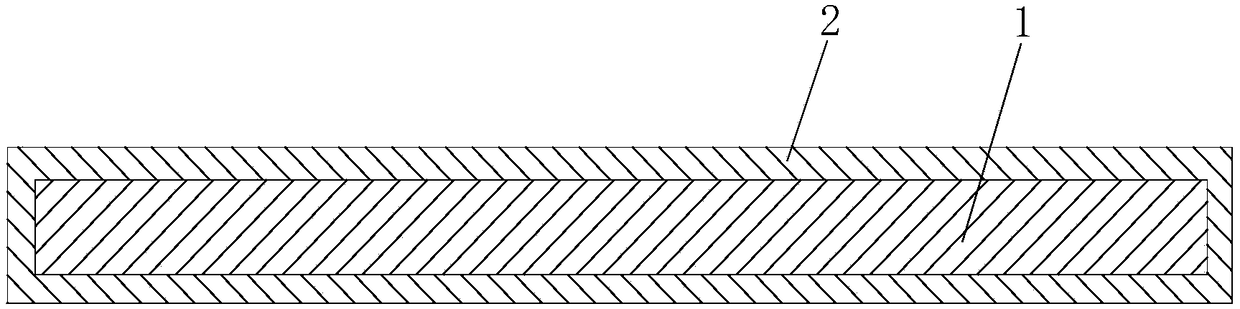

Aerogel heat insulation sheet

InactiveCN108587510ADoes not affect flame retardancyDoes not affect thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberAdhesive

The invention provides an aerogel heat insulation sheet which comprises an aerogel layer and a glue layer coating the outer surface of the aerogel layer; the glue layer covers the whole outer surfaceof the aerogel layer and is prepared from the following raw material components in part by weight: 0.03-1.5 parts of carbon powder, 0.5-5 parts of glass fiber powder, 0.2-5 parts of a flame retardantand 4-35 parts of a structural adhesive. The aerogel heat insulation sheet provided by the invention has the benefits that as the glue layer covers the whole outer surface of the aerogel layer, powderon the surface of an aerogel material is fixed in the glue layer, so that the problem of falling-off of the powder on the surface of the aerogel material is solved. Therefore, the aerogel heat insulation sheet can be applied to the automobile field, and is used as a heat insulation material for an automobile battery, and the problems of pollution and damage to an automobile product due to powderdrop of the aerogel material are effectively solved.

Owner:王宏宁 +3

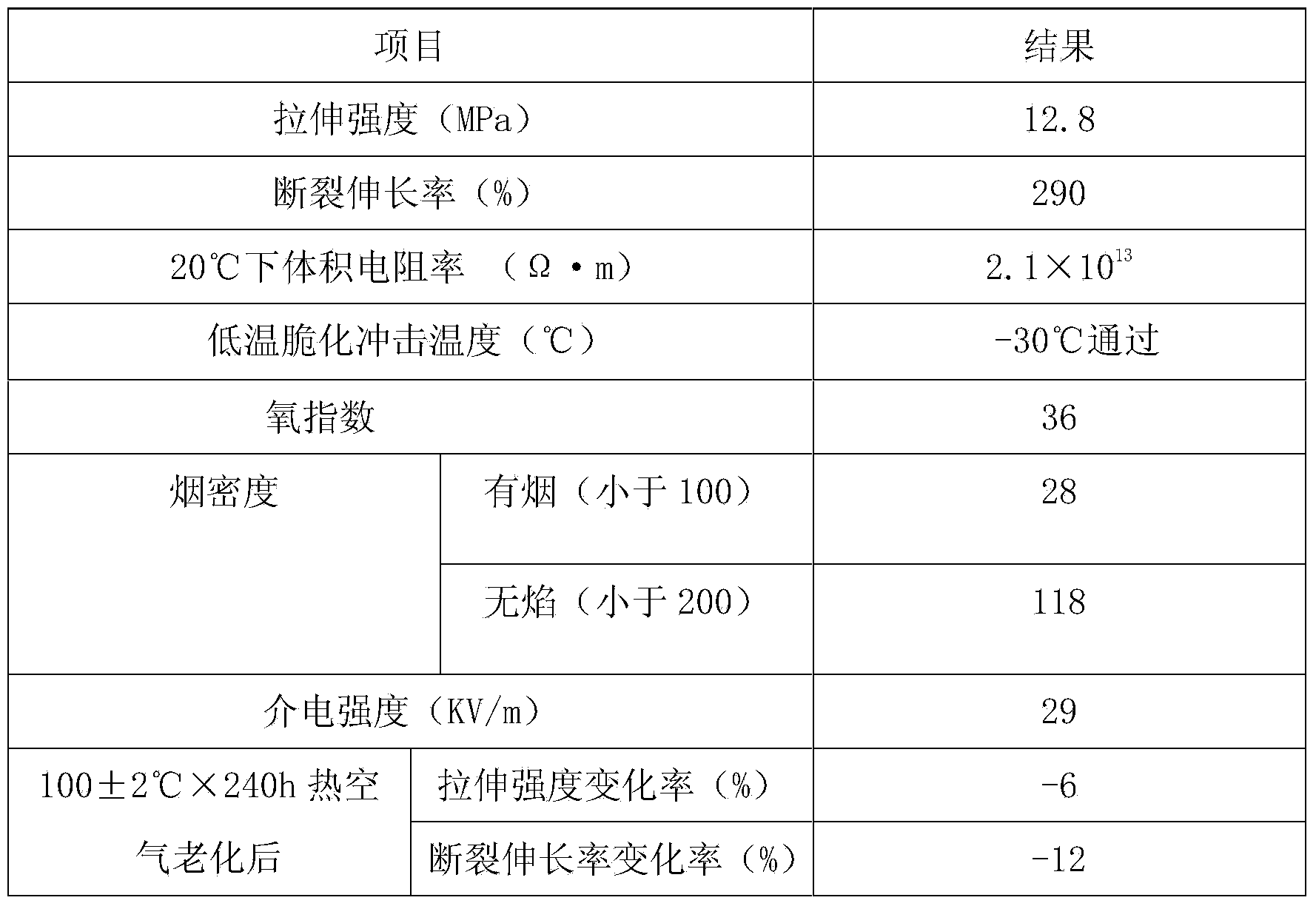

Soft environment-friendly polyolefin cable material

The invention provides a soft environment-friendly polyolefin cable material prepared from the following raw materials in parts by weight: 20-30 parts of a PE resin powder, 40-50 parts of EVA, 10-15 parts of a POE elastomer, 4-5 parts of ACR resin, 20-30 parts of magnesium hydroxide, 20-30 parts of aluminum hydroxide, 10-20 parts of a talcum powder, 4-5 parts of molybdenum trioxide, 2-3 parts of iron oxide, 8-10 parts of tributyl citrate, 1-2 parts of an antioxidant 1010, 20-30 parts of triethyl O-acetylcitrate, 1-2 parts of pentaerythritol, 1-2 parts of melamine cyanurate, 1-2 parts of polytetrafluoroethylene, 1-2 parts of stearic acid, 1-2 parts of paraffin, and 8-10 parts of a modified filler. The cable material has high softness degree and excellent mechanical properties, and can meet use in communication cables, weak electric cables and other industries having higher demands on the cable softness degree.

Owner:河北润丰塑料制品有限公司

Halogen-free flame retardant polycarbonate/glass fiber (PC/GF) composite material for electric meter shell

The invention belongs to the technical field of plastic modification, and particularly relates to a halogen-free flame retardant polycarbonate / glass fiber (PC / GF) composite material for an electric meter shell. The material comprises the following components in parts by mass: 75-90 parts of PC, 8-15 parts of glass fibers, 2-4 parts of flexibilizer, 0.3-0.5 part of coupling agent, 0.1-0.3 part of antioxidant,1-3 parts of halogen-free flame retardant, 0.1-0.4 part of anti-dripping agent, and 0.8-1.2 parts of composite floating fiber curing agent. The preparation method comprises the steps of mixing, extruding and pelletizing. By adopting the material provided by the invention, the cost performance and the safety of a product can be improved, and the material can be widely applied to the electric meter shell.

Owner:QINGDAO DADU NEW MATERIAL TECH

Process of terylene breathable flame-retardant fabric

InactiveCN103046268ADoes not affect flame retardancyLiquid/gas/vapor textile treatmentFire retardantCivil engineering

The invention discloses a process of a terylene breathable flame-retardant fabric. The process is characterized in that a protection film enabling the fabric not to be wetted easily can be formed on the breathable flame-retardant fabric by filling waterproof agents into fire retardants, and the flame-retardant performance of the fabric cannot be affected.

Owner:南通卓越纺织涂层有限公司

Environment-friendly phenolic foam insulation board and preparation method thereof

InactiveCN106432653ADoes not affect flame retardancyLow curing exothermThermal insulationPolyethylene glycol

The invention discloses an environment-friendly phenolic foam insulation board and a preparation method thereof. The insulation board is prepared from, by mass, 100 parts of phenol, 180-210 parts of formaldehyde, 1-5 parts of boric acid, 10-20 parts of polyethylene glycol, 10-20 parts of NaOH, 1-2 parts of citric acid, 1-5 parts of polyethylene glycol bis(2,3-epoxypropyl)ether, 5-10 parts of surface active agent, 20-30 parts of curing agent, 20-30 parts of catalyst, 10-20 parts of foaming agent and 10-15 parts of nano-carbon black. The preparation method includes the steps of firstly, mixing boric acid and polyethylene glycol to prepare boric acid ester; secondly, mixing formaldehyde and phenol to prepare phenolic resin; thirdly, mixing the products in the first step and the second step, adding citric acid to adjust the PH value, adding polyethylene glycol bis(2,3-epoxypropyl)ether to be sufficiently stirred and then depressurized and dewatered; fourthly, conducting compound foaming and demolding. The insulation board has the advantages that the toughness of the phenolic foam board can be improved, and the thermal insulation and flame retardance performance can not be influenced.

Owner:NANTONG DEMING PLASTIC NEW MATERIALS

Halogen-free and low-smoke flame retardant for preparing polyethylene material

InactiveCN105418975AImprove performanceDoes not affect flame retardancyCross-linkDimethyl methylphosphonate

The invention discloses a halogen-free and low-smoke flame retardant for preparing a polyethylene material. The halogen-free and low-smoke flame retardant is prepared by compounding DMMP (Dimethyl Methyl Phosphonate), Mg(OH)2 (available in the market) modified by sodium stearate, 2,3-dimethyl-2,3-diphenylbutane, palygorskite clay and zinc tetraphenylporphyrin. In the polyethylene material prepared by utilizing the halogen-free and low-smoke flame retardant, the oxygen index is not lower than 32, the smoke density under a flameless condition is not higher than 75, the tensile strength is not lower than 12MPa, and the elongation at break is not lower than 180 percent, so that the polyethylene material is a modified halogen-free, low-smoke and anti-flaming polyethylene composite material with a very good performance and can be widely applied to the fields of electric wires and cables, buildings and the like. The flame resistance of the polyethylene material cannot be affected after the polyethylene material is subjected to conventional irradiation cross-linking if cross-linking treatment needs to be carried out on a prepared product, and the mechanical performance of the polyethylene material can be further increased.

Owner:NORTHWEST NORMAL UNIVERSITY +1

Formula of environment friendly edge banding strips

The invention relates to the technical field of composite material, in particular to a formulation of an environment-friendly edge banding. The formulation is to prepare PVC materials with different hardness through adding a stabilizing agent, a reinforcing agent, a lubricant, a styrene modifier, a processing aid and other substances into polyvinyl chloride. The formulation not only reduces processing temperature and improves planeness of a product by adding the processing aid without affecting mechanical property, fire resistance, high-strength weather fastness and other physical performances of PVC, but also ensures excellent product performance of the edge banding with small usage of the polyvinyl chloride and low cost; and the product does not contain a heavy metallic salt stabilizingagent, and can protect human health from being hurt, thereby being an environment-friendly product.

Owner:XIONG YI PLASTIC PROD CO LTD

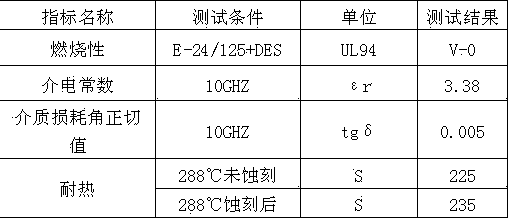

Method for preparing high-temperature-resistant high-frequency copper-clad plate resin adhesive liquid

The invention discloses a method for preparing a high-temperature-resistant high-frequency copper-clad plate resin adhesive liquid. The components comprise methylbenzene, allyl bisphenol A, polyphenyl ether, benzoyl peroxide, triallyl cyanate ester, dicumyl peroxide, decabromodiphenylethane and diphenyl phosphate, wherein the weight ratio of the components is (315-330): (1.30-1.60): (85.0-110.0): (2.21-2.38): (17.25-17.55): (50.00-50.80): (15.40-16.80): (8.50-9.60). The copper-clad plate resin adhesive liquid has low dielectric constant and high heat resistance.

Owner:TONGLING HAORONG ELECTRONICS TECH

Method for improving water permeability resistance performance of outer layer of fire protective clothing and recovering original appearance of outer layer of fire protective clothing

ActiveCN103721355AImprove water resistanceImprove surface moisture resistanceChemical protectionHeat protectionWaxHydrostatic pressure

The invention relates to a method for improving the water permeability resistance of an outer layer of fire protective clothing and recovering the original appearance of the outer layer of the fire protective clothing. According to the method, strong glue spray processing, lustering wax spray processing and first time waterproof spray processing are carried out on the outer layer of the fire protective clothing, the processed outer layer of the fire protective clothing maintains high surficial humidity resistance (spray rating is larger than or equal to four), higher water permeability resistance is provided (hydrostatic pressure reaches 5-8kPa), the icing resistance capacity is improved, and working efficiency of firefighters under low-temperature environment in cold region is guaranteed. Cleaning agent processing is carried out on the outer layer of the fire protective clothing by using the method continuously to remove sprayed glue, sprayed wax and sprayed agents effectively, finally second time waterproof spray processing is carried out to recover the surficial humidity resistance of the fire protective clothing, the original appearance of the fire protective clothing is recovered thereby, and normal use of the fire protective clothing by the firefighters under non-low-temperature environments can be guaranteed.

Owner:应急管理部天津消防研究所

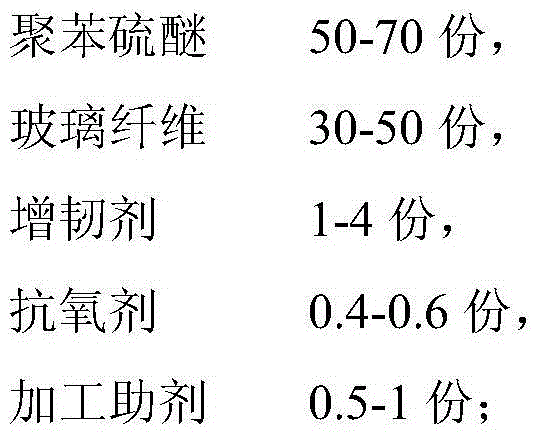

A kind of polyphenylene sulfide composite material and preparation method thereof

The invention belongs to the technical field of high polymer materials and discloses a glass fiber reinforced impact-resistant polyphenylene sulfide composite and a preparation method thereof. The composite is composed of, by weight, 50-70 parts of polyphenylene sulfide, 30-50 parts of glass fibers, 1-4 parts of flexibilizer, 0.4-0.6 part of antioxidant and 0.5-1 part of processing aid. The preparation method of the composite includes the steps: firstly, adding the 50-70 parts of polyphenylene sulfide, 1-4 parts of flexibilizer, 0.4-0.6 part of antioxidant and 0.5-1 part of processing aid into a mixer and mixing for 30min; and secondly, adding the mixture obtained at the step one into an extruding machine through a hopper, adding the 30-50 parts of glass fibers through a glass fiber port, and performing melt extrusion and granulating. The glass fiber reinforced impact-resistant polyphenylene sulfide composite has excellent impact resistance and high mechanical strength.

Owner:HEFEI GENIUS NEW MATERIALS

A kind of preparation method of dialkyl phosphinic acid metal salt

InactiveCN103172663BSmall particle sizeImprove fluidityGroup 5/15 element organic compoundsPhosphinic AcidsPhosphinidene

Owner:ZHUHAI WANTONG CHEM

High-toughness laser direct structuring glass fiber reinforced polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high-toughness laser direct structuring glass fiber reinforced polyphenylene sulfide composite material and a preparation method thereof, and belongs to the field of modified plastics. The high-toughness laser direct structuring glass fiber reinforced polyphenylene sulfide composite material is prepared from the following components in parts by weight: 40 to 60 parts of polyphenylene sulfide, 5 to 15 parts of phenolphthalein-based polyether ketone, 20 to 40 parts of glass fiber, 5 to 15 parts of mineral filler, 0.1 to 0.3 part of a high-temperature lubricating agent, 6 to 10 parts of a laser activating agent, 0.1 to 0.3 part of a metal deactivator and 0.2 to 1 part of a dispersing agent. The invention further discloses a preparation method. Compared with similar products, the high-toughness laser direct structuring glass fiber reinforced polyphenylene sulfide composite material disclosed by the invention has higher impact strength and flame retardant effect, a wide laser processing window and strong coating binding force.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Anti-ageing PVC (polyvinyl chloride) pelletizing formula

InactiveCN109486061ADoes not affect flame retardancyDoes not affect impedanceAntioxidantMixed materials

The invention discloses an anti-ageing PVC pelletizing formula and belongs to the technical field of chemical materials. The anti-ageing PVC pelletizing formula is composed of, by weight part, 40-85 parts of PVC, 0.1-0.25 part of stearic acid, 0.1-0.25 part of calcium stearate, 1-1.25 parts of ACR (acrylates), 4-6 parts of CPE (chlorinated polyethylene), 10-25 parts of DOTP (dioctyl terephthalate), 0.2-0.6 part of antioxidant, 1.5-2.5 parts of surfactant and 3-3.5 parts of stabilizer. The preparation method of the anti-ageing PVC pelletizing formula comprises blending the PVC, the ACR, the stabilizer and the DOTP inside a high-speed mixture for 3-5 minutes, then sequentially adding in the stearic acid, the calcium stearate, the CPE, the surfactant and the antioxidant for blending for 5-7 minutes to obtain a uniformly mixed material, and pelletizing the uniformly mixed material inside a pelletizing machine to obtain compact anti-ageing PVC pellets; cooling down the anti-ageing PVC pellets through a cooling pan to room temperature, and bagging and sealing the cooled anti-ageing PVC pellets. Without affecting other comprehensive properties such as fire resistance, impedance, strengthand plasticity, the anti-ageing PVC pelletizing formula is increased in anti-ageing performance, high in cost performance, simple in preparation and applicable to industrialized production.

Owner:广东正品智慧科技股份有限公司

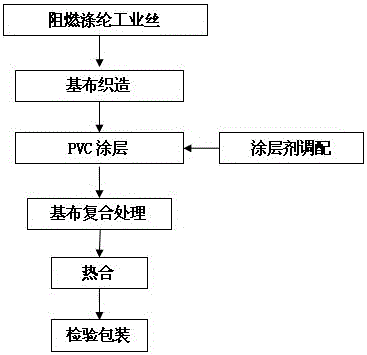

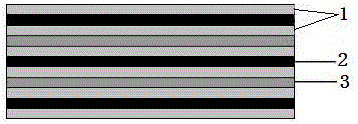

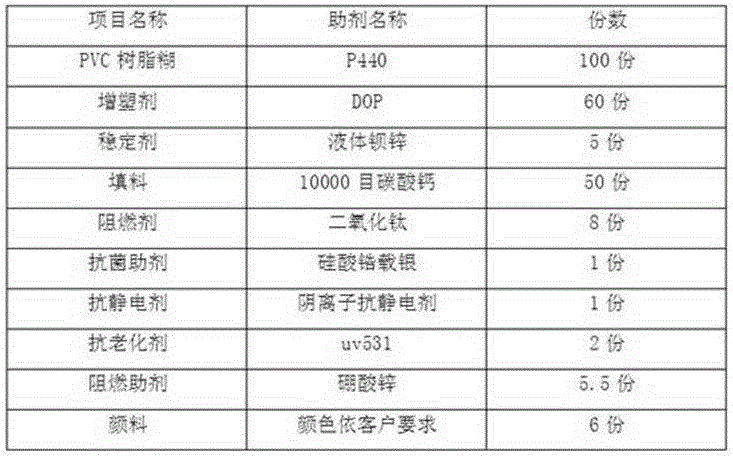

A kind of manufacturing method of multifunctional industrial cloth

The invention relates to a method for manufacturing multifunctional industrial cloth, which belongs to the technical field of textile manufacturing. Choose flame-retardant polyester fiber with a denier of 1000-2000dtex as raw material for weaving, the weaving density is (10-20)×(10-20), and the weight of the base cloth obtained by weaving is 150-450g / m2; Coating, the composition of the coating agent is PVC resin paste, plasticizer, stabilizer, filler and functional additives, the above-mentioned components are fully mixed, ground and filtered to obtain the coating agent, and the cross-linking agent is added during the coating process. After coating, drying, plasticizing and shaping, surface treatment is carried out to obtain the coated cloth, and the coating amount on the base cloth is 100-350 g / m2. The industrial fabric prepared by the invention not only has high strength, but also has functions such as anti-oxidation, anti-aging, anti-ultraviolet, etc., and can meet the requirements of various outdoor environments such as high temperature and high radiation.

Owner:ZHEJIANG KINGSWAY HIGH-TECH FIBER CO LTD

High-voltage resistant cable sheath material and preparation method thereof

InactiveCN109181068ADoes not affect flame retardancyImprove insulation performancePlastic/resin/waxes insulatorsSlurryHigh voltage

The invention provides a high-voltage resistant cable sheath material which contains the following raw materials: 70-80 parts of metallocene polyethylene, 6-12 parts of polymethacrylate resins, 12-18parts of ethylene-vinyl acetate copolymers, 1-3 parts of expanded graphite, 4-8 parts of paraffin, 8-16 parts of a plasticizer, 2-6 parts of a lubricating agent, 8-16 parts of carbon black, 0.2-0.6 part of thiopropyl dilauryl ester, 3-6 parts of magnesium hydroxide, 2-5 parts of a heat stabilizer and 25-35 parts of modified fillers. The preparation method comprises the following steps: adding theplasticizer, magnesium hydroxide, thiopropyl dilauryl ester and modified fillers into a three-roll grinder to be ground into slurry; and kneading the slurry and the rest raw materials, and performingtwin-screw extrusion granulation. The high-voltage resistant cable sheath material has excellent insulation and flame retardant properties and high hardness.

Owner:安庆市泽烨新材料技术推广服务有限公司

A kind of soft and environment-friendly polyolefin cable material

ActiveCN103524842BDoes not affect flame retardancyGood flexibilityInsulated cablesInsulatorsElastomerEnvironmental resistance

Owner:河北润丰塑料制品有限公司

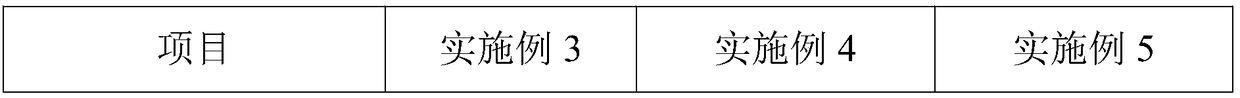

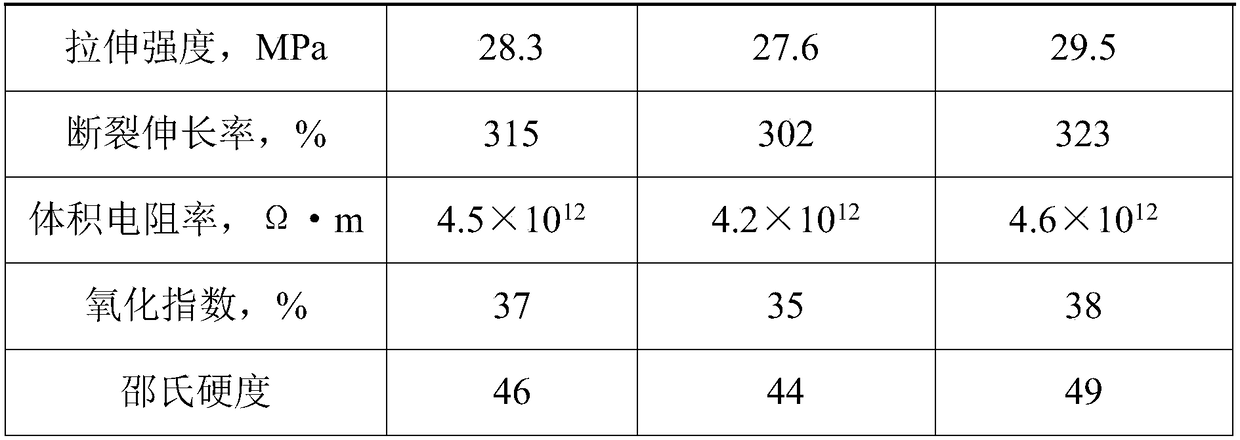

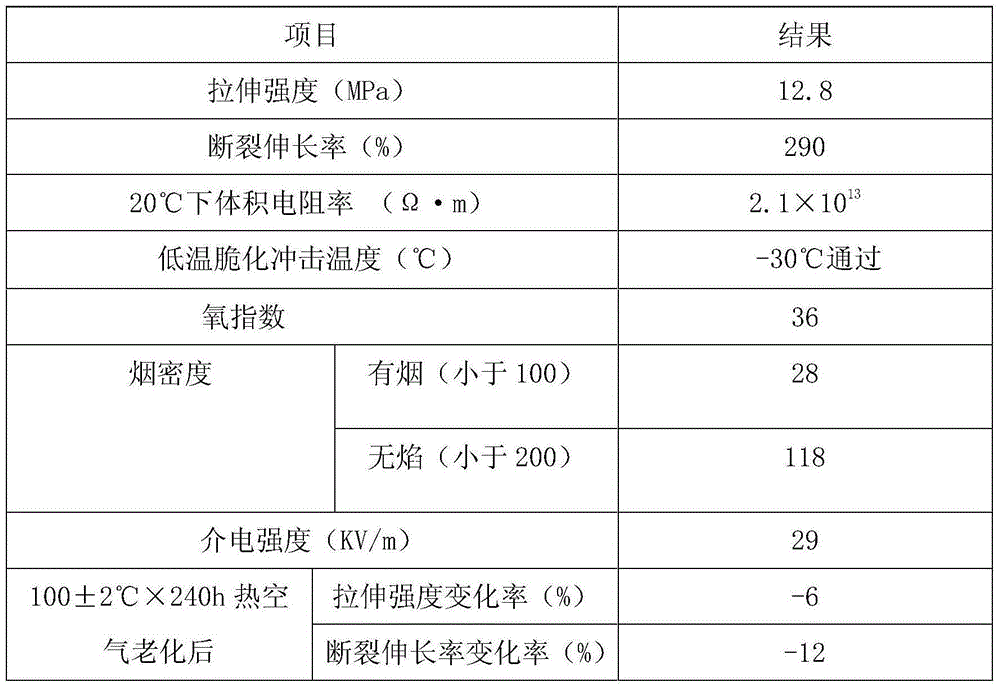

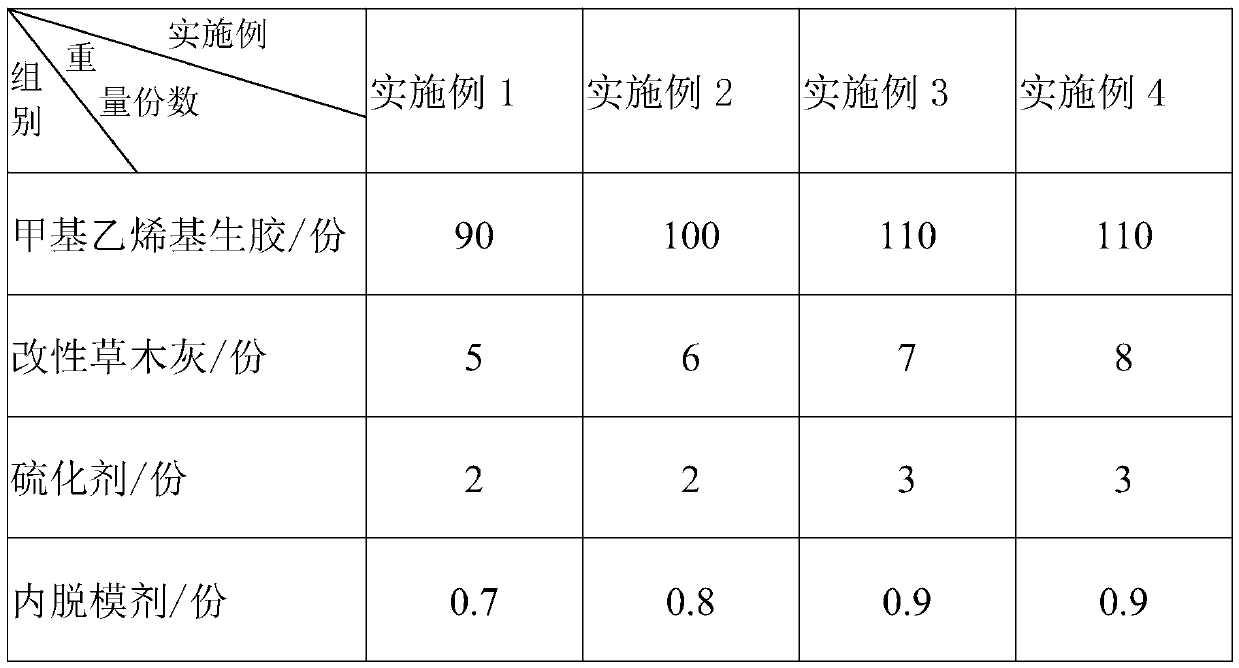

Flame-retardant silicone rubber and preparation method thereof

The invention discloses flame-retardant silicone rubber and a preparation method thereof, and relates to the field of silicone rubber. The technical key points are as follows: the raw materials of thesilicone rubber comprise the following components in parts by weight: 90-110 parts of methyl vinyl raw rubber; 5-8 parts of modified plant ash; 2-3 parts of a vulcanizing agent; 0.7 to 0.9 part of aninternal release agent; wherein the modified plant ash comprises granular plant ash and flame-retardant fibers embedded in the plant ash, one ends of the flame-retardant fibers penetrate out of the plant ash, and the modified plant ash has the advantages that the flame-retardant performance is high, plant ash waste is utilized, and the plant ash pollution problem is reduced.

Owner:厦门汉升橡塑制品有限公司

A method for improving the water resistance of the outer layer of fire-fighting protective clothing and restoring the original appearance of the outer layer

ActiveCN103721355BImprove water resistanceImprove anti-icing performanceChemical protectionHeat protectionWaxFire protection

The invention relates to a method for improving the water permeability resistance of an outer layer of fire protective clothing and recovering the original appearance of the outer layer of the fire protective clothing. According to the method, strong glue spray processing, lustering wax spray processing and first time waterproof spray processing are carried out on the outer layer of the fire protective clothing, the processed outer layer of the fire protective clothing maintains high surficial humidity resistance (spray rating is larger than or equal to four), higher water permeability resistance is provided (hydrostatic pressure reaches 5-8kPa), the icing resistance capacity is improved, and working efficiency of firefighters under low-temperature environment in cold region is guaranteed. Cleaning agent processing is carried out on the outer layer of the fire protective clothing by using the method continuously to remove sprayed glue, sprayed wax and sprayed agents effectively, finally second time waterproof spray processing is carried out to recover the surficial humidity resistance of the fire protective clothing, the original appearance of the fire protective clothing is recovered thereby, and normal use of the fire protective clothing by the firefighters under non-low-temperature environments can be guaranteed.

Owner:应急管理部天津消防研究所

A kind of foam ceramic insulation material and preparation method thereof

The invention discloses a foam ceramic insulation material and a preparation method thereof. The preparation method comprises the steps of injecting a filling medium for a foam ceramic insulation material into a foam ceramic filter by virtue of vacuum equipment until gaps inside the filter are filled with the filling medium, and drying in a drying oven at 90-110 DEG C, wherein the foam ceramic filter has a mesh number of 300-400mesh / inch, a filter accuracy of 50-80ppi and a thickness of 40-60mm; the filling medium for the foam ceramic insulation material is prepared from the following raw materials in percentage by weight: 2-3 percent of sodium carboxymethyl cellulose, 38.8-56.0 percent of glass microspheres and the balance of water. The foam ceramic insulation material has excellent insulation performance, excellent compression strength, relatively high size accuracy, good flame retardance, good thermal shock resistance, low hot-shrinkage rate, low heat expansion coefficient, low production cost, simple preparation process and no special equipment, and is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

A kind of lightweight vitrified microbead insulation material reinforced by cellulose derivatives and its preparation method

The invention discloses a light-weight vitrified microbead thermal insulation material reinforced by cellulose derivatives and a preparation method thereof. The raw materials used in the preparation of the light-weight vitrified micro-bead thermal insulation material reinforced by cellulose derivatives are calculated by weight percentage, and the ratio is 1.9- 2.7% sodium carboxymethyl cellulose, 36.0-50.3% glass microspheres, 7.2-10.1% glass fiber and the balance is water. The preparation method is to first mix and stir sodium carboxymethyl cellulose and water until a viscous liquid is formed Add glass microspheres and glass fibers into the container, then add the obtained viscous liquid, stir and mix evenly, put the obtained mixture into a mold, compact and form it, demould it, and then dry it at a temperature of 90-100°C to obtain a The light-weight vitrified microbead insulation material reinforced by cellulose derivatives with the characteristics of low density, excellent thermal insulation performance and high mechanical strength has low production cost, simple preparation process and no special equipment, and is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

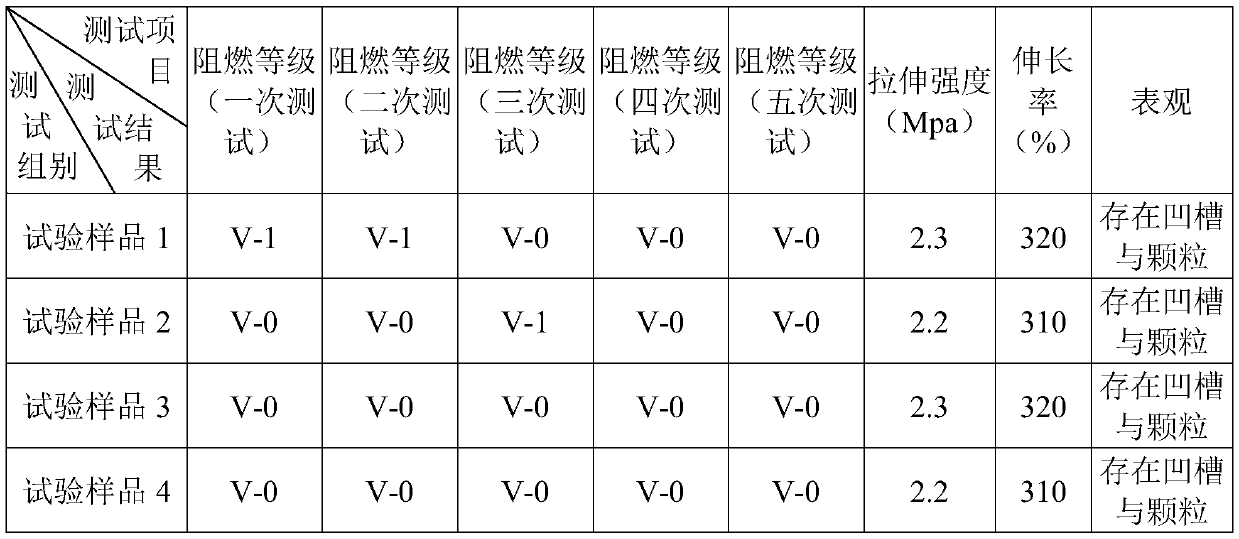

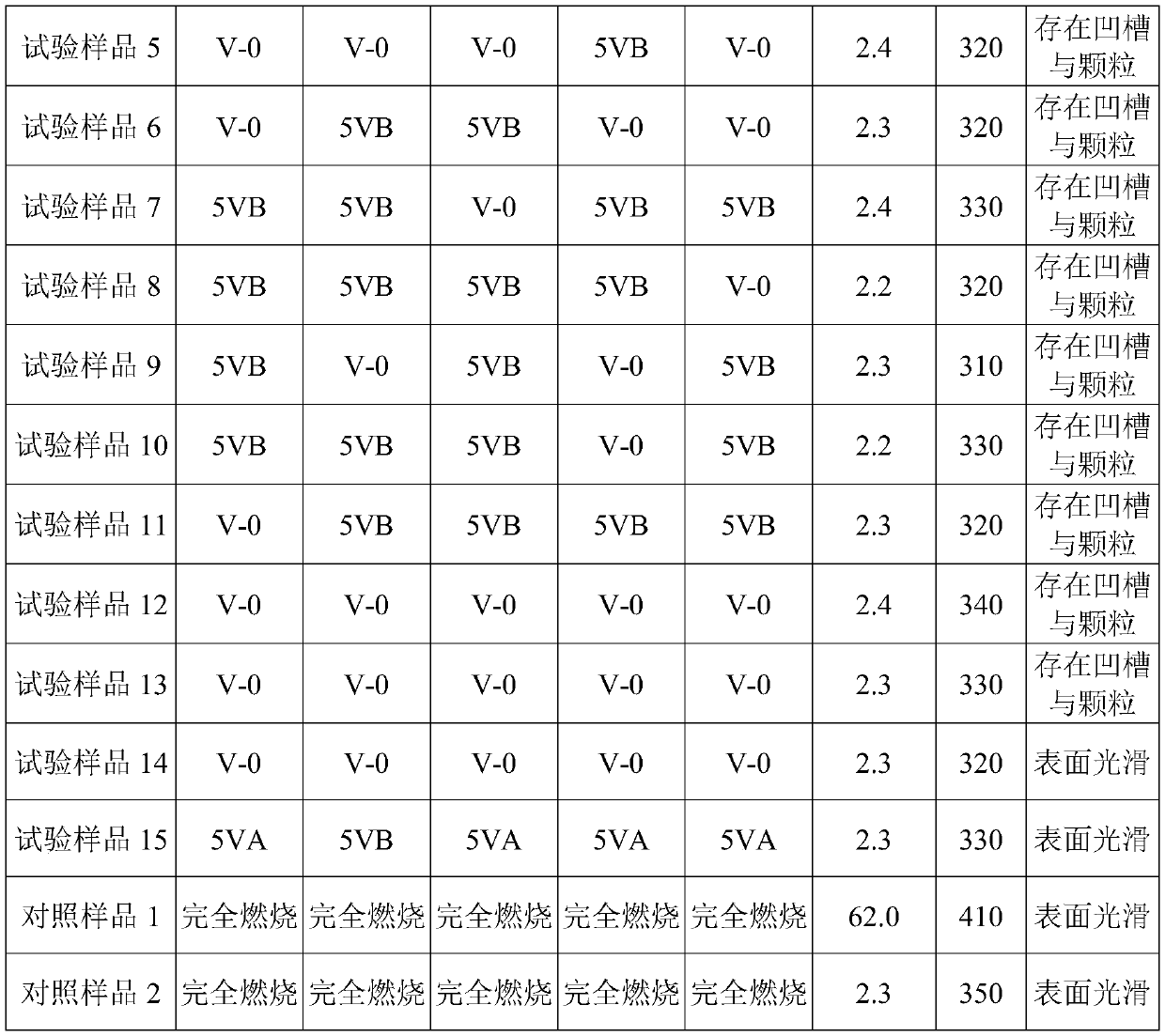

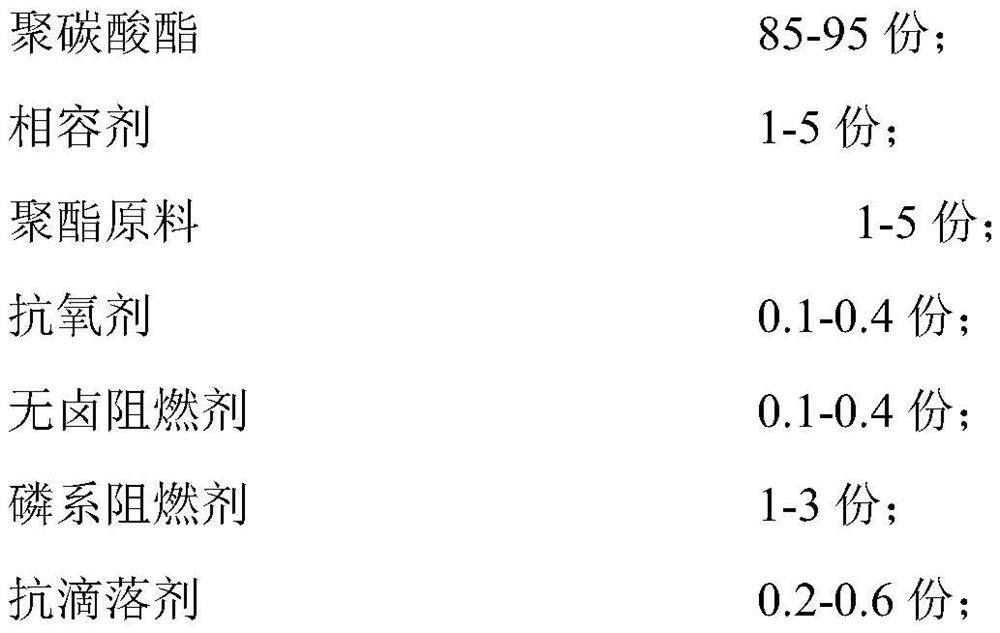

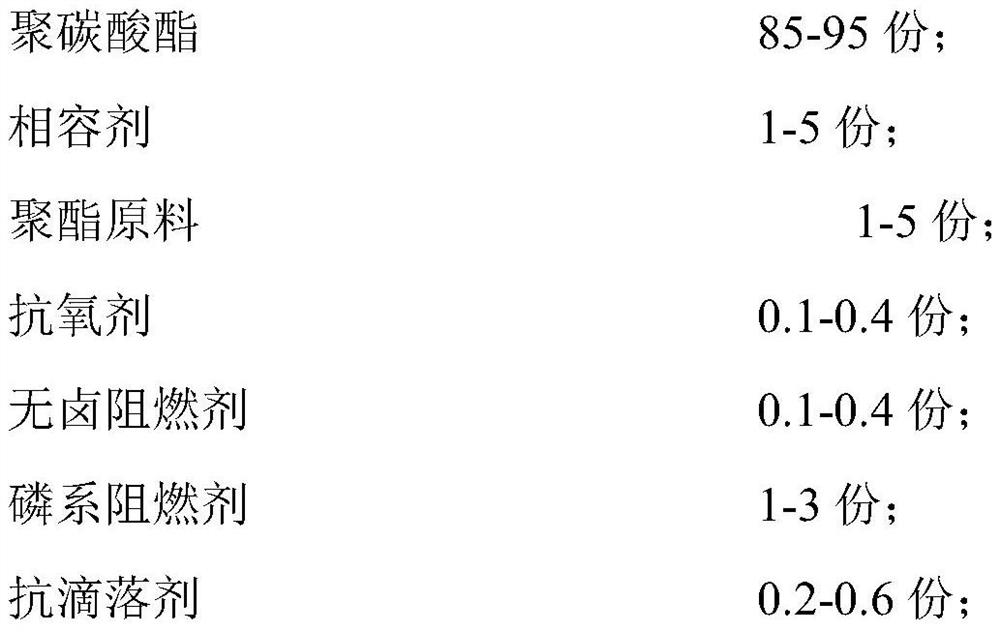

Oil-resistant electric-leakage-resistant halogen-free flame-retardant PC insulating material composition and a preparation method

The invention relates to an oil-resistant electric-leakage-resistant halogen-free flame-retardant PC insulating material composition and a preparation method. The oil-resistant electric-leakage-resistant halogen-free flame-retardant PC insulating material composition comprises polycarbonate, a compatilizer, polyester, an antioxidant, a halogen-free flame retardant, a phosphorus flame retardant and an anti-dripping agent. The oil-resistant compatibilizer and the polyester raw material are added into the polycarbonate for compounding according to the optimal proportion, and the oil-resistant compatibilizer and the polyester raw material can be uniformly distributed in the polymer, have good compatibility with the polycarbonate, and have excellent synergistic oil resistance, so that the flame retardance of a product with the thickness of 1.60 mm can reach the UL-94V-0 level, the mechanical property of the product is not influenced, the product is not cracked due to oil stains, the insulation effect is kept, the tracking resistance reaches 250V, and the safety standard of the electric melting shell of the electronic and electrical product is met.

Owner:上海品诚创奇新材料科技有限公司

A kind of polycarbonate composition and preparation method thereof

ActiveCN104987687BOvercoming the disadvantages of reducing flame retardancyImprove toughness and strengthHeat resistanceDiameter ratio

Disclosed is a polycarbonate composition, comprising the following components in parts by weight: a. 30.4 parts to 80.2 parts of polycarbonate; b. 8.4 parts to 49.6 parts of a butadiene copolymer; c. 5.4 parts to 25.2 parts of a flame retardant; and d. 0 parts to 9.6 parts of other additives, where the sum of the parts by weight of the four components, a, b, c, and d, is 100 parts. In the present invention, by selecting the butadiene copolymer composition to be in the formula of the polycarbonate composition, where the structure of a polybutadiene copolymer in the composition is a large sea-island structure rubber phase, 1 to 50 small sea-island structures are present within the large sea-island structure rubber phase, and, when the diameter ratio of 90% or more of the large sea-island structure rubber phase to the small sea-island structures therein of the least diameter is 1.01-80, the impact strength of the polycarbonate composition can be significantly increased without affecting the flame retardancy, fluidity, and heat resistance of the composition, which is especially suitable in scenarios of increase requirements on the use environment.

Owner:KINGFA SCI & TECH CO LTD

Alloy material edge banding strip

The invention relates to the technical field of composite material, in particular to a formulation of an alloy material edge banding. The formulation is to prepare PVC materials with different hardness by adding a complex calcium-zinc stabilizing agent, a strengthening agent, a lubricant, a styrene modifying agent, a processing addition agent and other substances into polyvinyl chloride. An ABS material is added into the PVC materials to improve the rigidity of the alloy material edge banding without affecting mechanical property, fire resistance, high-strength weather fastness and other physical performances of PVC, and the processing aid is added to reduce processing temperature and improve planeness of a product. The formulation has the advantages of small usage of the polyvinyl chloride, low cost and excellent product performance of the edge banding; and the product does not contain a heavy metallic salt stabilizing agent, and can protect human health from being hurt, thereby being an environment friendly product.

Owner:XIONG YI PLASTIC PROD CO LTD

A kind of preparation method of pva/sodium silicate modified ceramic flame-retardant fiber

ActiveCN106631160BSolve the problem of falling powderDoes not affect flame retardancyFiberPolyvinyl alcohol

The invention relates to a preparation method of polyvinyl alcohol (PVA) / sodium silicate modified ceramic flame retardant fiber. The preparation method comprises the following steps: dissolving sodium silicate into distilled water, then adding PVA, and stirring till no precipitates are generated to obtain a mixed solution; smearing the mixed solution on the surface of ceramic fiber, airing the solution at a room temperature, and obtaining the PVA / sodium silicate modified ceramic flame retardant fiber after the PVC is formed into a film. The method disclosed by the invention is quick, simple and convenient; no high-temperature and high-pressure equipment is needed, the energy consumption is low, and the preparation method is applicable to large-scale production.

Owner:DONGHUA UNIV +1

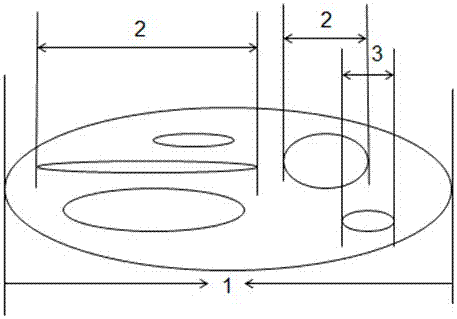

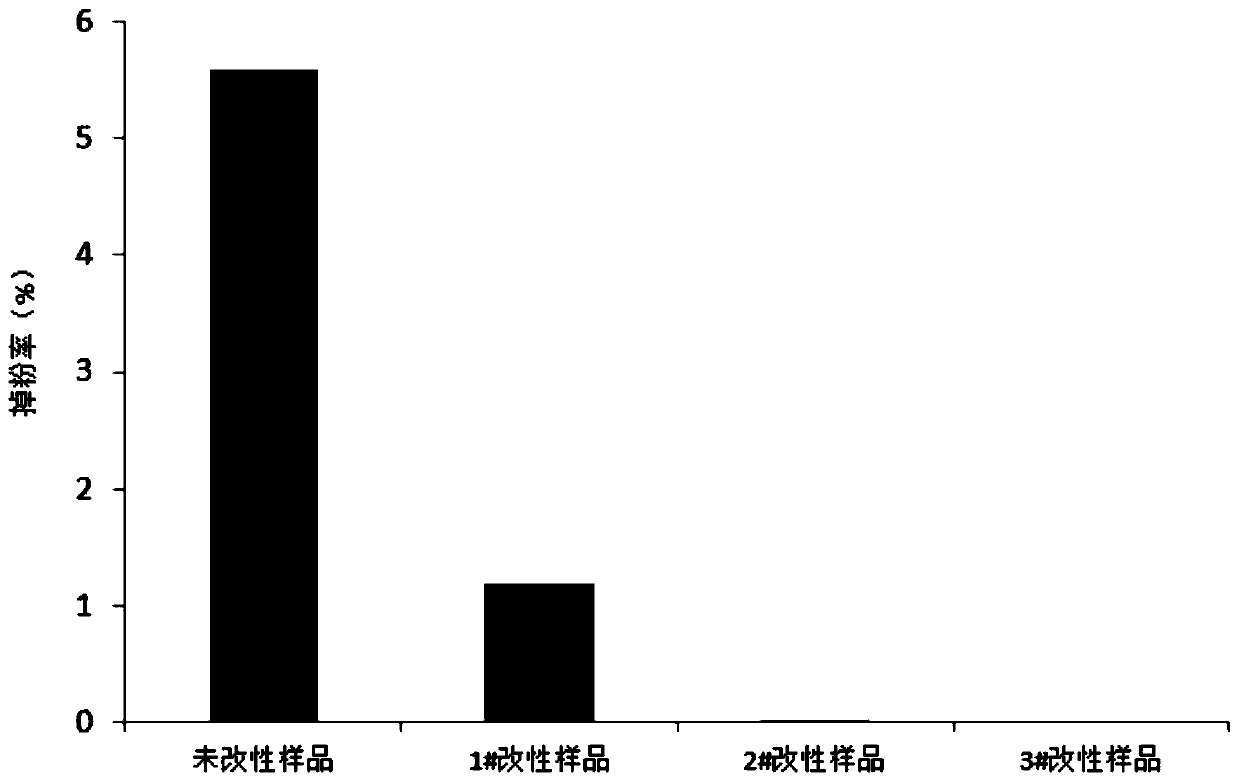

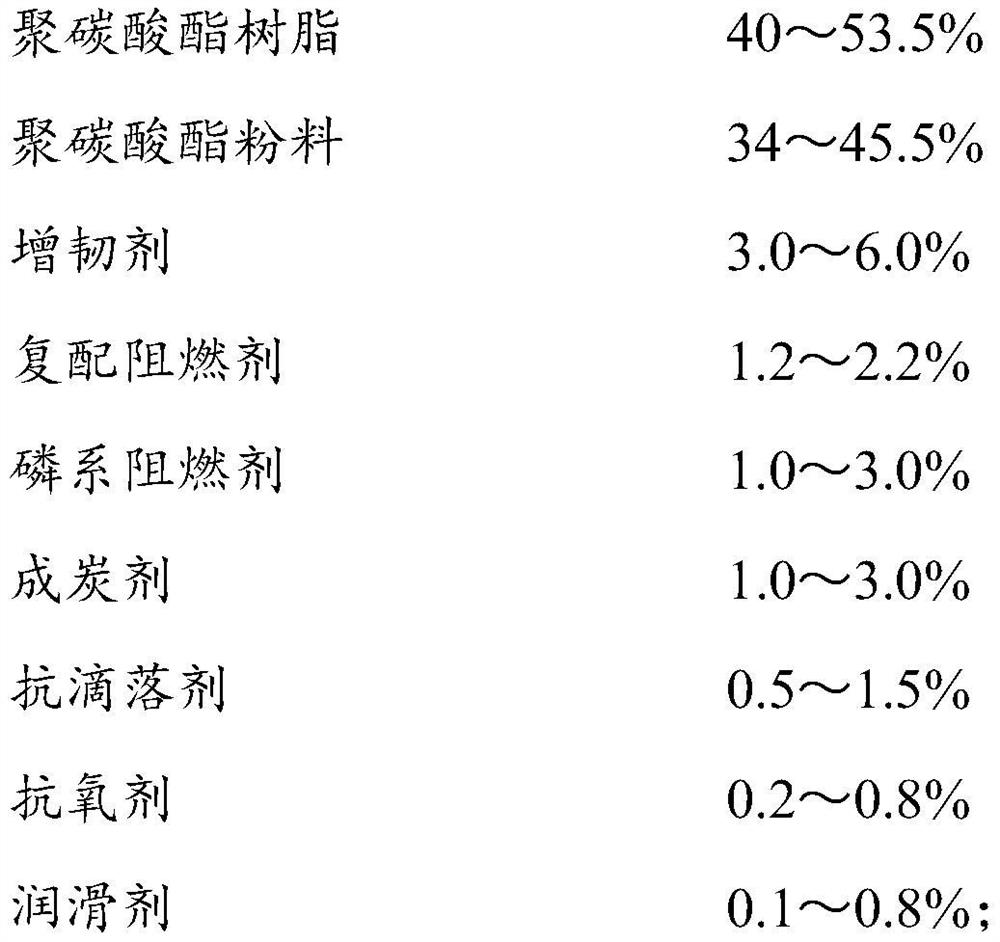

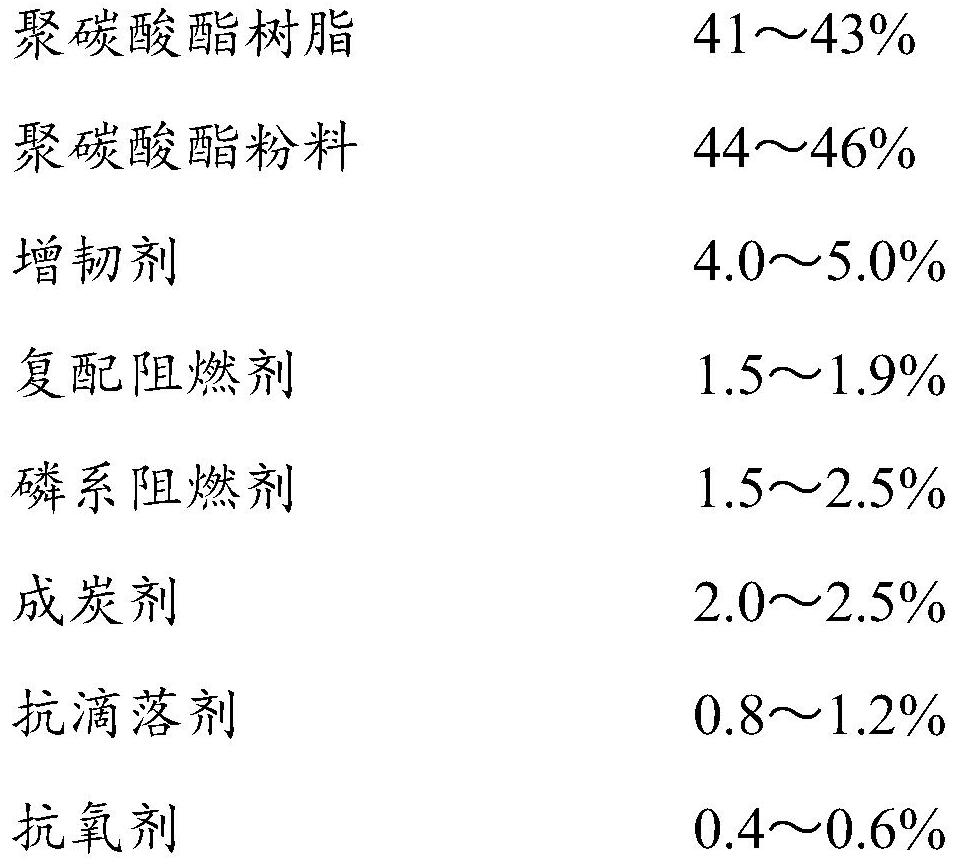

Thin-wall flame-retardant polycarbonate material and preparation method thereof

The invention discloses a thin-wall flame-retardant polycarbonate material and a preparation method thereof. The thin-wall flame-retardant polycarbonate material is prepared from the following raw materials: polycarbonate resin, polycarbonate powder, a flexibilizer, a compound flame retardant, a phosphorus flame retardant, a charring agent, an anti-dripping agent, an antioxidant and a lubricant, the toughening agent is an organic silicon-acrylate copolymer grafted by glycidyl methacrylate; the compound flame retardant is prepared from potassium diphenyl sulfone sulfonate, potassium perfluorobutanesulfonate and octaphenyl polyhedral oligomeric silsesquioxane; the charring agent is a hyperbranched triazine charring agent and / or hyperbranched polyester resin containing hydroxyl groups. The thin-wall flame-retardant PC material has excellent thin-wall flame-retardant performance while having good low-temperature impact resistance, hydrolysis resistance and high-temperature and high-humidity resistance, is good in processability and can be widely applied to thin-wall parts such as 5G communication, electronic and electrical shells and the like.

Owner:SINOPLAST NEW MATERIAL

Method for preparing acid corrosion resistant battery jar

The invention discloses a method for preparing an acid corrosion resistant battery jar. The method comprises the following operating steps: (1) uniformly mixing melamine and a formaldehyde solution, adding ammonium hydroxide into the mixture, and maintaining the temperature; (2) adding melamine pyrophosphate into the mixed solution obtained in the step (1), regulating the pH value of the mixture to be 3.5-4 by adopting a phosphoric acid solution, maintaining the temperature and reacting, centrifuging to obtain a precipitate, washing and drying the precipitate to prepare an acid corrosion resistant flame retardant; and (3) adding an ABS (Acrylonitrile Butadiene Styrene) resin, talcum powder, an antioxidant, the acid corrosion resistant flame retardant, hexadecyl trimethyl ammonium chlorideand dioctyl sebacate into a high-speed mixer, extruding, granulating, and performing injection molding, thereby obtaining the acid corrosion resistant battery jar. According to the method for preparing the acid corrosion resistant battery jar provided by the invention, the prepared battery jar is high in impact resistance, high in hardness, high in electrical resistivity, high in breakdown voltagestrength and excellent in flame-retardant property, and particularly after the flame retardant is added, the problem that the acid resistance is decreased is solved.

Owner:蚌埠市华鼎机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com