A kind of preparation method of pva/sodium silicate modified ceramic flame-retardant fiber

A technology of flame-retardant fiber and ceramic fiber, which is applied in the field of preparation of PVA/sodium silicate modified ceramic flame-retardant fiber, can solve the problems of production workers' health, adverse environmental impact, ceramic fiber dust pollution, etc., and achieve a broad market application prospect , low energy consumption, and the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Stir and dissolve 1.029g of sodium silicate in 10ml of distilled water. After the sodium silicate is completely dissolved, add 2.007g of PVA particles with a polymer of 1750 and continue to stir and dissolve. The stirring speed is 70rpm until the PVA particles are completely dissolved. , a viscous solution was obtained.

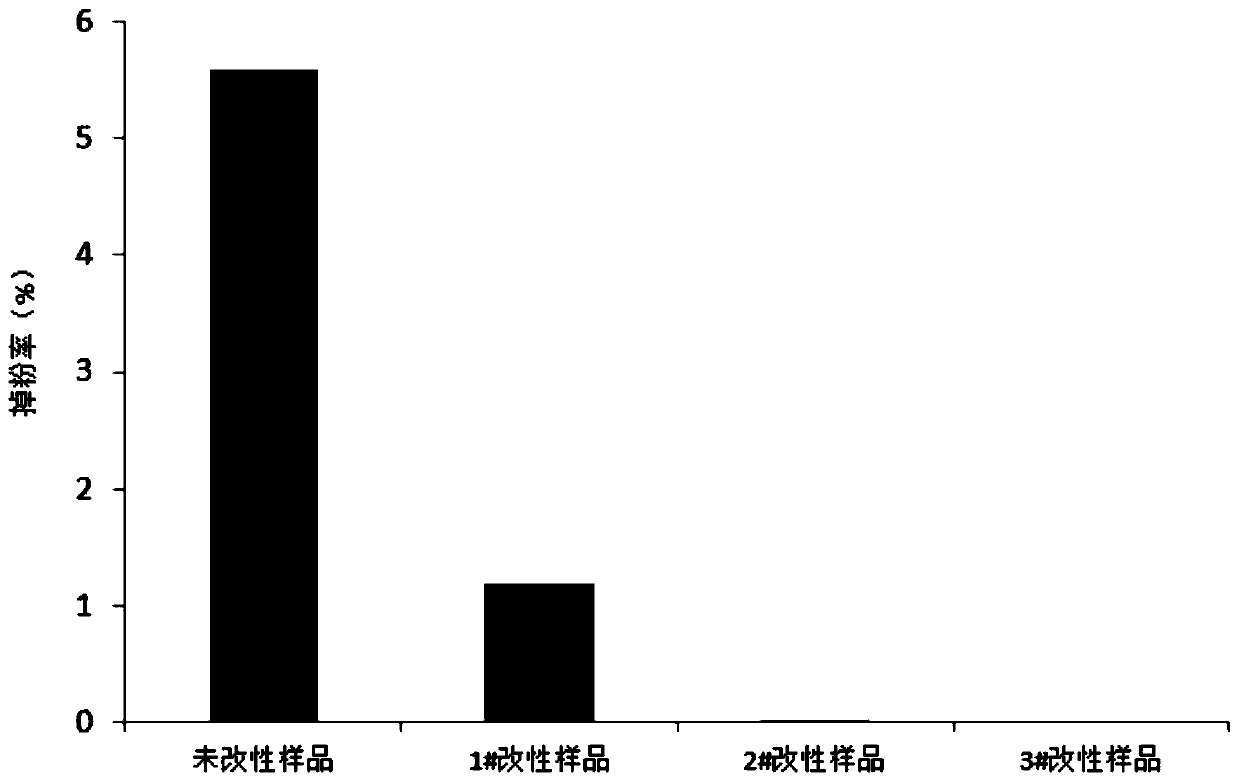

[0026] Then, speed up the stirring speed to 100rpm, and increase the temperature to be 50°C constant, stir for 2 hours, until no precipitation occurs, stop stirring, and use a glass rod to smear the viscous solution on the ceramic fiber surface equably to obtain PVA / Sodium silicate modified ceramic flame-retardant fiber; wherein, the mass ratio of solution and ceramic fiber is 1:15, as 1# modified ceramic fiber; the mass ratio of solution and ceramic fiber is 1:10, as 2# modified ceramic Fiber; the mass ratio of solution and ceramic fiber is 1:6, as a comparative example, it is recorded as 3# modified ceramic fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com