A kind of polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and composite materials, applied in the field of polymer materials, can solve the problems of high brittleness, low impact strength, poor toughness, etc., and achieve improved toughness, improved notched impact strength, increased tensile strength and notched impact The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

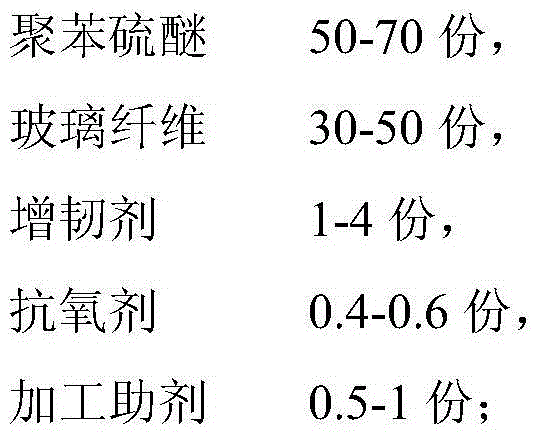

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 50 parts of polyphenylene sulfide pre-dried at 120°C for 4 hours, 1 part of toughening agent A-663, 0.2 part of antioxidant 1098, 0.2 part of antioxidant 168, and 0.5 part of silicone powder into the mixer and stir 30min;

[0029] (2) Add the mixture obtained in step (1) from the hopper of the extruder, add 50 parts of glass fiber through the glass fiber port, melt and extrude, and granulate.

[0030] The temperature of each section from the first zone to the sixth zone of the extruder is 260-290°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, and the head temperature is 290°C -300°C. The performance test results are shown in Table 1.

Embodiment 2

[0032] (1) Add 60 parts of polyphenylene sulfide pre-dried at 120°C for 4 hours, 2.5 parts of toughening agent A-663, 0.2 parts of antioxidant 1010, 0.3 parts of antioxidant 168, and 0.75 parts of pentaerythritol stearate into the mixer Stir in medium for 30min;

[0033] (2) Add the mixture obtained in step (1) from the hopper of the extruder, add 40 parts of glass fiber through the glass fiber port, melt and extrude, and granulate.

[0034] The temperature of each section from the first zone to the sixth zone of the extruder is 260-290°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, and the head temperature is 290°C -300°C. The performance test results are shown in Table 1.

Embodiment 3

[0036] (1) 70 parts of polyphenylene sulfide pre-dried at 120°C for 4 hours, 4 parts of toughening agent A-663, 0.3 parts of antioxidant 1098, 0.3 parts of antioxidant 168, 0.5 parts of pentaerythritol stearate, 0.5 parts Add the silicone powder into the mixer and stir for 30 minutes;

[0037] (2) Add the mixture obtained in step (1) from the hopper of the extruder, add 30 parts of glass fibers from the glass fiber port, melt and extrude, and granulate.

[0038] The temperature of each section from the first zone to the sixth zone of the extruder is 260-290°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, 290-300°C, and the head temperature is 290°C -300°C. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com