Thin-wall flame-retardant polycarbonate material and preparation method thereof

A flame-retardant polycarbonate and thin-wall technology, which is applied in the field of thin-wall flame-retardant polycarbonate materials and its preparation, can solve problems such as brittleness and cracking, achieve good hydrolysis resistance, increase compatibility, and improve impact resistance intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

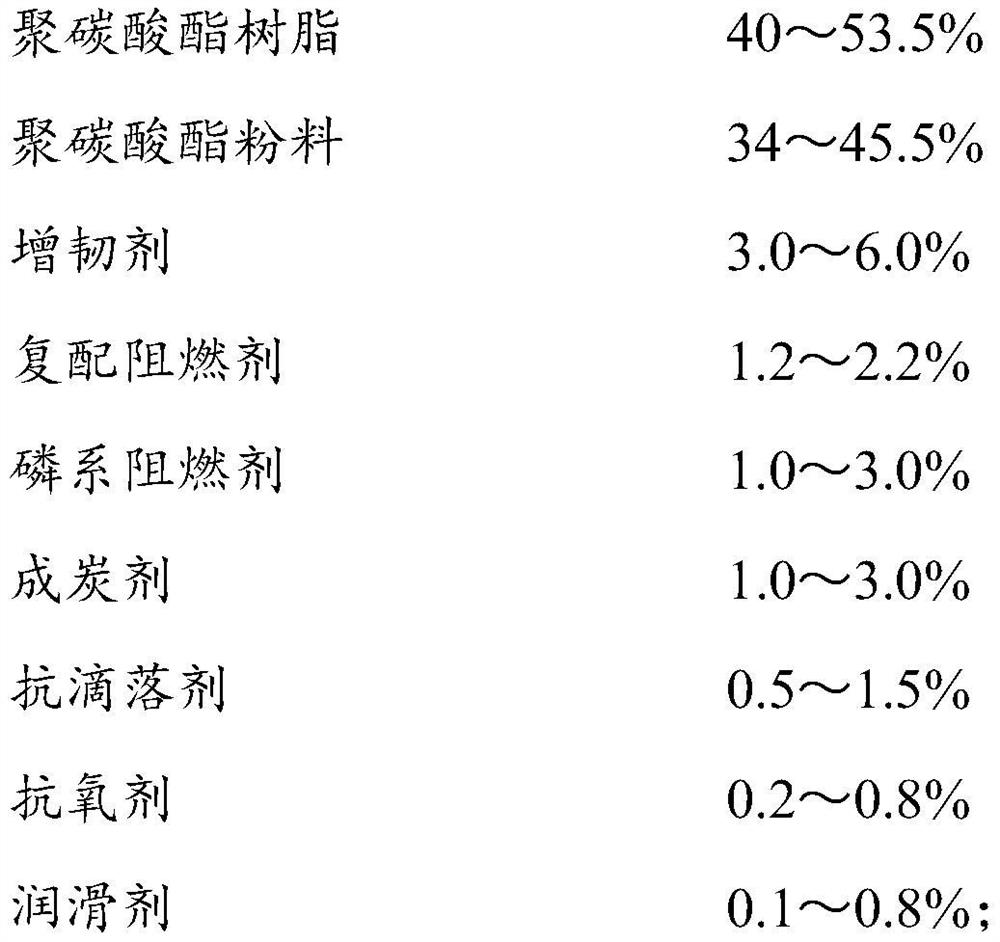

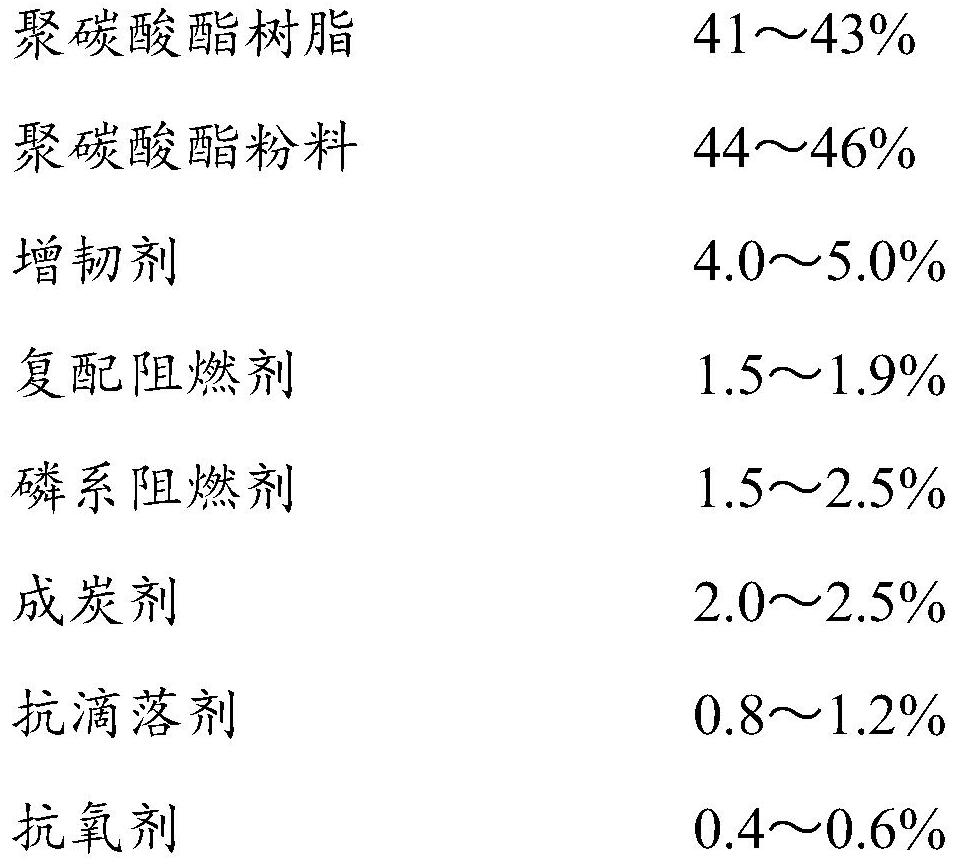

Method used

Image

Examples

Embodiment 1

[0072] A thin-walled flame-retardant PC material provided in this embodiment, its preparation method includes the following steps:

[0073] (1) Mix 100 parts by weight of silicone-acrylate copolymer XT-641A, 0.2 parts by weight of tert-butyl peroxybenzoate and 2 parts by weight of glycidyl methacrylate (GMA), and extrude from a single screw The main feeding port of the machine is added, and the reaction is extruded and granulated to obtain a GMA-grafted silicone-acrylate copolymer, which is recorded as the toughening agent PSi / PA-GMA. The processing temperature of each zone of the single-screw extruder is: the temperature of the first zone is 170°C, the temperature of the second zone is 180°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 200°C, the head temperature is 200°C, and the screw speed is 250r / min.

[0074] (2) Dry PC resin 2800 and PC powd...

Embodiment 2

[0077] A thin-walled flame-retardant PC material provided in this embodiment, its preparation method includes the following steps:

[0078] (1) Mix 100 parts by weight of silicone-acrylate copolymer XT-641A, 0.2 parts by weight of tert-butyl peroxybenzoate and 2 parts by weight of GMA, and add it from the main feeding port of the single-screw extruder, Reactive extrusion and granulation to obtain a GMA-grafted silicone-acrylate copolymer, which is recorded as the toughening agent PSi / PA-GMA. The processing temperature of each zone of the single-screw extruder is: the temperature of the first zone is 170°C, the temperature of the second zone is 180°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 200°C, the head temperature is 200°C, and the screw speed is 250r / min.

[0079] (2) Dry PC resin 115 and PC powder 2100 at 120°C for 2 to 4 hours, so that th...

Embodiment 3

[0082] A thin-walled flame-retardant PC material provided in this embodiment, its preparation method includes the following steps:

[0083] (1) Mix 100 parts by weight of silicone-acrylate copolymer XT-641A, 0.2 parts by weight of tert-butyl peroxybenzoate and 2 parts by weight of GMA, and add it from the main feeding port of the single-screw extruder, Reactive extrusion and granulation to obtain a GMA-grafted silicone-acrylate copolymer, which is recorded as the toughening agent PSi / PA-GMA. The processing temperature of each zone of the single-screw extruder is: the temperature of the first zone is 170°C, the temperature of the second zone is 180°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, the temperature of the fifth zone is 190°C, and the temperature of the sixth zone is 200°C, the head temperature is 200°C, and the screw speed is 250r / min.

[0084](2) Dry PC resin CH8225 and PC powder 2100 at 120°C for 2 to 4 hours, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com