Soft environment-friendly polyolefin cable material

A polyolefin cable material and environmental protection technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor low temperature resistance, poor weather resistance, affecting the physical and mechanical properties and processing performance of cable materials, and achieve reduction The effect of adding amount, high softness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

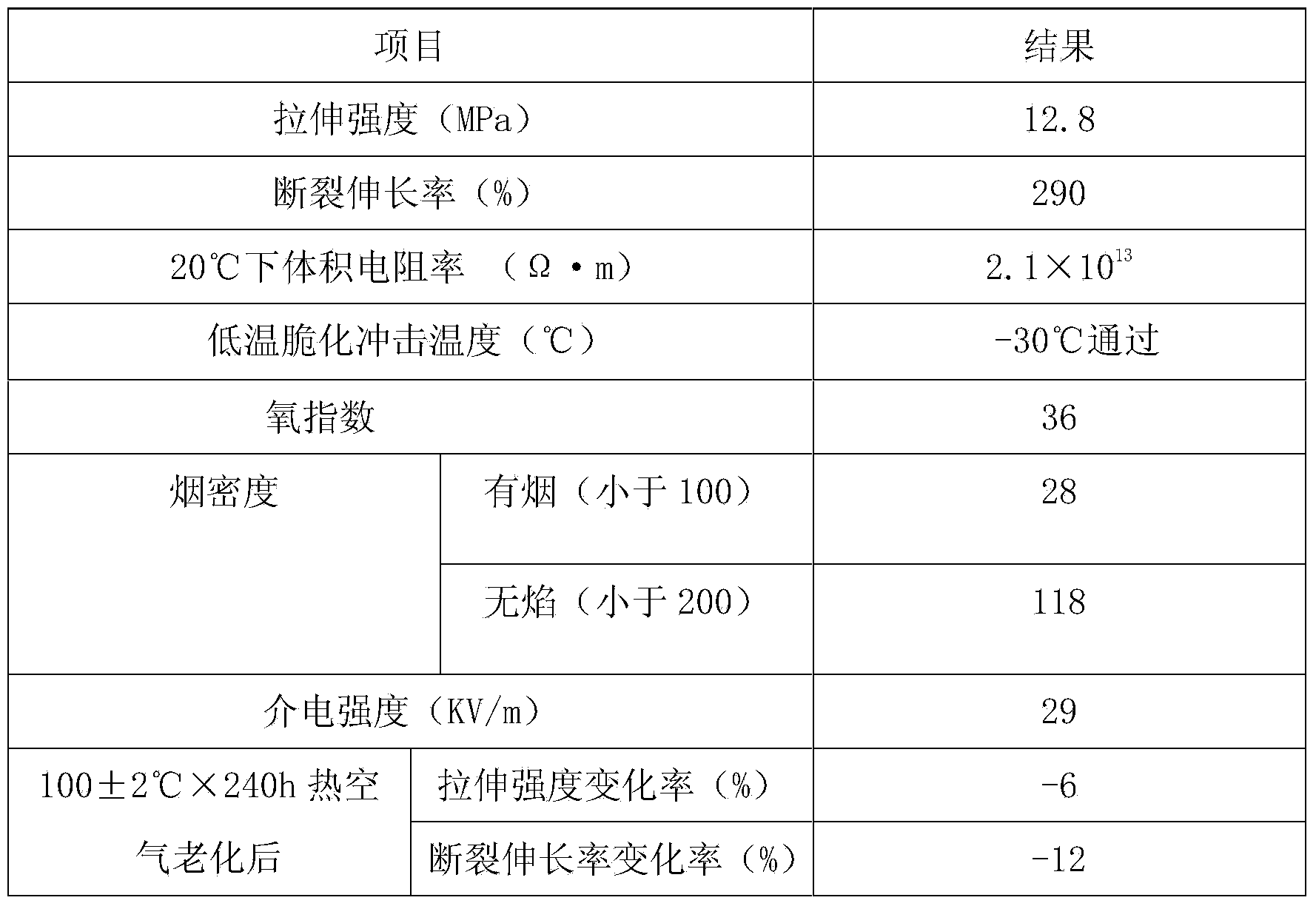

Examples

Embodiment Construction

[0012] Soft and environmentally friendly polyolefin cable compound, made of raw materials with the following weight (kg):

[0013] PE resin powder 25, EVA45, POE elastomer 14, ACR resin 4, magnesium hydroxide 25, aluminum hydroxide 25, talcum powder 15, molybdenum trioxide 5, iron oxide 2, tributyl citrate 8, antioxidant 1010 2. Acetyl triethyl citrate 26, pentaerythritol 1, melamine cyanurate 2, polytetrafluoroethylene 1, stearic acid 1, paraffin wax 2, modified filler 9.

[0014] The preparation method of cable material of the present invention:

[0015] Weigh the raw materials of each component according to the proportion of the formula, stir the weighed raw materials in a high-speed mixer, and then banbury in an internal mixer at a temperature range of 155-175°C, extrude with twin-screws, and grind the surface eagerly Granulating, feeding by cyclone separator, screening by vibrating screen and then packaging to get the finished cable material.

[0016] Wherein, the modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com