A kind of polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, applied in the field of engineering plastics, can solve the problems of affecting the strength of materials, increasing the cost of materials, and decreasing the impact strength, etc.

Active Publication Date: 2018-04-27

KINGFA SCI & TECH CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is well known that the addition of aromatic phosphate compounds can meet the high requirements for flame retardancy of materials, but its addition usually reduces the notched impact strength of the mixture, so in many applications, higher requirements are placed on the impact resistance of materials. Require

[0004] Patent US20130079443A1 discloses a method for improving PC / ABS resin alloys, using maleic anhydride grafted ethylene propylene rubber to improve the impact strength of the mixture, but the use of toughening agents will affect the strength of the material and increase the cost of the material. In addition The addition of rubber often also negatively affects flame retardancy

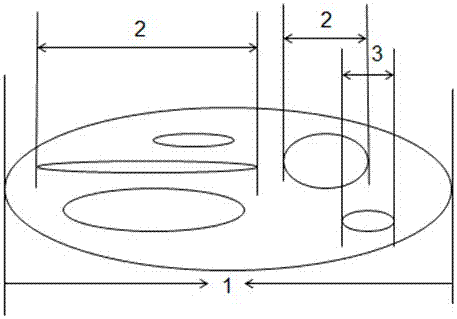

[0005] So far, regarding the polybutadiene copolymer structure in the butadiene copolymer component in the polycarbonate composition exhibiting a large island structure rubber phase, further 1 to 50 A small sea-island structure, wherein 90% and more than 90% of the large-island structure rubber phase and its internal minimum long-diameter small-sea-island structure have an aspect ratio of 1.01-80. The impact on the impact strength of the polycarbonate composition has not been reported.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-12 and comparative example 1-6

[0126] Embodiment 1-12 and comparative example 1-6: the preparation of polycarbonate composition

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed is a polycarbonate composition, comprising the following components in parts by weight: a. 30.4 parts to 80.2 parts of polycarbonate; b. 8.4 parts to 49.6 parts of a butadiene copolymer; c. 5.4 parts to 25.2 parts of a flame retardant; and d. 0 parts to 9.6 parts of other additives, where the sum of the parts by weight of the four components, a, b, c, and d, is 100 parts. In the present invention, by selecting the butadiene copolymer composition to be in the formula of the polycarbonate composition, where the structure of a polybutadiene copolymer in the composition is a large sea-island structure rubber phase, 1 to 50 small sea-island structures are present within the large sea-island structure rubber phase, and, when the diameter ratio of 90% or more of the large sea-island structure rubber phase to the small sea-island structures therein of the least diameter is 1.01-80, the impact strength of the polycarbonate composition can be significantly increased without affecting the flame retardancy, fluidity, and heat resistance of the composition, which is especially suitable in scenarios of increase requirements on the use environment.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a polycarbonate composition and a preparation method thereof. Background technique [0002] Polycarbonate PC has high impact resistance and heat resistance. In order to improve its processing performance and the shortcomings of notch impact sensitivity, rubber modified polymers, such as ABS, MBS, etc., can usually be added, especially PC PC / ABS alloy with ABS as the main raw material is an important engineering plastic. On the one hand, it can improve the heat resistance and tensile strength of ABS, on the other hand, it can reduce the viscosity of PC melt, improve processing performance, and reduce internal stress of products. And the sensitivity of impact strength to product thickness. [0003] Due to the high requirements for flame retardancy of materials in electronics, electrical appliances, construction, and office equipment, it is desired to improve the flame...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L69/00C08L53/02C08L55/02C08L51/04

CPCC08L69/00C08L2201/02C08L2201/08C08L2205/025C08L2205/03C08L2205/06C08L55/02C08L27/18C08K5/523C08K5/1345C08L51/04

Inventor 董相茂岑茵佟伟艾军伟李明昆何继辉孙东海

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com