Method for preparing high-temperature-resistant high-frequency copper-clad plate resin adhesive liquid

A technology of resin glue and copper-clad laminate, which is applied in the field of preparation of high-temperature-resistant and high-frequency copper-clad laminate resin glue, which can solve the problems of broken lines in holes, low pass rate, and easy falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

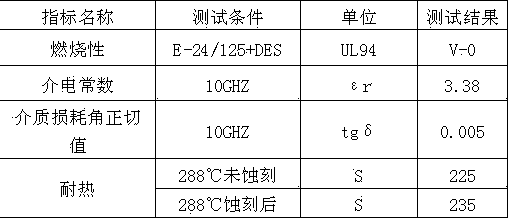

Image

Examples

Embodiment 1

[0018] The method for preparing high-temperature-resistant and high-frequency copper-clad laminate resin glue, the components include: toluene, allyl bisphenol A, polyphenylene ether, benzoyl peroxide, triallyl cyanate, diisoperoxide Propylbenzene, decabromodiphenylethane and diphenyl phosphate, the ratio of each component by weight is:

[0019] 315:1.30:85.0:2.21:17.25:50.00:15.40:8.50;

[0020] First dissolve polyphenylene ether and benzoyl peroxide with toluene, after mixing, add allyl bisphenol A; after the temperature of the solution is raised to 85-92°C, keep it warm for 1.5 hours; then add dicumyl peroxide and Triallyl cyanate, keep the temperature at 85-92 ° C, continue to react for 2 hours; immediately cool the resin temperature to below 60 ° C after the completion of the reaction time; finally add the composite flame retardant decabromodiphenylethane and di Phenyl phosphate, stir well;

[0021] After the resin is made, keep the resin temperature at 60°C, impregnate...

Embodiment 2

[0029] The method for preparing high-temperature-resistant and high-frequency copper-clad laminate resin glue, the components include: toluene, allyl bisphenol A, polyphenylene ether, benzoyl peroxide, triallyl cyanate, diisoperoxide Propylbenzene, decabromodiphenylethane and diphenyl phosphate, the ratio of each component by weight is:

[0030] 312:1.41:90:2.3:17.35:50.65:15.53:8.85;

[0031] First dissolve polyphenylene ether and benzoyl peroxide with toluene, after mixing, add allyl bisphenol A; after the temperature of the solution is raised to 85-92°C, keep it warm for 1.5 hours; then add dicumyl peroxide and Triallyl cyanate, keep the temperature at 85-92 ° C, continue to react for 2 hours; immediately cool the resin temperature to below 60 ° C after the completion of the reaction time; finally add the composite flame retardant decabromodiphenylethane and di Phenyl phosphate, stir well;

[0032] After the resin is made, keep the resin temperature at 60°C, impregnate th...

Embodiment 3

[0040] The method for preparing high-temperature-resistant and high-frequency copper-clad laminate resin glue is characterized in that the components include: toluene, allyl bisphenol A, polyphenylene ether, benzoyl peroxide, triallyl cyanate, peroxide Dicumyl oxide, decabromodiphenylethane and diphenyl phosphate, the ratio of each component by weight is:

[0041] 330:1.52:115.0:2.28:17.4:50.6:16.20:8.95;

[0042] First dissolve polyphenylene ether and benzoyl peroxide with toluene, after mixing, add allyl bisphenol A; after the temperature of the solution is raised to 85-92°C, keep it warm for 1.5 hours; then add dicumyl peroxide and Triallyl cyanate, keep the temperature at 85-92 ° C, continue to react for 2 hours; immediately cool the resin temperature to below 60 ° C after the completion of the reaction time; finally add the composite flame retardant decabromodiphenylethane and di Phenyl phosphate, stir well;

[0043] After the resin is made, keep the resin temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com