High-frequency resin composition as well as semi-cured sheet and laminated board manufactured by high-frequency resin composition

A resin composition and prepreg technology, used in integrated circuit packaging, high-frequency, high-speed and high-density interconnection, and electronic materials fields, can solve the problems of insufficient curing, falling off downstream lines, and poor hole wall quality, and achieve excellent copper Effects of foil peel strength and heat resistance, increased concentration, and increased benzene ring content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]According to the method in the synthesis example, 60g of prepolymer of diaminodiphenylmethane-type benzoxazine: styrene maleic anhydride = 100:36 was obtained by reacting at 140°C for 60 minutes, and the gelation time was controlled at 210°C. After 500~550 seconds, add an appropriate amount of methyl ethyl ketone to dissolve; after the anhydride-modified benzoxazine prepolymer is completely dissolved, add 23g of phosphorus-containing epoxy resin (XZ92530, Dow Chemical), 17g of phosphorus-containing flame retardant (XZ92741, Dow Chemical), 0.01g 2-ethyl-4 methylimidazole, 40g spherical silica, appropriate amount of butanone solvent, stir and mix evenly to obtain a glue with a solid content of 60%.

[0037] The glue is dipped and coated on E glass fiber cloth (2116, the unit weight is 104g / m 2 ) and baked in an oven at 135°C for 5 minutes to obtain a prepreg with a resin content of 50%.

[0038] The prepared prepreg with a resin content of 50% was placed with a metal copp...

Embodiment 2

[0041] According to the method in the synthesis example, react at 130°C for 40 minutes to prepare 60 g of prepolymer of bisphenol F type benzoxazine: 3,3',4,4'-biphenyltetracarboxylic dianhydride=100:100, condensate The gelation time is controlled at 700-750 seconds at a temperature of 210°C, and an appropriate amount of methyl ethyl ketone is added to dissolve; after the anhydride-modified benzoxazine prepolymer is completely dissolved, 25g of phosphorus-containing epoxy resin (XZ92530, Dow Chemical), 15g of phosphorus-containing flame retardant (XZ92741, Dow Chemical), 0.05g of stannous octoate, 40g of spherical silica, and an appropriate amount of butanone solvent were stirred and mixed evenly to obtain a glue with a solid content of 60%.

[0042] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

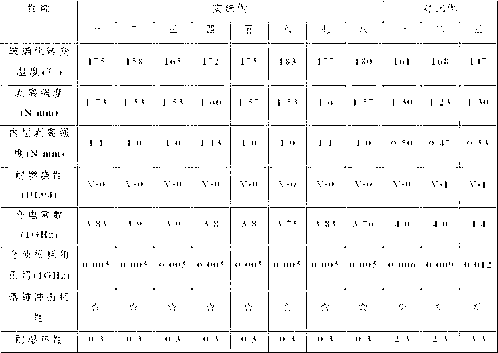

[0043] The properties of the obtained copper-clad laminates are shown in Table 1.

Embodiment 3

[0045] According to the method in the synthesis example, react at 150°C for 50 minutes to prepare 55g of prepolymer of bisphenol A benzoxazine: 3,3',4,4'-diphenyl ether tetra-acid dianhydride=100:70, The gelation time is controlled at 1000-1100 seconds at a temperature of 210°C, and an appropriate amount of methyl ethyl ketone is added to dissolve; after the anhydride-modified benzoxazine prepolymer is completely dissolved, 25g of naphthalene ring epoxy resin (NC-7300, Japan Chemicals), 20g phosphorus-containing flame retardant (XZ92741, Dow Chemical), 0.05g 2-ethyl-4 methylimidazole, 40g spherical silica, appropriate amount of butanone solvent, stir and mix evenly to obtain 60% solid content glue.

[0046] The preparation methods of the prepreg and the copper-clad laminate are the same as in the first embodiment.

[0047] The properties of the obtained copper-clad laminates are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com