Flame-retardant silicone rubber and preparation method thereof

A technology of silicone rubber and flame-retardant fiber, which is applied in the field of silicone rubber to achieve the effect of improving flame-retardant effect, increasing utilization value, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: A flame-retardant silicone rubber, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0051] Step 1: Add the plant ash after straw burning and flame-retardant fiber into the mixing tank according to the weight ratio of 1:4. Wherein, the length of the flame-retardant fiber is between 8mm and 10mm. Add water into the mixing tank, the weight ratio of water to plant ash is 1:6, and stir for 15 minutes at a stirring speed of 20r / min to obtain wet modified plant ash.

[0052] The wet modified plant ash is taken from the mixing tank and kneaded into several granules to obtain the modified plant ash wet granules, wherein the particle size of the plant ash wet granules is controlled between 0.2-4 mm. When rubbing the wet modified plant ash, ensure that the surface of the wet modified plant ash is distributed with flame-retardant fibers, and make one end of the flame-retardant fiber embedded in ...

Embodiment 2~4

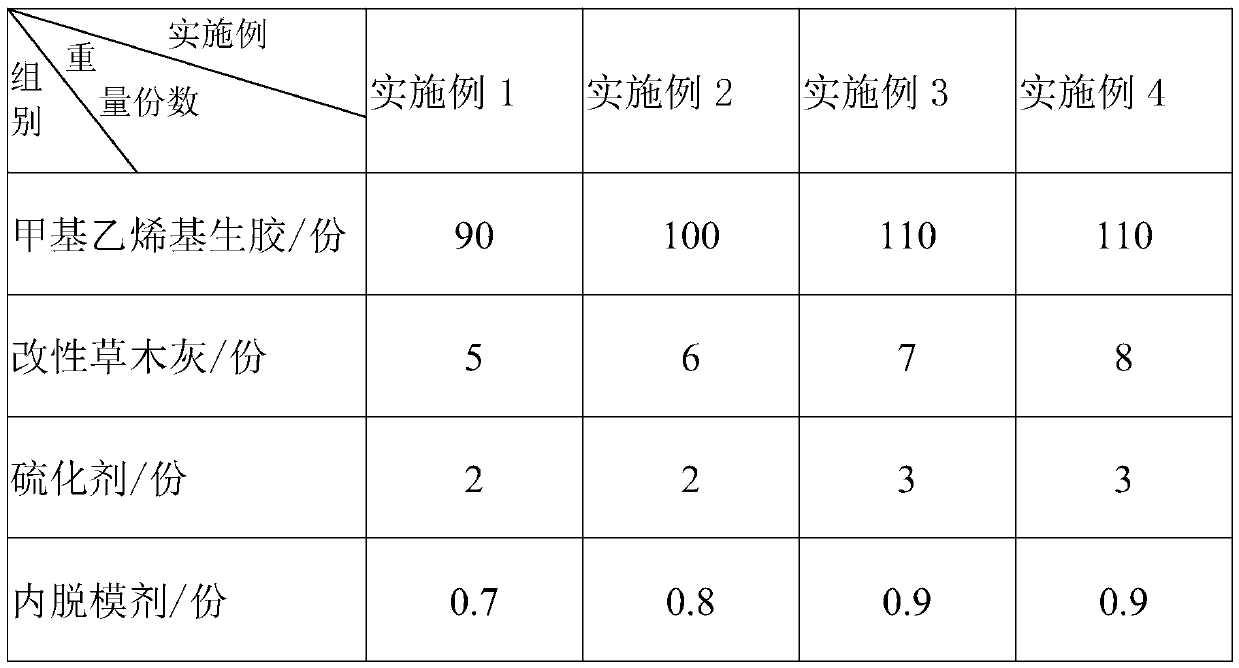

[0055] Embodiments 2-4: a flame-retardant silicone rubber, the difference from Embodiment 1 is that each component and its corresponding weight parts are shown in Table 1.

[0056] Each component and parts by weight thereof in Table 1 embodiment 1~4

[0057]

Embodiment 5

[0058] Embodiment 5: A kind of flame-retardant silicone rubber, the difference from Example 1 is that the raw material of silicone rubber also adds glass microspheres that are 1 part by weight, glass microspheres and methyl vinyl raw rubber Add it to the No. 1 mold together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com