A preparation method of silver tin oxide contact material improving sinterability of ingot

A silver tin oxide, sintering technology, applied in the direction of contacts, circuits, electrical components, etc., can solve the problems of hindering the contact and diffusion of Ag between powders, poor processing performance, and complicated chemical co-precipitation process, and achieve enhanced mutual sintering Effect of diffusion, improvement of processability, and superior sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh each component according to the following mass percentage, place it in an intermediate frequency induction melting furnace and melt it into a uniform alloy melt, and then atomize it through a high-pressure water atomization equipment, dry the obtained powder slurry, pass 200 Mesh sieve, very fine silver tin alloy powder;

[0035] Sn: 9.5%;

[0036] Additives: Bi 0.1%;

[0037] The balance is Ag;

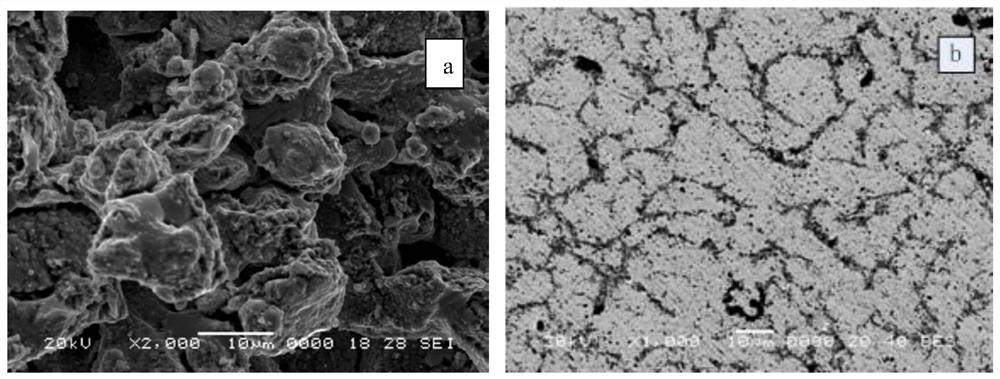

[0038] 2) Put the silver-tin alloy powder in a high-pressure oxidation furnace, oxidize it at an oxygen partial pressure of 1 MPa and a temperature of 700°C for 6 hours, take it out, crush it, and pass it through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0039] 3) Put the silver-tin oxide composite powder in a high-energy ball mill, and carry out wet milling treatment under the protection of atmosphere (Ar), until the particle size of the obtained powder is 1-2 μm, and put the wet-milled powder in an oven at Dry at 80°C for 10 hours to obtai...

Embodiment 2

[0051] 1) Weigh each component according to the following mass percentage, place it in an intermediate frequency induction melting furnace and melt it into a uniform alloy melt, and then atomize it through a high-pressure water atomization equipment, dry the obtained powder slurry, pass 200 Mesh sieve, very fine silver tin alloy powder;

[0052] Sn: 8%;

[0053] Additives: In 1%, Cu 1%, Ni 1%;

[0054] The balance is Ag;

[0055] 2) Put the silver-tin alloy powder in a high-pressure oxidation furnace, oxidize it at an oxygen partial pressure of 2 MPa and a temperature of 800°C for 4 hours, take it out, crush it, and pass it through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0056] 3) Put the silver tin oxide composite powder in a high-energy ball mill, and carry out wet milling treatment under the protection of atmosphere (Ar), until the particle size of the obtained powder is 2-4 μm, and put the wet-milled powder in an oven at Dry at 100°C for 6 hour...

Embodiment 3

[0061] 1) Weigh each component according to the following mass percentage, place it in an intermediate frequency induction melting furnace and melt it into a uniform alloy melt, and then atomize it through a high-pressure water atomization equipment, dry the obtained powder slurry, pass 200 Mesh sieve, very fine silver tin alloy powder;

[0062] Sn: 10%;

[0063] Additives: Zn2%;

[0064] The balance is Ag;

[0065] 2) Put the silver-tin alloy powder in a high-pressure oxidation furnace, oxidize it at an oxygen partial pressure of 0.5 MPa, and a temperature of 800°C for 8 hours, take it out, crush it, and pass it through a 100-mesh sieve to obtain a silver-tin oxide composite powder;

[0066] 3) Put the silver tin oxide composite powder in a high-energy ball mill, and carry out wet milling treatment under the protection of the atmosphere (Ar), until the particle size of the obtained powder is 3-5 μm, and put the wet-milled powder in an oven at Dry at 90°C for 9 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com