An external water cooling pulverizer

A technology of water cooling and pulverizer, which is applied in the direction of grain processing, etc. It can solve the problems of high airtightness requirements of the interlayer cooling chamber, the pulverizer cannot work for a long time, and the vibration of the shell is relatively severe, so as to achieve good pulverization effect and favorable temperature transmission, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

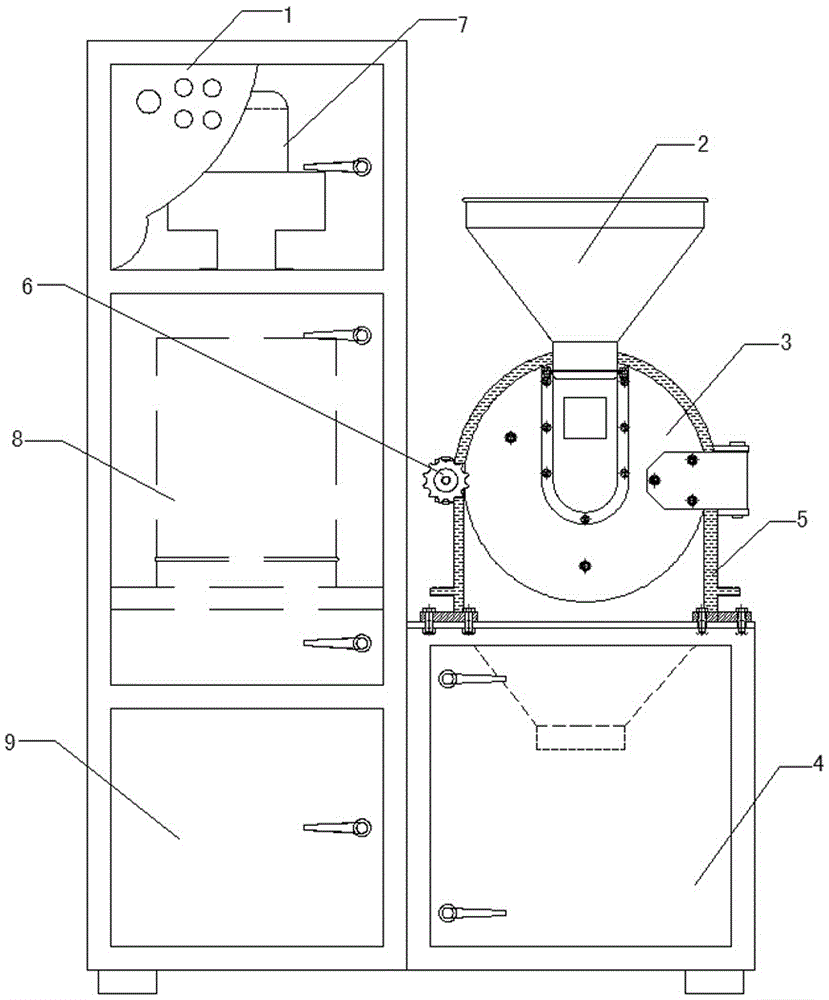

[0013] An external water-cooled pulverizer according to the present invention has a structure such as figure 1 As shown, it includes a motor room 1 and a crushing device.

[0014] The motor room 1 of this embodiment provides power for the whole pulverizer. At the same time, a dust suction fan 7 is arranged in the motor room 1, a filter box 8 and a dust collection box 9 are arranged at the bottom of the motor room 1, and the dust outlet of the dust suction fan 7 It is connected to the filter box 8, and the outlet of the filter box 8 is connected to the dust collection box 9, so that the dust is filtered by the filter box 8 and then enters the dust collection box 9 for recovery. There is no dust flying during the production process, and the utilization rate of materials can be improved. Through the cooling effect of cooling water, the melting phenomenon of heat-sensitive materials in the crushing process is solved, the utilization rate of materials is improved, and the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com