A kind of preparation method of titanium powder or titanium alloy powder special for porous titanium film

A titanium alloy and porous titanium technology, which is applied in the field of preparation of titanium powder or titanium alloy powder for porous titanium film, can solve the problem of high-precision corrosion-resistant porous titanium and titanium alloy film, large particle size difference of titanium powder, powder Oxygen content and iron content are high, to avoid incomplete hydrogenation, improve the degree of hydrogenation embrittlement, and reduce the effect of oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

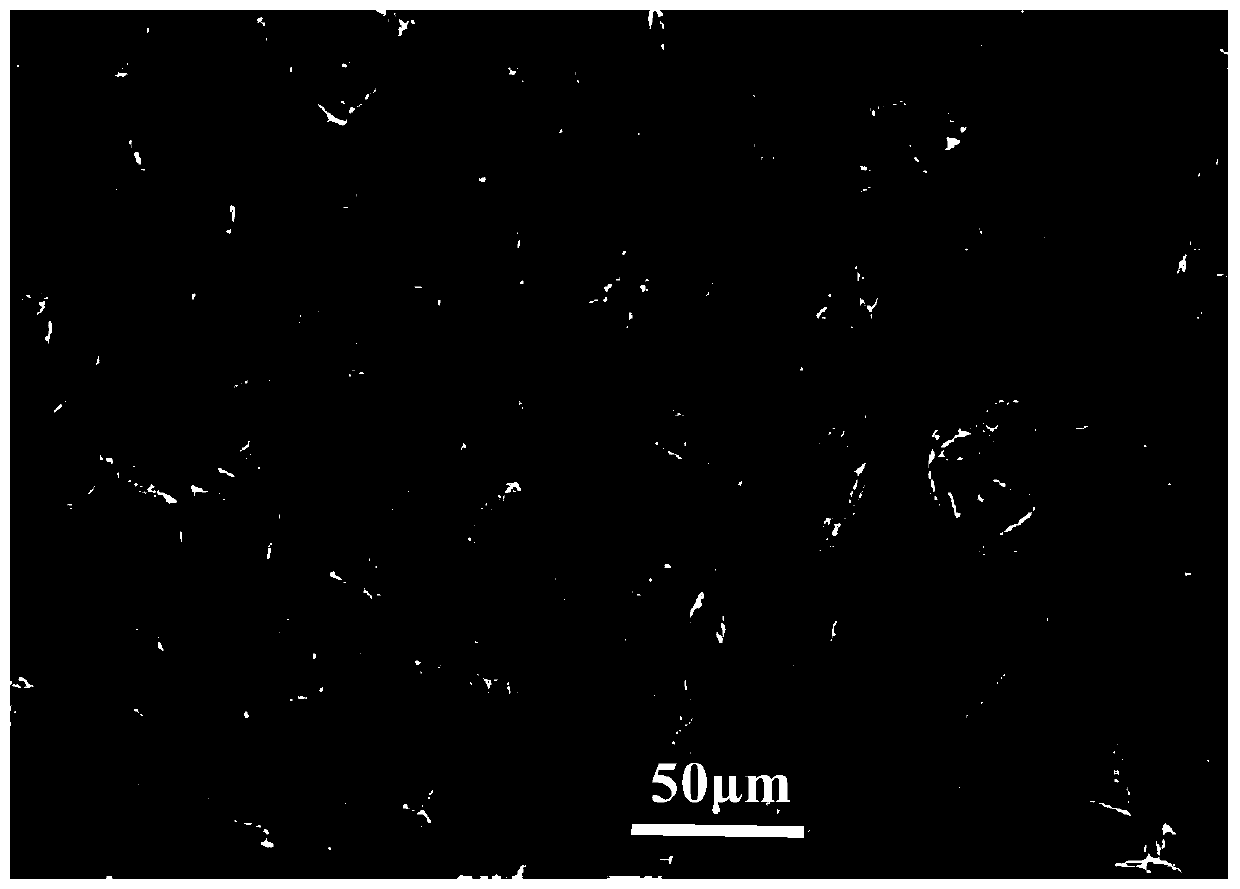

Image

Examples

Embodiment 1

[0034] The furnace and the heating furnace shell of the dual-purpose heating furnace adopted in the preparation method of this embodiment can be freely separated. The two ends of the furnace are respectively the furnace door end and the airtight end. It is connected with the hydrogen gas inlet, a vacuum valve is arranged between the furnace door end and the vacuum system, and a hydrogen valve and a pressure gauge are arranged between the furnace door and the hydrogen gas inlet. The method includes the following steps:

[0035] Step 1. Press 3 kg of purified titanium scraps into shape to obtain titanium blocks, and then place the titanium blocks in the furnace of a dual-purpose heating furnace; washing and drying;

[0036] Step 2, open the vacuum valve of the dual-purpose heating furnace described in step 1, use a diffusion pump and use a mechanical pump as the backing pump to evacuate the furnace until the vacuum degree is 10 -3 Pa, then push the furnace from the closed end i...

Embodiment 2

[0044] The furnace and the heating furnace shell of the dual-purpose heating furnace adopted in the preparation method of this embodiment can be freely separated. The two ends of the furnace are respectively the furnace door end and the airtight end. It is connected with the hydrogen gas inlet, a vacuum valve is arranged between the furnace door end and the vacuum system, and a hydrogen valve and a pressure gauge are arranged between the furnace door and the hydrogen gas inlet. The method includes the following steps:

[0045] Step 1. Compress 100kg of titanium sponge to obtain a titanium block, and then place the titanium block in the furnace of a dual-purpose heating furnace;

[0046] Step 2, open the vacuum valve of the dual-purpose heating furnace described in step 1, use a diffusion pump and use a mechanical pump as a backing pump to evacuate the furnace until the vacuum degree is 10 -3 Pa, then push the furnace into the furnace shell from the closed end and heat it to 25...

Embodiment 3

[0054] The furnace and the heating furnace shell of the dual-purpose heating furnace adopted in the preparation method of this embodiment can be freely separated. The two ends of the furnace are respectively the furnace door end and the airtight end. It is connected with the hydrogen gas inlet, a vacuum valve is arranged between the furnace door end and the vacuum system, and a hydrogen valve and a pressure gauge are arranged between the furnace door and the hydrogen gas inlet. The method includes the following steps:

[0055] Step 1, press 10 kg of purified TC4 titanium alloy chips to obtain TC4 titanium alloy blocks, and then place the TC4 titanium alloy blocks in the furnace of a dual-purpose heating furnace; the purification treatment of the TC4 titanium alloy chips follows For sorting and separation, acid-base washing, water washing and drying;

[0056] Step 2. Open the vacuum valve of the dual-purpose heating furnace described in step 1, and use a diffusion pump and use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com