Micro-fine processing system of femtosecond laser for material surface modification

A femtosecond laser and surface modification technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced processing efficiency, low processing efficiency, poor space quality, etc., and achieve smooth, smooth and precise processing surface Effect of less processing and processing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

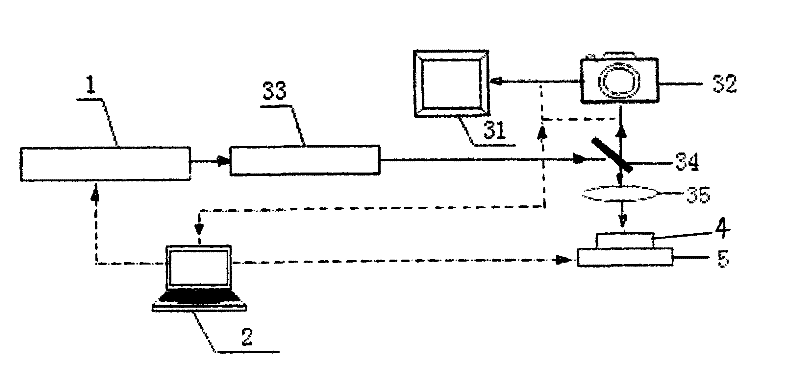

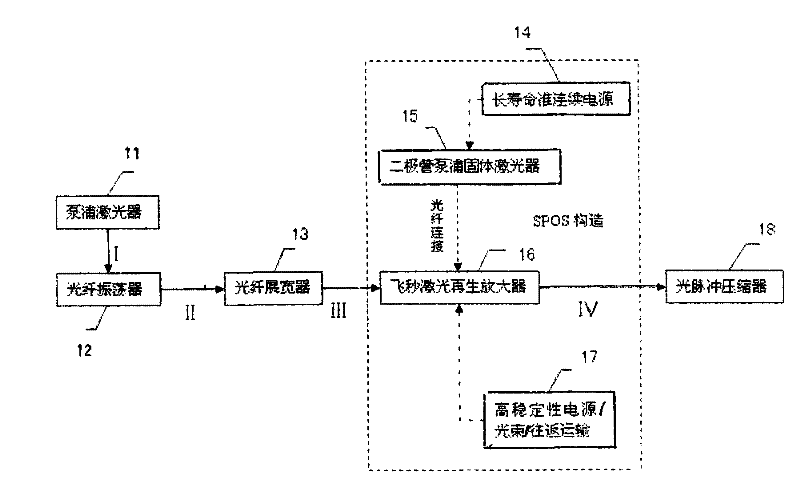

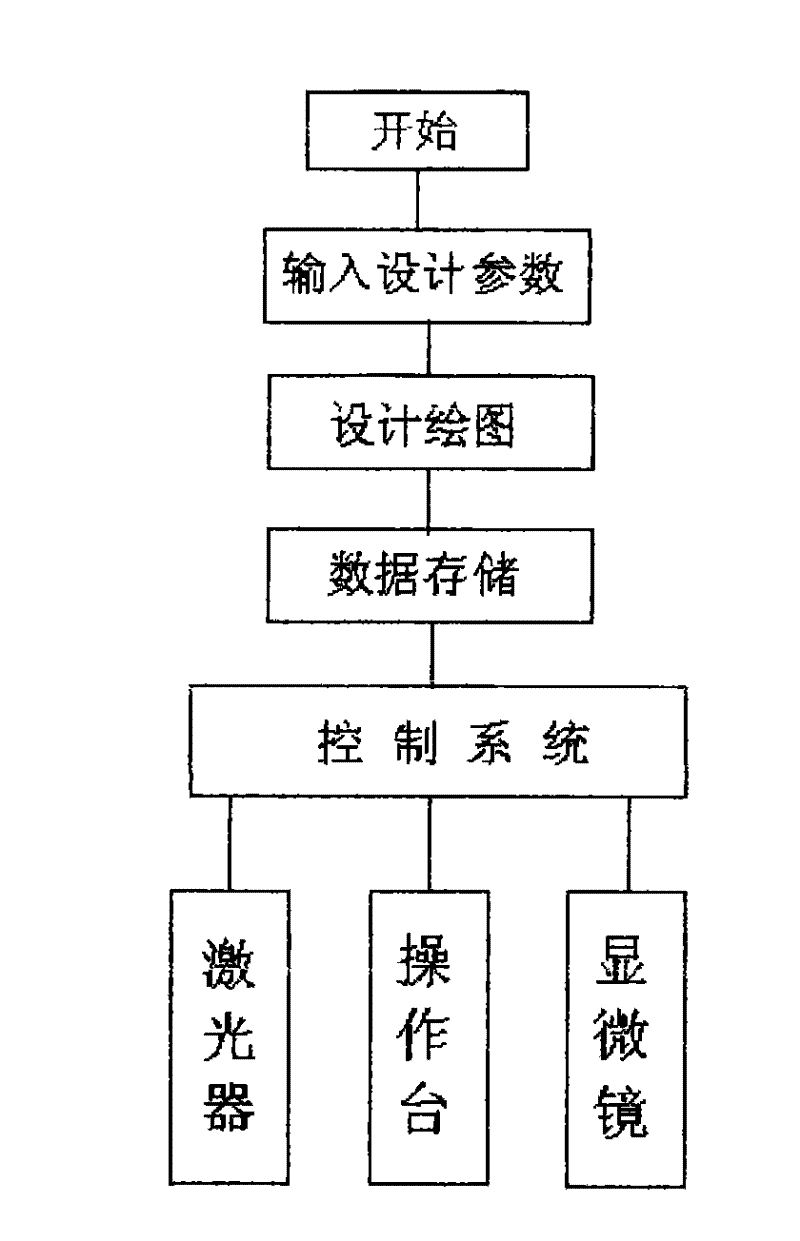

[0021] See attached figure 1 , the femtosecond laser of the present invention modifies the microfine processing system of material surface by femtosecond laser 1, microscopic optical path system, high-precision three-dimensional workbench 5 and control system host computer (system control management software) 2 four parts constitute . The laser beam emitted by the femtosecond laser 1 is focused and irradiated on the processed part 4 located at the three-dimensional workbench 5 through the microscopic optical system. Connection, the mobile control input end of the three-dimensional workbench 5 is connected with the workbench work signal output end of the control system host 2, the signal output / input end of the CCD monitoring imaging unit in the microscopic optical path system is connected with the CCD signal input / input end of the control system host 2 Output connection.

[0022] In the process of material surface modification by femtosecond laser, the laser energy and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com