Patents

Literature

44results about How to "Smooth processing surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

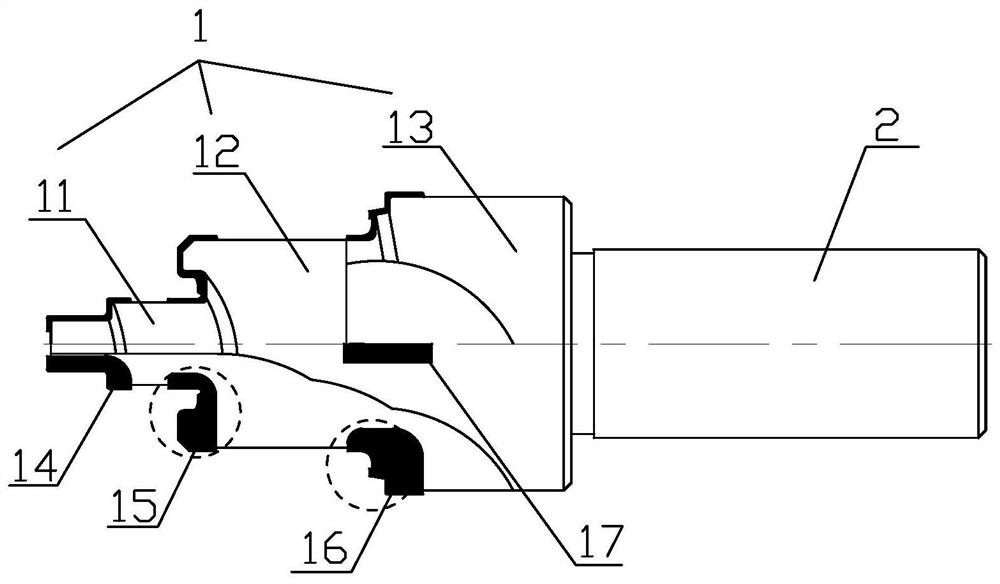

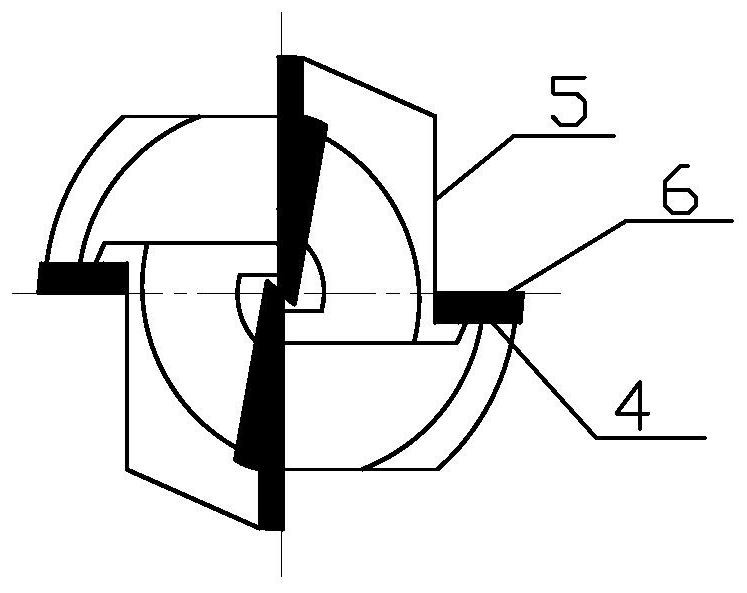

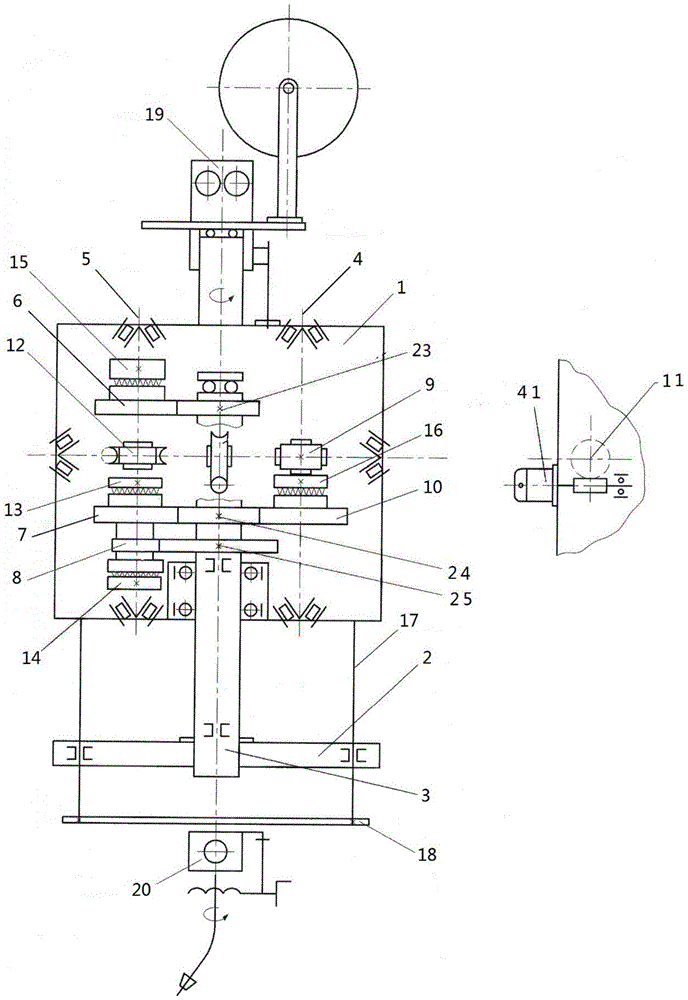

Multifunctional laser processing tool bit with measuring apparatus

InactiveCN101134266AImprove processing efficiencyGood performanceLaser beam welding apparatusMeasurement devicePlane mirror

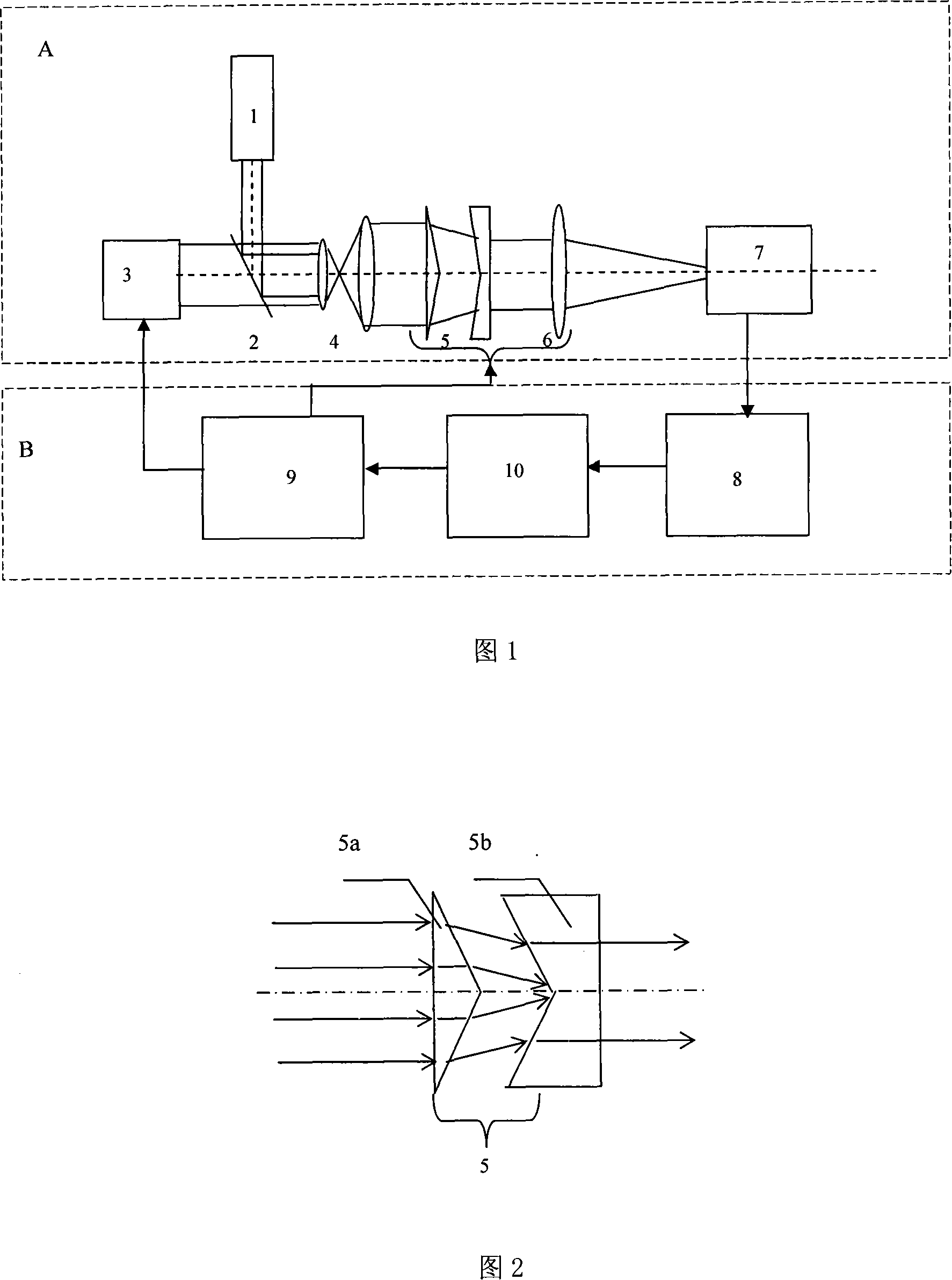

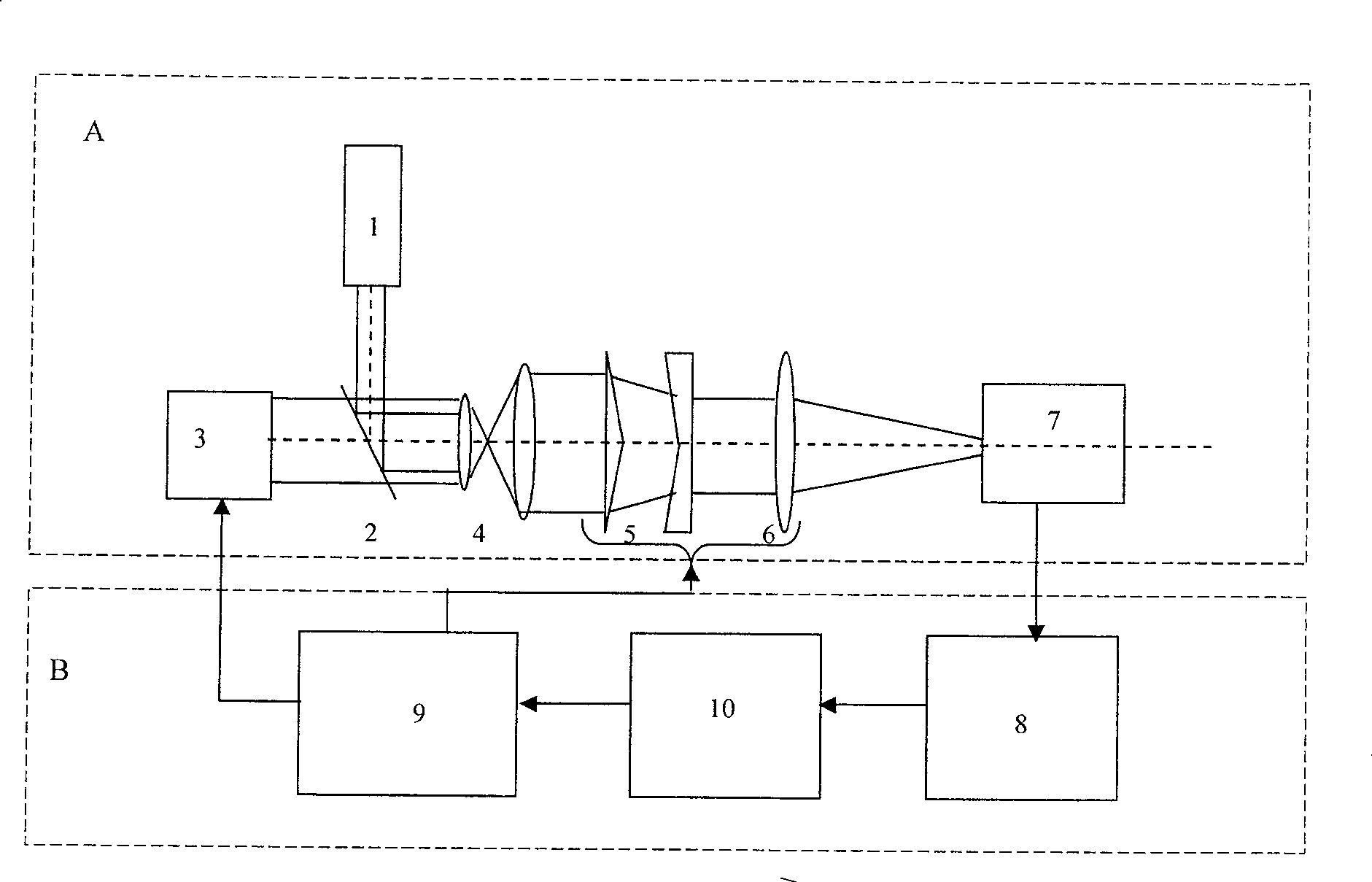

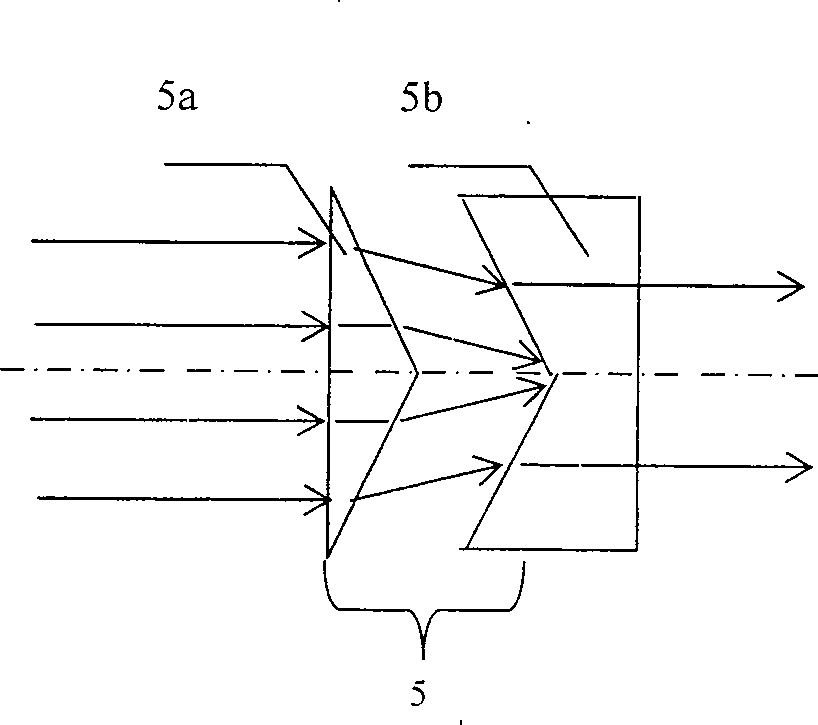

The present invention relates to laser processing, opto electromechanical technology and image processing technology, and is especially one multifunctional laser cutter with one measurement unit. The multifunctional laser cutter has adjustable laser spot with changeable spot shape and energy distribution for boring, cutting, welding and other functions. It includes one optical system and one signal acquiring, signal processing and controlling device. The optical system includes an He-Ne laser, a CO2 laser, a plane mirror, a beam expanding collimator, a positive rotating prism, a negative rotating prism and a focusing lens; and the signal acquiring, signal processing and controlling device includes a signal acquiring and processing unit, a controller and a feedback circuit.

Owner:XIAMEN UNIV

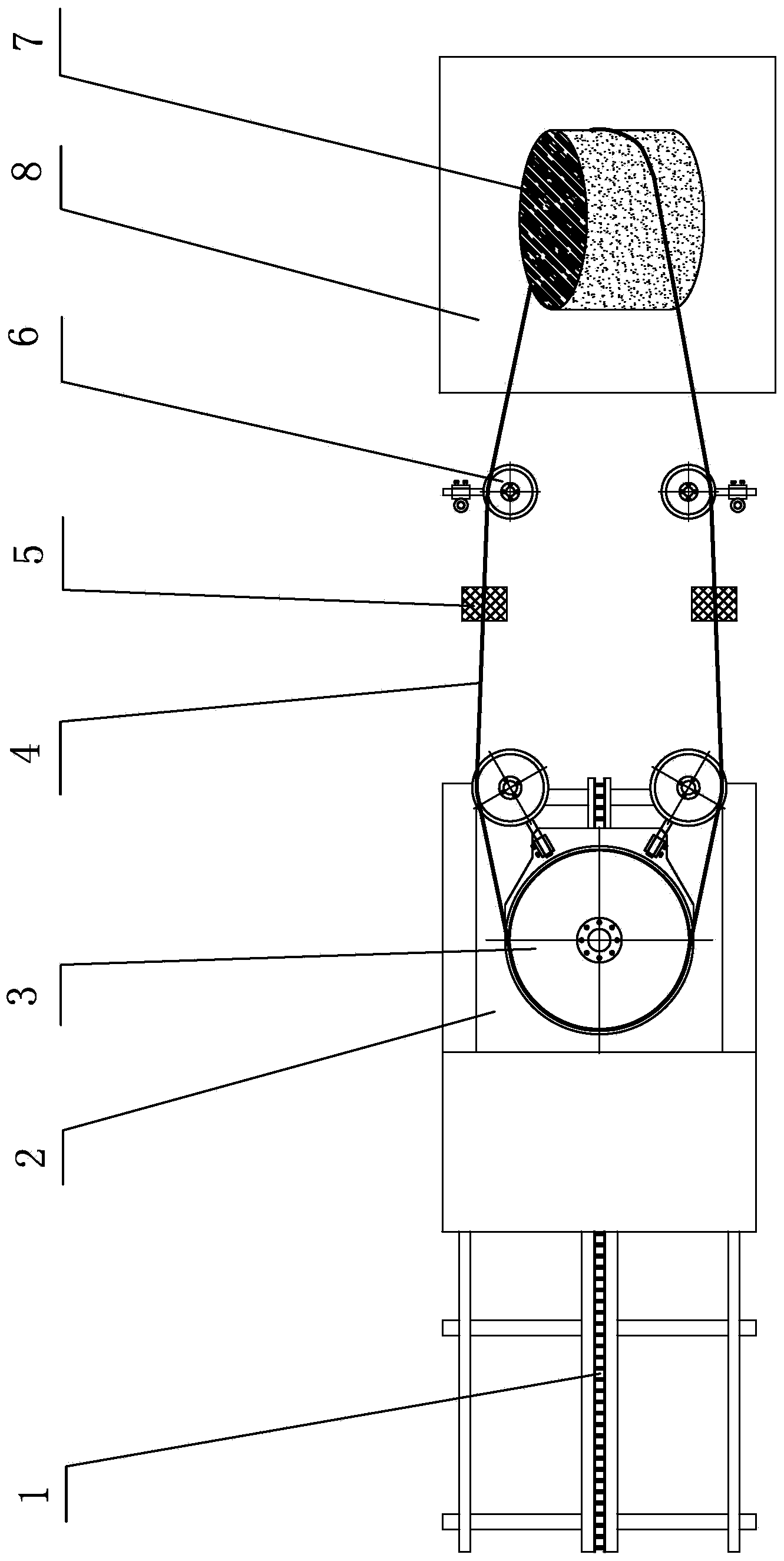

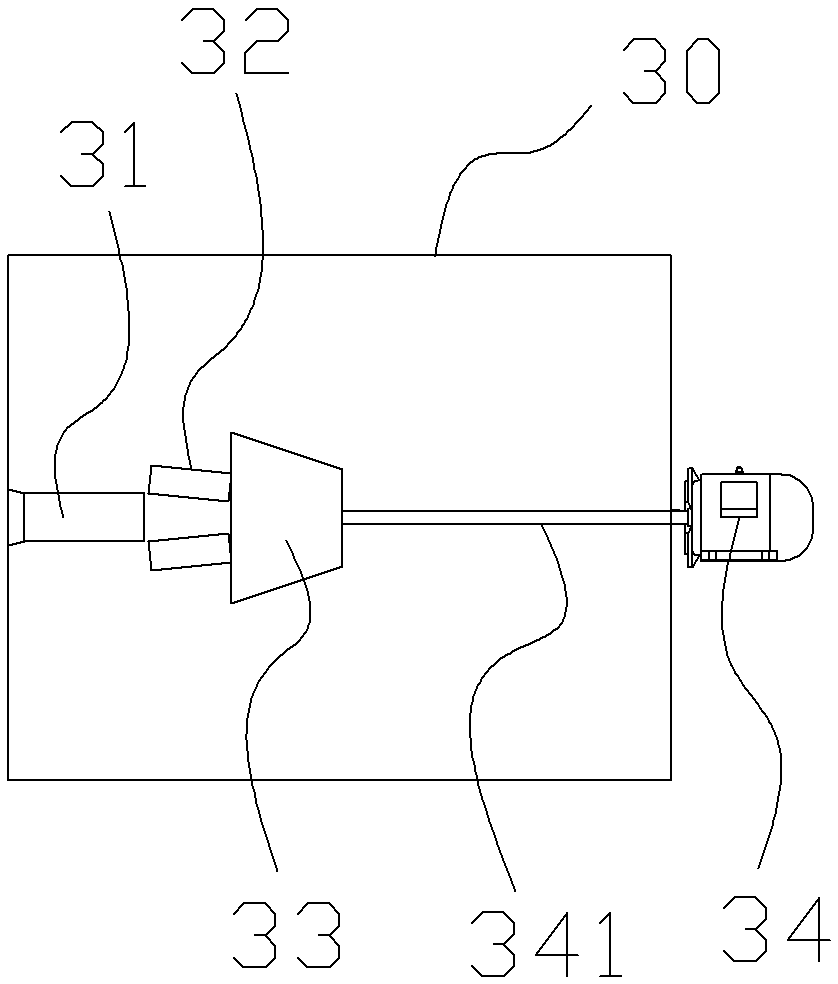

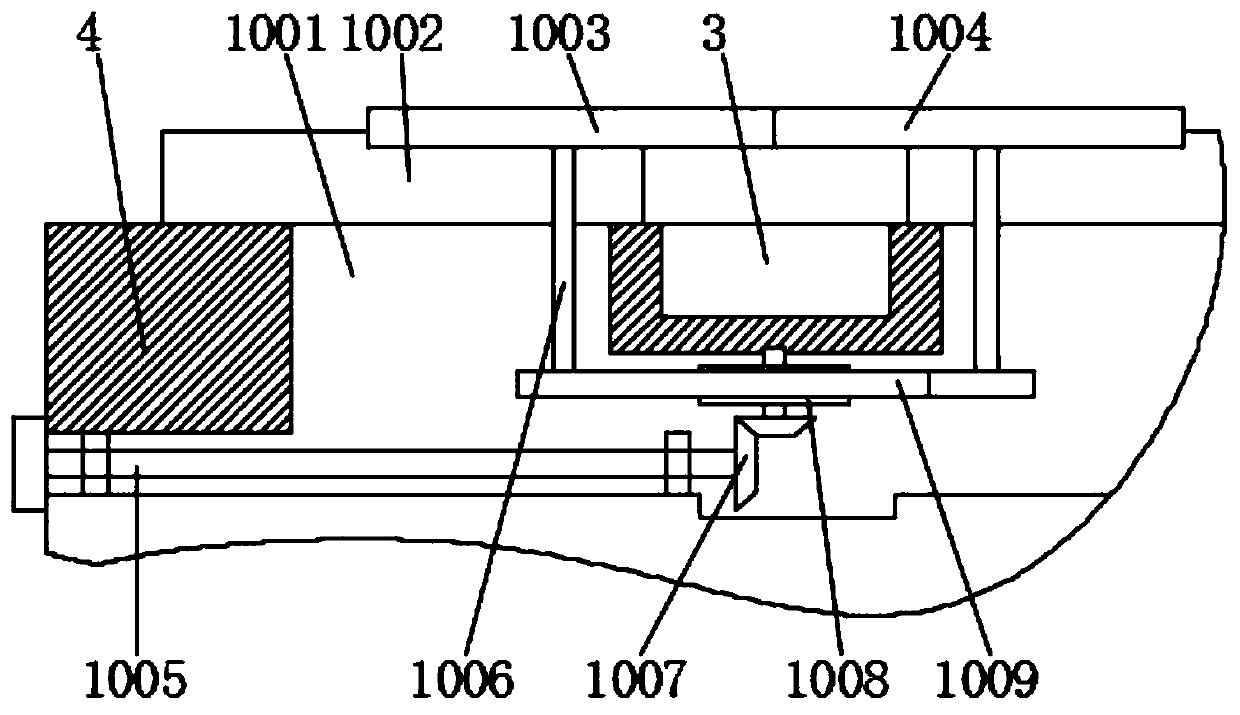

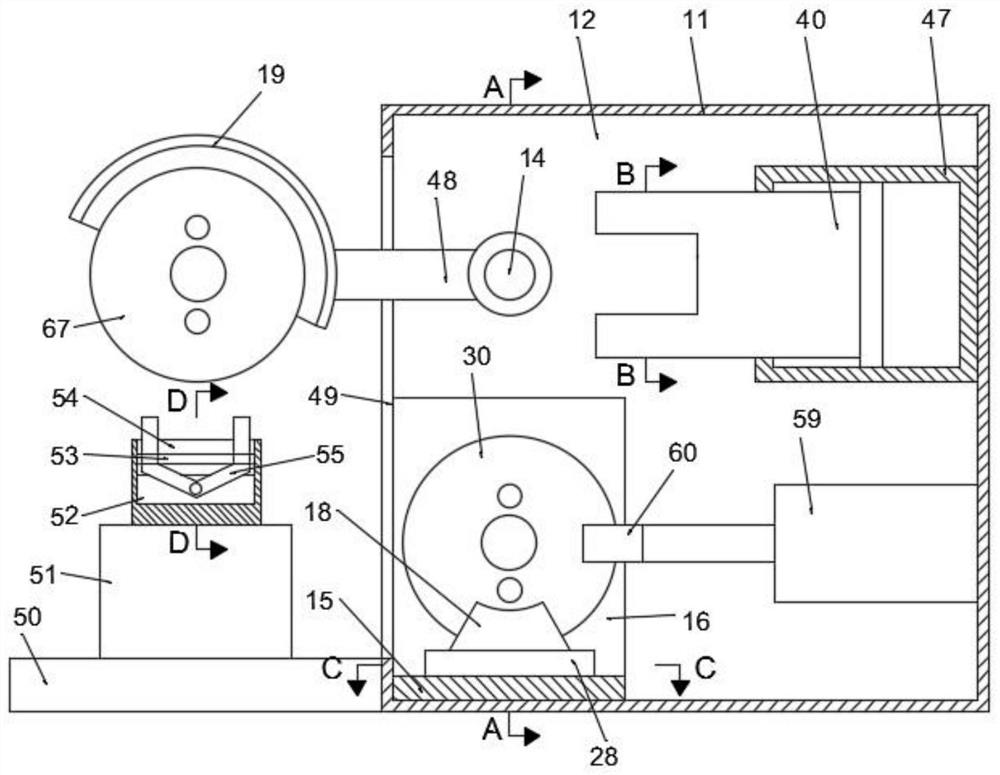

Full-automatic silicon single-crystal rod rolling and grinding integrated equipment

ActiveCN106475878AReduce time between processesImprove processing efficiencyGrinding carriagesGrinding drivesManipulatorEcological environment

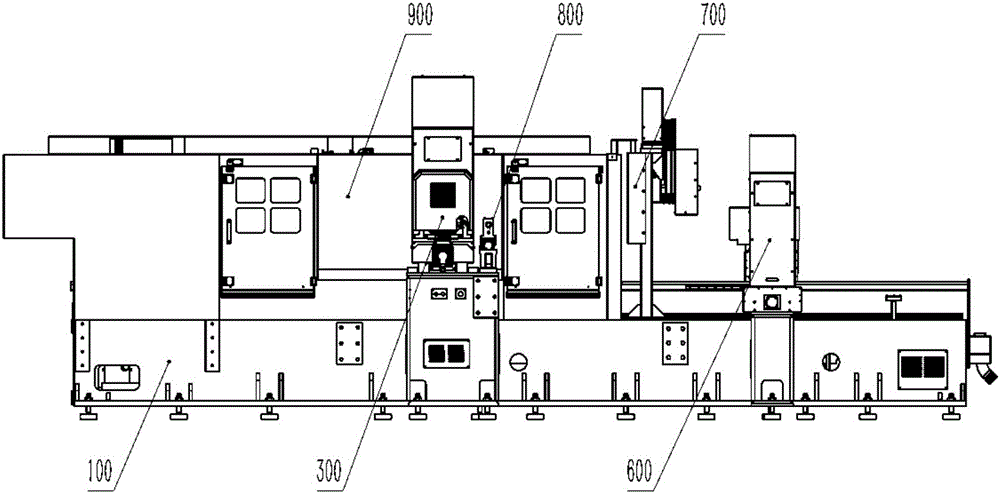

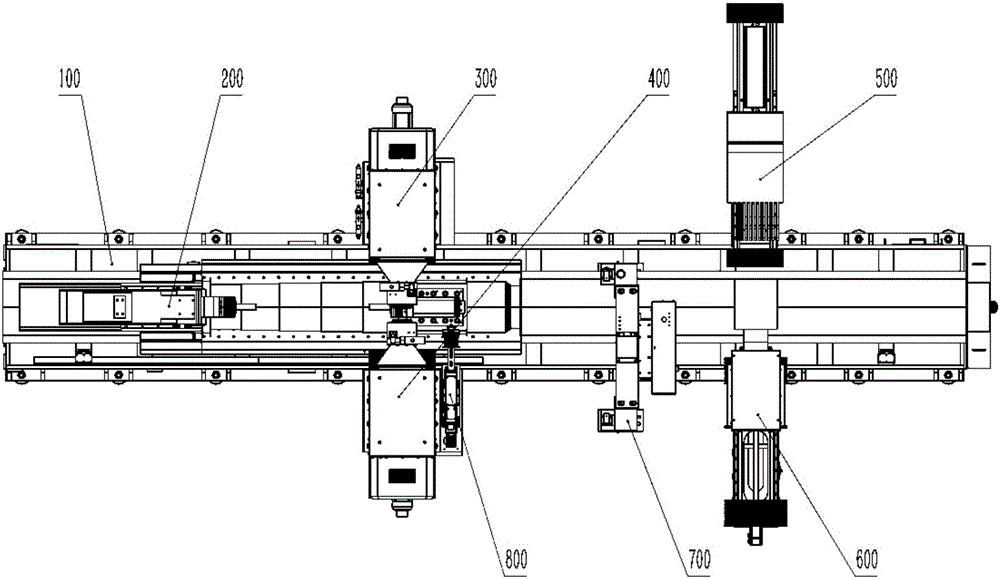

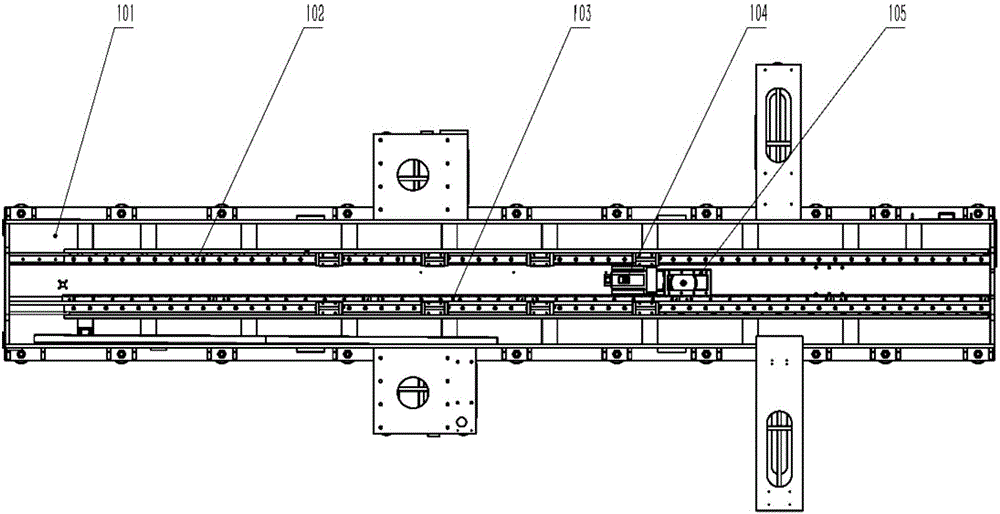

The invention relates to silicon single-crystal rod machining equipment and aims to provide full-automatic silicon single-crystal rod rolling and grinding integrated equipment which comprises a long-strip-shaped large bottom frame. Two parallel main guide rails are arranged on the surface of the large bottom frame in the length direction. A grinding work table assembly is movably installed on the two main guide rails, and a main driving motor drives a connecting mechanism so that the grinding work table assembly can move along the main guide rails. Four platforms used for bearing are arranged on the two sides of the large bottom frame and used for bearing a coarse grinding power head assembly, a fine grinding power head assembly, a feeding mechanical hand assembly and a centering mechanical hand assembly correspondingly. A crystal orientation detecting device and a radius detecting unit are further arranged on the large bottom frame. The machining range of the crystal rod rolling and grinding equipment is widened greatly, the machining ability of the crystal rod rolling and grinding equipment is improved greatly, and a silicon bar can be centered automatically; the machining efficiency is improved, and cost of manpower and logistics is saved; long and stable high-precision operation of the equipment can be ensured; and the production noise is remarkably reduced, no organic matter emission is generated, less waste is generated, and the ecological environment is protected.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Large alloy steel part cutting method through diamond wire saw

InactiveCN104070231ASmooth surfaceReduce cutting lossMetal sawing devicesAlloy steelDiamond wire saw

The invention discloses a large alloy steel part cutting method through a diamond wire saw. Firstly, hanging a large alloy steel part to be cut to a cutting working platform, determining a cutting position of the large alloy steel and making a marker line, then mounting a diamond wire saw, putting the diamond wire saw to the position of the marker line, and adjusting the cutting device to enable the diamond wire saw to be perpendicular to the marker line; secondly, cooling the large alloy steel part with coolant, performing grinding and cutting through closed-loop high-speed rotating of the diamond wire saw; finally, cutting the large alloy steel part to finish cutting. According to the large alloy steel part cutting method through the diamond wire saw, the selected diamond saw is flexible and belongs to high-speed cold machining, not only machining damage and deformation of the large alloy steel part to be cut can be avoided, but also the cutting efficiency and accuracy of the large alloy steel part can be improved, and labor intensity can be effectively reduced.

Owner:GUILIN TEBON SUPERHARD MATERIAL

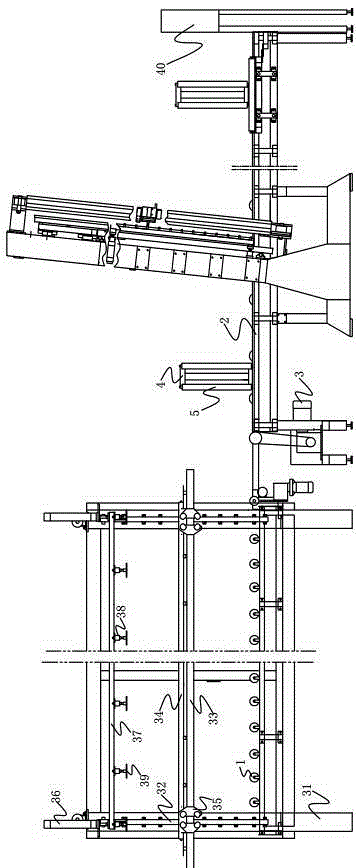

Foam plate cutting machine

ActiveCN105291164ASolve the blocking problemEasy to transportMetal working apparatusAutomationEngineering

The invention discloses a foam plate cutting machine. The foam plate cutting machine comprises a workbench with wheels. The wheels are driven through a motor arranged on the workbench. Linkage cutting devices used for evenly cutting a large plate into a plurality of thin plates are arranged on the two sides of the workbench. The cutting devices are provided with wire adjusting devices used for adjusting the number of cutting wires and the distance between the cutting wires. The workbench is further provided with a segmented cutting device used for cutting the thin plates into finished plates in a segmented manner. The foam plate cutting machine further comprises a control device used for controlling the motor, the cutting devices, the wire adjusting devices and the segmented cutting device. The foam plate cutting machine is high in automation degree, wide in machining range and capable of achieving rapid cutting. The cut planes of the cut plates are smooth, the cutting quality is good, the cutting efficiency is high, the cutting process is free of retardation, and environment friendliness is high.

Owner:QINGDAO HEINOSKY TECH CO LTD

Efficient precise grinding process for titanium alloy material

The efficient precise grinding process of titanium alloy workpiece in a conventional apparatus includes the following steps: trimming super high speed resin adhered diamond grinding wheel or ceramic bonder adhered CBN grinding wheel to outer jiggling within 5 micron and sharpening; performing real-time dynamic balancing of the grinding wheel with a dynamic balancing system to unbalance amount within 0.1 micron; and grinding titanium alloy workpiece in the conditions of water-base cooling liquid supplying pressure of 7-9 MPa, grinding wheel grinding rate of 3.3-180 cu mm / mm.s, grinding wheel linear speed of 60-150 m / s, grinding depth of 0.1-1.8 mm and workpiece feeding speed of 1-6 m / min. The present invention has high titanium alloy workpiece grinding efficiency, low cost and high grinding quality.

Owner:HUNAN UNIV

Film sandpaper production method

The invention discloses a film sandpaper production method. The method includes the steps of PET (polyester) film treating, primer coating, abrasive embedding, pre-drying, composite adhesive coating, primary drying, curing and anti-clogging coating applying. A PET film treated through corona or chemical coating has strong adhesion. The primer is a bottom layer adhesive composed of polyamine resin, a curing agent and an organic solvent of xylene. A second layer adhesive comprises modified phenolic resin, a coupling agent and a grinding aid, enables abrasive to be firm in adhesion and can obtain good sharpness and cutting polishing capacity. The anti-clogging coating is composed of lubricating filler, an adhesive and an antistatic agent. By means of the film sandpaper production method, sandpaper good in flexibility, not prone to deformation, high in strength, good in anti-clogging effect and flat in machining surface can be produced.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

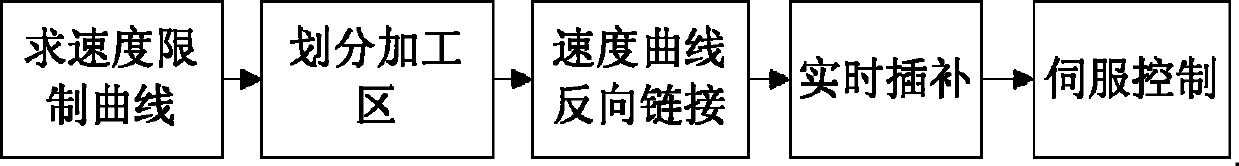

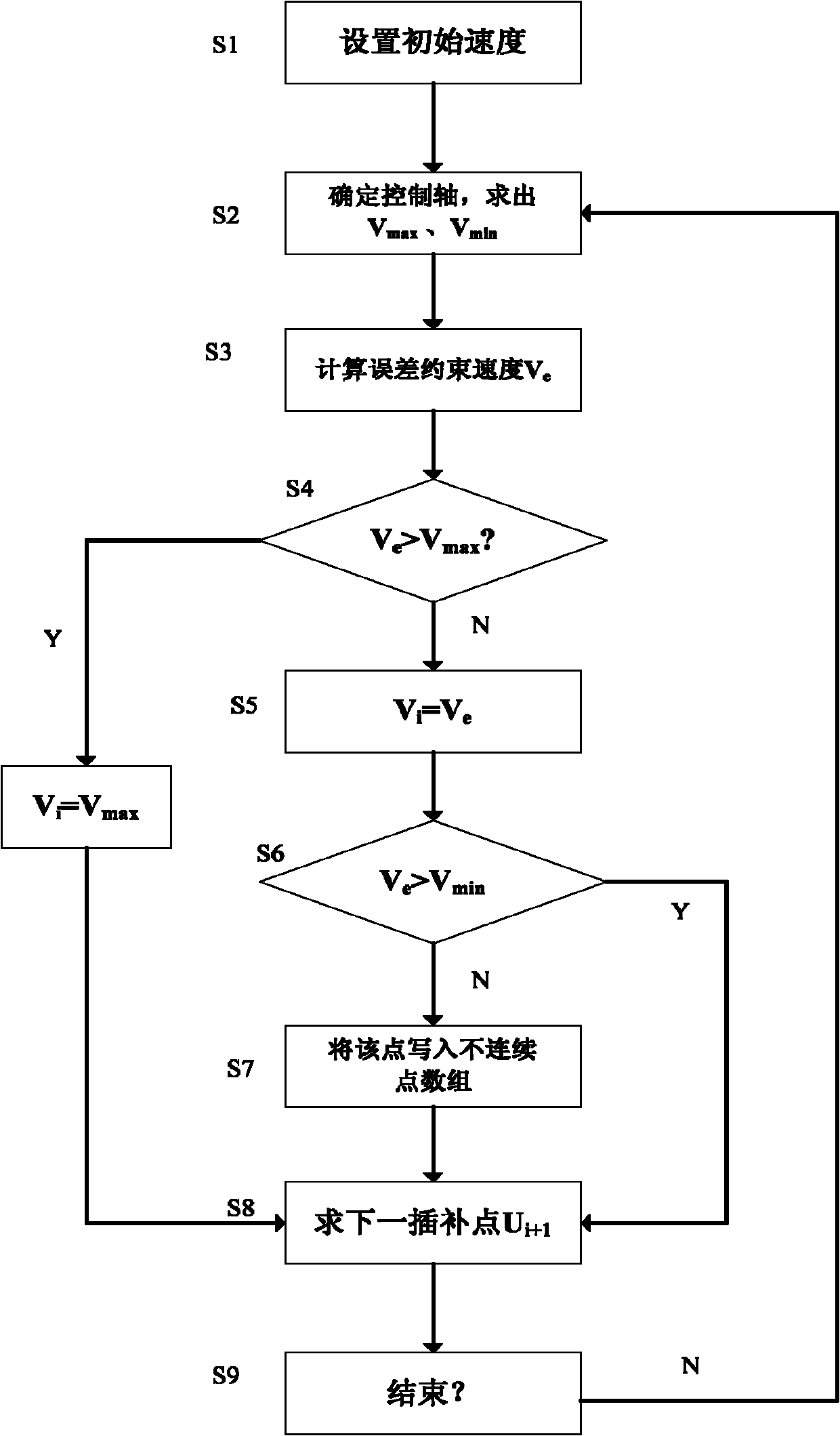

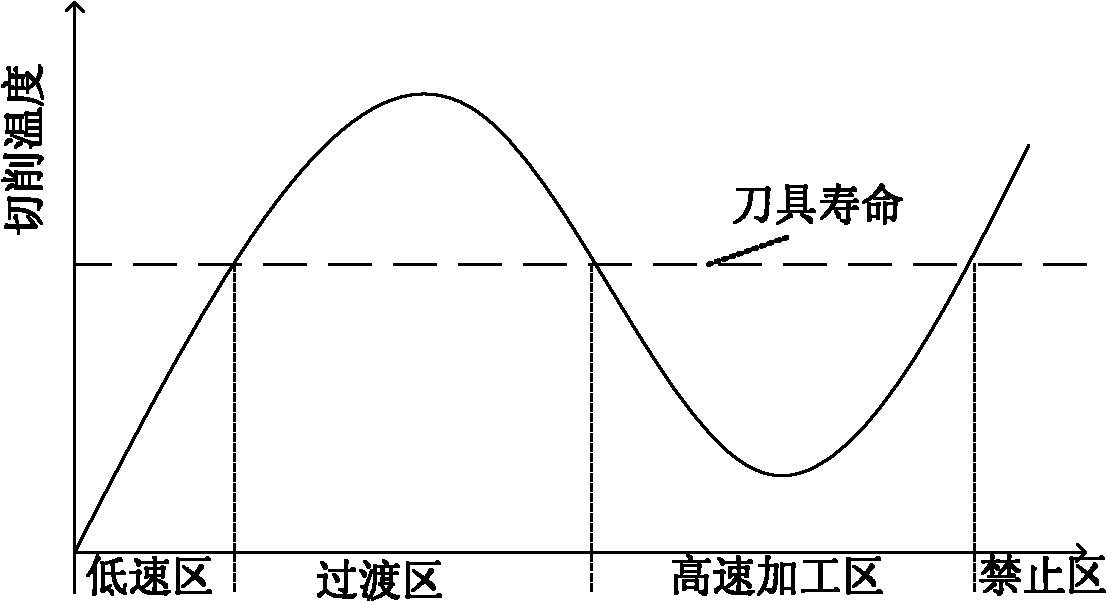

Speed-priority spline real-time interpolation method facing high-speed processing

ActiveCN102566510AImprove processing efficiencyCompromise of tool wear and machining qualityProgramme controlComputer controlNumerical control systemCritical speed

The invention relates to a speed-priority spline real-time interpolation method facing the high-speed processing, which comprises the following steps of: obtaining a speed limit curve, i.e. obtaining the speed limit curve according to a processing error and constraint conditions of the maximum acceleration of each movement shaft in an interpreter of a numerical control system; dividing a processing region, i.e. according to information of a critical speed that processed materials enter the high-speed processing region, dividing the speed processing region and modifying an initial speed curve to obtain a modified speed curve; carrying out backward chaining on the speed curve, i.e. removing speed discontinuous points on the modified speed curve, so that the integral speed curve is continuous; and carrying out real-time interpolation, i.e. according to the speed curve subjected to backward chaining, carrying out interpolation algorithm to complete the speed-priority spline real-time interpolation. The invention provides a time approximation optimal spline curve interpolation method. In the speed-priority spline real-time interpolation method, on the premise of ensuring the stable operation of a machine tool, the maximum acceleration capacity of a single shaft is sufficiently utilized, so that the requirement of the numerical control system on the high-speed processing is met.

Owner:中国科学院沈阳计算技术研究所有限公司

Point molding method for full silica gel hemodialysis catheter

The invention provides a point molding method for a full silica gel hemodialysis catheter. The point molding method comprises the following steps that firstly, the silica gel catheter is placed in an airtight container provided with a placement valve allowing liquid nitrogen to be placed, a release valve for releasing the liquid nitrogen and a turnover door allowing entering and going-out of the silicone rubber catheter; secondly, the liquid nitrogen is poured into the airtight container to enable the liquid nitrogen to immerse the silica gel catheter, soaking is conducted for at least one minute, and the silica gel catheter is hardened through cooling of the liquid nitrogen; and thirdly, the liquid nitrogen in the airtight container is quickly released, then the hardened silica gel catheter is taken out from the airtight container, and the hardened silica gel catheter is immediately machined into a silica gel catheter with a point through a chamfering machine. Using the low-temperature freezing effect of the liquid nitrogen, the temperature of a silica gel material reaches -100 DEG C, the silica gel material is hardened, then the hardened silica gel catheter is quickly taken out to be machined , the machined appearance and size are greatly improved, namely, the machining surface is further relatively smooth, and the size is stable.

Owner:佛山特种医用导管有限责任公司

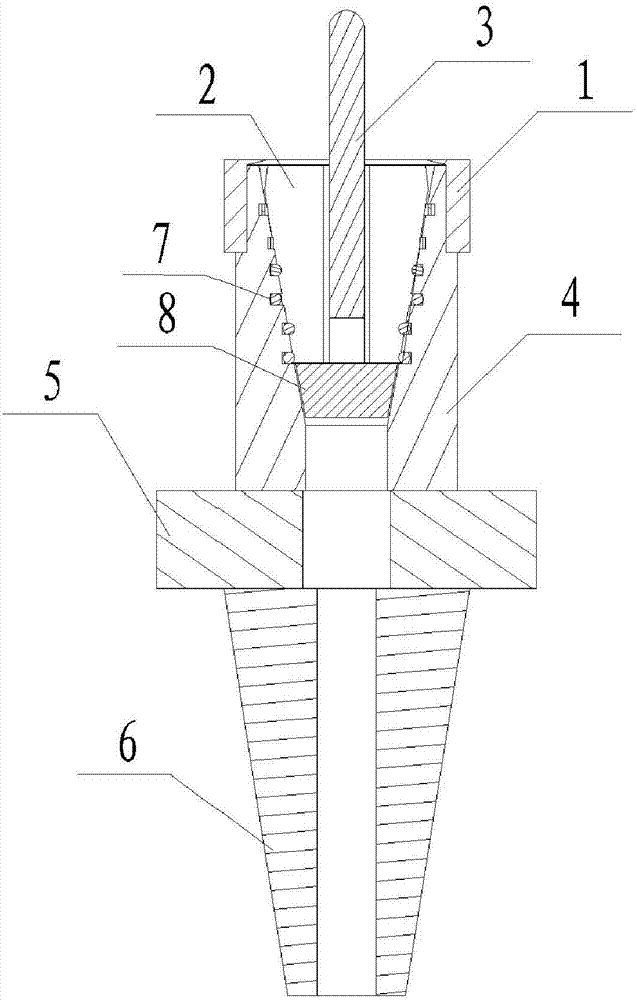

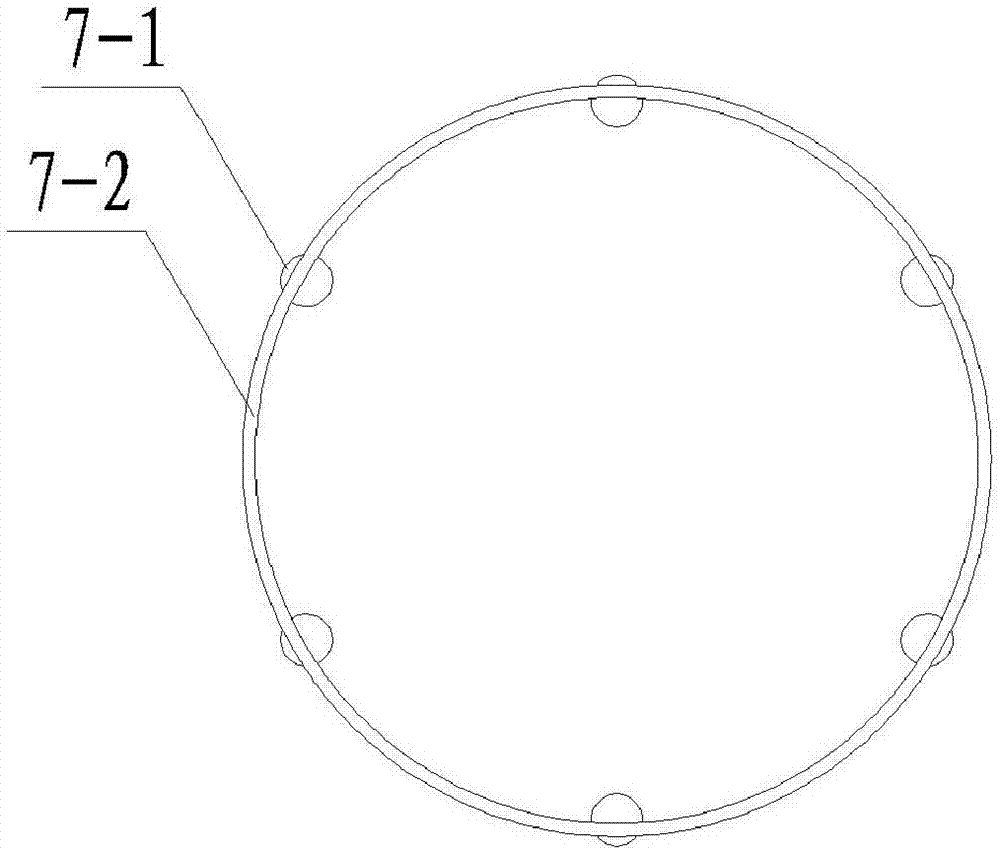

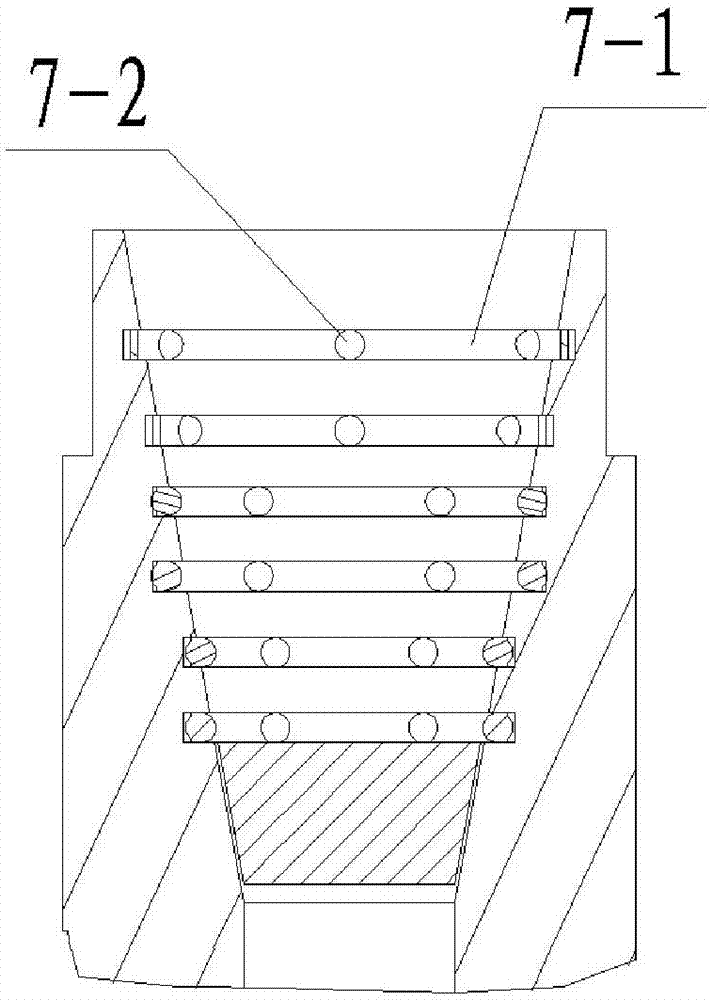

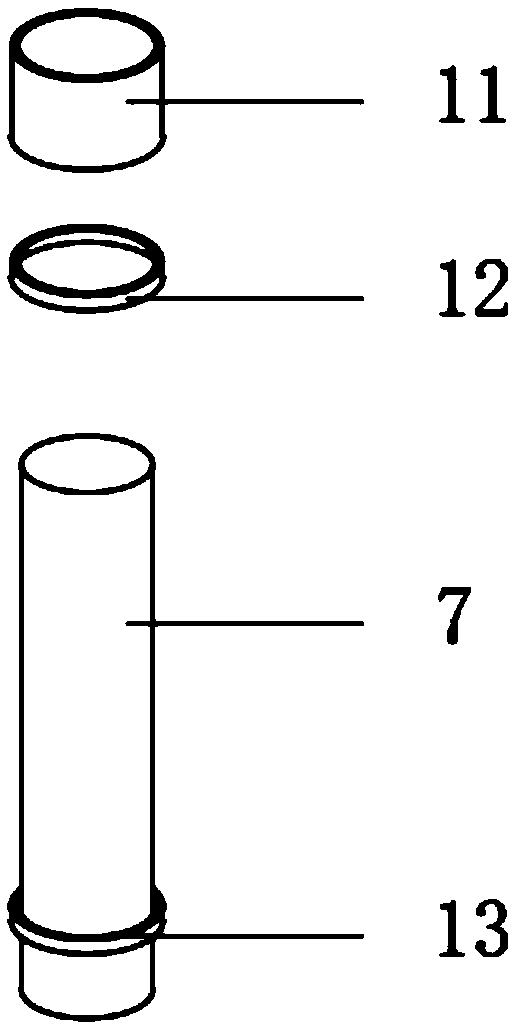

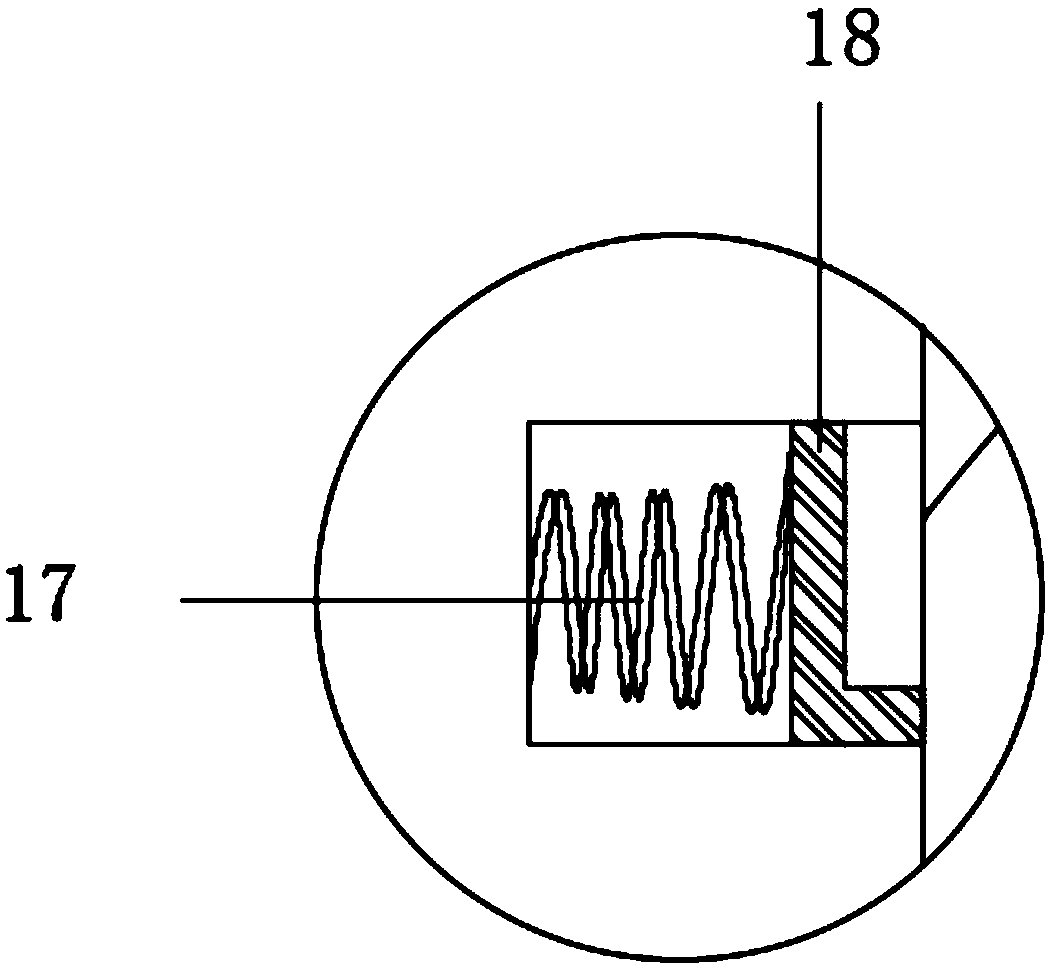

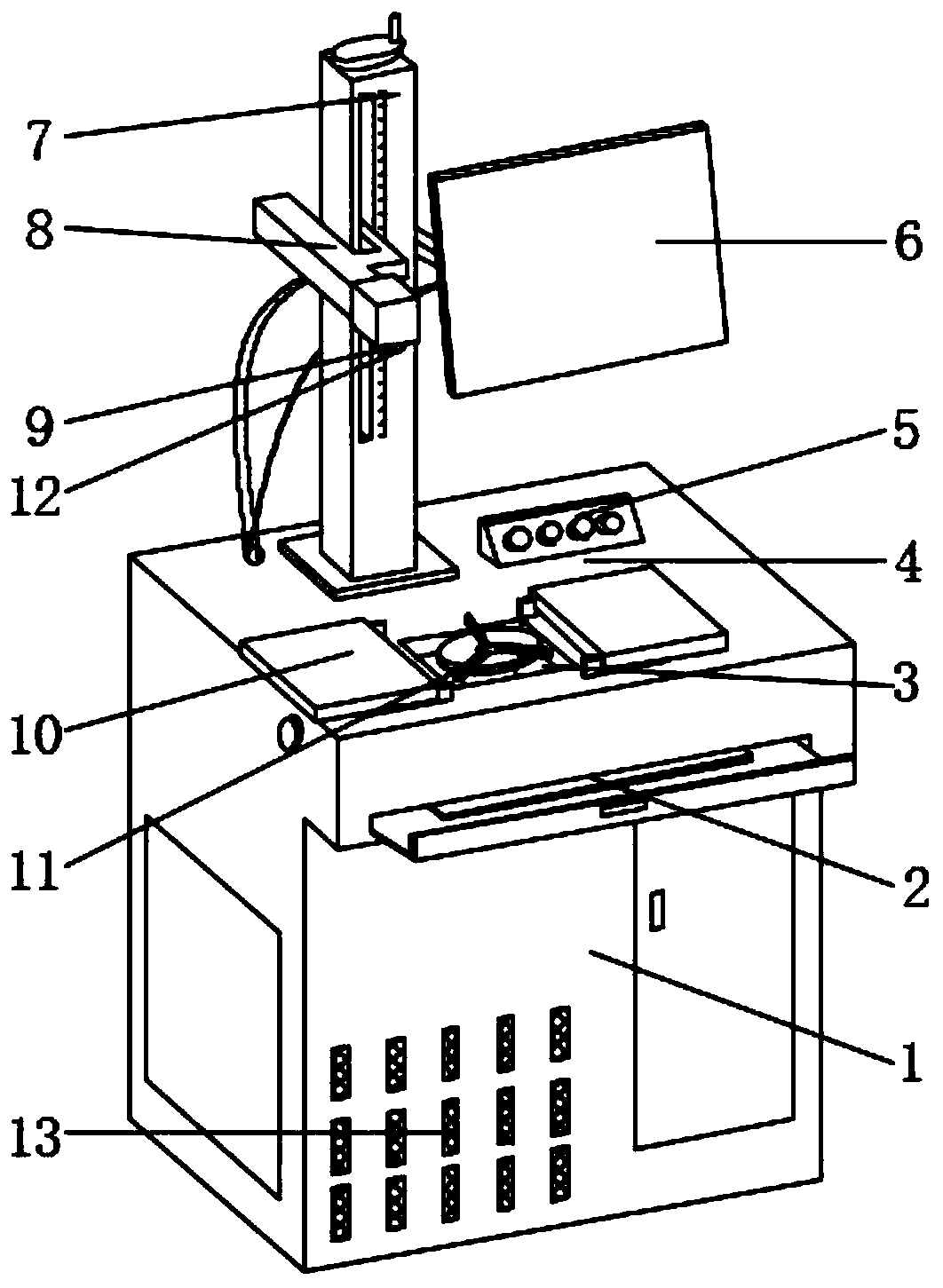

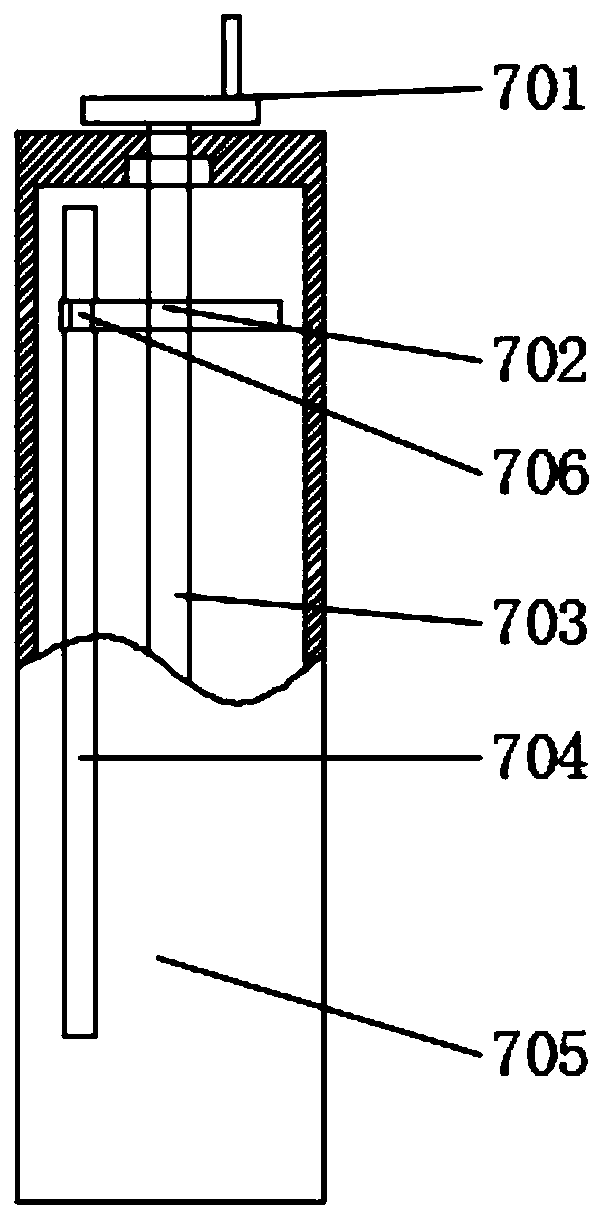

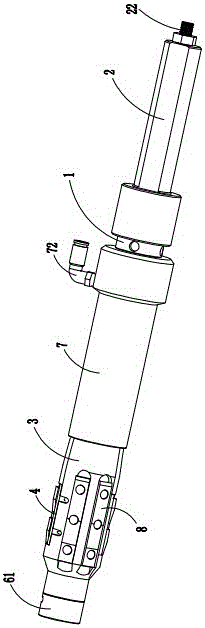

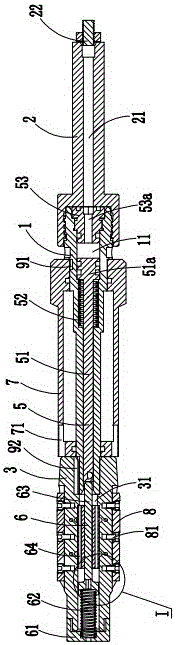

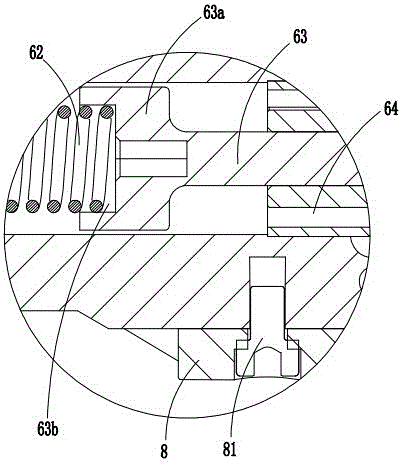

Cutter handle with shock absorption function

PendingCN107972185AWith damping functionSimple structureStone-like material working toolsVibration amplitudeMilling cutter

The invention relates to a cutter handle with a shock absorption function. The cutter handle with the shock absorption function comprises a handle body, a damping block and a clamping head, wherein aninner hole is formed in the handle body and used for holding the damping block and the clamping head. The damping block is arranged at the bottom of the inner hole. The clamping head is arranged on the upper portion of the damping block. Four to six circles of grooves are formed in the surface of the inner hole. Shock absorption devices are arranged in the grooves and surround the periphery of the clamping head. The cutter handle with the shock absorption function is simple in structure, and convenient to use. When stone is machined, shaking or vibration of the surface of the stone is reduced. The damping block and the shock absorption devices convert kinetic energy into potential energy, the vibration amplitude of the milling cutter clamping head is relieved, vibration of a milling cutter is further relieved, and the surface coating of the milling cutter is protected. The machining accuracy of the surface of the stone is improved, and the service life of the coated cutter can also beprolonged.

Owner:SHENYANG JIANZHU UNIVERSITY

Carbon steel pipe forging and stamping process

InactiveCN106944583AEliminate work hardeningGrain refinementMetal-working apparatusHeating timeStamping process

The invention relates to a carbon steel pipeline forging process. The carbon steel pipeline forging process comprises the following steps: 1) theoretical analysis, drawing a carbon steel pipeline heating curve, the abscissa is the heating time, and the ordinate is the heating temperature; 2) according to the steps 1) The obtained heating curve of the carbon steel pipeline. The carbon steel pipeline is subjected to heat treatment; 3) The heated carbon steel pipeline is subjected to pier thickening and elongation treatment. The invention provides a carbon steel pipeline forging process with high process precision, good surface quality and simple and reliable casting process.

Owner:陈顶凯

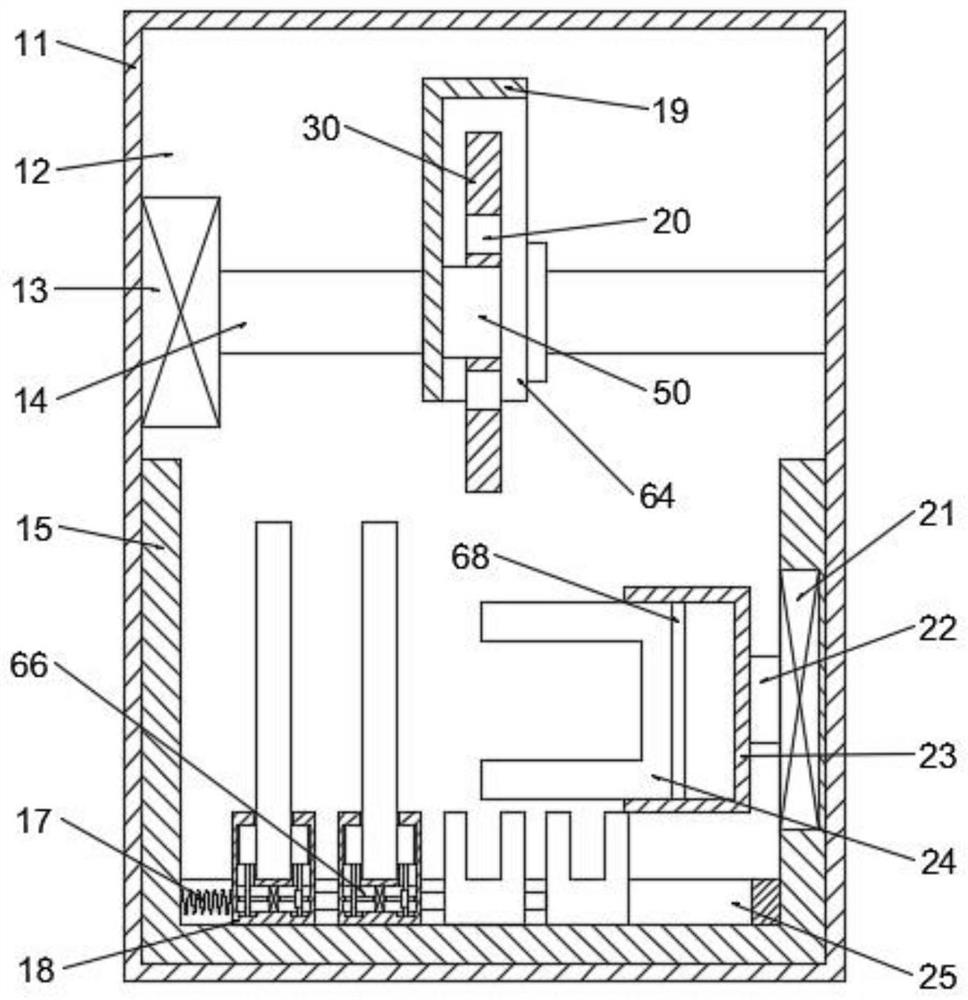

Multifunctional laser processing tool bit with measuring apparatus

InactiveCN100493814CSmooth processing surfaceImprove processing efficiencyLaser beam welding apparatusMeasurement devicePlane mirror

The present invention relates to laser processing, opto electromechanical technology and image processing technology, and is especially one multifunctional laser cutter with one measurement unit. The multifunctional laser cutter has adjustable laser spot with changeable spot shape and energy distribution for boring, cutting, welding and other functions. It includes one optical system and one signal acquiring, signal processing and controlling device. The optical system includes an He-Ne laser, a CO2 laser, a plane mirror, a beam expanding collimator, a positive rotating prism, a negative rotating prism and a focusing lens; and the signal acquiring, signal processing and controlling device includes a signal acquiring and processing unit, a controller and a feedback circuit.

Owner:XIAMEN UNIV

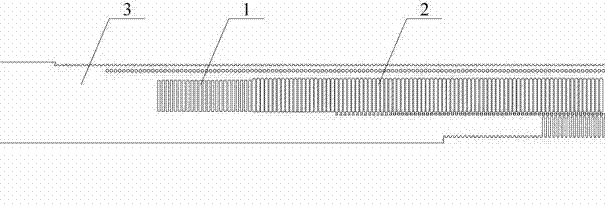

Production process of soft copper-clad steel wire

InactiveCN105321625AReduce the number of pullsReduce manufacturing costCable/conductor manufactureDecompositionCopper-clad steel

The invention relates to a production process of a soft copper-clad steel wire. The production process of the soft copper-clad steel wire successively comprises the steps of drawing, high-temperature tempering, electro-deposition pretreatment, acid electrolyzation, washing, pretreatment electro-deposition, washing, thick processing electro-deposition, washing, anti-oxidation, drying, drawing, washing, anti-oxidation treatment and ammonia-decomposition high-temperature tempering. The production process of the soft copper-clad steel wire has the advantages that the elongation rate of the copper-clad steel wire is greater than or equal to 10%, which is more than one time of the elongation rate of the copper-clad steel wire produced by a traditional tempering process.

Owner:刘振宇

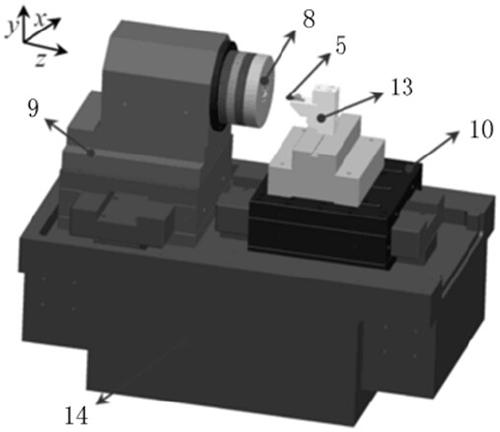

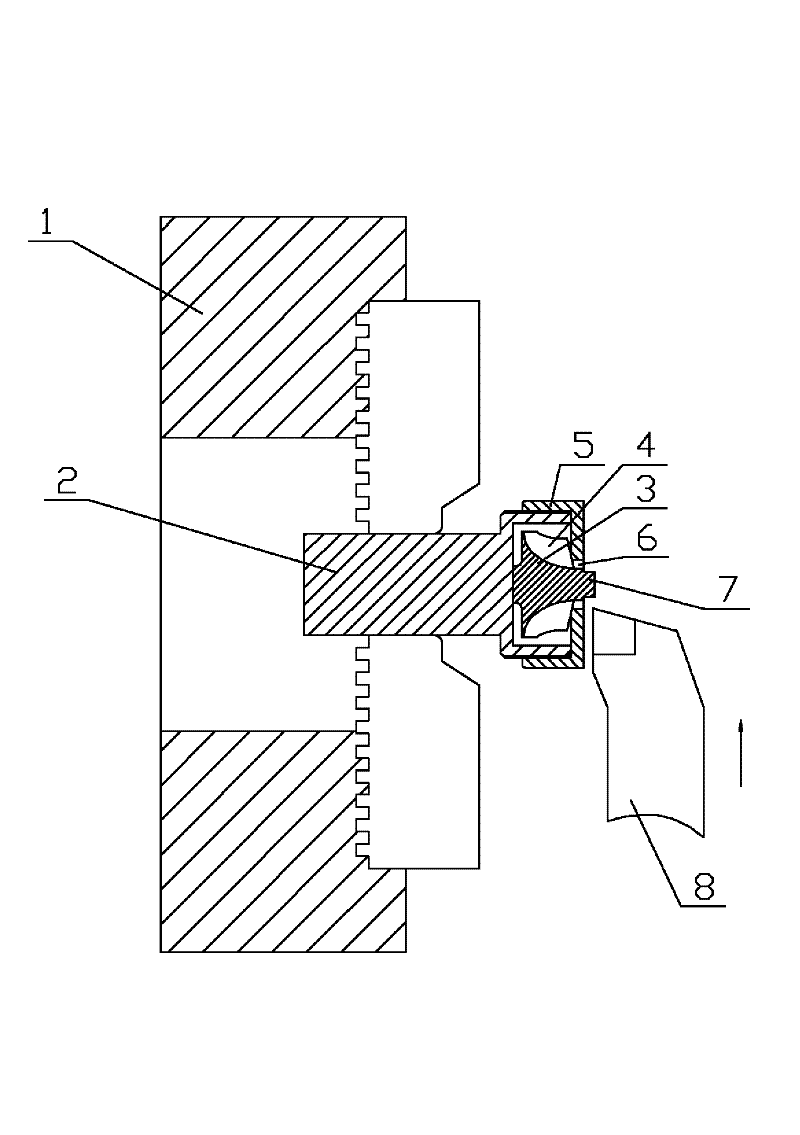

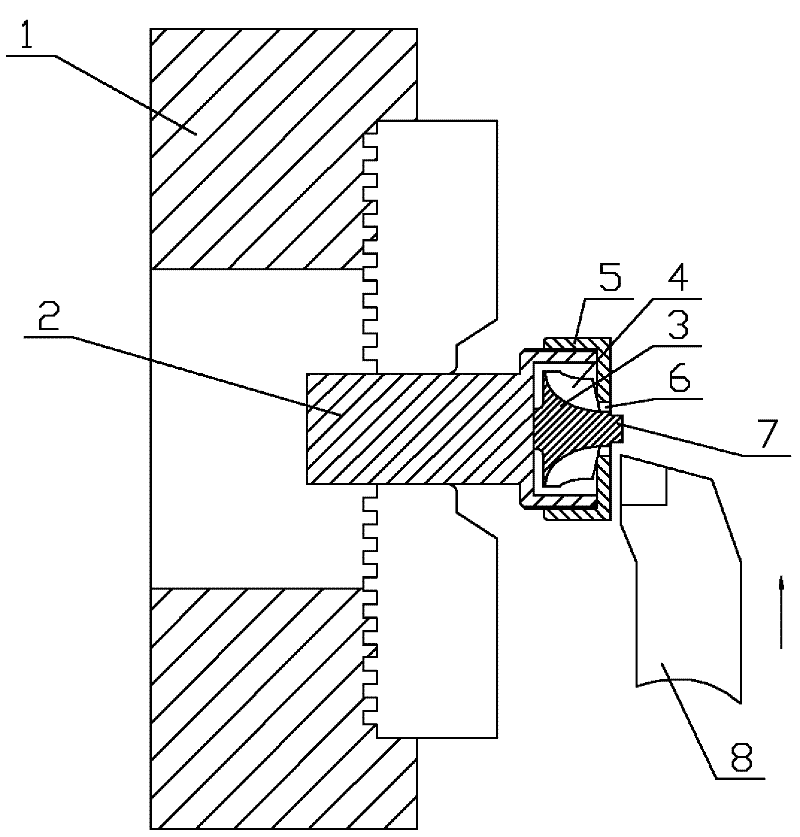

An ultra-precision machining method of titanium alloy based on ultrasonic elliptical vibration cutting technology

ActiveCN109048390BInstantaneous depth of cut is smallReduce cutting forceMeasurement/indication equipmentsMetal working apparatusMachined surfaceTitanium alloy

The invention discloses a titanium alloy ultraprecision machining method based on an ultrasonic elliptical vibration cutting technology. The titanium alloy ultraprecision machining method comprises the following steps: I, adjusting and controlling the temperature, the humidity and the air cleanliness of an ultraprecision machining laboratory; II, performing a pilot run on a machine tool; III, debugging an ultrasonic elliptical vibration cutting system; IV, mounting an ultrasonic elliptical vibration cutting device; V, mounting a titanium alloy material; VI, performing rough cutting; VII, performing semi-finished cutting; VIII, performing finish cutting; IX, performing ultrasonic elliptical vibration assisted cutting; and X, stopping an ultraprecision machine tool and the ultrasonic elliptical vibration cutting system, taking down a titanium alloy workpiece, cleaning the titanium alloy workpiece with absolute ethyl alcohol, performing drying, and then storing the titanium alloy workpiece to obtain an ultraprecision titanium alloy surface machined by the ultrasonic elliptical vibration cutting technology. The ultrasonic elliptical vibration cutting technology is adopted to realize ultraprecision machining of titanium alloy. The titanium alloy ultraprecision machining method has the advantages that abrasion of a cutter can be effectively inhibited, pits and microcracks on a machined surface are inhibited, the surface integrity of the workpiece is improved, and the damage degree of a subsurface of the workpiece can be effectively reduced.

Owner:HARBIN INST OF TECH

Clamp special for flat turbine head end face

InactiveCN102380785AReduce jumpingImprove processing efficiencyPositioning apparatusMetal-working holdersEdge surfaceMachined surface

The invention provides a clamp special for a flat turbine head end face. By using the clamp, the clamping positioning of a three-jaw chuck meets a clamping requirement, the machining efficiency is high, a machined surface is smooth, a fracture phenomenon is not easy to cause, and the centre beat of a machined component is low. The clamp special for the flat turbine head end face comprises the three-jaw chuck, a base and a flat turbine, and is characterized in that: the upper part of the base is provided with an open cavity body; the flat turbine is arranged in the cavity body; an end cover is covered on the outer end surface of the cavity body; a centre hole is formed in the end cover; the head end surface of the flat turbine is exposed from the centre hole of the end cover; the outer circumference of a worm wheel of the flat turbine is adhered to the inner end surface of the cavity; and the three-jaw chuck clamps the outer edge surface of the base.

Owner:WUXI MINGZHU TURBOCHARGER MFG

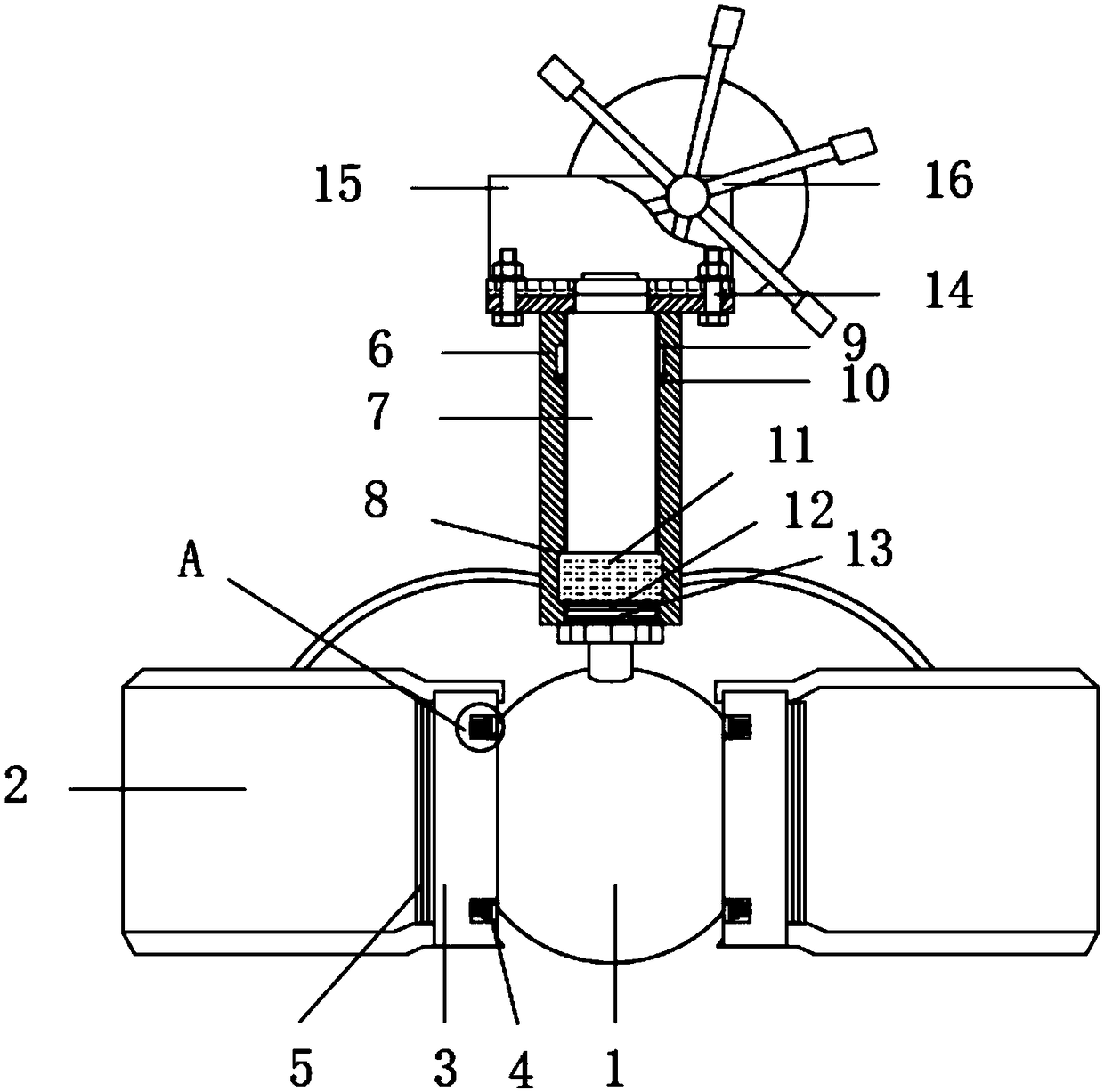

Thermal ball valve resistant to leakage

PendingCN108799540AGreatly use efficiencyIncreased twisting strengthSpindle sealingsPlug valvesFiberCarbon fibers

The invention discloses a thermal ball valve resistant to leakage. The thermal ball valve resistant to leakage comprises a sphere. Floating valve seats are connected with the two sides of the sphere.Buffer limiting mechanisms are connected with both the upper end and the lower end of the side, close to the sphere, of each floating valve seat. According to the thermal ball valve resistant to leakage, a valve rod is made of 20Cr13 stainless steel, the valve rod is high in torsional strength and smooth in machined surface, and a lubricating sealing effect is improved; the valve rod is installedfrom the lower part of the interior of a valve rod connecting sleeve, pressure is pushed towards the valve rod by using a thrust washer support made of a low-friction material, and therefore the valverod only plays a role in transmitting torque without generating load; meanwhile, because the valve seats are composed of carbon fiber reinforced polytetrafluoroethylene and springs, self lubrication,friction resistance and resistance to temperature as high as 200 DEG C are achieved; an O-shaped sealing ring is made of VITON fluororubber, and thereby being good in temperature resistance, resistant to friction and high in corrosion resistance; and a first sealing ring is assembled at a low temperature, and thereby being high in adaptive capacity of changes of pressure and temperature, and no leakage is likely to happen within the marked range of pressure and temperature.

Owner:JIANGSU CHENGGONG VALVE TECH

Aluminum ingot code marking device

PendingCN110640304AIncrease the support surfaceAvoid damageLaser beam welding apparatusMachined surfaceEngineering

The invention discloses an aluminum ingot code marking device. The aluminum ingot code marking device comprises a device body and a workbench. The workbench is arranged on the upper surface of the device body. A lifting platform is arranged on the workbench. A clamping base is arranged on the upper part of the lifting platform. a protection device is welded to one end of the clamping base. A laserhead is arranged at one end of the clamping base and is arranged inside the protection device. Carrying platforms are arranged inside the workbench, at the top end of the workbench and below the laser head. A reserved groove is formed in the surface of the workbench and between the carrying platforms. A clamping device is arranged inside the reserved groove. With the aluminum ingot code marking device, because a large supporting surface can be obtained for large workpieces, and a slope of a silver ingot or some specially shaped workpieces can be clamped, and the device is applicable to different workpieces, a machined surface is smoother; and the laser head can be protected, not only is dust prevented from falling onto the laser head, but also the laser head is prevented from being damaged by collision.

Owner:ZHEJIANG RUIQI TECH CO LTD

Forging technology for square steel

InactiveCN106270334AEliminate work hardeningGrain refinementMetal-working apparatusHeating timeEngineering

The invention relates to a forging technology for square steel. The forging technology for the square steel comprises the following steps of 1), making a square steel heating curve graph, wherein the abscissa of the square steel heating curve graph represents the heating time and the ordinate of the square steel heating curve graph represents the heating temperature; 2), heating the square steel according to the square steel heating curve graph obtained in the step 1); and 3), performing upsetting and drawing-out treatment on the heated square steel. The forging technology for the square steel is high in technology precision and good in surface quality, and the casting technology is simple and reliable.

Owner:姜蕾

A kind of preparation method of film sandpaper

The invention discloses a film sandpaper production method. The method includes the steps of PET (polyester) film treating, primer coating, abrasive embedding, pre-drying, composite adhesive coating, primary drying, curing and anti-clogging coating applying. A PET film treated through corona or chemical coating has strong adhesion. The primer is a bottom layer adhesive composed of polyamine resin, a curing agent and an organic solvent of xylene. A second layer adhesive comprises modified phenolic resin, a coupling agent and a grinding aid, enables abrasive to be firm in adhesion and can obtain good sharpness and cutting polishing capacity. The anti-clogging coating is composed of lubricating filler, an adhesive and an antistatic agent. By means of the film sandpaper production method, sandpaper good in flexibility, not prone to deformation, high in strength, good in anti-clogging effect and flat in machining surface can be produced.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

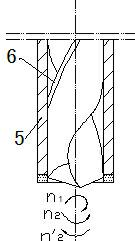

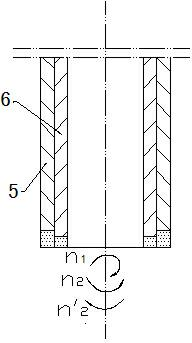

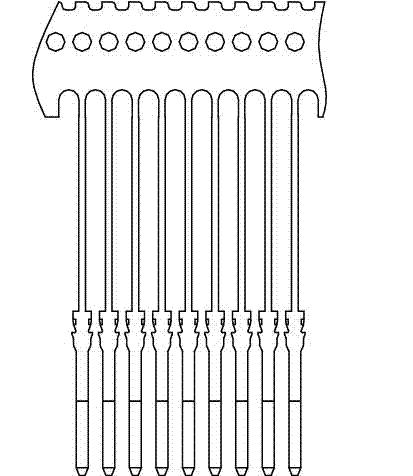

Processing cutter for differential cutting of combined holes of reinforced fiber composite materials

InactiveCN102601427AImprove surface qualityImproved enhanced surface qualityTransportation and packagingTrepanning drillsEngineeringFibrous composites

The invention relates to a processing cutter for differential cutting of combined holes of reinforced fiber composite materials. The processing cutter comprises a main cutter, a differential cutter and a differential, the main cutter and the differential cutter are coaxial, the main cutter is a hole processing cutter, the differential cutter is a tubular cutter, the processing cutter for the combined holes is driven by the differential, an output shaft I and an output shaft II of the differential are coaxial, the output shaft II of the differential is connected with the main cutter, and the output shaft I of the differential is connected with the differential cutter. The main cutter is an internal cutter and has the function of removing most of processing allowance, the differential cutter is an external cutter, fibers are drawn out by the internal cutter, at the moment, the fibers are cut off by the external cutter due to differential rotation of the external cutter and the internal cutter when the main cutter works, so that normal cutting is realized, and a processed surface is smooth. In addition, the quality of the processed surface of a hole of a reinforced fiber composite material is improved by the aid of the processing cutter. Besides, the processing cutter is reasonable in design, simple in structure and convenient in utilization and operation.

Owner:HEFEI UNIV OF TECH

Angle grinder system

InactiveCN114290182AAchieve lockingRealize replacement of old and newGrinding wheel securing apparatusGrinding machinesAngle grinderMachined surface

The angle grinder system comprises a shell, a working cavity is formed in the shell, an opening penetrating through the left end face of the shell is formed in the left wall of the working cavity, a U-shaped mounting block is fixedly arranged on the bottom wall of the working cavity, a U-shaped cavity is formed in the U-shaped mounting block, and a strip-shaped mounting block is fixedly arranged on the bottom wall of the U-shaped cavity; by arranging the clamping mounting block, the U-shaped connecting block and the locking connecting block, a workpiece can be locked, the grinding wheel is used for cutting and grinding, the U-shaped connecting block extends into the through hole to drive the grinding wheel to rotate to be loosened or connected with the threaded mounting block, new and old replacement of the grinding wheel is achieved, and the beneficial effects of being high in machining precision and convenient and fast to replace are achieved. And the wedge-shaped block, the abutting block and the threaded mounting block are further arranged, the grinding wheel can be fixed when the workpiece is cut, the machining process is stable, the machining surface is smooth, waste components can be replaced through connection of the threaded mounting block and the grinding wheel, and the beneficial effects that machining work is stable, and the working efficiency is improved are achieved.

Owner:殷玉柱

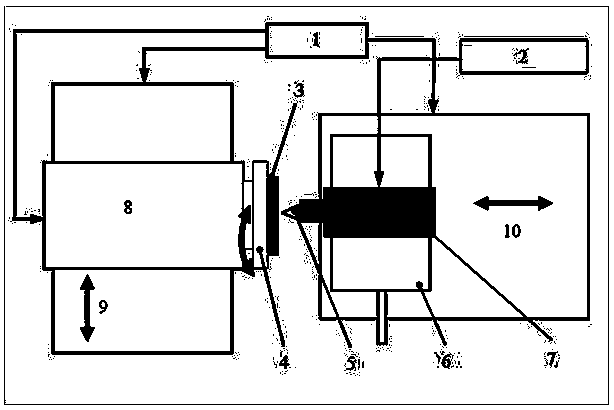

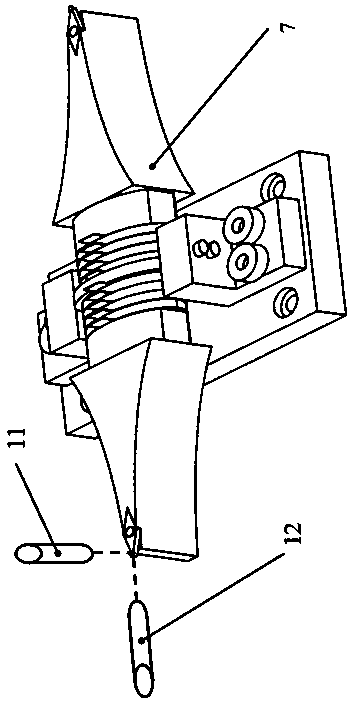

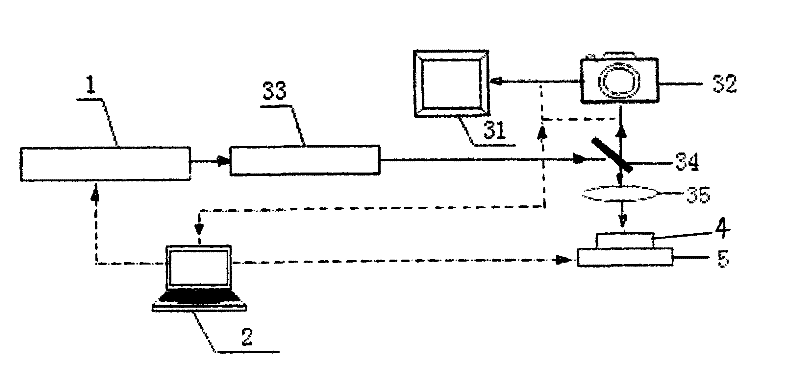

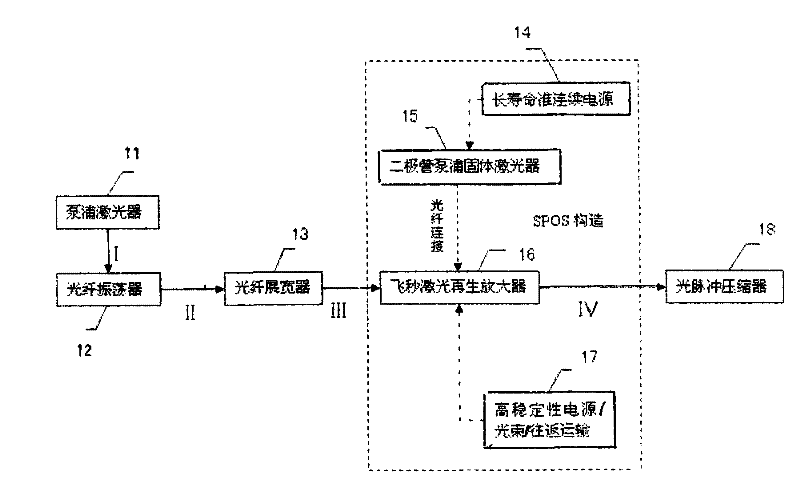

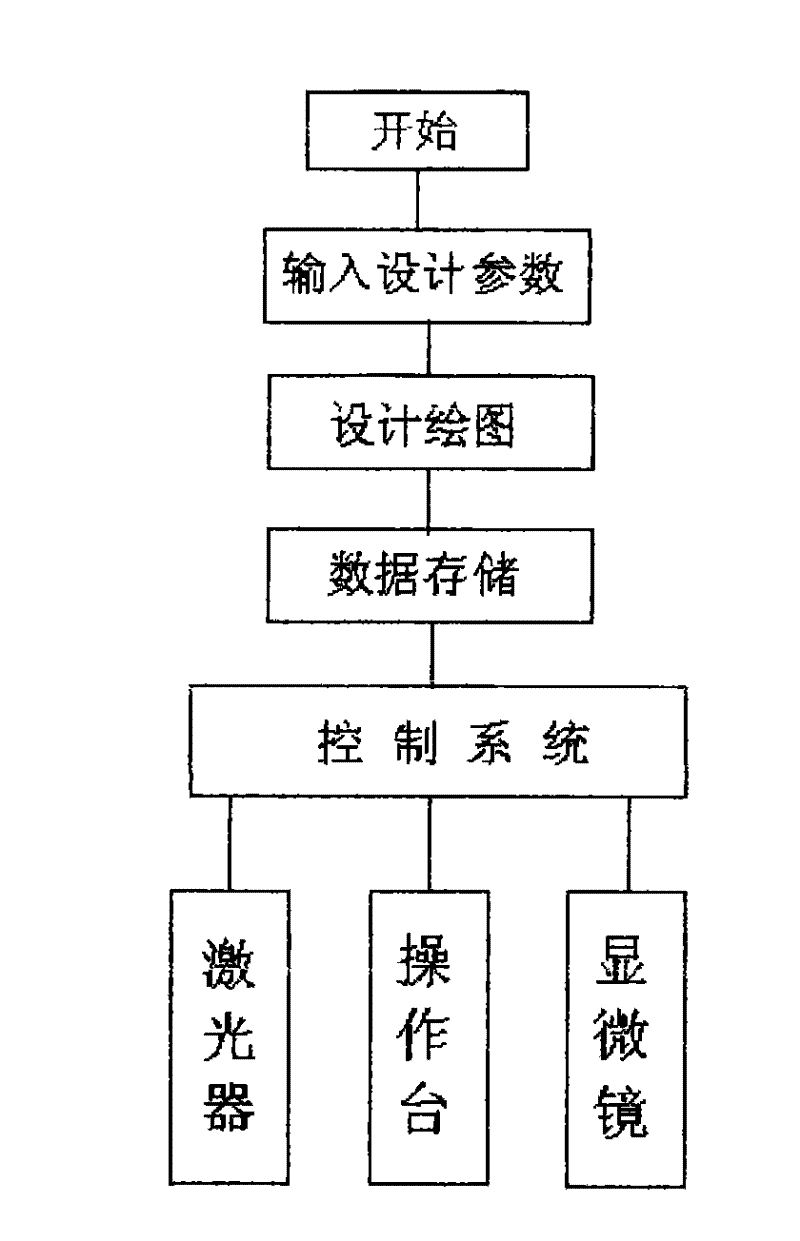

Micro-fine processing system of femtosecond laser for material surface modification

InactiveCN101480757BImprove machining accuracyImprove accuracyLaser beam welding apparatusHeat-affected zoneFemto second laser

The invention discloses a micro-fine processing system for the surface modification of materials using femto-second laser, comprising a femto-second laser, a micro-light path system, a high-precision three-dimensional working platform and a control system host machine, wherein the femto-second laser acquires an emitted laser beam to focus and irradiate onto processed components on the three-dimensional working platform through the micro-light path system; the micro-light path system comprises a microscope for the observation of processing, a light batch system with a CCD monitor imaging unit,and the three-dimensional working platform is connected with the control system host machine in a control way. The micro-fine processing system uses the femto-second laser as a processing light source to precisely process the surface modification of material through the characteristics of unique ultra-short duration and ultra-strong peak power of the femto-second laser, the cooperation of the optical system and the high-precision three-dimensional working platform and the control of a software program in order to achieve the ultra-precise processing in the sub-micron level for no presence of heat affected zone during the processing and to provide a useful tool for automobile industry, semiconductor, communication industry, and the like needing the high-precision processing.

Owner:陕西午禾科技有限责任公司

PCD reamer

PendingCN112935402AReduce processing textureHigh precisionReaming toolsStructural engineeringShock resistance

The invention relates to a PCD reamer. The reamer comprises a reamer handle and a reamer body; the reamer handle is of a cylindrical structure, the other end of the reamer handle is fixedly connected with the reamer body, and a groove is formed in the circumferential direction of a connecting portion of the reamer handle; the reamer body comprises a first cutting portion, a second cutting portion and a third cutting portion; the third cutting portion is of a cylindrical structure, a chamfer is arranged at one end, close to the reamer handle, of the third cutting portion, and a plurality of cutting ends are distributed at one end, away from the reamer handle, of the third cutting portion in the circumference at equal angles; the second cutting portion is of a cylindrical structure, and comprises two cutting ends which are symmetrically distributed in the circumferential direction of the second cutting portion; the first cutting portion is composed of two sections of cylindrical portions and is fixedly connected with the second cutting portion, and two cutting ends are symmetrically distributed in the circumferential direction of the first cutting portion; and the three cutting portions are all provided with PCD blades. The blades have the advantages of being high in hardness, good in abrasion resistance, good in shock resistance, high in sharpness degree and the like, machining lines of workpieces can be effectively reduced, and the precision and the effect of finished products are improved.

Owner:常州冶戈工具有限公司

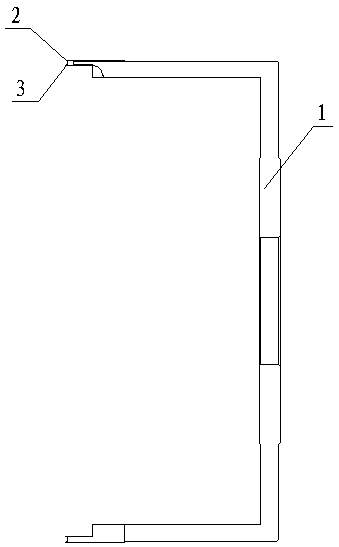

A flexible scraper

ActiveCN103752952BIncrease processing sizeImprove machining accuracyMaintainance and safety accessoriesPunchingEngineering

The invention discloses a flexible scraper. The flexible scraper comprises a spindle, a tool handle and a scraping head, wherein the tool handle is connected to one end of the spindle, and the scraping head is connected to the other end of the spindle and provided with at least two floating blade sets, each floating blade set is provided with a rough scraping blade and a fine scraping blade, a first through hole is axially formed in the spindle, an ejector rod mechanism is arranged in the first through hole, a second through hole which is coaxial with the first through hole is formed in the scraping head, a blade adjusting mechanism is arranged in the second through hole, and the ejector rod mechanism abuts against and is matched with the blade adjusting mechanism. The spindle is sleeved with a cooling chip removal sleeve, at least one chip punching hole is formed in the end, close to the scraping head, of the cooling chip removal sleeve, and a cooling liquid pipe is arranged on the cooling chip removal sleeve. According to the flexible scraper, the floating blade sets are adopted and provided with the rough scraping blades and the fine scraping blades, rough machining and fine machining are finished at the same time in one machining, and therefore machining accuracy is improved. By the arrangement of the chip punching holes, chips are more smoothly removed, and the structure is simple.

Owner:宁波市精恒凯翔机械有限公司

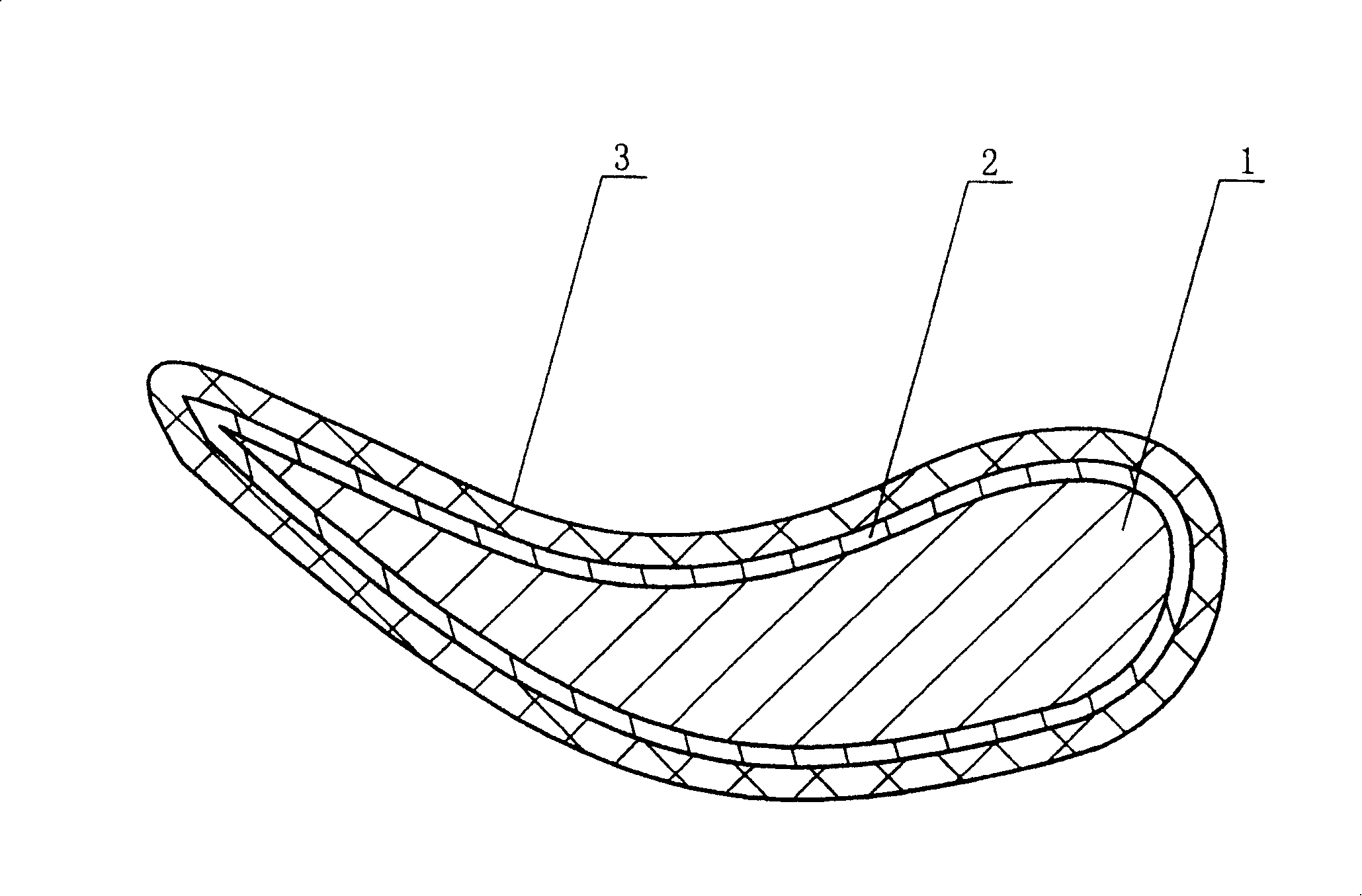

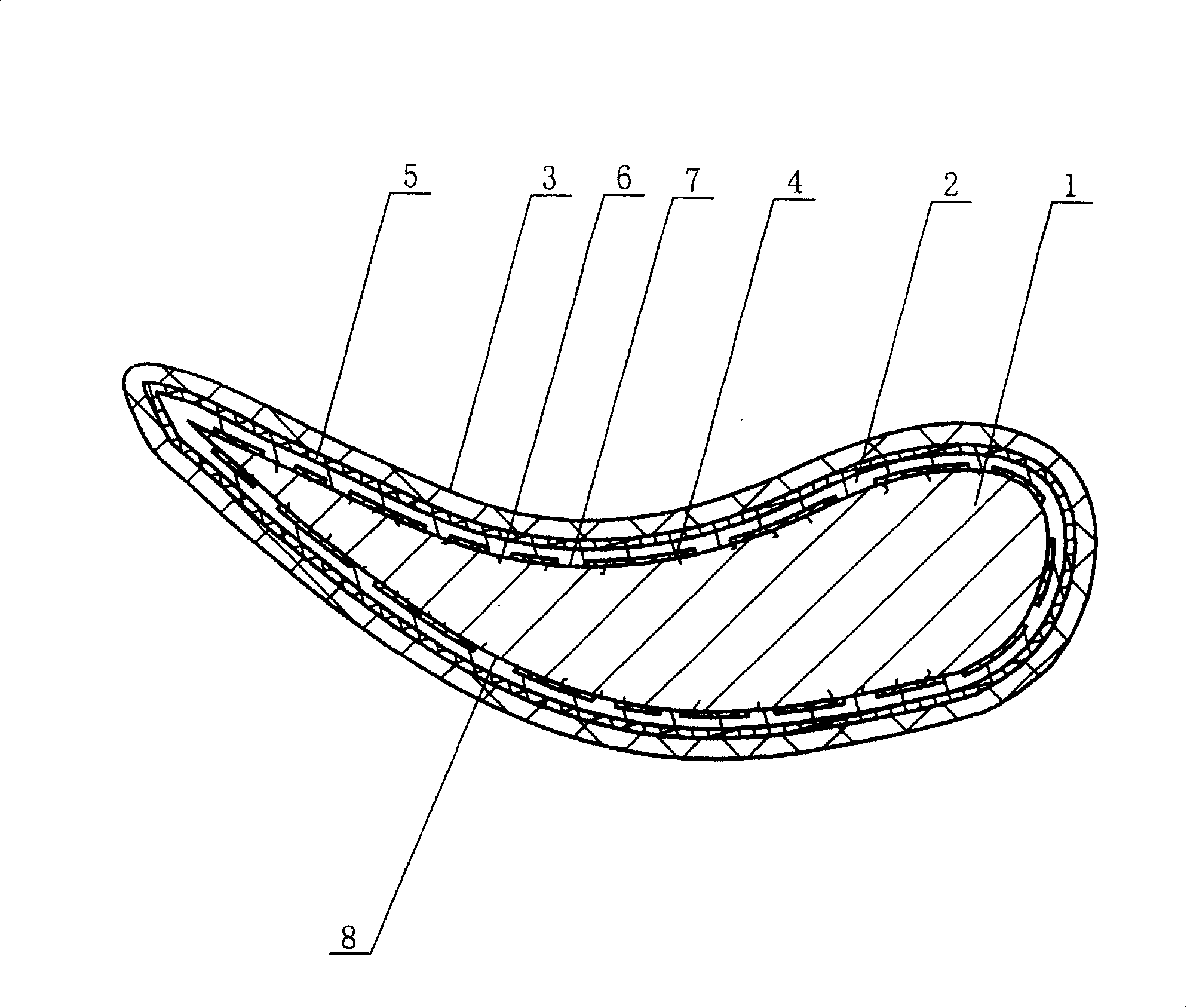

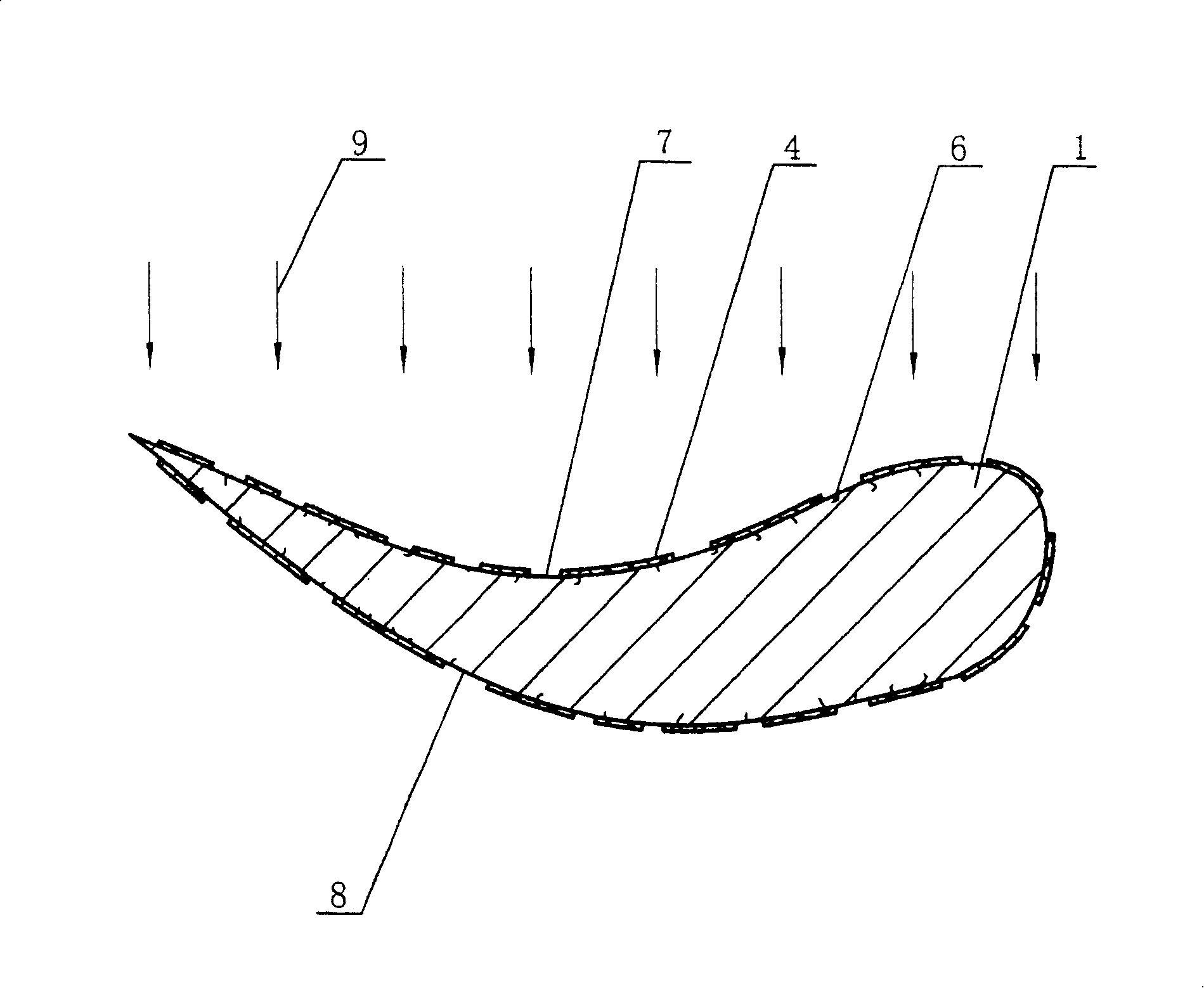

Cleaning and servicing technology for turbine blade basal body surface by strong current pulsed ionizing beam

ActiveCN100398699CNo contactNo pollution in the processBlade accessoriesMachines/enginesTurbine bladeStrong pulse

The invention relates to a turbine blades cleaning and mending technology in maintenance engineering, which comprises the following steps: first, placing turbine blades on sample table and exposing it in strong pulsed ionizing beam; second, radiating the blades for 1-20 times with strong pulsed ionizing beam of 5-60J / cm2 to remove oxide compound; third, radiating the blades for 1-10 times with strong pulsed ionizing beam of 1-5J / cm2 to weld microcrack; forth, rotating blades and cleaning back curved face. Compared with existing technology, the invention doesn't require high-temperature and corrosion-proof equipment and produces product with smooth surface.

Owner:DALIAN UNIV OF TECH

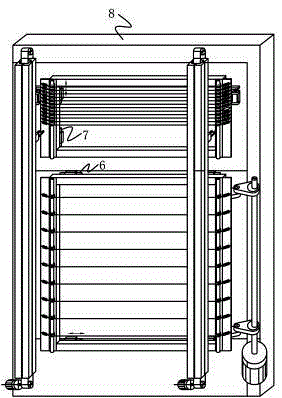

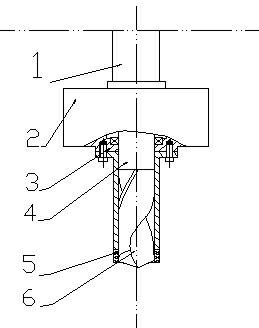

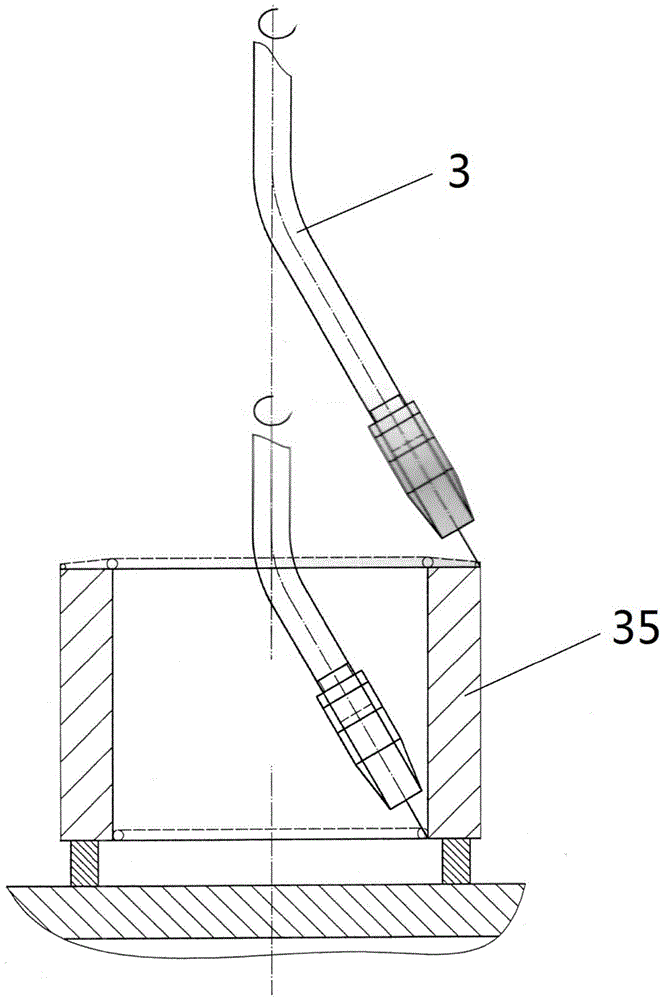

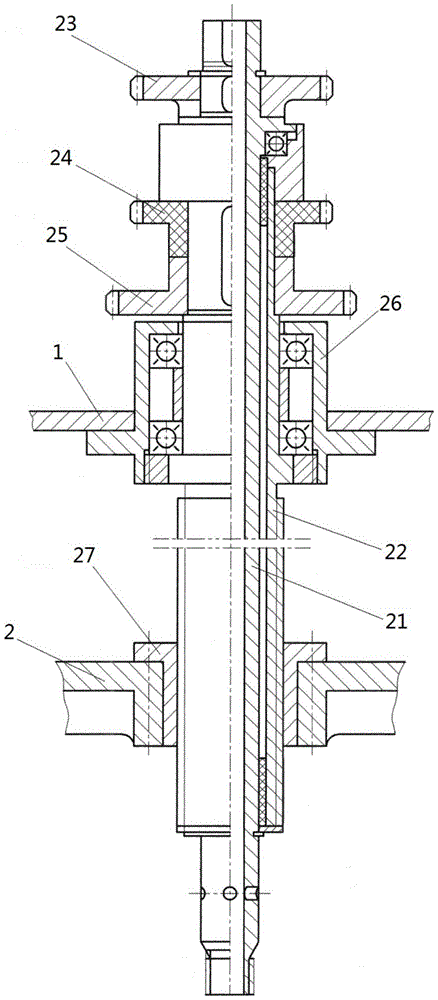

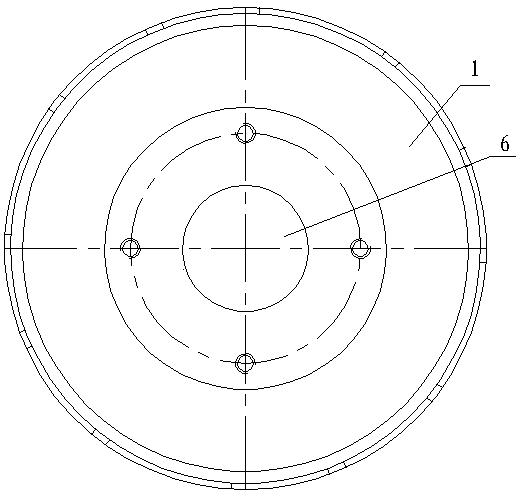

Automatic inner hole surfacing head

InactiveCN104551345BEasy to operateSmooth processing surfaceWelding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

The invention discloses an automatic inner bore overlay welding machine head which comprises a lifting screw rod and a welding gun rotating rod, wherein the welding gun rotating rod is arranged in the lifting screw rod in a penetrating manner and can move up and down together with the lifting screw rod; the welding gun rotating rod and the lifting screw rod rotate independently respectively; the welding gun rotating rod is used for connecting with a welding gun. The inner bore overlay welding machine head is capable of realizing full-automatic operation, is applicable to long-time operation, and is flat in finished surface and uniform in processing allowance; according to the inner bore overlay welding machine head, not only can the welding production be improved, but also the welding quality can be ensured.

Owner:上海东升焊接集团有限公司 +3

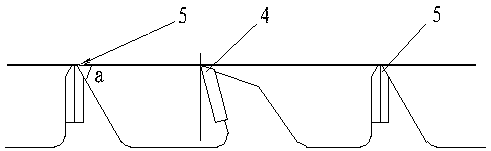

Single-sheet cylindrical cutter

PendingCN109227822ASmooth processing surfaceCut brisklyRotary cutting toolsEngineeringMechanical engineering

Disclosed is a single-sheet cylindrical cutter. Flat blades and burr guide blades are uniformly distributed on the circumference of a cutter body at intervals, the bur guide blades are provided with left burr guide blade bodies and right burr guide blade bodies, the tooth tips of the burr guide blades are 0.5 mm higher than the flat blades, and the included angle between the front and back portions of the tooth tips of the burr guide blades and the horizontal line is 45 degrees. According to the single-sheet cylindrical cutter, the structure of the burr guide blades is additionally arranged, the processing face is brighter and cleaner for processing of cork materials, cutting is easier, no burrs are generated, the cost for processing and repairing in the later period is reduced, and the service life is longer.

Owner:大连金河精密工具有限公司

Frosted painting method for surfaces of automobile aluminum alloy hubs

InactiveCN109079445AGood matte effectSmooth processing surfaceFurnace typesMetallic material coating processesAluminium alloyMachining

Owner:KINGHWA TOPTRUE WHEEL

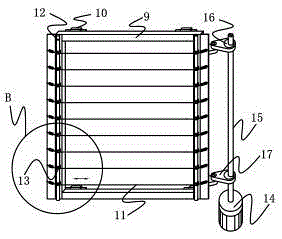

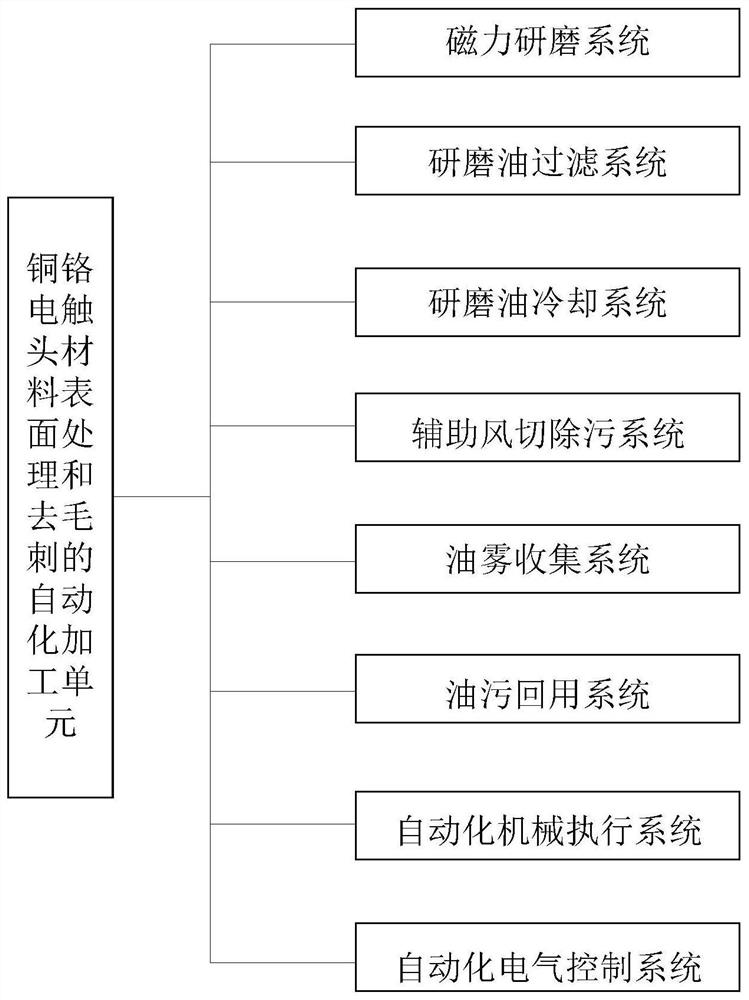

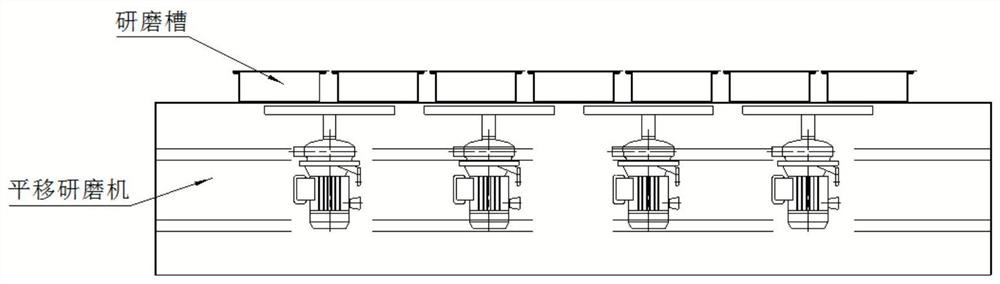

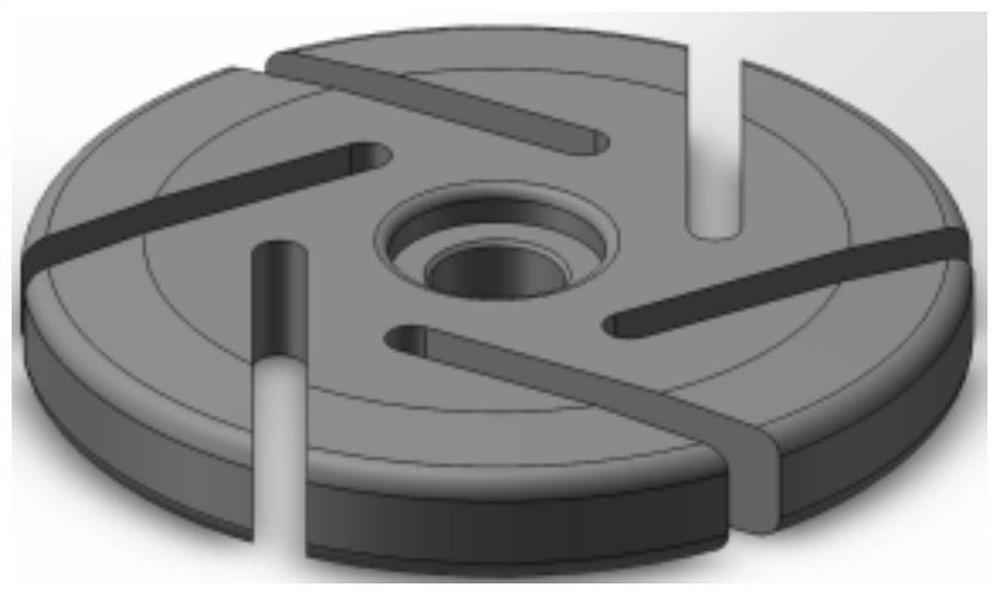

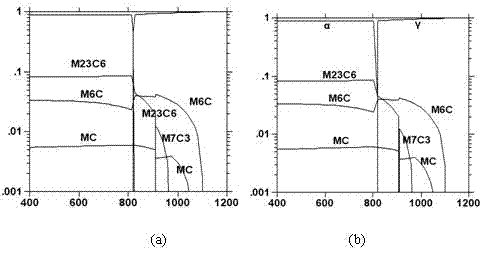

An automatic processing unit for surface treatment and deburring of copper-chromium electrical contact materials

ActiveCN113927467BSmooth edge transitionSmooth processing surfaceEdge grinding machinesPolishing machinesSurface oxidationSurface cleaning

The invention discloses an automatic processing unit for surface treatment and deburring of copper-chromium electric contact materials, which includes a magnetic grinding system, a grinding oil filtering system, a grinding oil cooling system, an auxiliary wind removal system, an oil mist collection system, and an oil dirt return system. system, automatic mechanical execution system and automatic electrical control system. The automatic processing unit of the present invention can well solve the bad defects such as surface cleanliness, surface structure state, edge state, and surface oxidation in the manufacturing process of copper-chromium electrical contact materials, and can produce high-quality and consistent copper-chromium contact materials. Head material, thereby reducing or eliminating the probability of the above-mentioned failure of copper chromium electrical contact material in the vacuum interrupter. Moreover, based on the processing technology of the automation unit, the process flow is short, the process connection is compact, and the automation level is high. It has high efficiency, environmental protection, and economical application value, and can be applied to batch industrial production.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Superfine carbide high-alloy tool steel shear-steel splicing mechanical blade

InactiveCN101962738BReasonable proportionImprove pass rateFurnace typesHeat treatment furnacesCarbideQuenching

The invention relates to the technical field of mechanical blades, in particular to a superfine carbide high-alloy tool steel shear-steel splicing mechanical blade which is manufactured by the steps of: firstly, manufacturing superfine carbide high-alloy tool steel shear-steel, wherein the shear-steel comprises the following components in percentage by weight: 0.52-0.62 percent of C, 0.40-0.60 percent of Si, 0.25-0.50 percent of Mn, 5.2-6.2 percent of Cr, 2.20-2.70 percent of W, 1.40-1.70 percent of Mo, 0.40-0.50 percent of V, 0.18-0.30 percent of Co or Ni, less than or equal to 0.015 percentof S, less than or equal to 0.02 percent of P and the balance of Fe; remelting electroslag by adopting an electric induction furnace or the electric induction furnace, forging and rolling at 870-1,100 DEG C; manufacturing a mechanical blade on a low-carbon steel plate by adopting high-temperature non-oxidation pressure rolling and splicing; and finally, annealing, quenching, tempering. The invention improves the yield of semi-finished products of the splicing procedure.

Owner:常州机械刀片有限公司

Stamping method for producing precise HDMI (high definition multimedia interface) terminals

The invention discloses a stamping method for producing precise HDMI (high definition multimedia interface) terminals and relates to a cold stamping die. The invention aims to solve the following problem: pins are easy to bend and even lean against each other during existing interface terminal cold stamping production, thus causing short circuit of terminal products. The stamping method comprises the following steps: (1) blanking: punching preprocessed metal sheets to prepare blanked finished products; (2) forming: bending and forming the punched blanked finished products to prepare the interface terminals; and (3) die releasing: releasing the interface terminals from a stamping die, wherein the blanking step comprises rough cutting blanking and accurate cutting blanking in sequence. The stamping method is especially suitable for producing the precise HDMI terminals.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com