Single-sheet cylindrical cutter

A cylindrical, single-piece technology, applied in the field of woodworking slotting knives, can solve problems such as burrs on the product surface, achieve long service life, light cutting, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

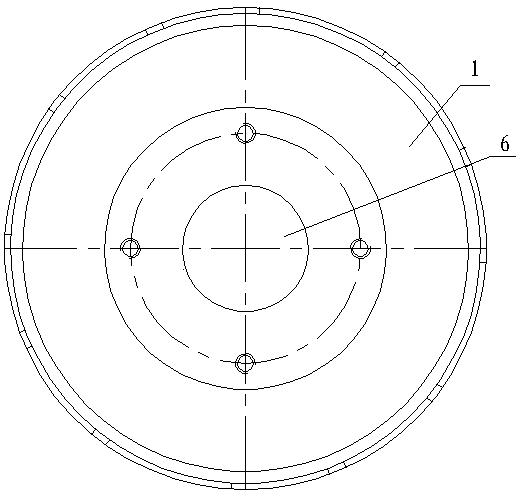

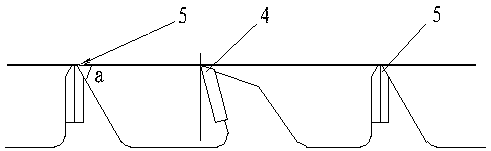

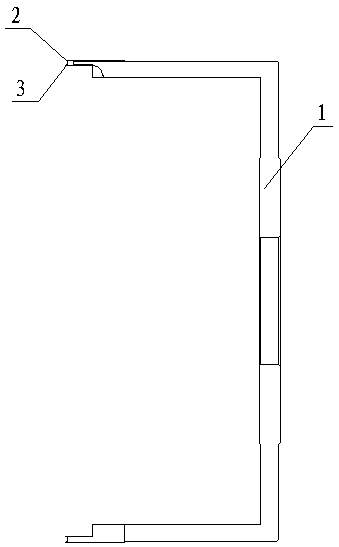

[0013] The structure of the monolithic cylinder knife of the present invention is as Figure 1-3 As shown, the flat edge 4 and the hair leading edge 5 are evenly spaced on the circumference of the knife body 1, the left hair leading edge 2 and the right hair leading edge 3 are arranged on the hair leading edge 5, and the tooth tip height of the hair leading edge 5 is higher than that of the flat blade 4 The height is 0.5mm, and the angle a between the front and back of the 5 tooth tips of the hair leading edge and the horizontal line is 45°.

[0014] Assembly structure such as Figure 4 As shown, the single-piece cylindrical knife is fixed on the tool rotating shaft 9 through the centering disc 7, and the bearing 8 is installed between the centering disc 7 and the shaft 9. Through the precision bearing structure, the centering disc 7 is guided Smoother and more precise.

[0015] The single-piece cylindrical knife of the present invention adopts 0° hairline, and the tip of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com