An automatic processing unit for surface treatment and deburring of copper-chromium electrical contact materials

A technology for electrical contact materials and surface treatment, which is applied in the field of surface treatment of copper-chromium electrical contact materials, can solve the problems of poor overall surface quality and consistency, unfavorable product first-time yield, and low degree of automation, so as to avoid grinding The effect of temperature increase, elimination of quality influence, and reduction of evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

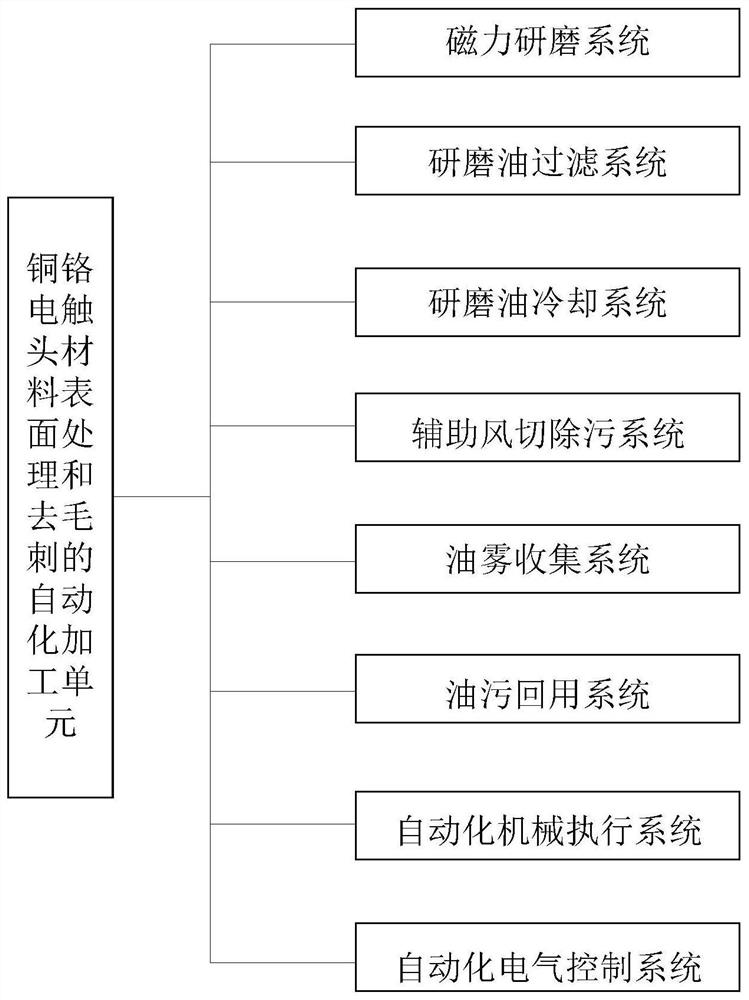

[0071] like figure 1 An automatic processing unit for surface treatment and deburring of copper-chromium electrical contact materials shown, including:

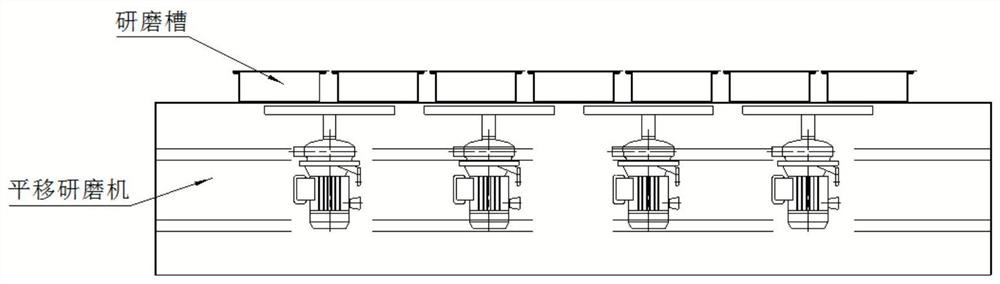

[0072]A magnetic grinding system 1 for magnetically grinding products to remove surface burrs. The magnetic grinding system 1 includes a translational magnetic grinding machine and a grinding tank located above the translational magnetic grinding machine; figure 2 As shown, there are 4 sets of permanent magnetic disks at equal intervals in the translational magnetic grinding machine; the grinding tank is an integral PP plate welding assembly, and 7 independent space grinding tank working positions are arranged linearly and evenly above the translational magnetic grinding machine, and the grinding tank as a whole The geometric center of the moving magnetic grinding machine coincides with the geometric center of the working plane. Driven by the translation mechanism, the permanent magnetic disk in the translational magnetic g...

Embodiment 2

[0083] The difference from Example 1 is that the automatic processing unit for surface treatment and deburring of copper-chromium electrical contact materials in this embodiment also includes a fully automatic vacuum cleaning and drying system, which includes cleaning equipment, vacuum Degreasing equipment, vacuum drying equipment, fully enclosed liquid supply system and online distillation system.

[0084] The cleaning equipment includes ultrasonic cleaning equipment and spray cleaning equipment, and the degreasing equipment is an integrated gas phase jet degreasing equipment.

Embodiment 3

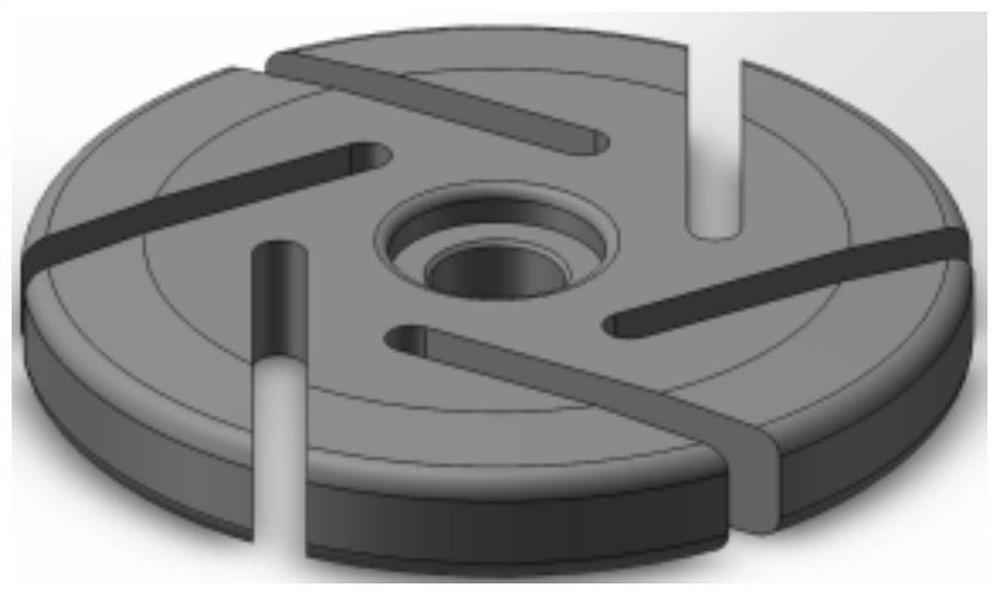

[0086] This embodiment is based on the processing unit of embodiment 1 to carry out the automatic processing technology of copper chromium electric contact material surface treatment and deburring, and this copper chromium electric contact material is Transverse magnetic 6-slope structure contacts,

[0087] Include the following steps:

[0088] S1. Feeding:

[0089] Prepare the loading material frame, lay the processed contact blanks into the material frame, and control the three-axis carriage-type manipulator in the automatic mechanical execution system 7 through the automatic manipulator PLC control system in the automatic electrical control system 8. The material frame moves to the loading position;

[0090] S2. Magnetic grinding:

[0091] The PLC control system of the translational magnetic grinding in the automatic electrical control system 8 controls the three-axis rack-type manipulator in the automatic mechanical execution system 7 to grab and drive the material fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com