A kind of coating method of cylindrical parts

A technology for parts and cylinders, applied in the field of cylinder parts coating, to reduce edge warping and avoid costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for coating cylindrical parts, comprising:

[0033] 1), the improved settings for the structure of the cylinder parts:

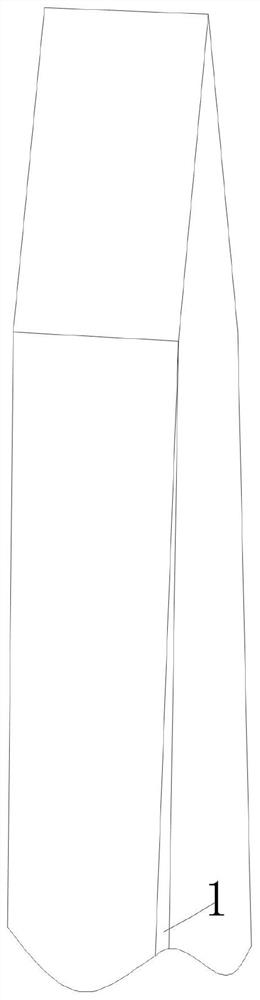

[0034] The structure of the column body includes a column head and a column rod, and multiple facets are arranged between the adjacent sides on the column head to avoid grooving on the adjacent sides. Specifically:

[0035] The to-be-sprayed surface of the column part includes the end-to-end stigma to be sprayed and the pole to be sprayed, the stigma to be sprayed has a stigma to be sprayed side, and the stigma to be sprayed in the length direction. The first spray surface, the second spray Surface, the third spraying surface and the fourth spraying surface, the first spraying surface and the third spraying surface are arranged oppositely, the second spraying surface and the fourth spraying surface are oppositely arranged, and there is a first spraying surface between the first spraying surface and the second spraying surface. facets, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com