Patents

Literature

83results about How to "Reduce oil pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water purifying device for river regulation

InactiveCN109667252AImprove work efficiencyReduce labor intensityFatty/oily/floating substances removal devicesWater cleaningRiver regulationEngineering

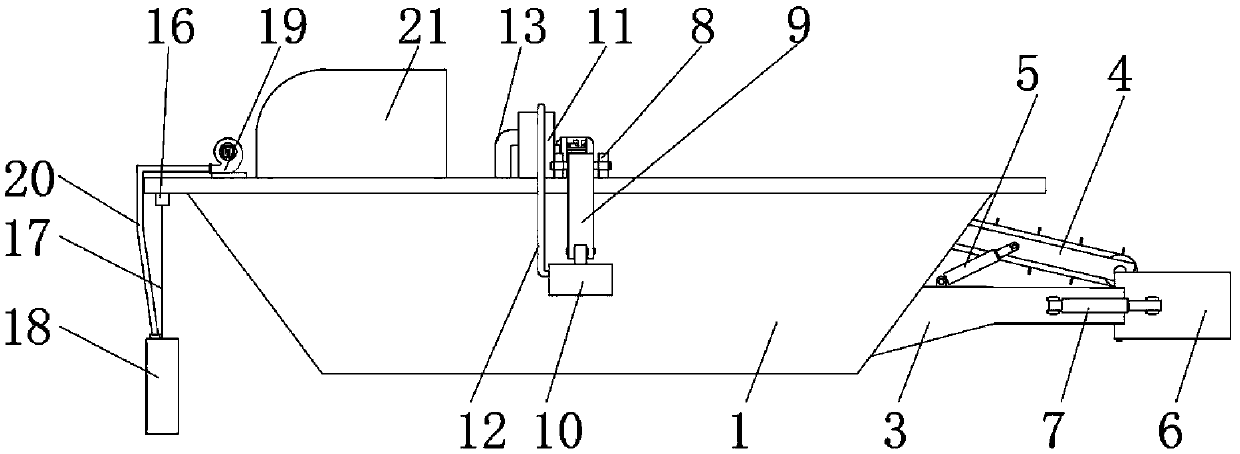

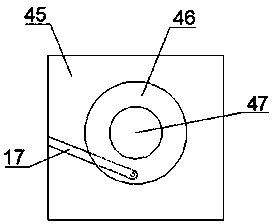

The invention discloses a water purifying device for river regulation. The water purifying device comprises a hull; a rotating base is fixedly connected with one side of an inner wall of the hull; a support frame is fixedly jointed on one side of an outer wall of the hull on a position corresponding to the rotating base; a collecting device is in rotatable connection with the center of the rotating base; a guide plate is in rotatable connection with one end of the support frame away from the hull; support bases are fixedly connected with the top of the hull on the two sides of the middle partof the hull; rotating rods are in rotatable connection with the centers of the support bases; floating cleaning boxes are in rotatable connection with one end of the rotating rods away from the support bases; self-priming pumps are fixedly connected with the top center of the hull on the positions corresponding to the support bases; a support plate is fixedly jointed between the two opposite sidesof the inner wall of the hull; a filtering device is fixedly connected with the top of the support plate. The invention relates to the technical field of river regulation. The water purifying devicefor river regulation is capable of solving the problems of low working efficiency and high labor intensity of manual salvage and is capable of cleaning phytoplankton and oil contamination on water surface.

Owner:朱晶晶

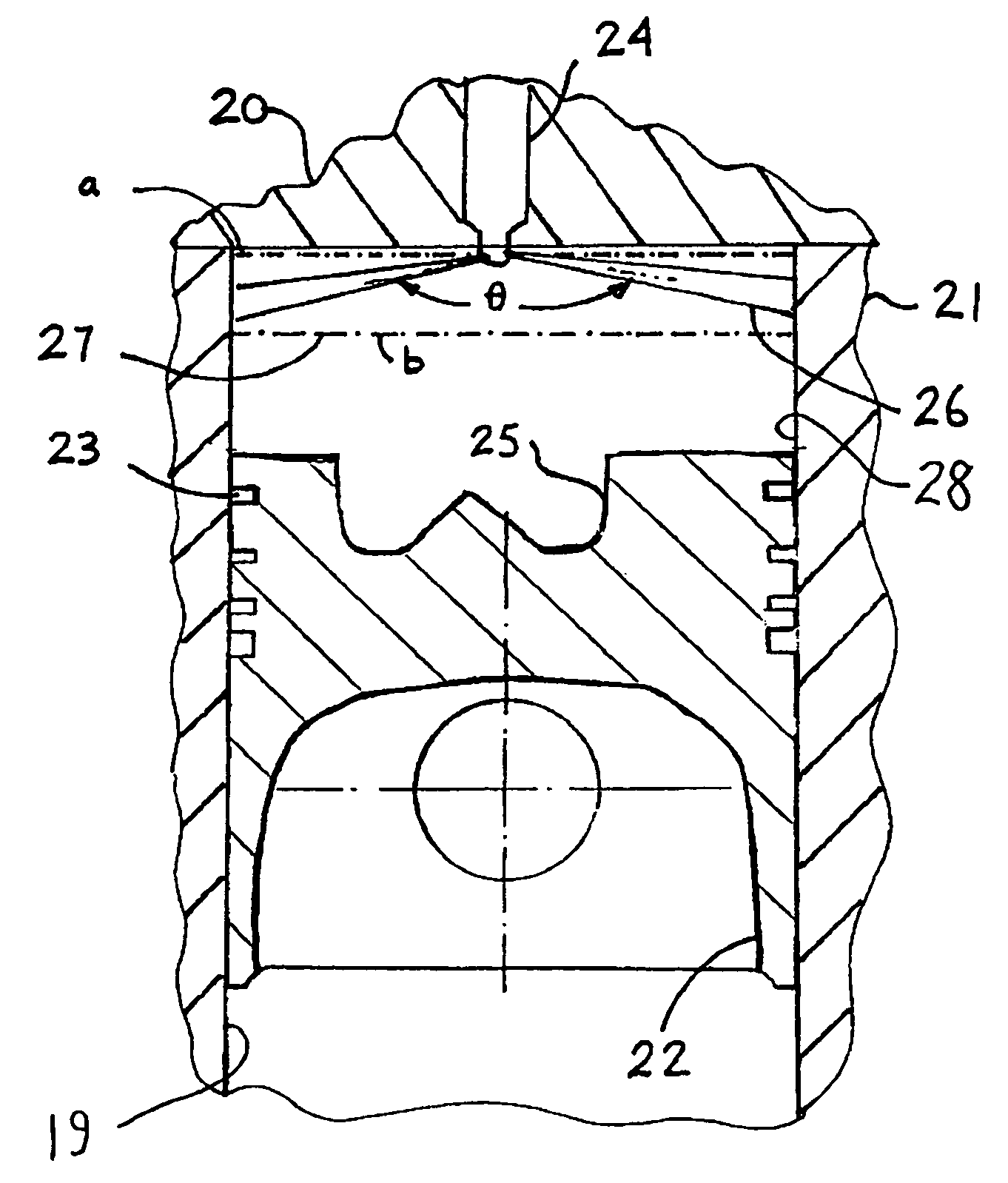

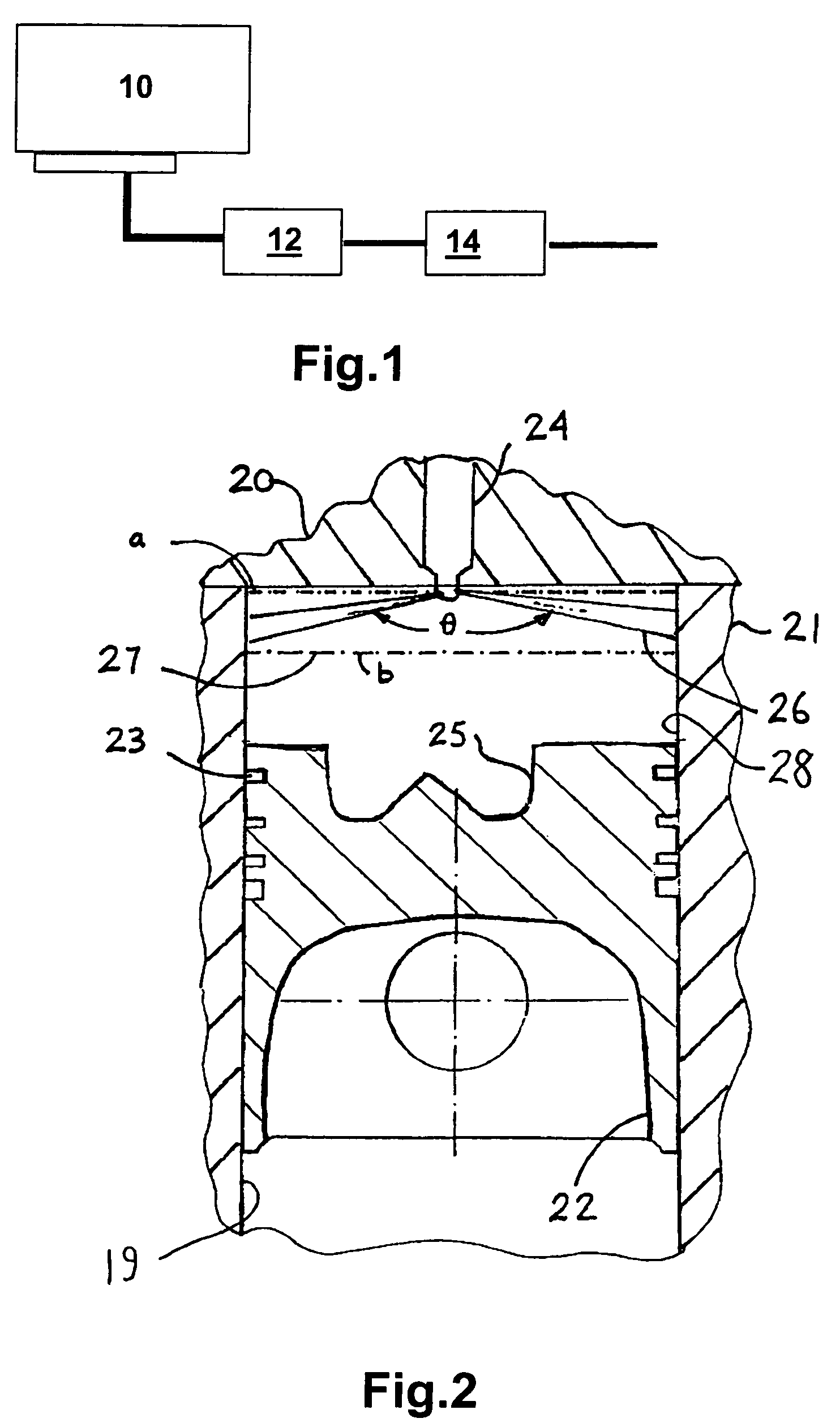

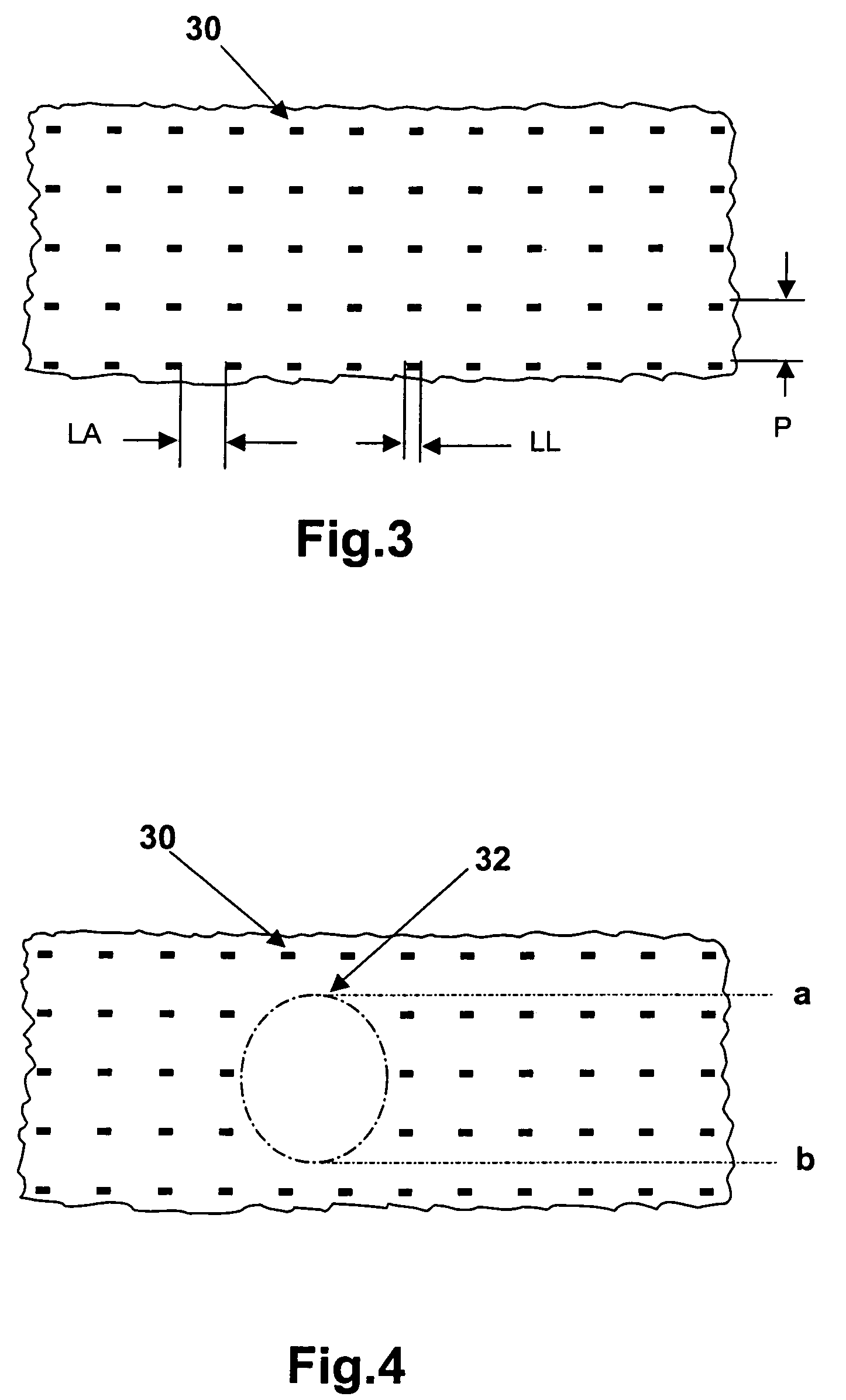

Engine and a method of making same

ActiveUS7685991B2Reduce oil pollutionReduce transferCylinder headsCombustion enginesSurface finishNO storage

Owner:FORD GLOBAL TECH LLC

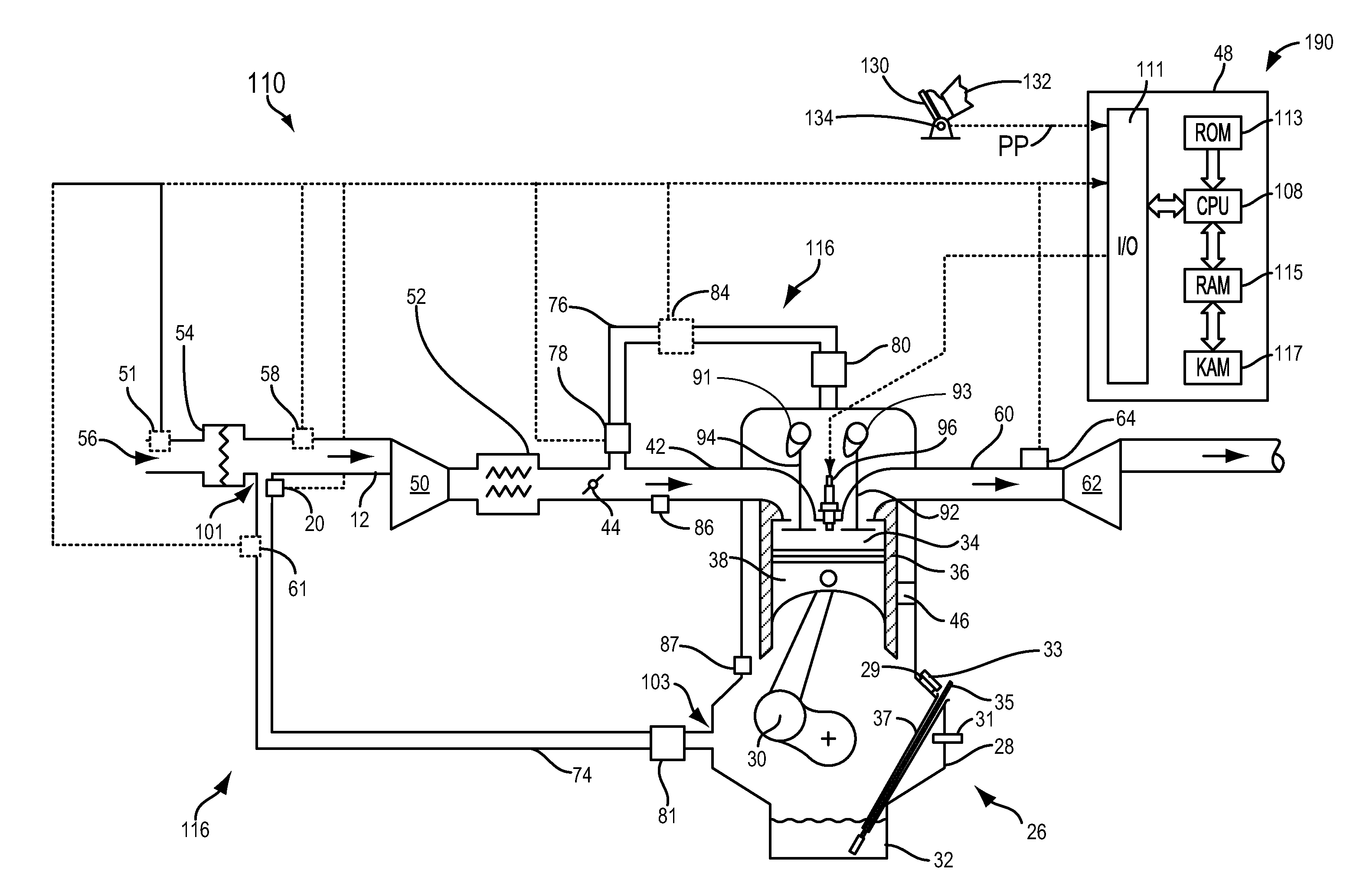

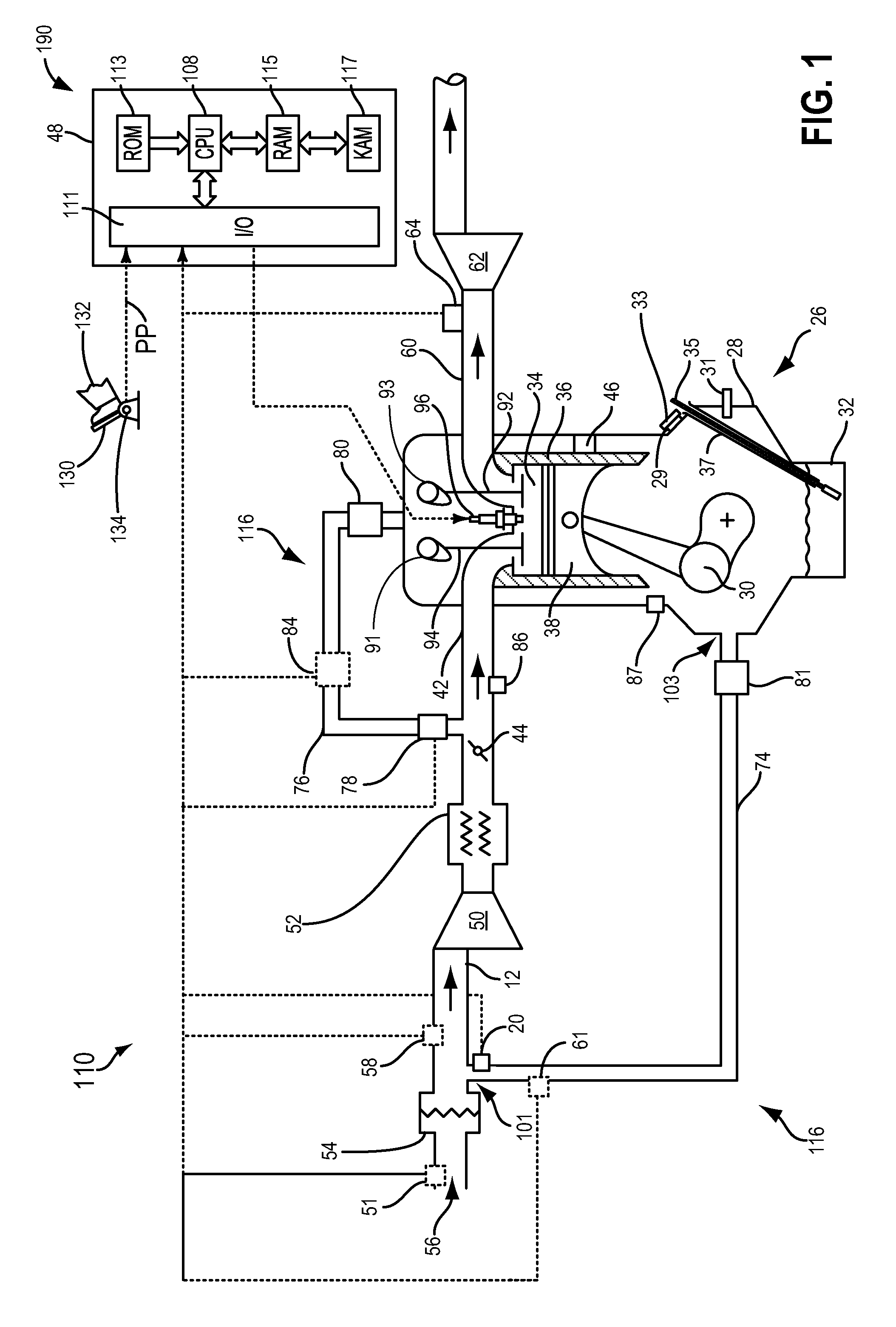

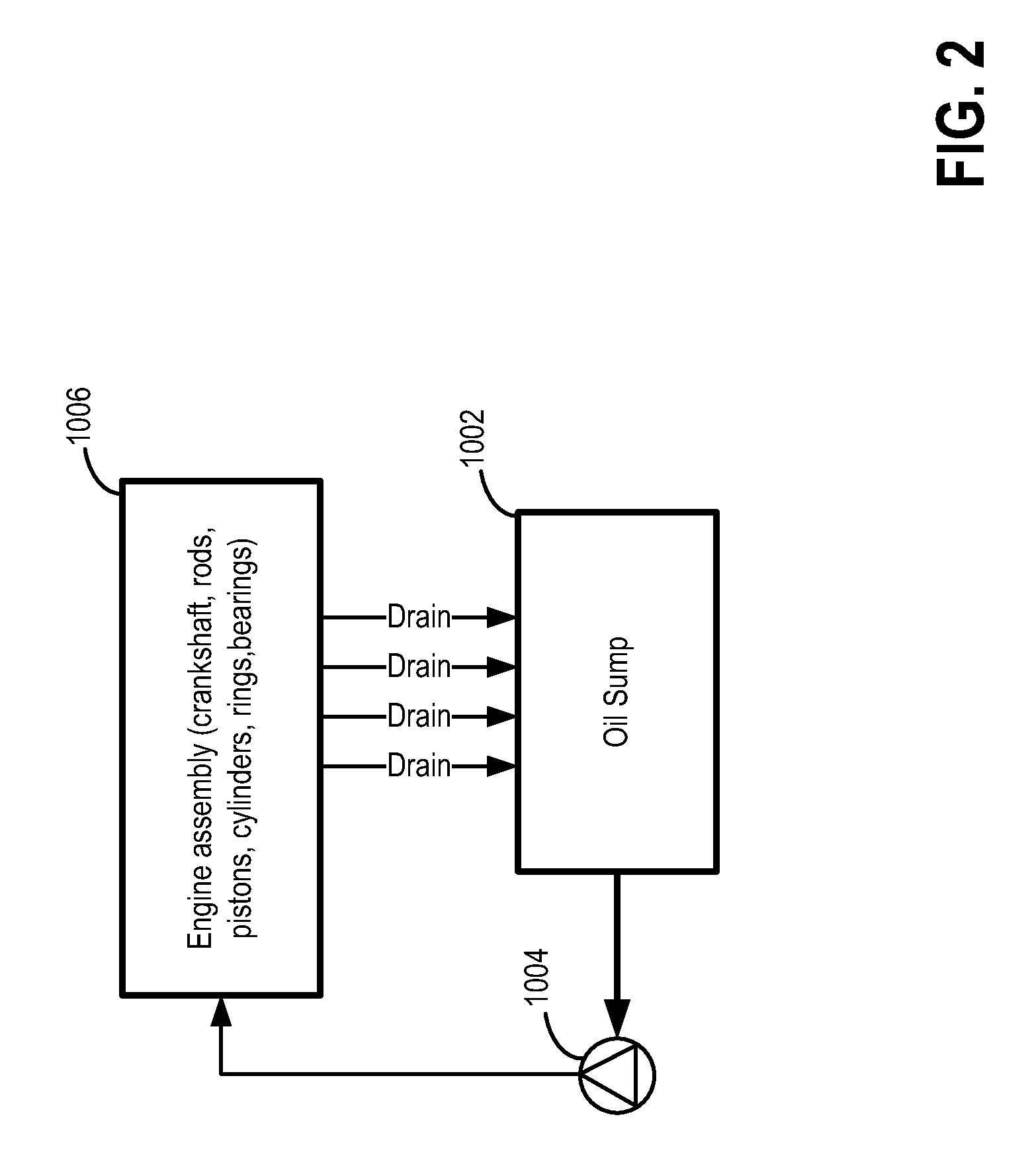

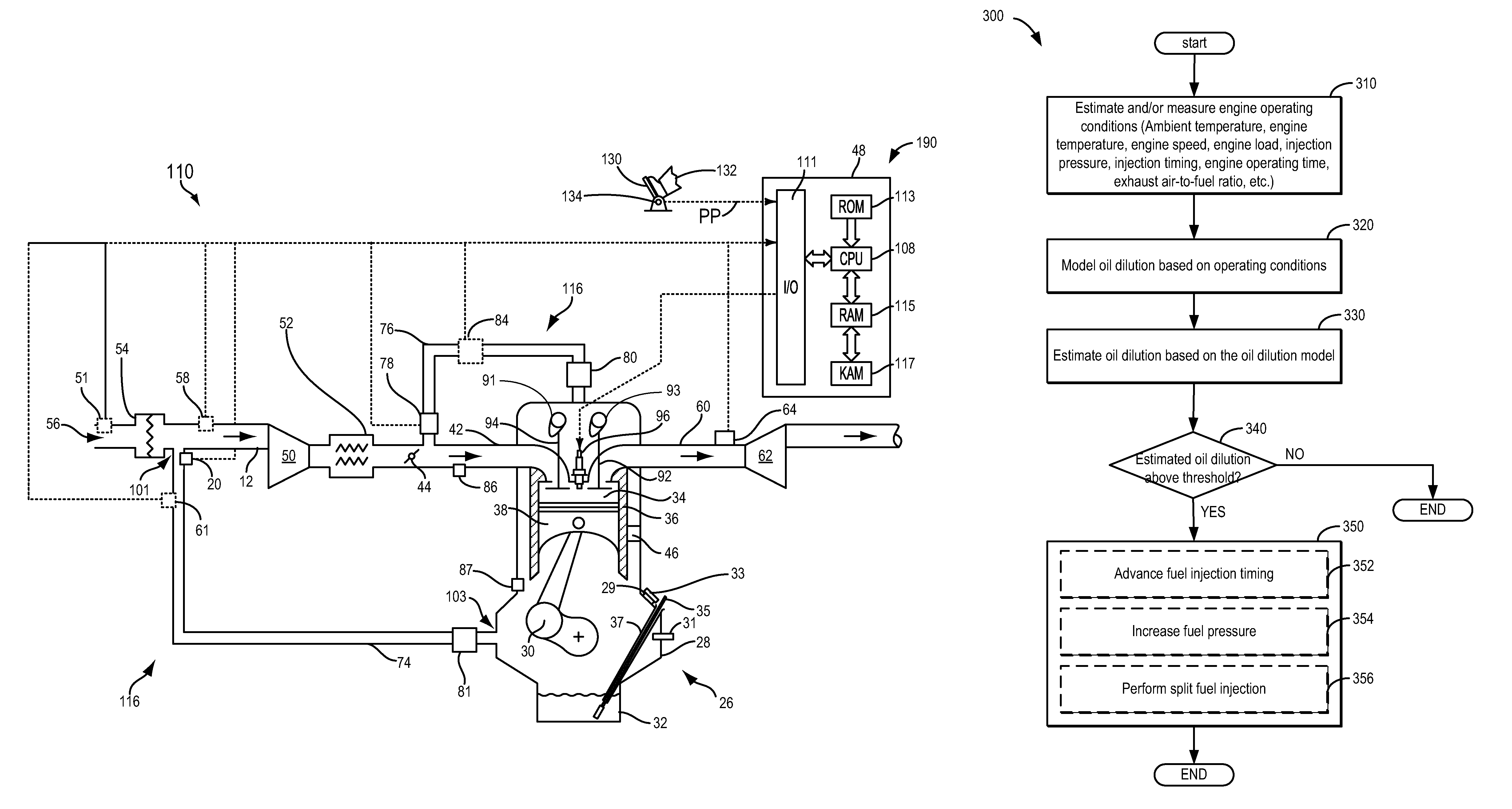

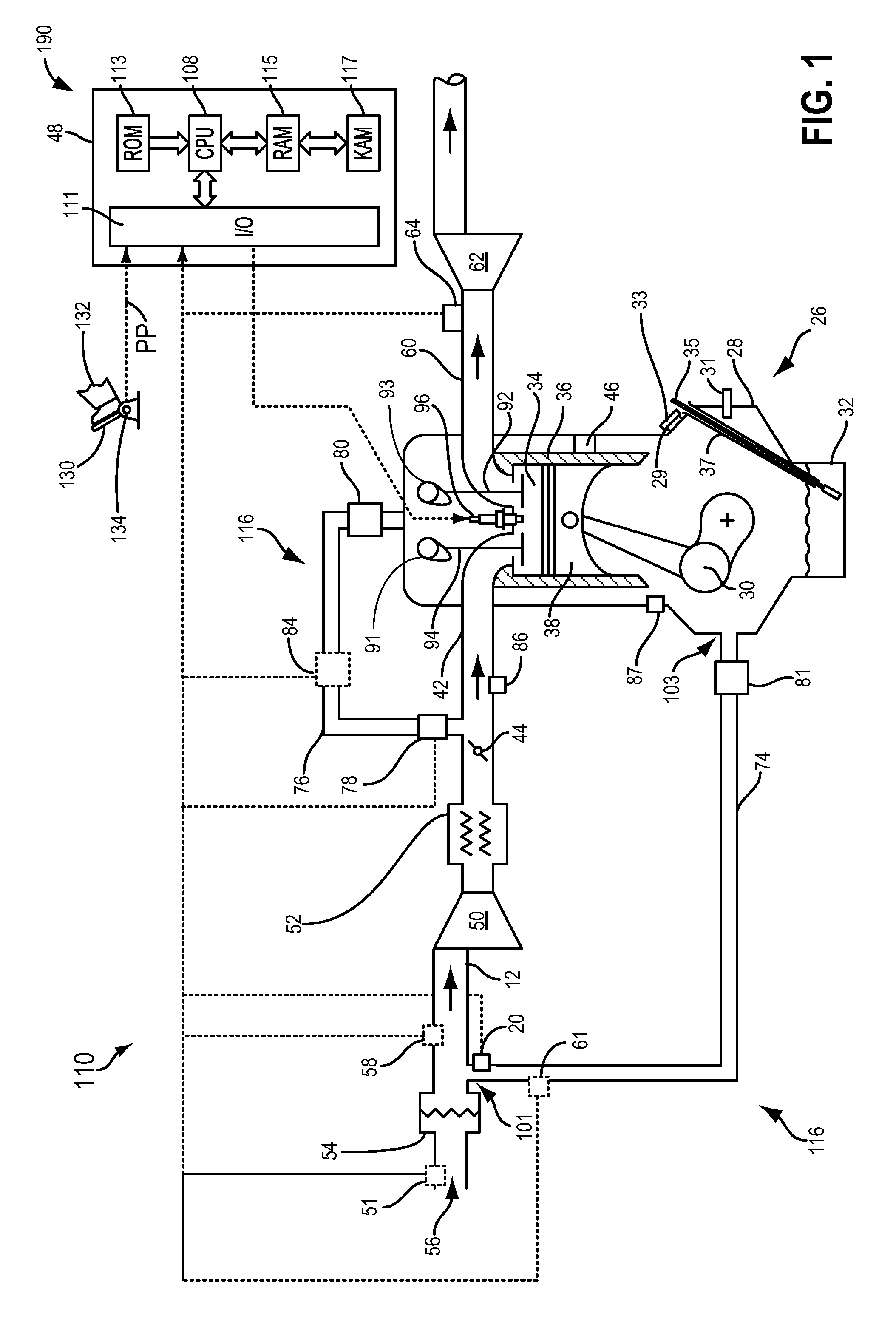

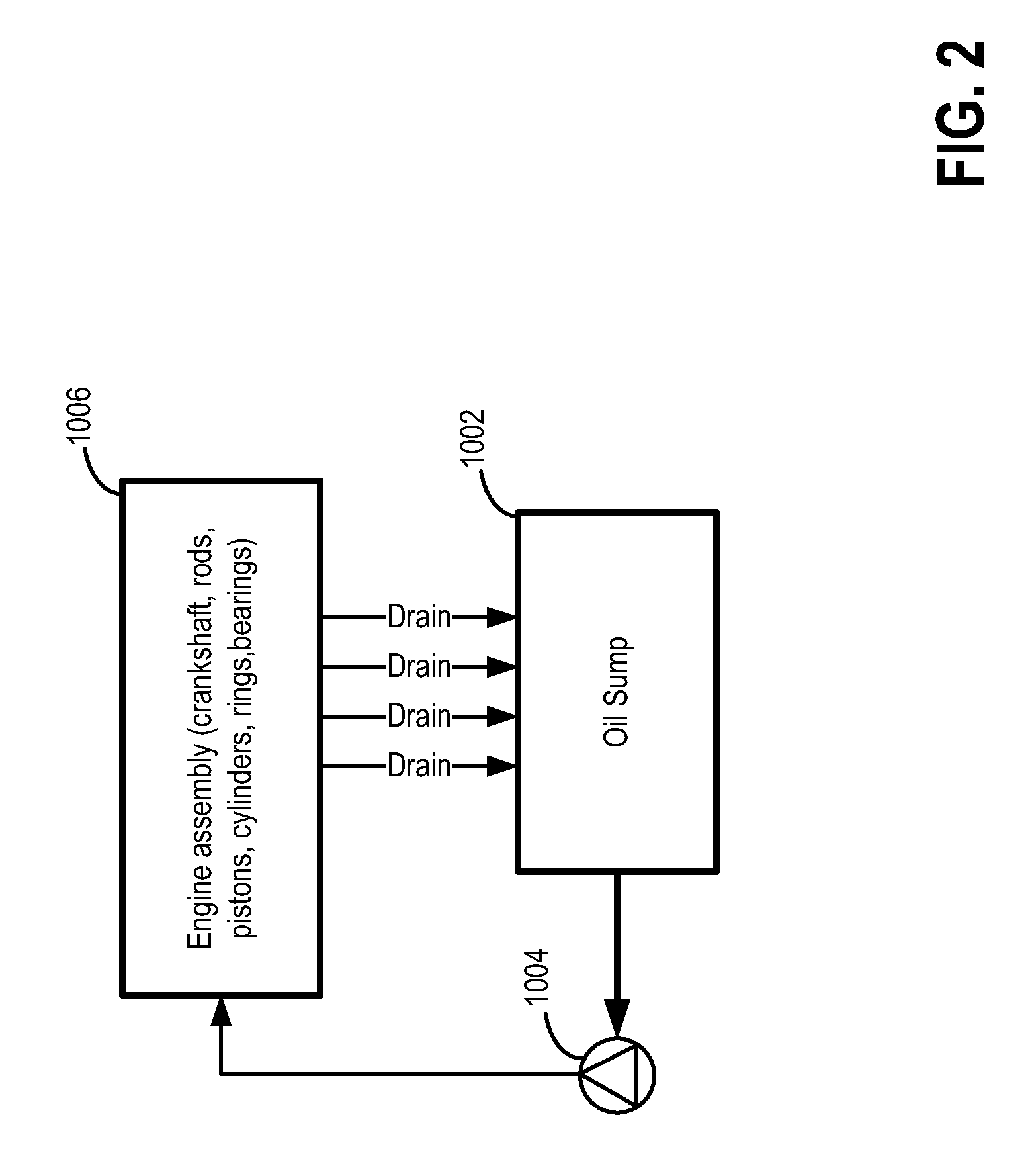

System and method for reducing engine oil dilution

InactiveUS20150369157A1Excess oil dilutionAccelerate emissionsElectrical controlInternal combustion piston enginesOxygen sensorFuel injection

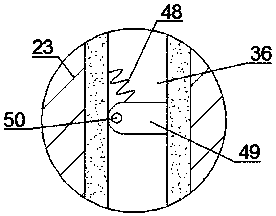

Methods and systems are provided for modeling an oil dilution qualitative indicator based on an integrated difference between a commanded air-to-fuel ratio and an engine air-to-fuel ratio as determined via an oxygen sensor, cumulative cold engine temperature operating duration, and fuel injection characteristics (timing, duration, number of injections) allowing fuel injection timing modifications that minimize oil dilution when the oil dilution qualitative indicator is greater than a threshold level.

Owner:FORD GLOBAL TECH LLC

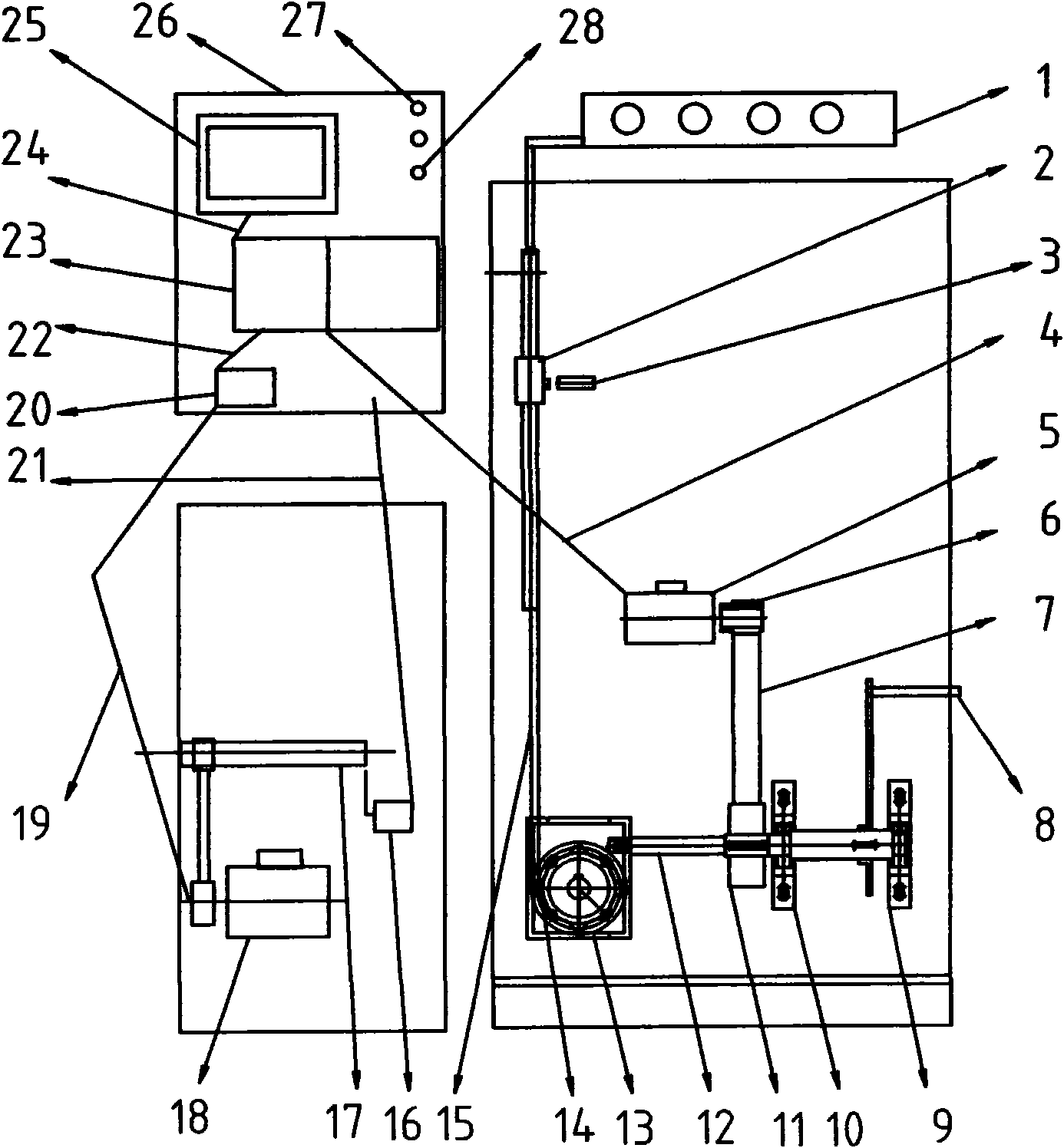

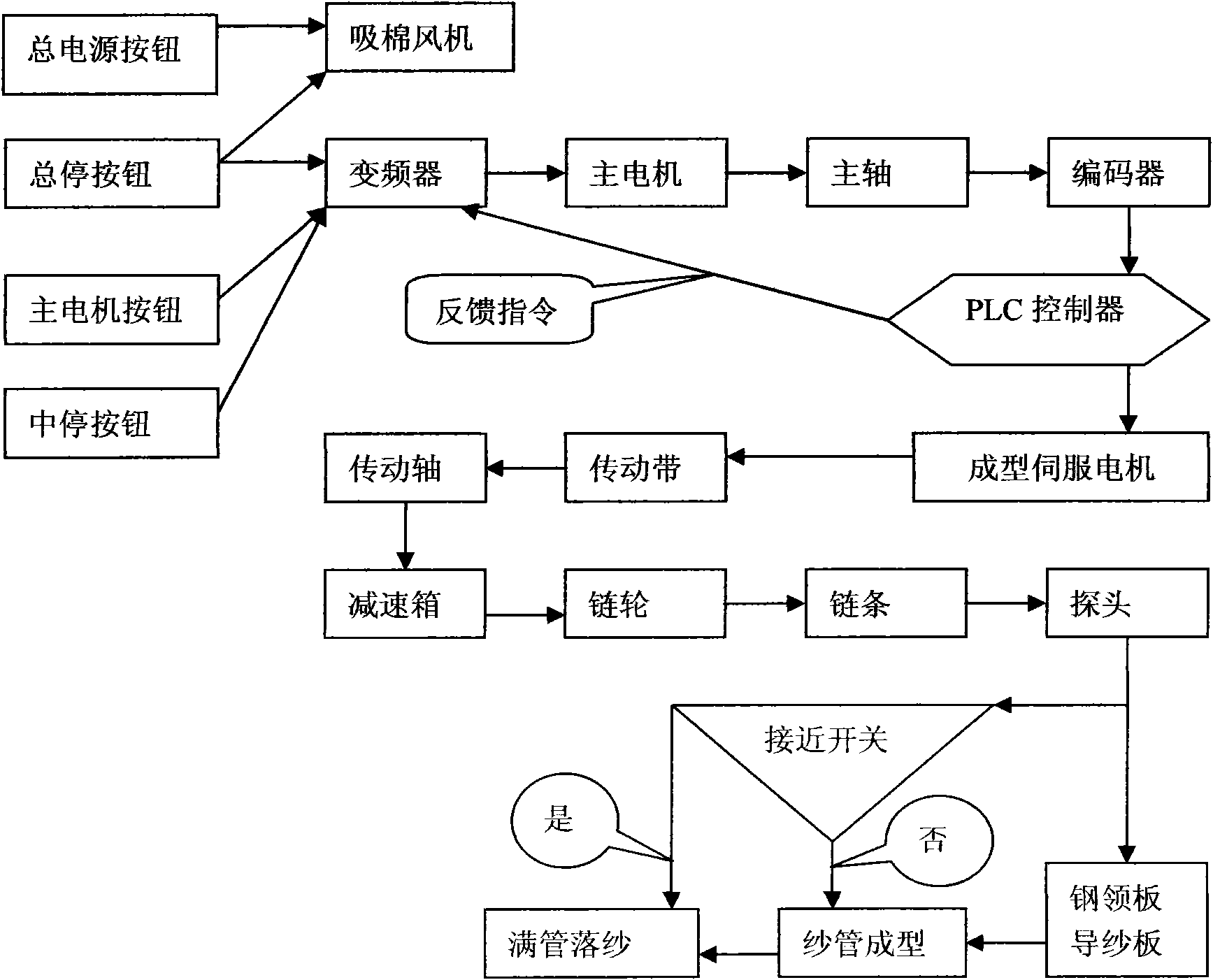

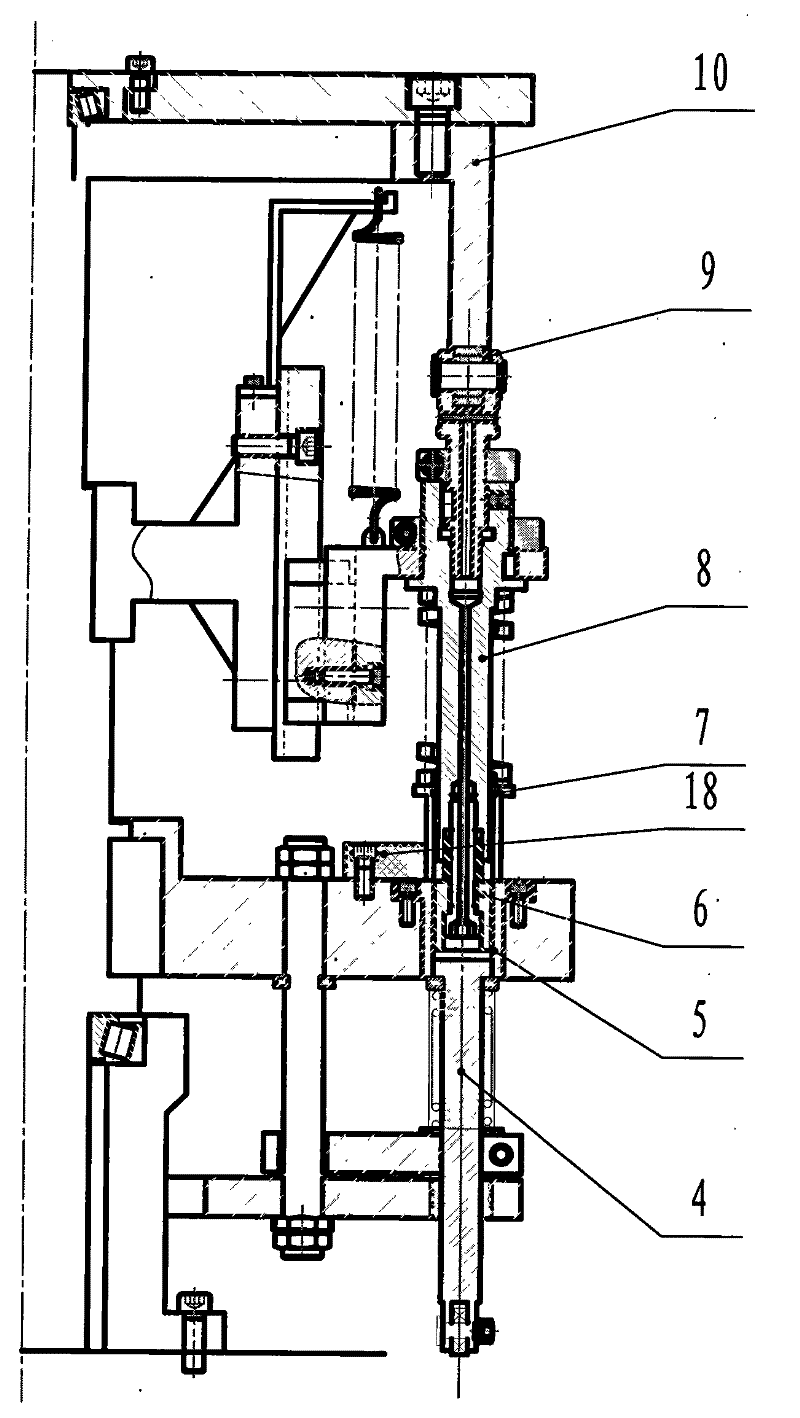

Numerical control molding system of spinning frame

The invention provides a numerical control molding system of a spinning frame. The numerical control molding system comprises a chain, a proximity switch, a worm-gear reduction box, a transmission shaft, a driven wheel disc, a synchronous belt, a driving wheel disc, a molding servo motor and a main shaft, and further comprises components such as an encoder, a PLC (programmable logic controller), a man-machine conversation control screen and the like, wherein the chain is connected with a ring rail. The rotation of the molding servo motor is controlled by virtue of a numerical control way, so as to control the lifting of the ring rail and a yarn guide plate and achieve the purpose of controlling the molding of a yarn cop. The numerical control molding system can control a molding shape in a numerical control way, can conveniently change parameters, has low noise and few oil stains, and is suitable to be used as the molding component of an automatic spinning frame.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

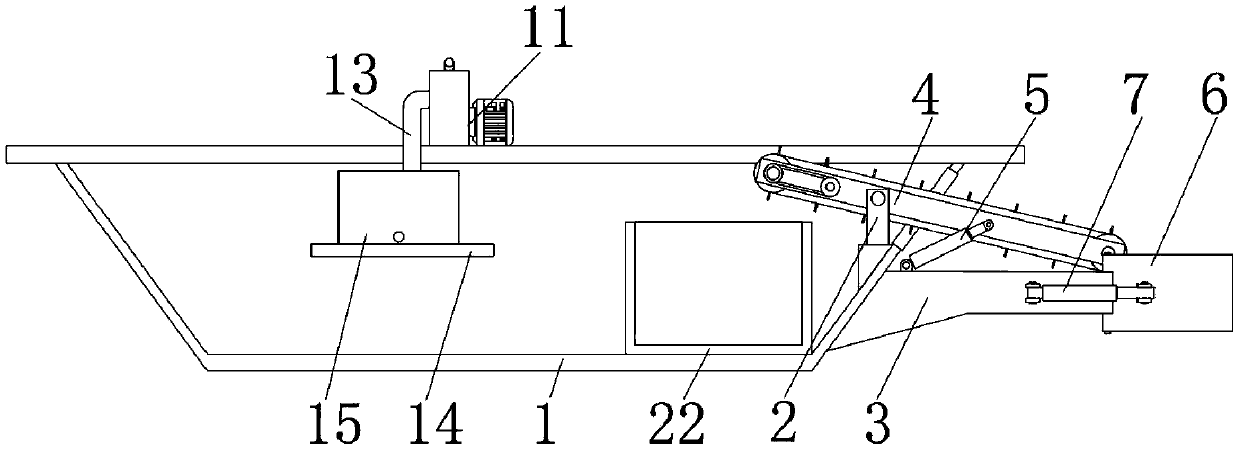

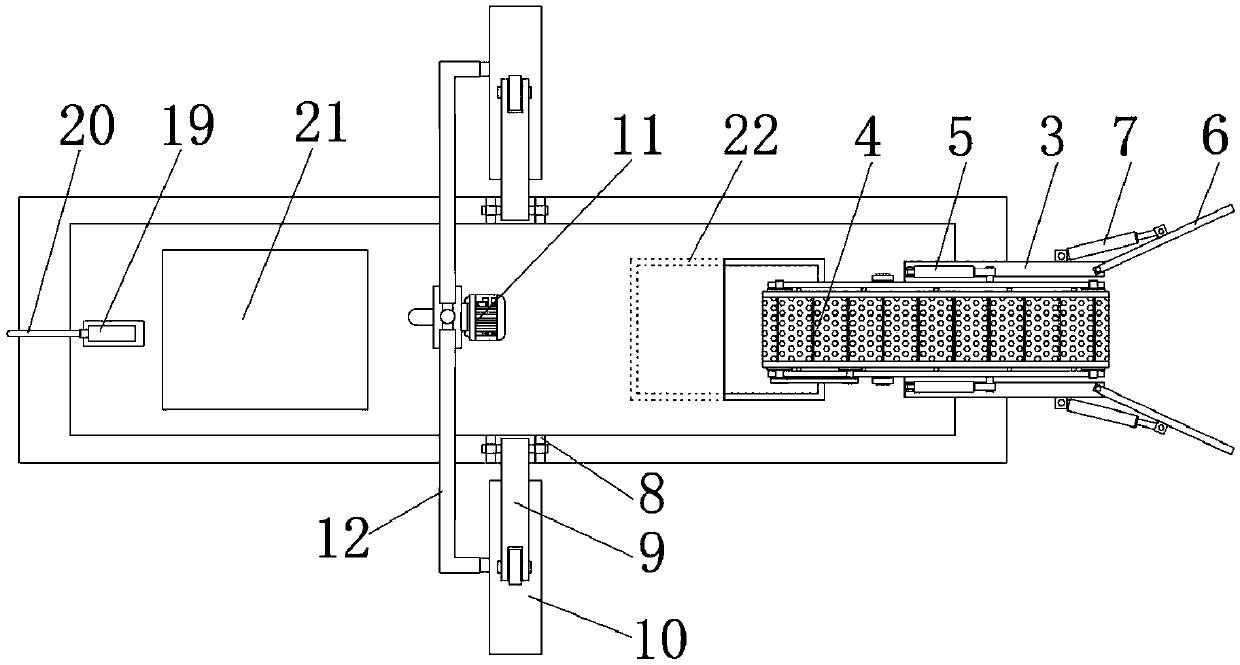

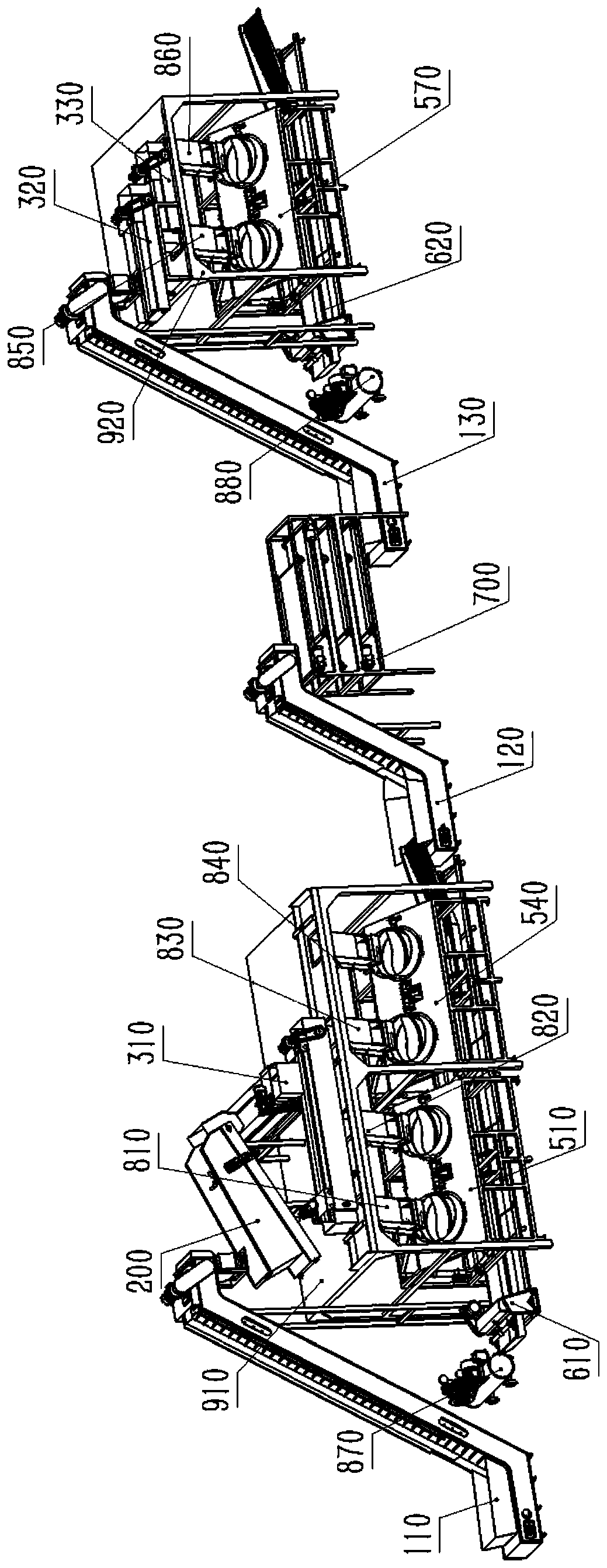

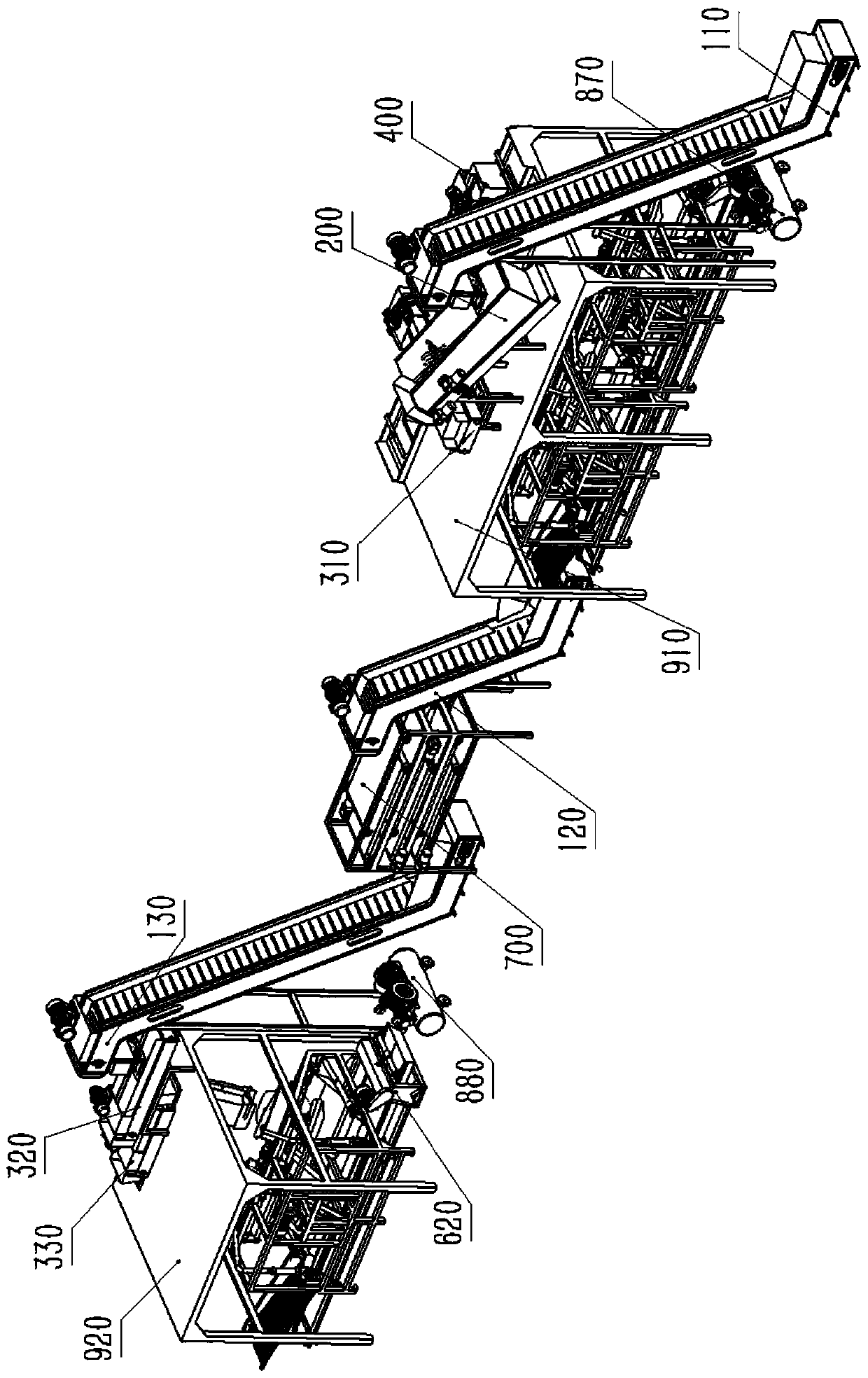

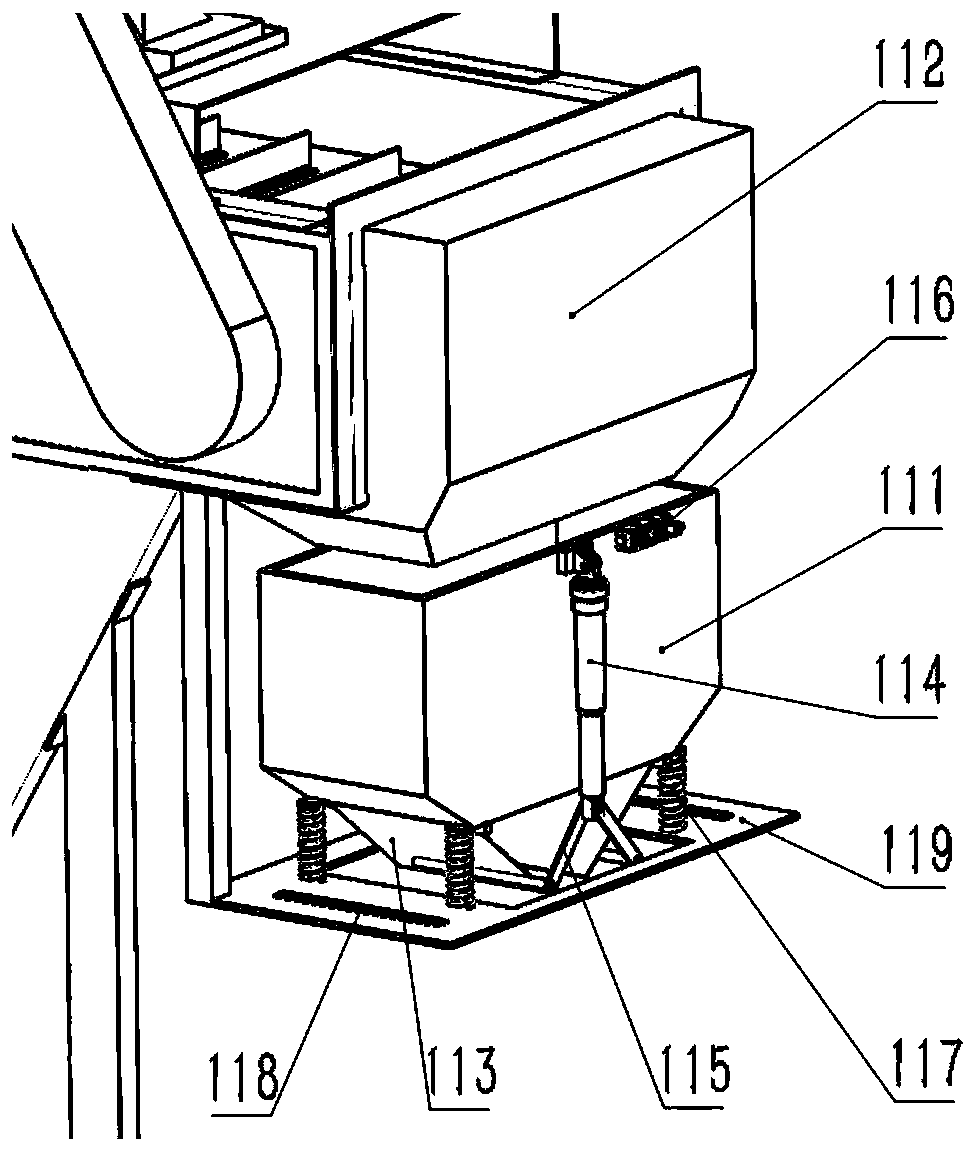

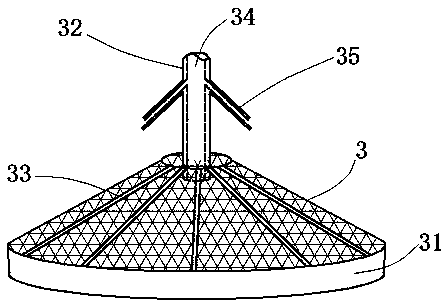

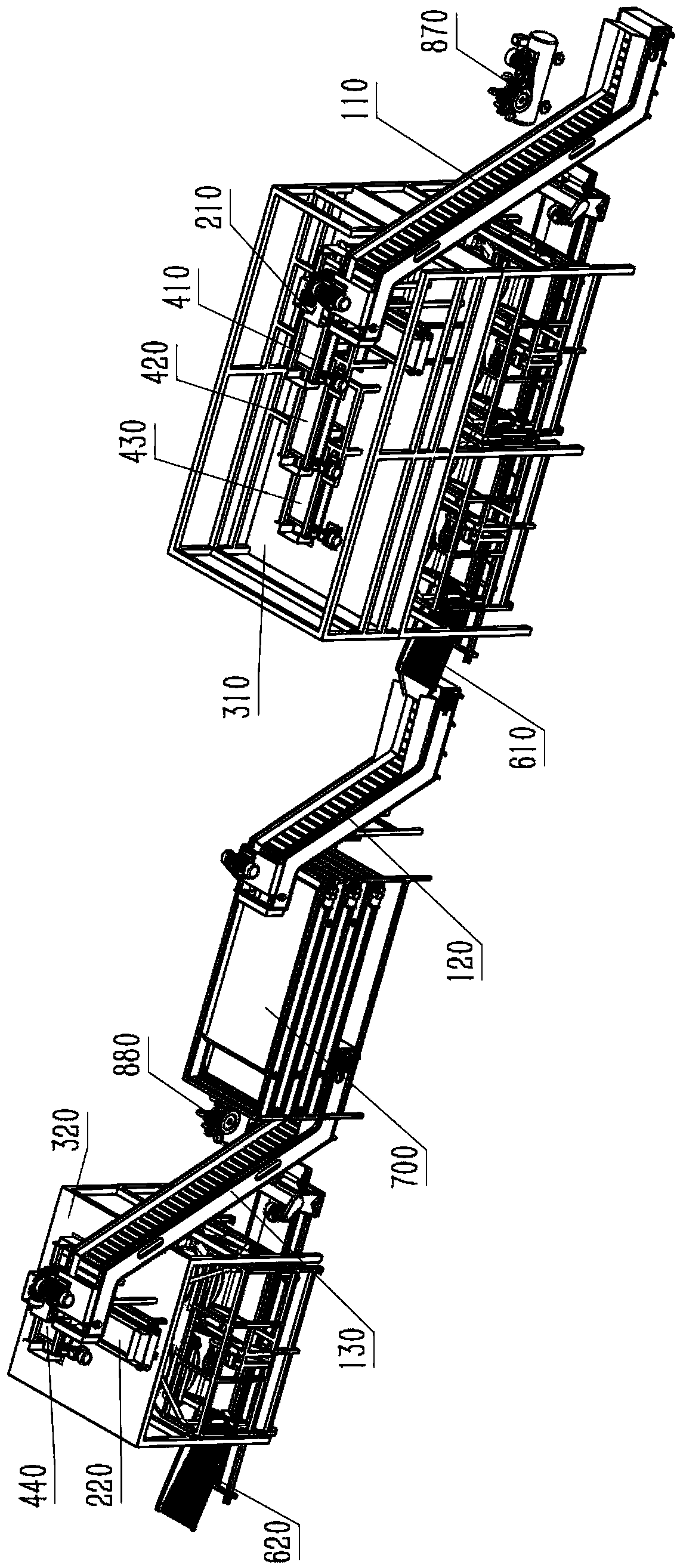

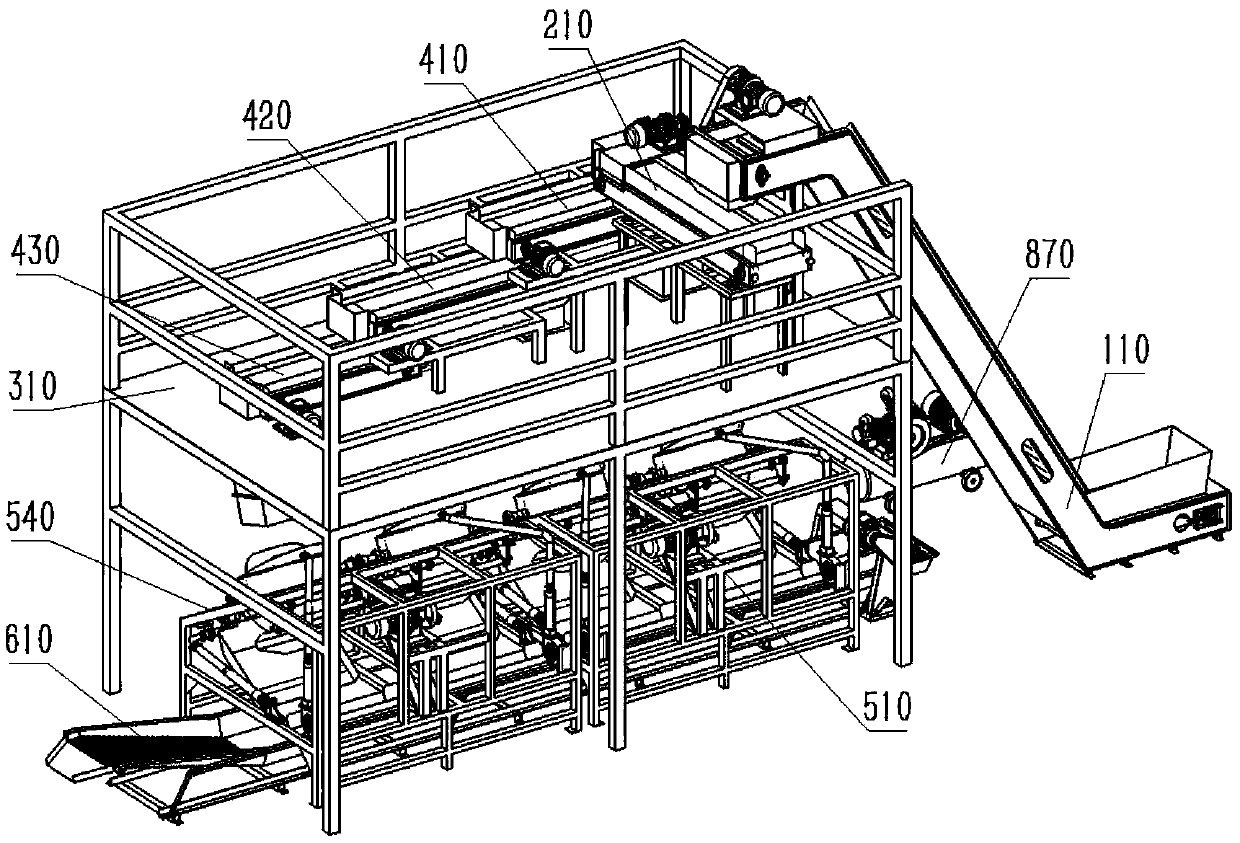

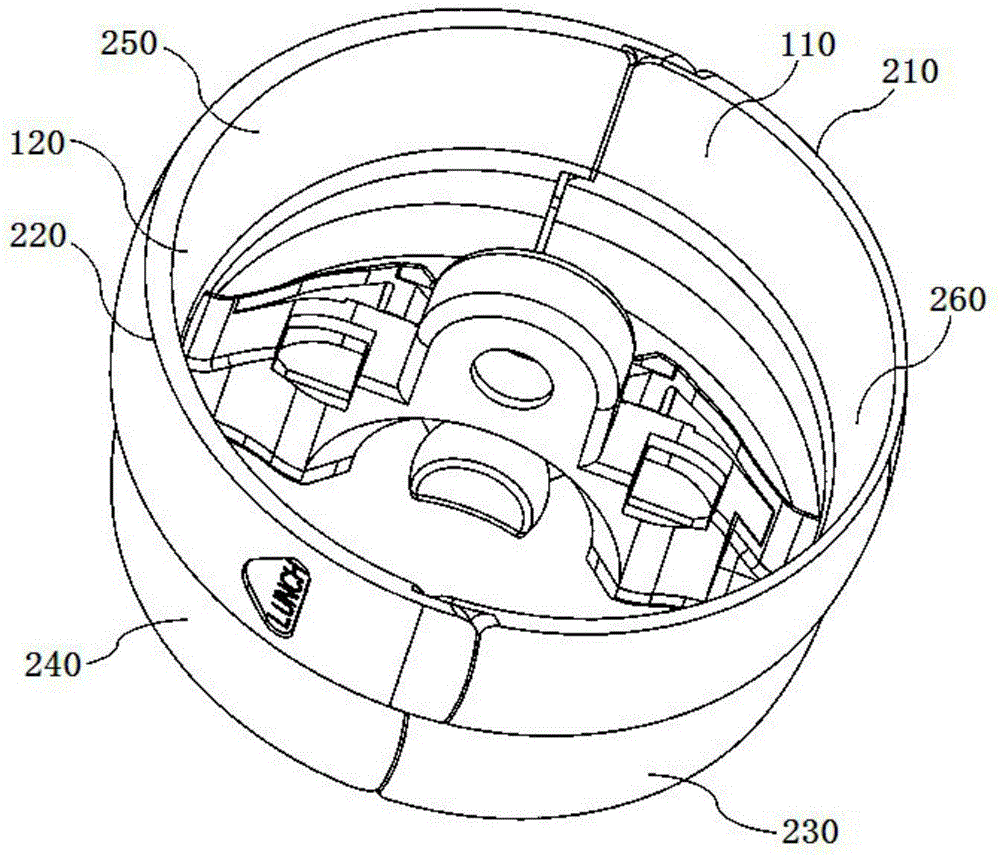

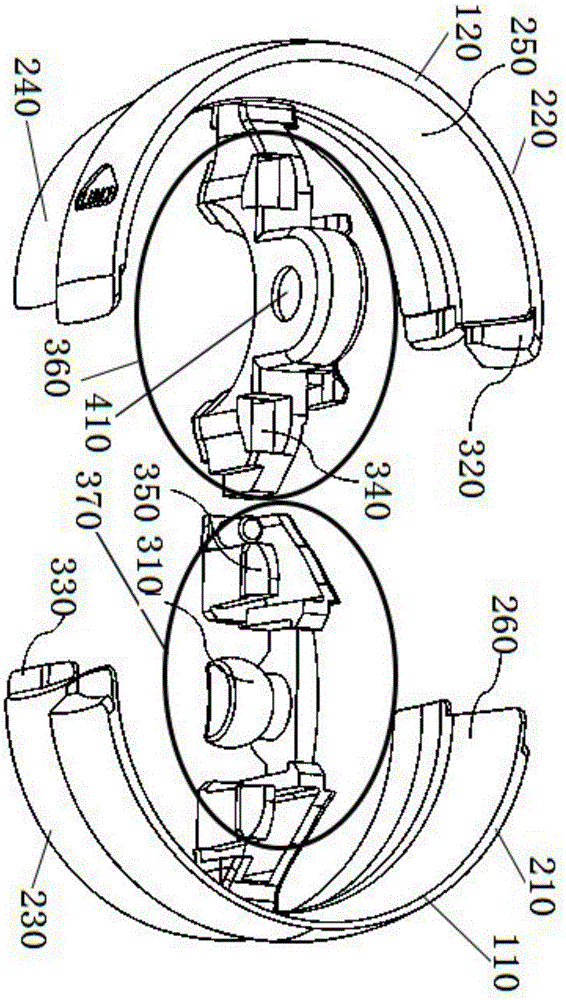

Bead tea continuous forming system based on automatic feeding and control method thereof

ActiveCN109733903AImprove qualityGuaranteed qualityWeighing apparatus using elastically-deformable membersWeighing apparatus with automatic feed/dischargeEngineeringMaterial distribution

The invention relates to a bead tea continuous forming system based on automatic feeding and a control method thereof. The system comprises a PLC control unit, an initial frying unit, a spreading andcooling unit and a refrying unit, a vertical lifting machine, a weighing mechanism, a material distribution mechanism and a vibration type conveyor are arranged on the initial frying unit and the refrying unit, so that automatic feedingg, automatic pan-frying are realized, the continuous making of the pearl tea production is realized, and the production efficiency and the quality of the pearl teaare greatly improved. The control method comprises a primary frying feeding link, a primary frying link, a spreading and cooling link, a refrying and feeding link and a re-frying link control process.According to the control method, the automation degree of the forming system is higher.

Owner:ANHUI AGRICULTURAL UNIVERSITY

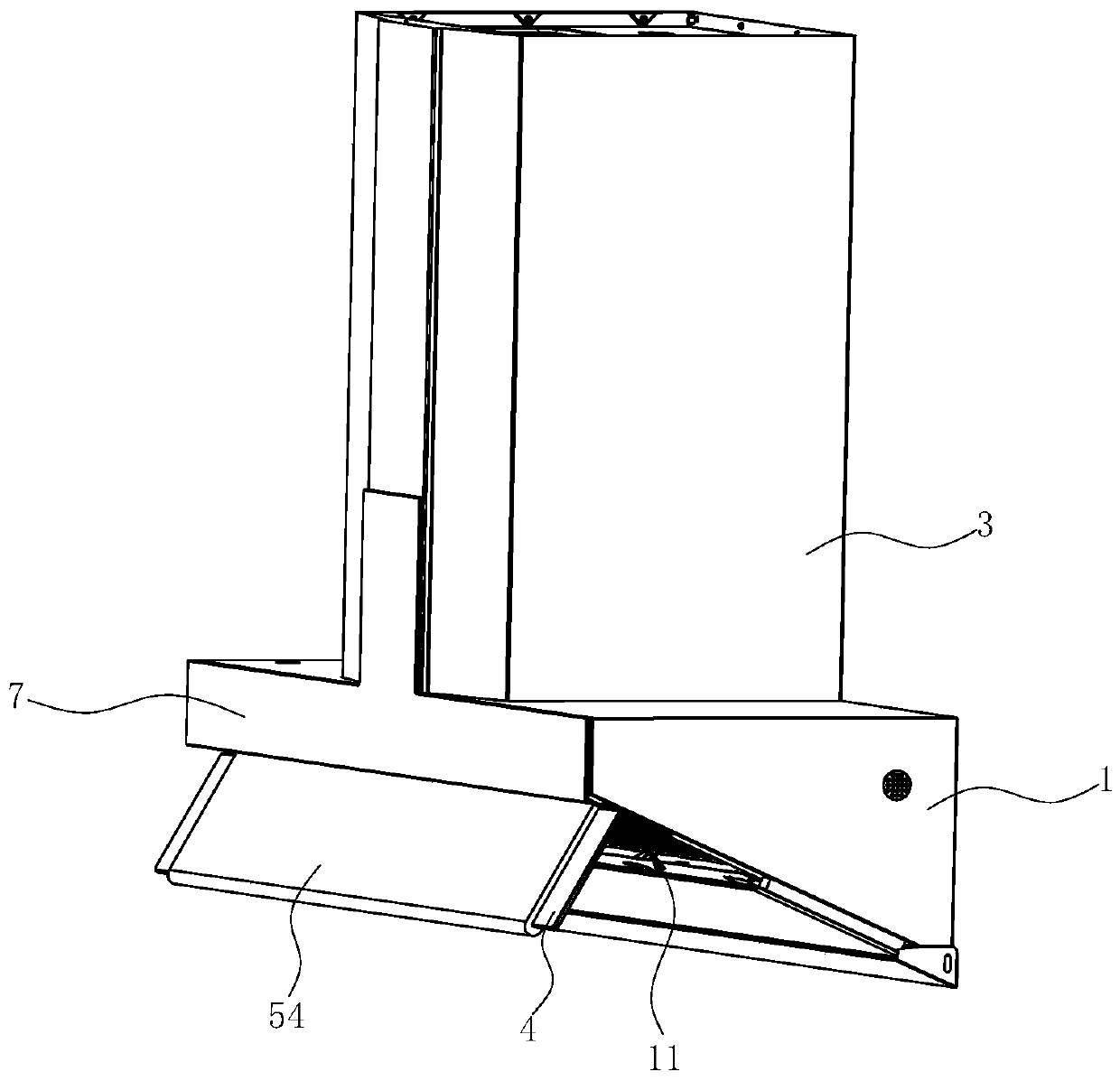

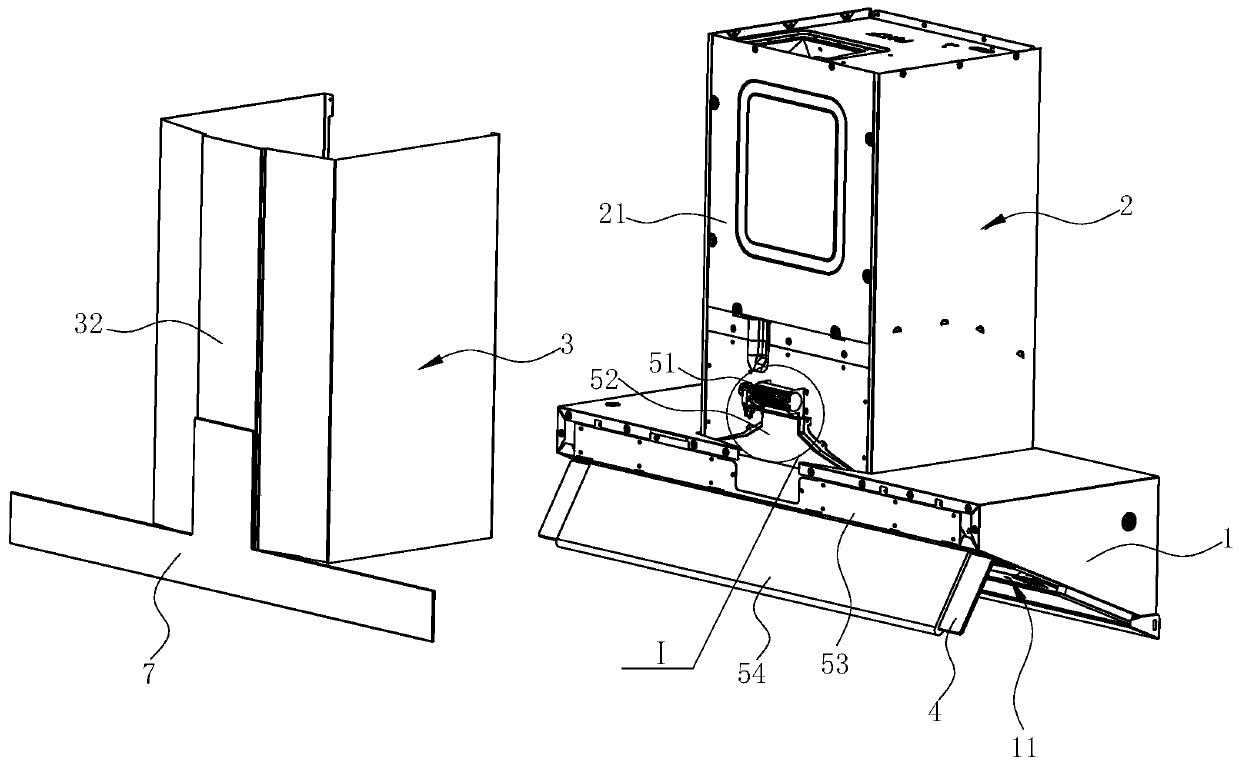

High-efficiency range hood

InactiveCN108506986AImprove capture abilityReduce frequencyDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

Owner:丁向峰

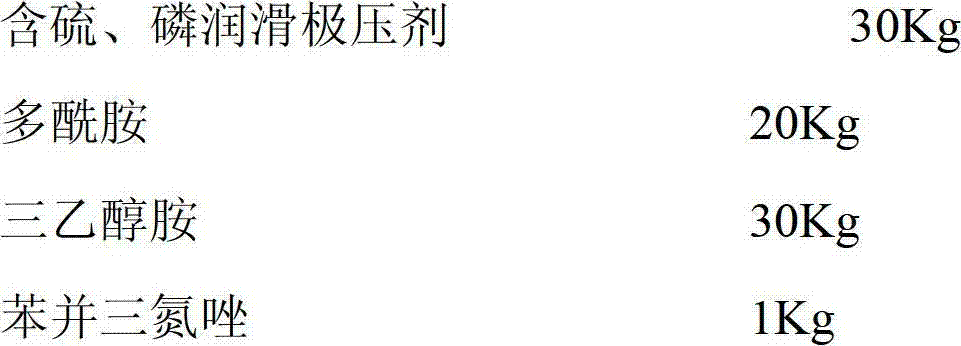

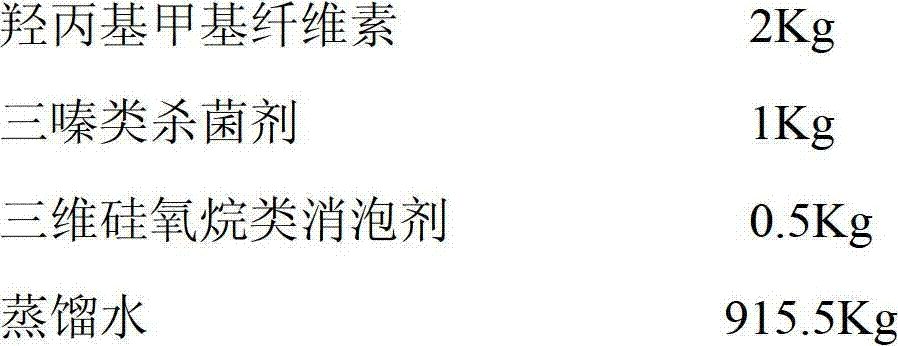

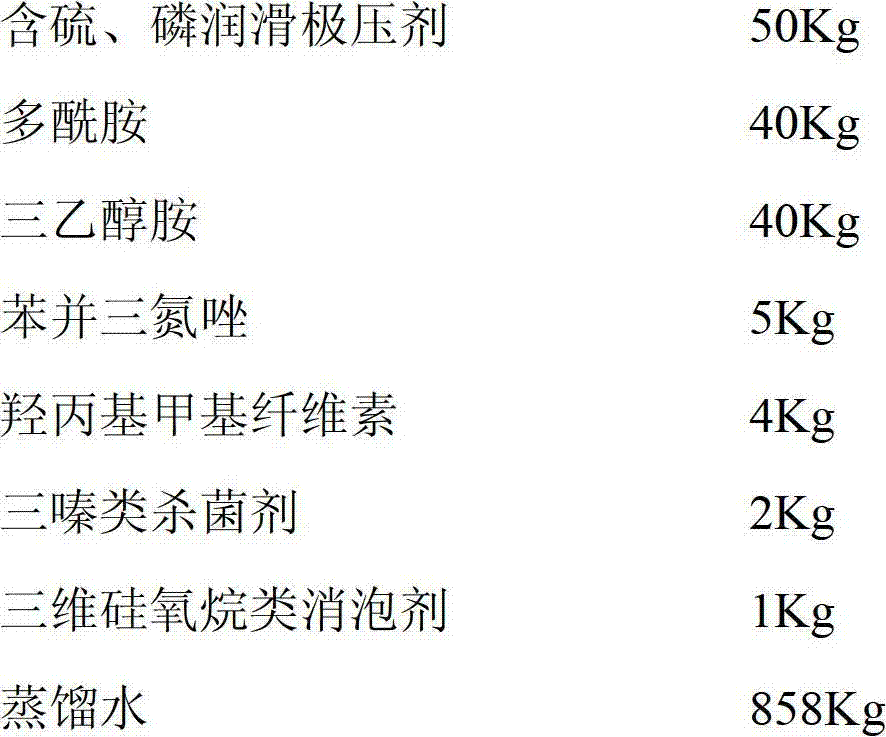

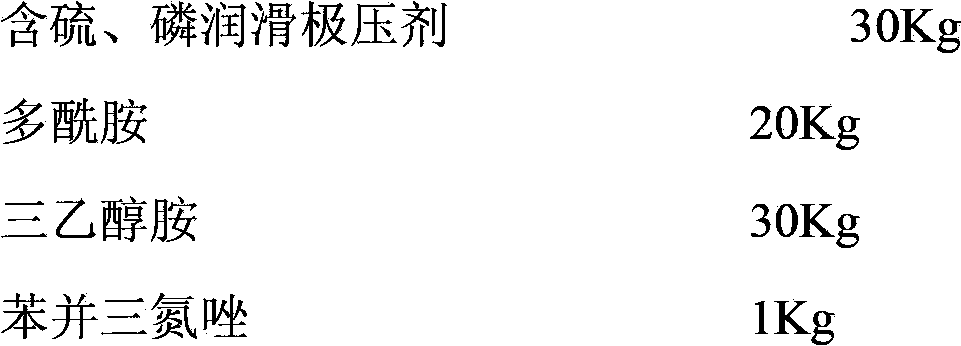

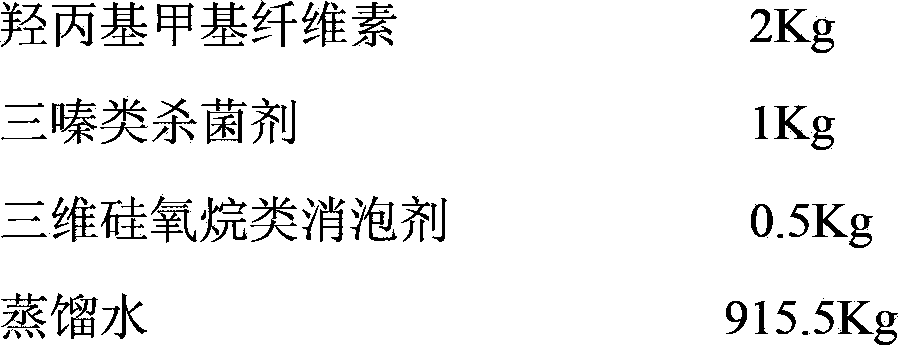

Metal water-based stamping liquid and preparation method thereof

The invention relates to metal water-based stamping liquid and a preparation method of the metal water-based stamping liquid. The metal water-based stamping liquid comprises the components by weight: 3-5% of lubricating extreme pressure agent, 2-4% of polyamide, 3-4% of triethanolamine, 0.1-0.2% of triazole fungicide, 0.1-0.5% of benzotriazole, 0.2-0.4% of hydroxypropyl methylcellulose, 0.05-0.1% of three-dimensional siloxane defoaming agent and the balance of distilled water. The preparation method comprises the main steps of: firstly, adding the distilled water, and then, orderly adding the lubricating extreme pressure agent, polyamide, triethanolamine, triazole fungicide, benzotriazole, hydroxypropyl methylcellulose and three-dimensional siloxane defoaming agent to mix. The action mechanism provided by the invention is simple and scientific; punch forming and anti-dusting effects of the metal achieve the optimal state by synergistic effect of the components; the water-based stamping liquid contains the triazole fungicide, so that decaying of the stamping liquid in storing and working processes can be effectively prevented; and the hydroxypropyl methylcellulose can assist film forming, and the fluid friction resistance is reduced, so that the water-based stamping liquid better protects the metal in the metal stamping and molding processes, and the anti-dusting time is more effectively increased after a workpiece is processed.

Owner:华阳新兴科技(天津)集团有限公司

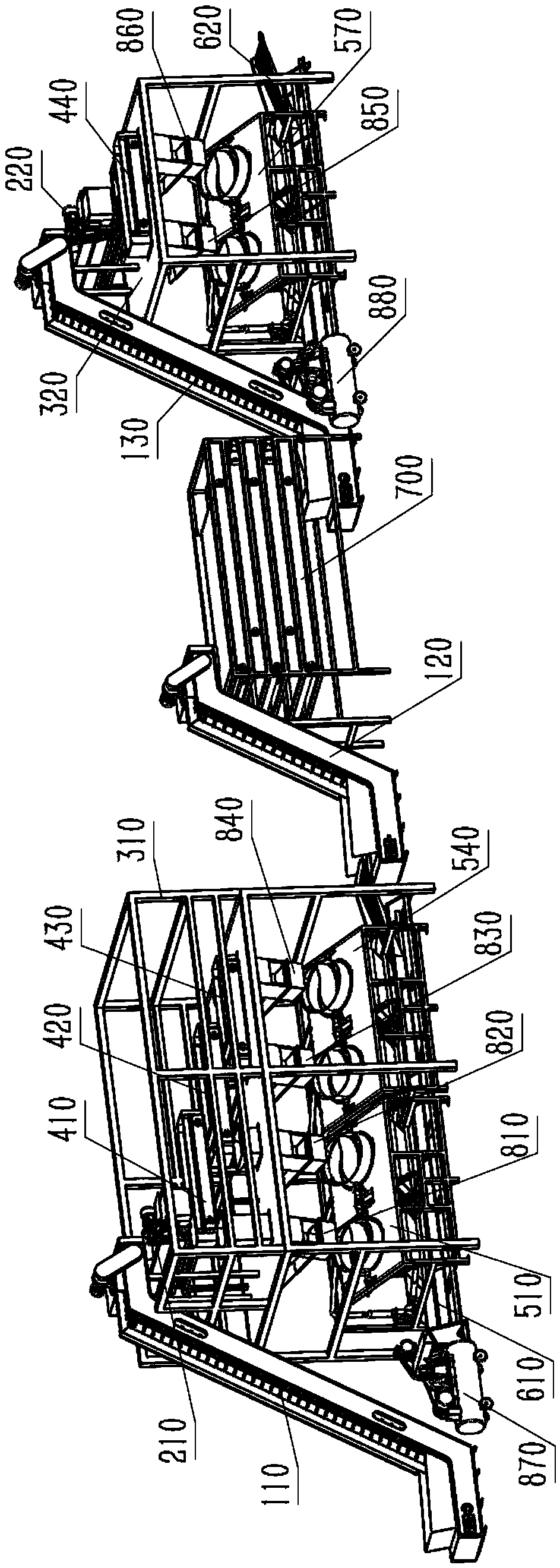

Pinhead tea continuous shaping system based on automatic weighing and control method thereof

ActiveCN109566777AFully automatedRealize continuous productionPre-extraction tea treatmentWeighing apparatus with automatic feed/dischargeCooling UnitsAutonomation

The invention relates to a pinhead tea continuous shaping system based on automatic weighing and a control method thereof. The system comprises a PLC control system, a primary roasting unit, a spreading and cooling unit and a re-roasting unit, wherein a vertical lifting machine, a weighing conveyor, a material distribution mechanism and a vibration type conveyor are arranged at the primary roasting unit and the re-roasting unit for realizing automatic feeding, discharging and automatic pot combination re-roasting; the continuous shaping of the pinhead tea production is realized; the productionefficiency and the pinhead tea quality are greatly improved. The control method comprises the control processes of a primary roasting feeding link, a primary roasting link, a spreading and cooling link, a re-roasting feeding link and a re-roasting link. Through the control method, the automation degree of the shaping system is higher.

Owner:ANHUI AGRICULTURAL UNIVERSITY

System and method for reducing engine oil dilution

InactiveUS9470173B2Reduce oil pollutionImproved heat outputElectrical controlInternal combustion piston enginesOxygen sensorFuel injection

Owner:FORD GLOBAL TECH LLC

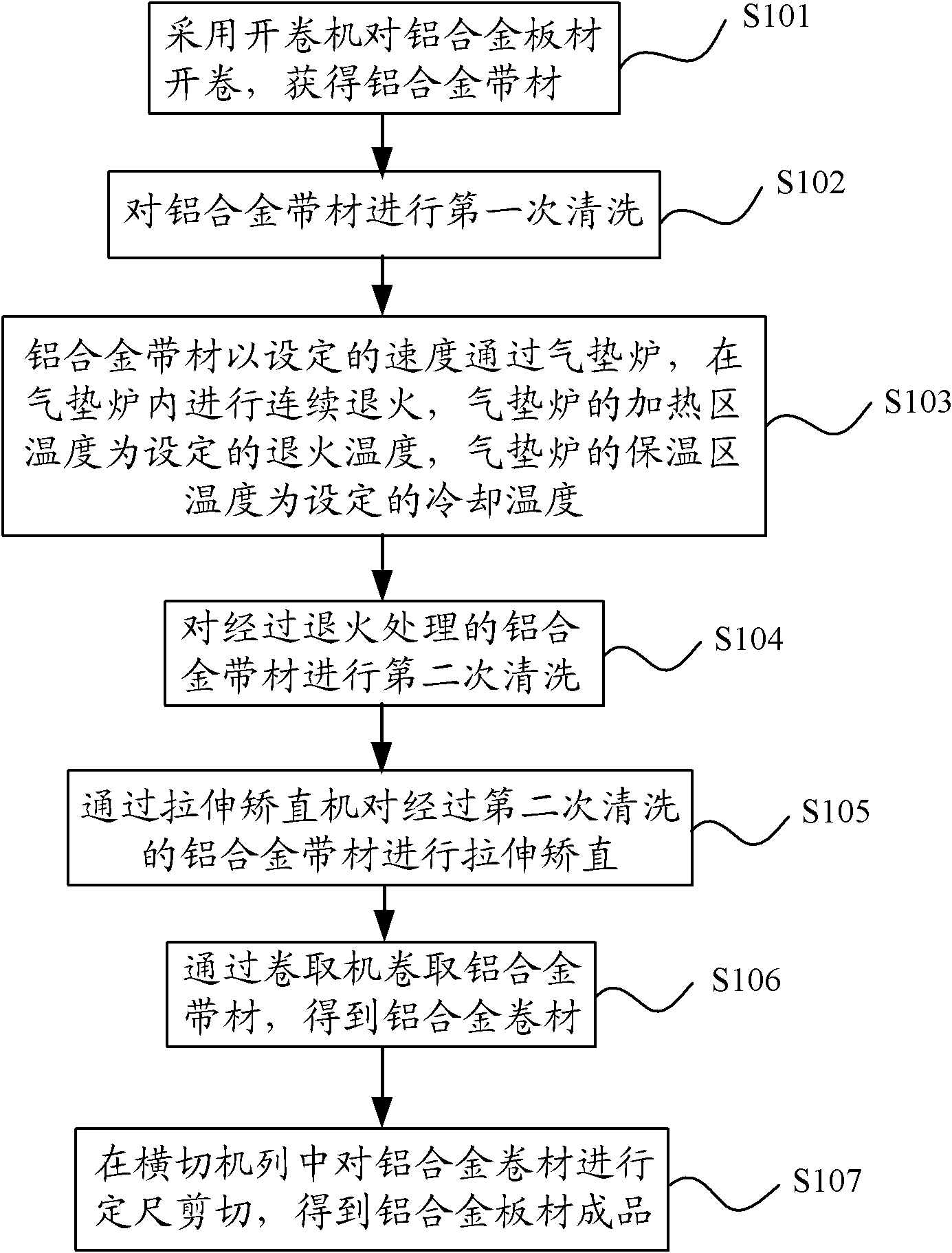

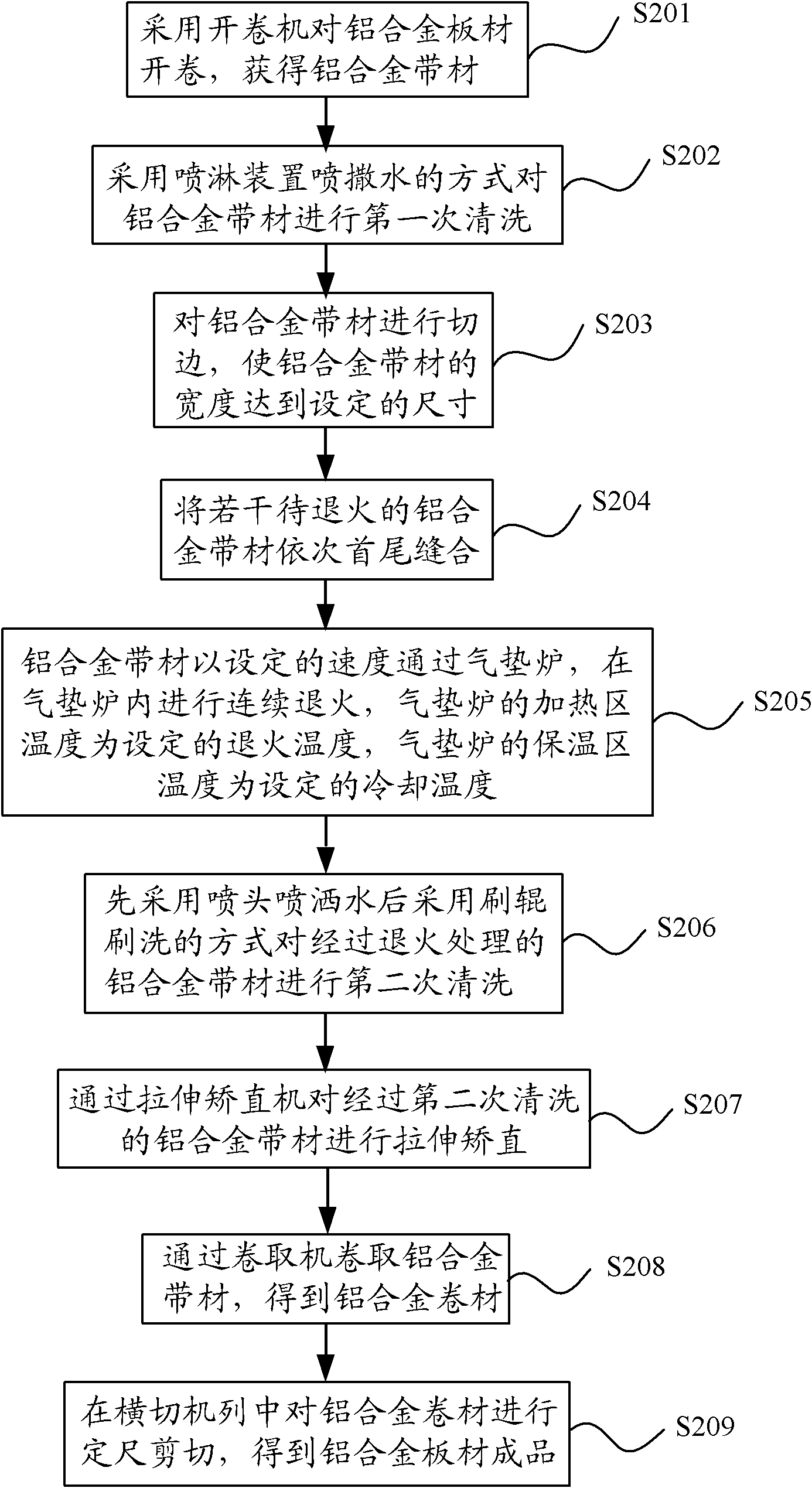

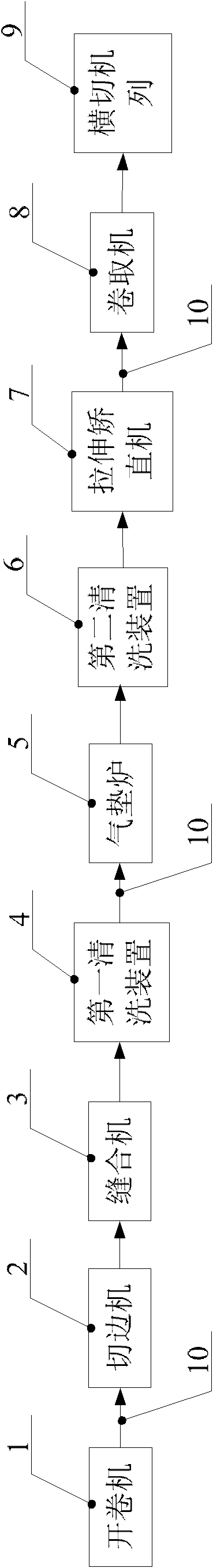

Production method and system of aluminum alloy plates

InactiveCN102424905AReduce oil pollutionReduces aluminum ash residueProcess efficiency improvementContinuous annealingCooling temperature

The invention provides a production method of aluminum alloy plates, comprising the following steps of: decoiling aluminum alloy plates by a decoiler to obtain aluminum alloy tapes; cleaning the aluminum alloy tapes for the first time; enabling the aluminum alloy tapes to pass through an air cushion furnace at a set speed, performing continuous annealing in the air cushion furnace, wherein the temperature of a heating section of the air cushion furnace is a set annealing temperature, and the temperature of a holding section of the air cushion furnace is a set cooling temperature; cleaning the aluminum alloy tapes for the second time; performing stretch leveling on the aluminum alloy tapes by a stretcher leveler; coiling the aluminum alloy tapes by a coiler to obtain aluminum alloy coils; and cutting the aluminum alloy coils to length in a transverse cutting unit to obtain finished products of aluminum alloy plates. The production method of aluminum alloy plates reduces scratches, oil stain and aluminum ash residue on the surfaces of the aluminum alloy plates, and meets the requirements on surface quality of aluminum alloy plates for electrommunication control cabinets. The invention also provides a production system of the aluminum alloy plates.

Owner:SOUTHWEST ALUMINUM GRP

Cable cleaning and drying equipment

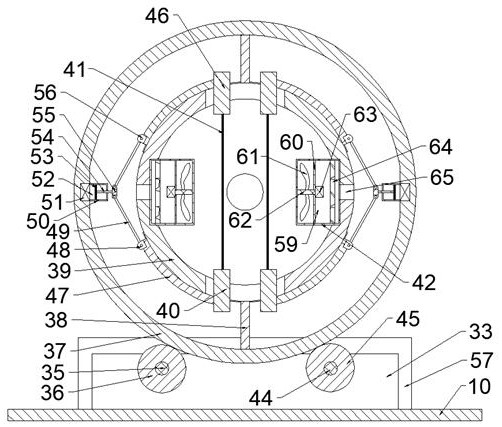

InactiveCN112058757AReduce oil pollutionReduce the impact of impuritiesDrying gas arrangementsCleaning using toolsStructural engineeringElectric cables

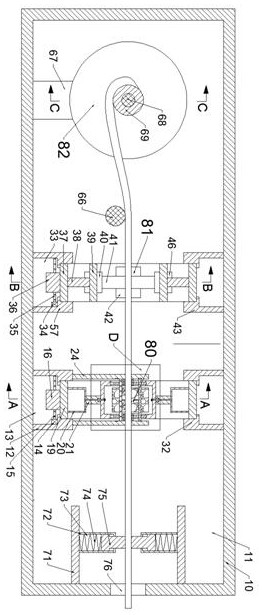

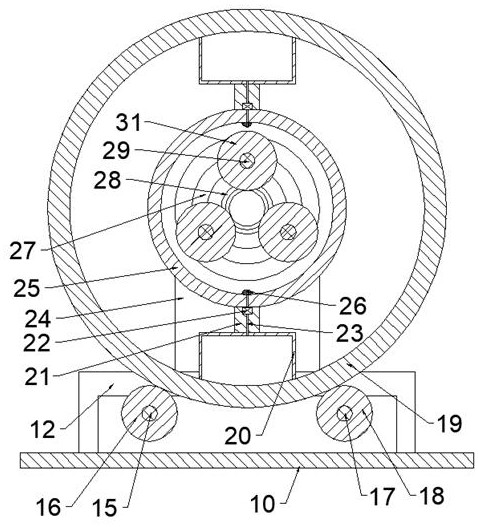

The invention discloses cable cleaning and drying equipment. The cable cleaning and drying equipment comprises a machine body. A storage cavity is formed in the machine body, and a cleaning mechanismis arranged in the storage cavity. The cleaning mechanism comprises a first base and a second base which are fixedly arranged on the inner walls of the upper side and the lower side of the storage cavity correspondingly, and the second base is located on the lower side of the first base. A first rotating cylinder is rotatably arranged between the first base and the second base, and two fixed plates are fixedly arranged at the upper end of the second base in left-right symmetry with the first rotating cylinder as the center. Sliding grooves are formed in the ends, close to the first rotating cylinder, of the two fixed plates correspondingly, and three first rotating shafts are arranged between the two sliding grooves slidably. In the using process of the cable cleaning and drying equipment,a cable is conveyed into the cable cleaning and drying equipment, and the built-in cleaning mechanism rotates and brushes the cable in all directions, so that the influence of oil stains and impurities is greatly reduced; and then the cleaned cable is wiped and dried by a drying mechanism, so that the impurities on the surface of the cable are further removed.

Owner:DONGYANG ZONGTIAN ELECTRONICS TECH CO LTD

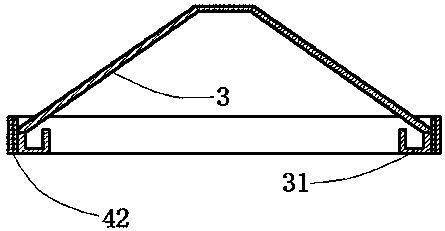

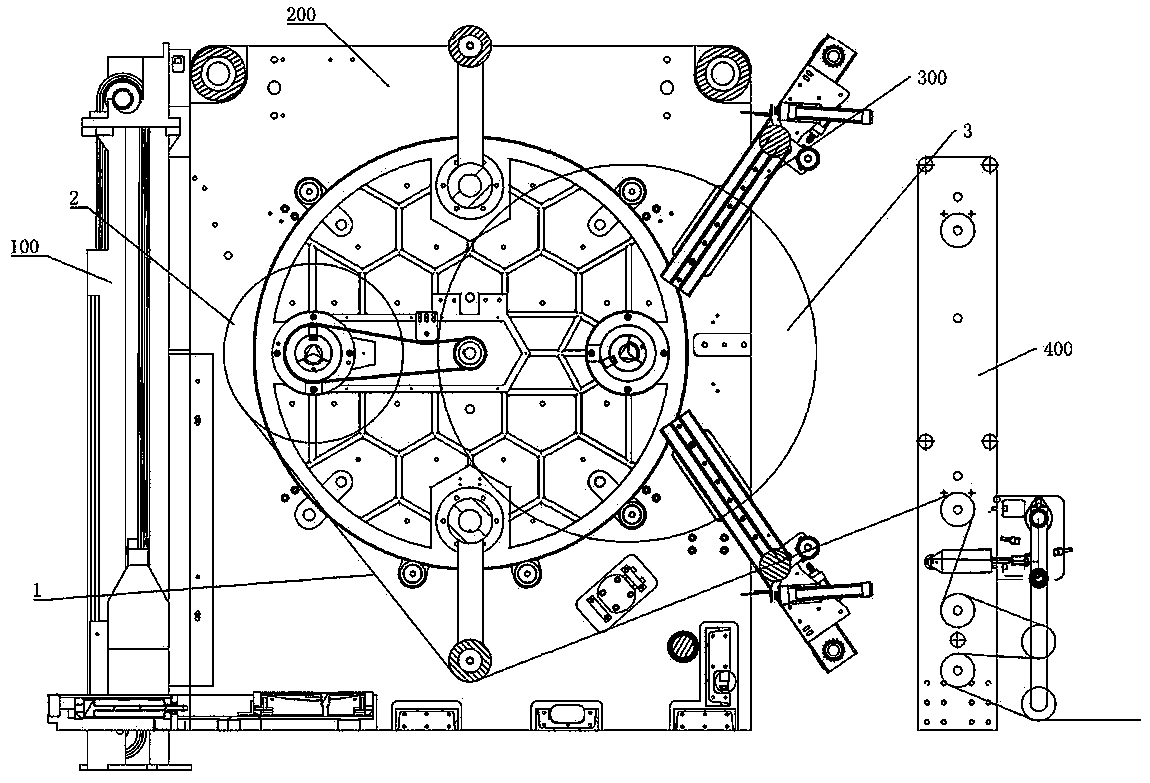

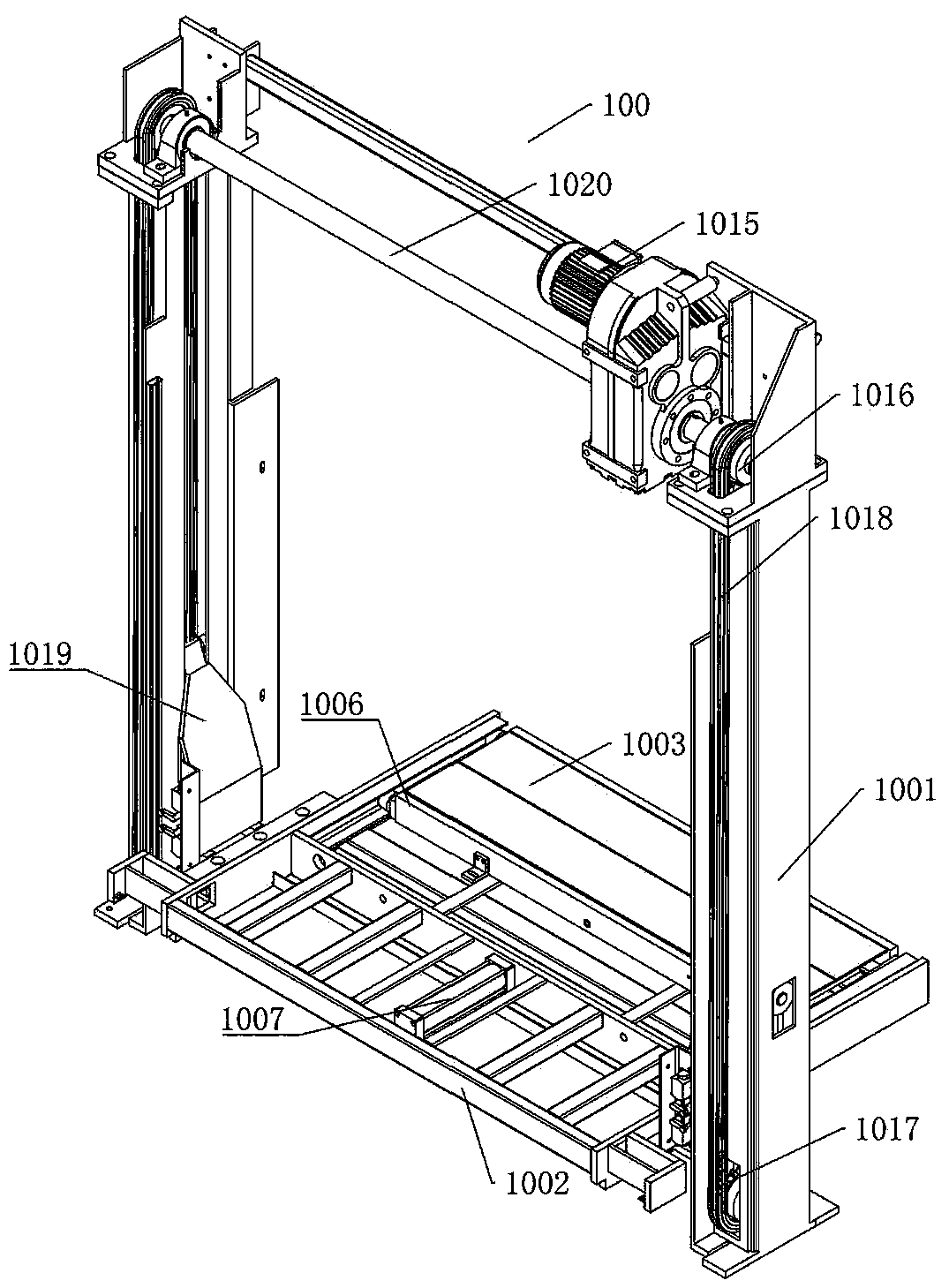

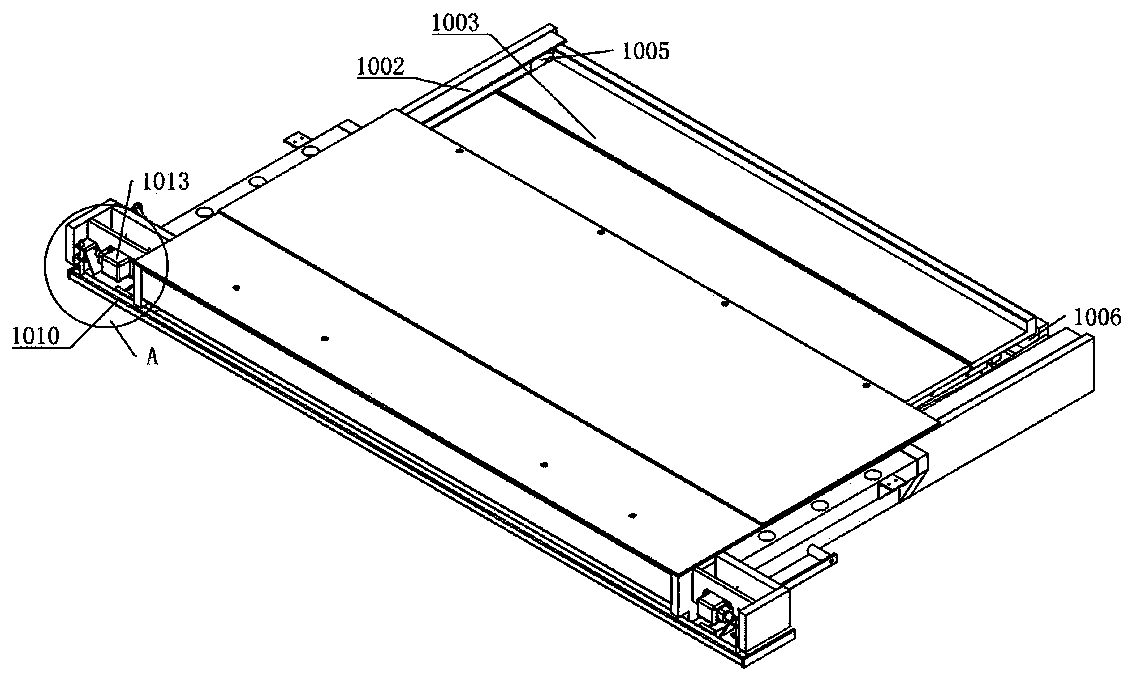

Rotary tower type non-stop unwinding equipment

ActiveCN111532846AImprove efficiencyEasy to put in and take outWebs handlingWall plateIndustrial engineering

The invention provides rotary tower type non-stop unwinding equipment. The rotary tower type non-stop unwinding equipment comprises a scroll lifting part, a scroll rotating part, a cutting part and apaper path buffer part, wherein the scroll lifting part comprises a supporting frame and a tray frame; a V-shaped disc driven by a regulating mechanism is arranged on the tray frame; one end of the tray frame is provided with a protective mechanism; the scroll rotating part comprises two unwinding wall boards and a rotary disc; a supporting positioning mechanism is arranged between each rotary disc and each unwinding wall board; two scroll clamping mechanisms are arranged on the two rotary discs; a transmission mechanism is arranged between each unwinding wall board and each scroll clamping mechanism; the cutting part comprises two groups of cutting devices; and ach cutting device comprises a pressing mechanism and a cutter. A non-shaft type two-side synchronous drive way is adopted, so that the problems such as poor unwinding stability and poor accuracy are solved; and moreover, the rotary tower type non-stop unwinding equipment is stable for positive and negative unwinding ways, andhas characteristics of transmission stability, high safety and applicability to smaller-roll-diameter scroll cutting.

Owner:青州蒙特机械有限公司

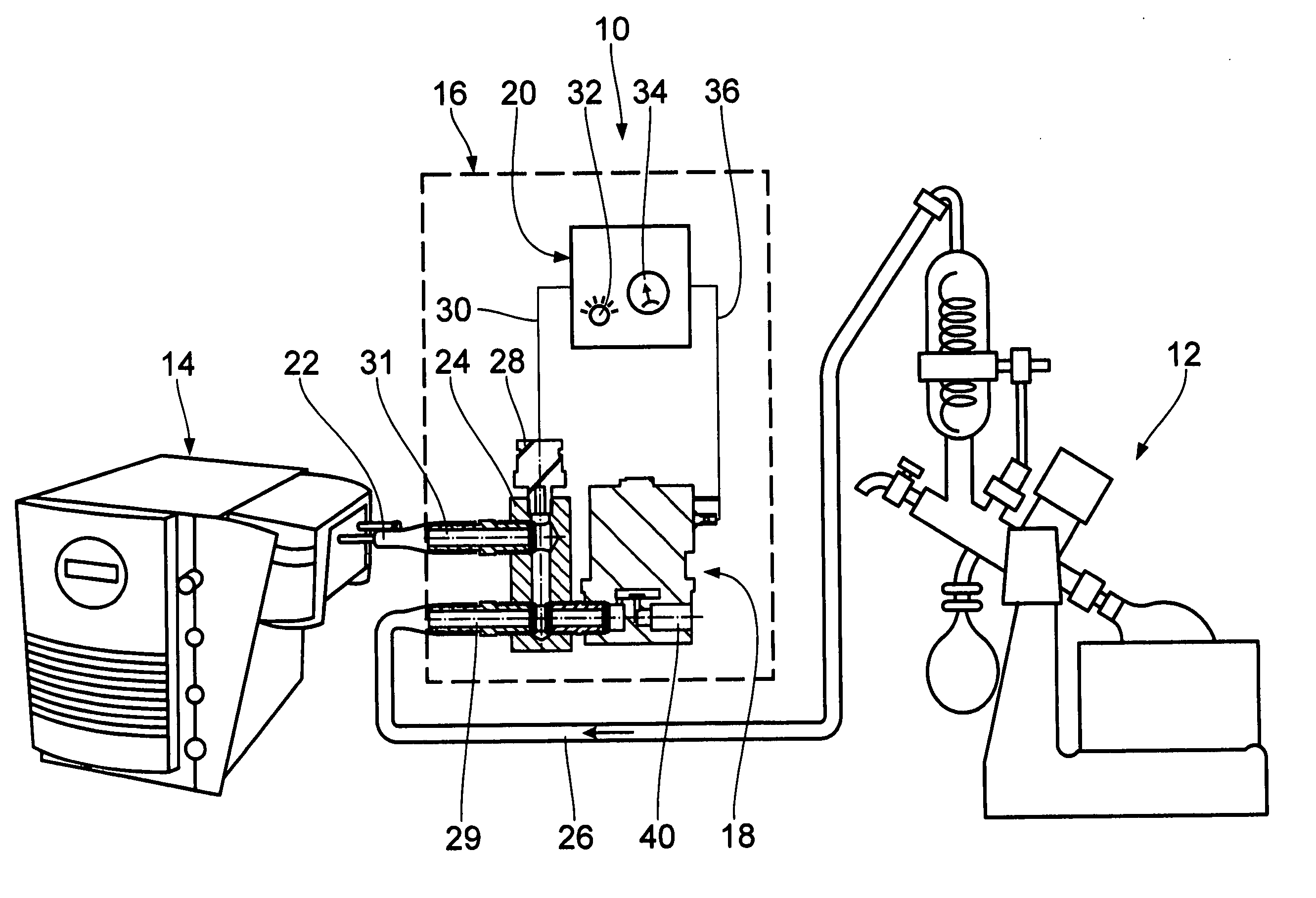

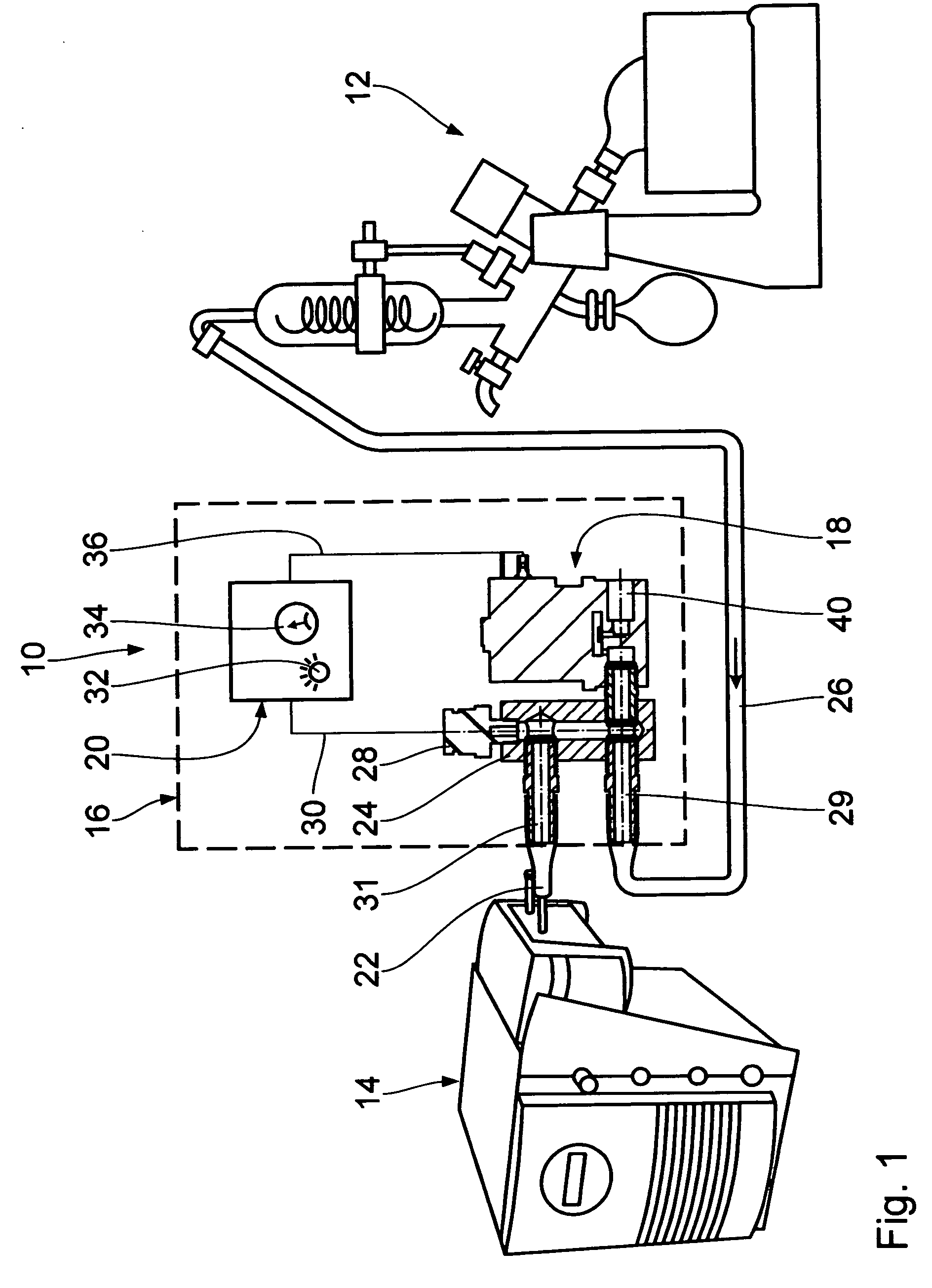

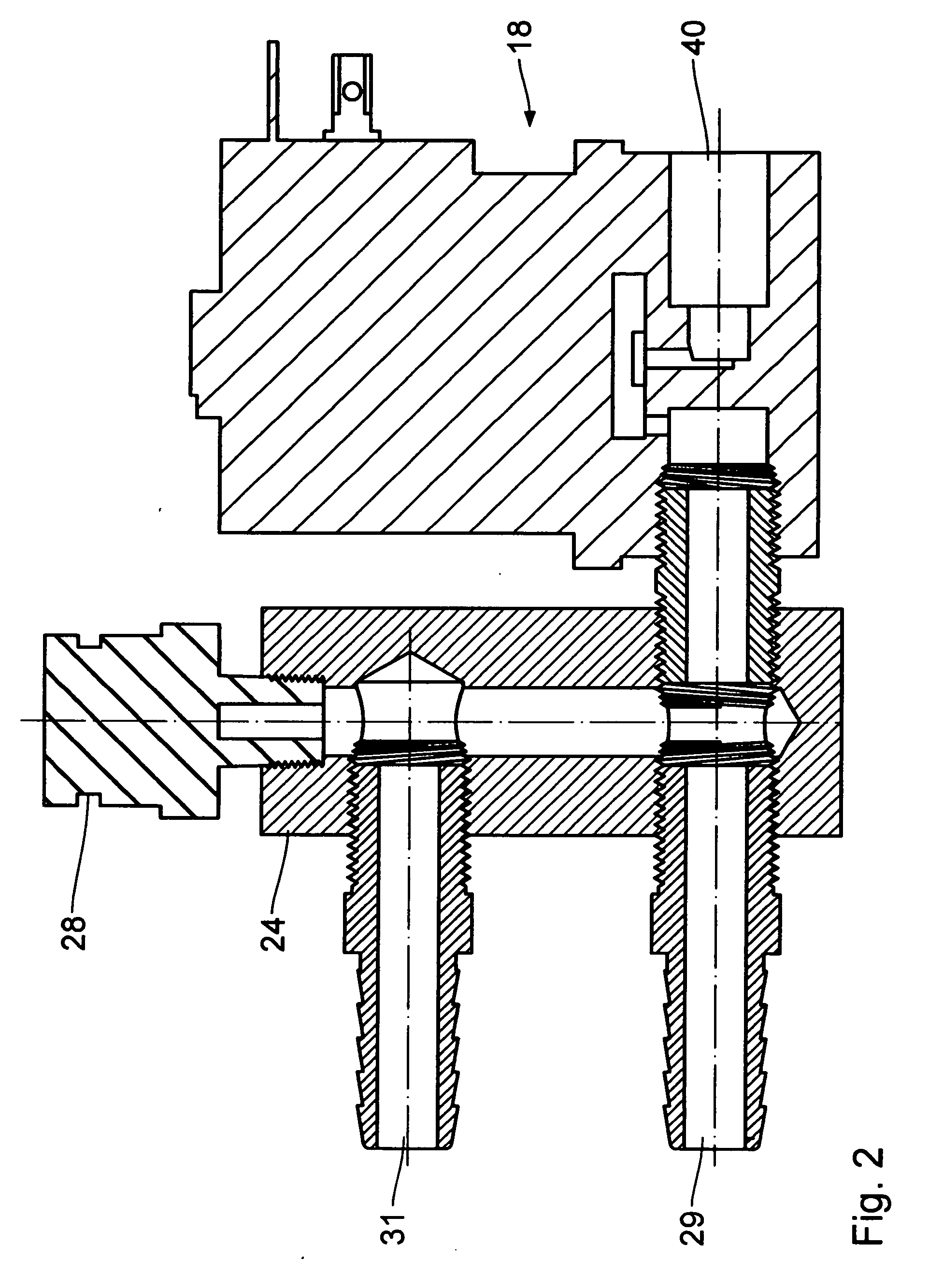

Vacuum pressure controller

InactiveUS20060210405A1Avoid condensationPromote recoveryVacuum distillation separationPump controlVacuum pressureVacuum distillation

A vacuum pressure controller for vacuum distillation equipment is controlled to mix a dilution gas with the distillation vapors to control the vacuum pressure to which the distillation equipment is subjected.

Owner:THOMAS IND INC

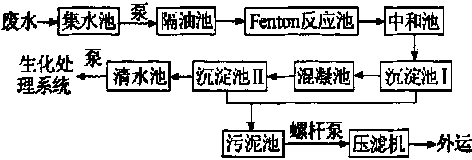

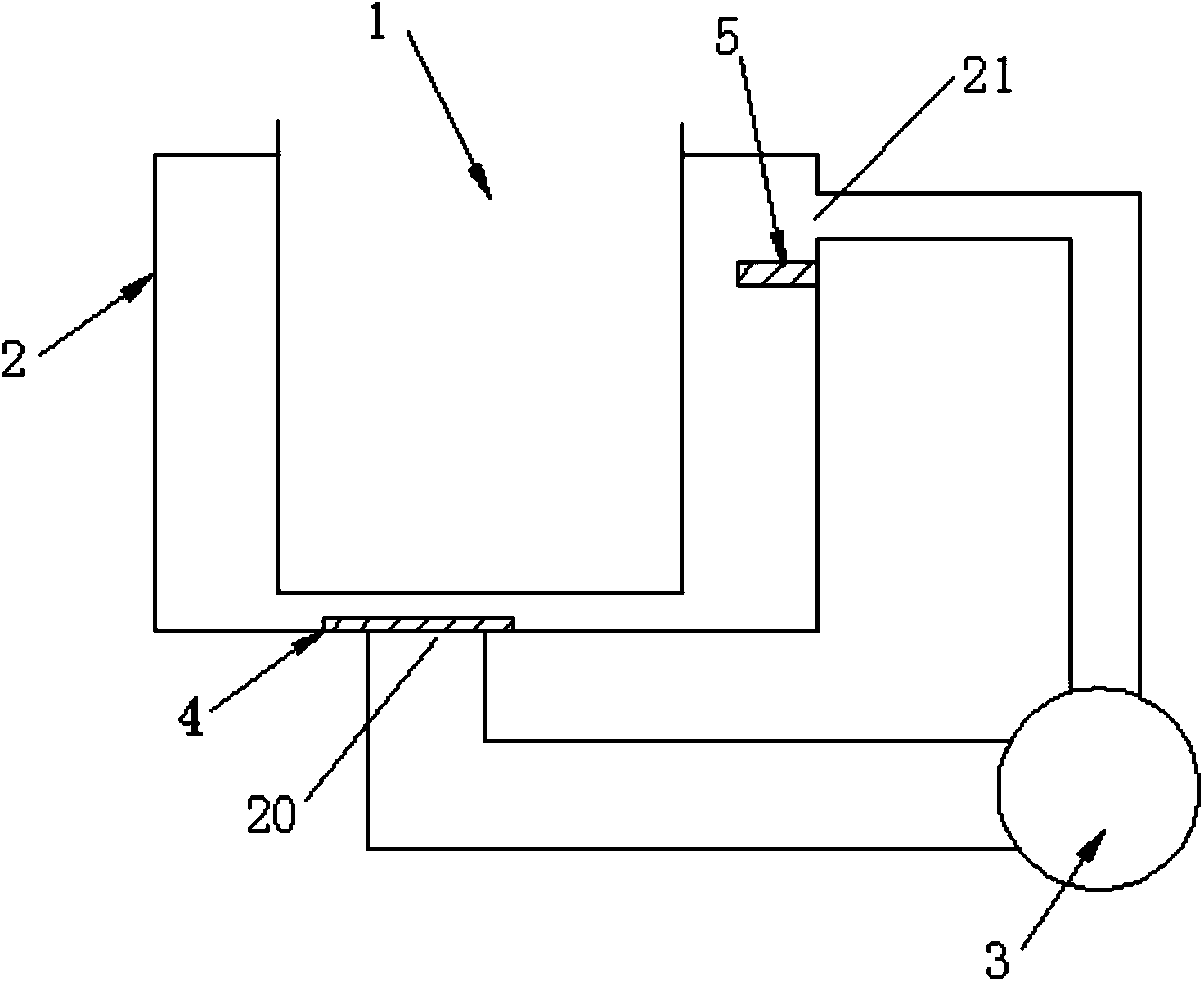

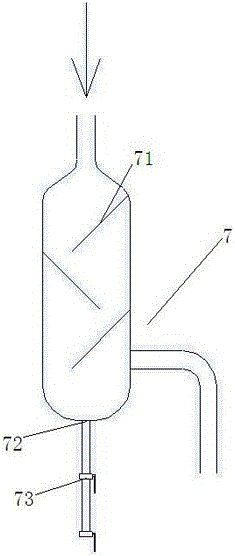

High-concentration spinning oil wastewater pretreatment system

InactiveCN103523958AReduce oil pollutionSeawater treatmentMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a sewage treatment device, and discloses a high-concentration spinning oil wastewater pretreatment system. The high-concentration spinning oil wastewater pretreatment system comprises successively connected a water collection pool, an oil separation pool, a Fenton reaction pool, a neutralization pool, a sedimentation pool A, a coagulation pool, a sedimentation pool B and a clean water pool. According to the high-concentration spinning oil wastewater pretreatment system, oil contamination and organic matters in wastewater can be greatly reduced, the pretreatment COD (chemical oxygen demand) removal rate can reach above 70%, and outlet water has little effects on the comprehensive sewage treatment system.

Owner:SHAANXI SHENGMAI PETROLEUM

Self-cleaning colorized solar heat reflecting coating

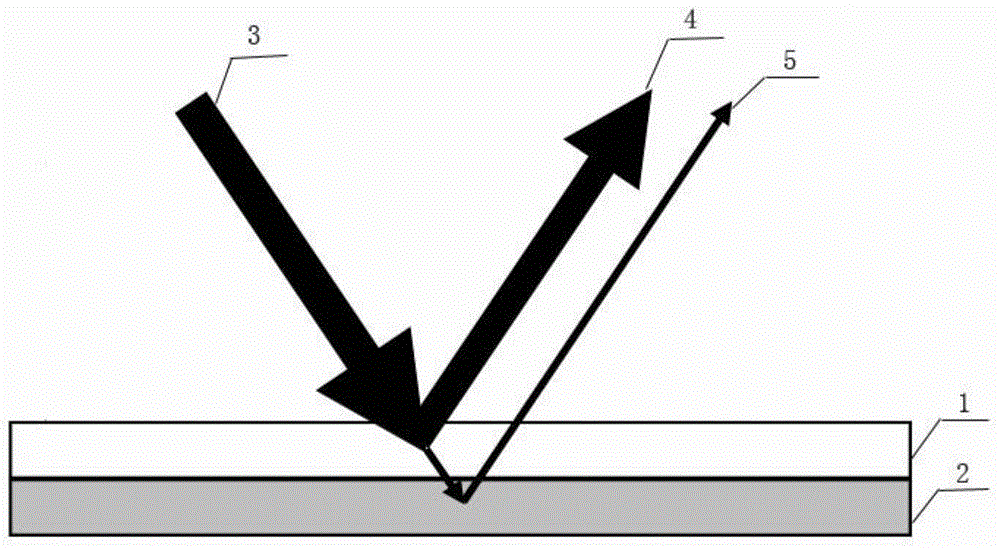

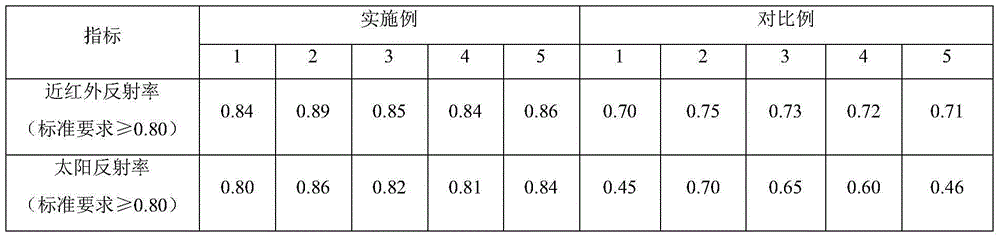

ActiveCN105754427ASmall attenuationExcellent infrared reflectionAntifouling/underwater paintsPaints with biocidesOrganic solventAerogel

Self-cleaning colorized solar heat reflecting coating is disclosed. The coating comprises a top coating composition and a primer composition. The top coating composition comprises fluorocarbon resin, titanium dioxide, near-infrared reflection pigment, an anti-settling agent, a defoamer, a dispersant, a levelling agent, a super-hydrophobic agent and an organic solvent. The primer composition comprises the fluorocarbon resin, the titanium dioxide, silicon dioxide aerogel, the anti-settling agent, the defoamer, the dispersant, the levelling agent, and the organic solvent. The coating can effectively reflect solar heat radiation and has a good self-cleaning property.

Owner:太原市誉远涂料有限公司

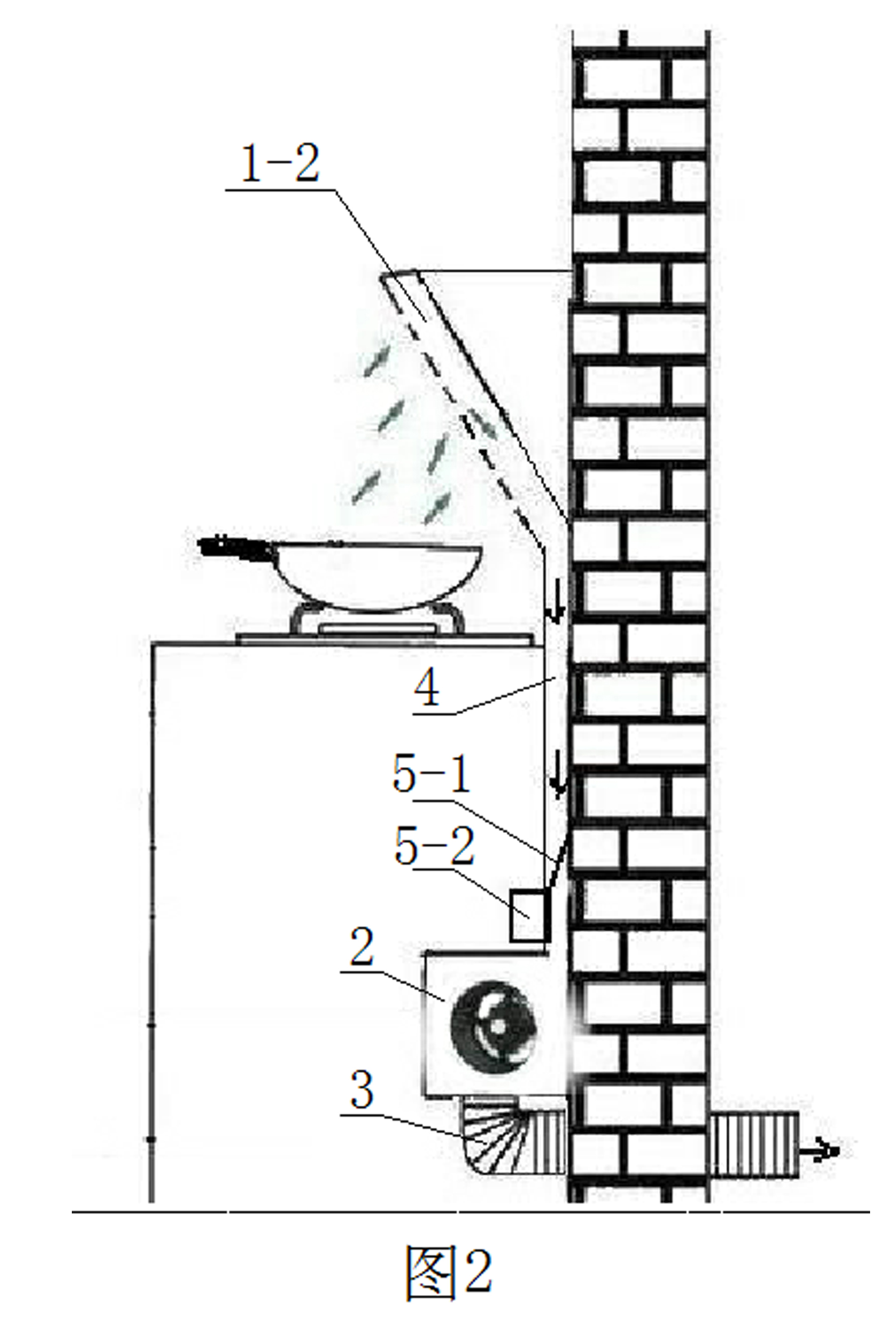

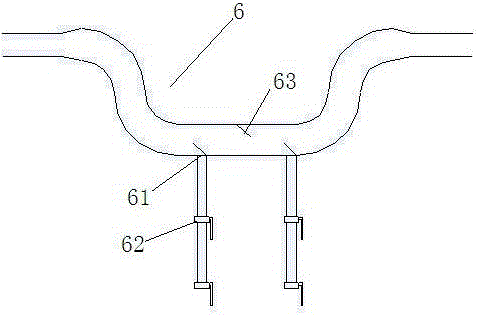

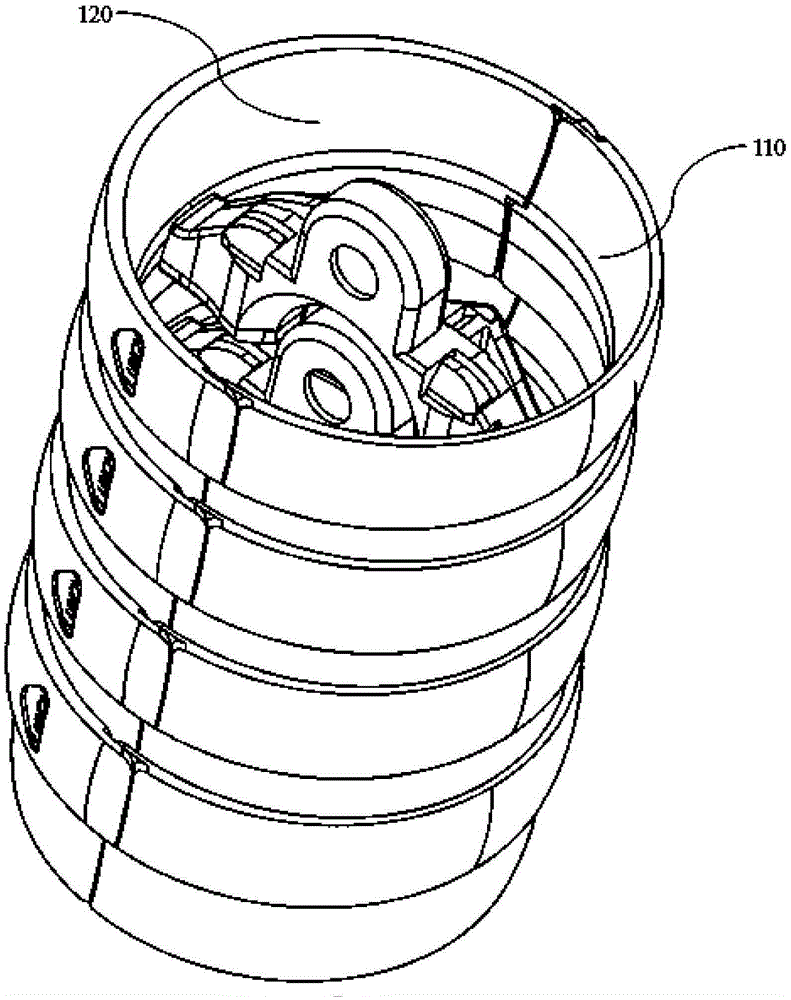

Lower-suction range hood

InactiveCN102022767AImprove oil fume absorption rateFew accessoriesDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

The invention relates to a lower-suction range hood, comprising a smoke exhaust hood arranged above or at side top of a stove, a suction device arranged below the smoke exhaust hood, a connection passage for connecting the smoke exhaust hood and the suction device and a vent passage connected with an air outlet of the suction device, wherein the suction device is arranged below the stove so that a suction motor is far from ears of cooking staff with relatively small noise, the noise can be smaller if the suction device is arranged in a cabinet below the stove; (2) fewer circuit and less accessories are arranged in the smoke exhaust hood which is easy to clean; (3) the structure is rational, the smoke exhaust hood, the connection passage and the suction device are separately connected with each other, so that the product is convenient to package and transport, the influence to fitment is avoided, the wall cupboard space cannot be occupied and the appearance is beautiful; the connection passage can be composed of a plurality of pipelines so that the change to old kitchen is convenient.

Owner:翁家瑜 +1

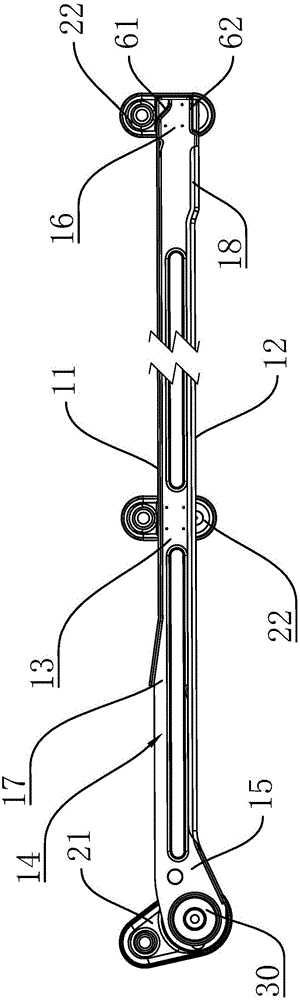

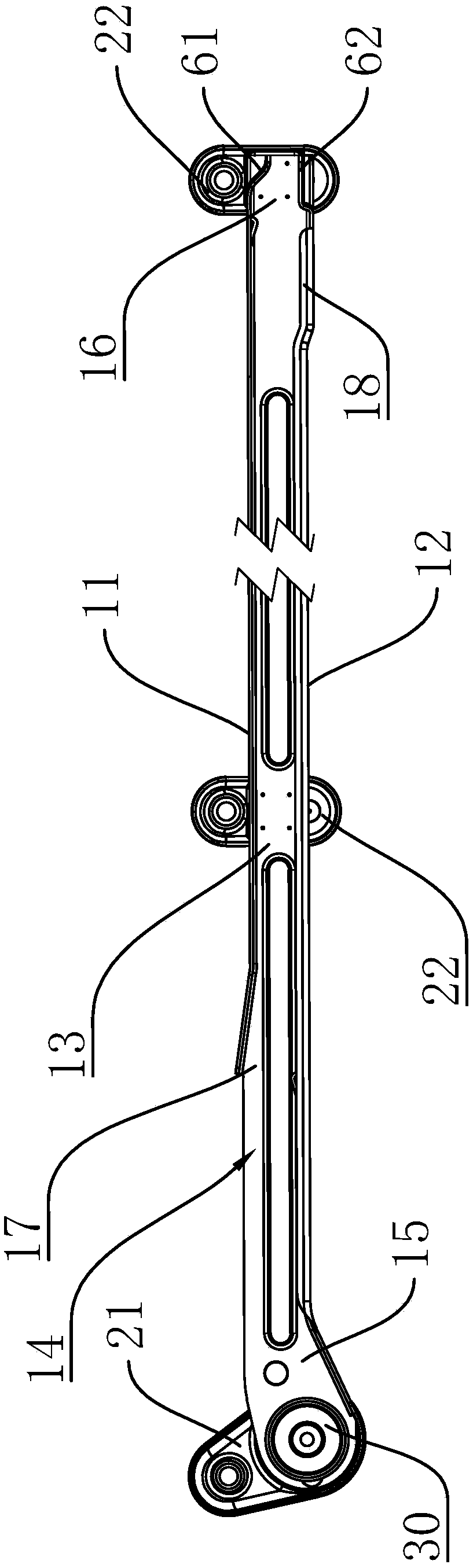

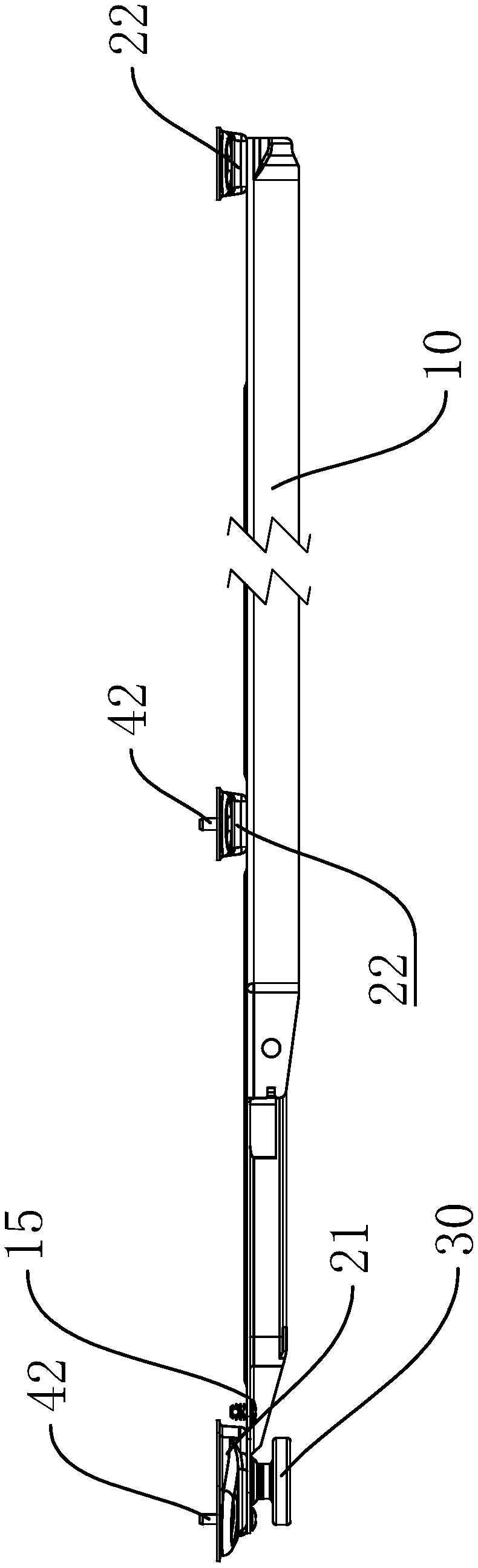

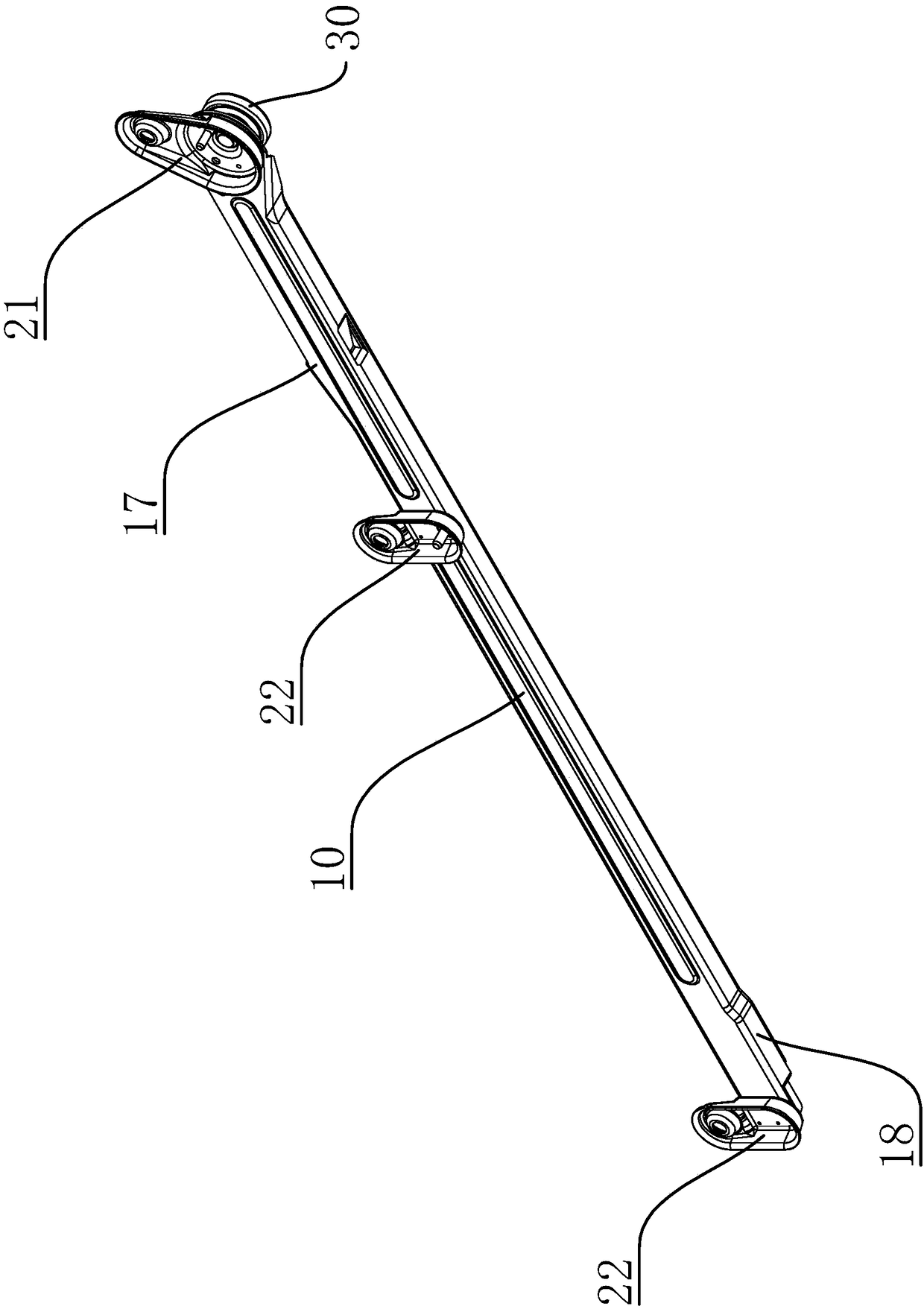

Slide rail with lubrication function

The invention discloses a slide rail with a lubrication function. The slide rail comprises a slide rail body. The slide rail body comprises a top plate, a bottom plate and side plates which are integrally formed, and a slide groove is formed after the top plate, the bottom plate and the side plates are punched; the slide rail body is provided with a first end and a second end, a first fixing portion is riveted at the first end, a second fixing portion is welded at the second end, at least one other second fixing portion is further welded between the first end and the second end, and the first fixing portion and the second fixing portions are arranged on the outer walls of the side plates; a pulley is mounted at the first end, the pulley and the first fixing portion are respectively positioned on two sides of the first end, and the pulley is movably riveted with the first fixing portion; a bumper is further mounted at the first end, and the bumper and the first fixing portion face the same side of the slide rail; abrasion-resistant layers are plated on the surfaces of the slide rail body, oil film layers are attached to the inner wall of the slide groove, oil is coated to form the oil film layers, the oil film layers are attached to the surfaces of the abrasion-resistant layers of the slide groove, an oil storage groove for oil storage and lubrication is formed in the inner wall of the bottom plate, and oil injection holes are formed in the slide rail body and are communicated with the oil storage groove.

Owner:HAINING JINMAO HARDWARE

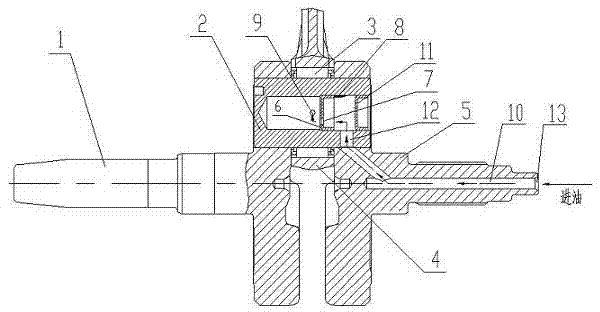

Crankshaft connecting rod assembly

ActiveCN103758608AReduce oil pollutionNot easy to wearMachines/enginesPressure lubricationNeedle roller bearingSpecific gravity

The invention relates to a crankshaft connecting rod assembly which comprises a left crank, a right crank and a connecting rod. The connecting rod is positioned between the left crank and the right crank and is connected with the left crank and the right crank by a crankpin; a needle roller bearing is arranged between the crankpin and the connecting rod; a cavity is arranged in the crankpin, an oil plug is arranged on one side of the cavity, the right crank is communicated with an oil channel of the cavity via an inclined oil hole formed in the right crank, and a small oil hole which is communicated with the needle roller bearing is further formed in the cavity. The crankshaft connecting rod assembly is characterized by further comprising an oil stain separating part, the oil stain separating part is mounted in the cavity and is a bowl-shaped part, a separating oil hole is formed in the bottom of the bowl-shaped part, and the bowl-shaped part is mounted between the small oil hole and the inclined oil hole. The crankshaft connecting rod assembly has the advantages that lubricating oil is retained when flowing through the oil stain separating part, oil stain with high specific gravity can be thrown to side walls of the cavity under the effect of centrifugal force, the side walls of the cavity are far away from a rotating center, accordingly, oil stain which flows into the needle roller bearing can be greatly reduced, and the needle roller bearing cannot be easily abraded; the crankshaft connecting rod assembly is simple in machining and manufacturing, and a good service effect can be realized.

Owner:JIANGSU GANGYANG

Purification device of PCB (printed circuit board) etching liquid medicine

The invention discloses a purification device of a PCB (printed circuit board) etching liquid medicine. The purification device comprises an etching groove, a liquid medicine tank for containing an OSP (organic solderability preservatives) antioxidant and a sprayer nozzle assembly, wherein the liquid medicine tank is positioned and placed at the periphery of the etching tank and is communicated with the etching tank by virtue of the sprayer nozzle assembly; a reflux outlet and a reflux inlet are positioned and formed on the liquid medicine tank and are communicated by virtue of a circulating pipeline, and the circulating pipeline is further provided with a circulating pump device; in addition, a filter dreg screen is positioned and arranged at the reflux outlet and a purification piece for breaking foam and adsorbing oil stains are positioned and formed at the reflux inlet, so that not only can air bubbles generated by circulating the OSP antioxidant liquid medicine be broken, but also the air bubbles can be decomposed to suspended oil stains which are adsorbed, thereby effectively reducing the oil stains carried when the OSP antioxidant liquid medicine is circulated, preventing the surface of the PCB from being polluted and improving the yield of the PCBs.

Owner:竞陆电子(昆山)有限公司

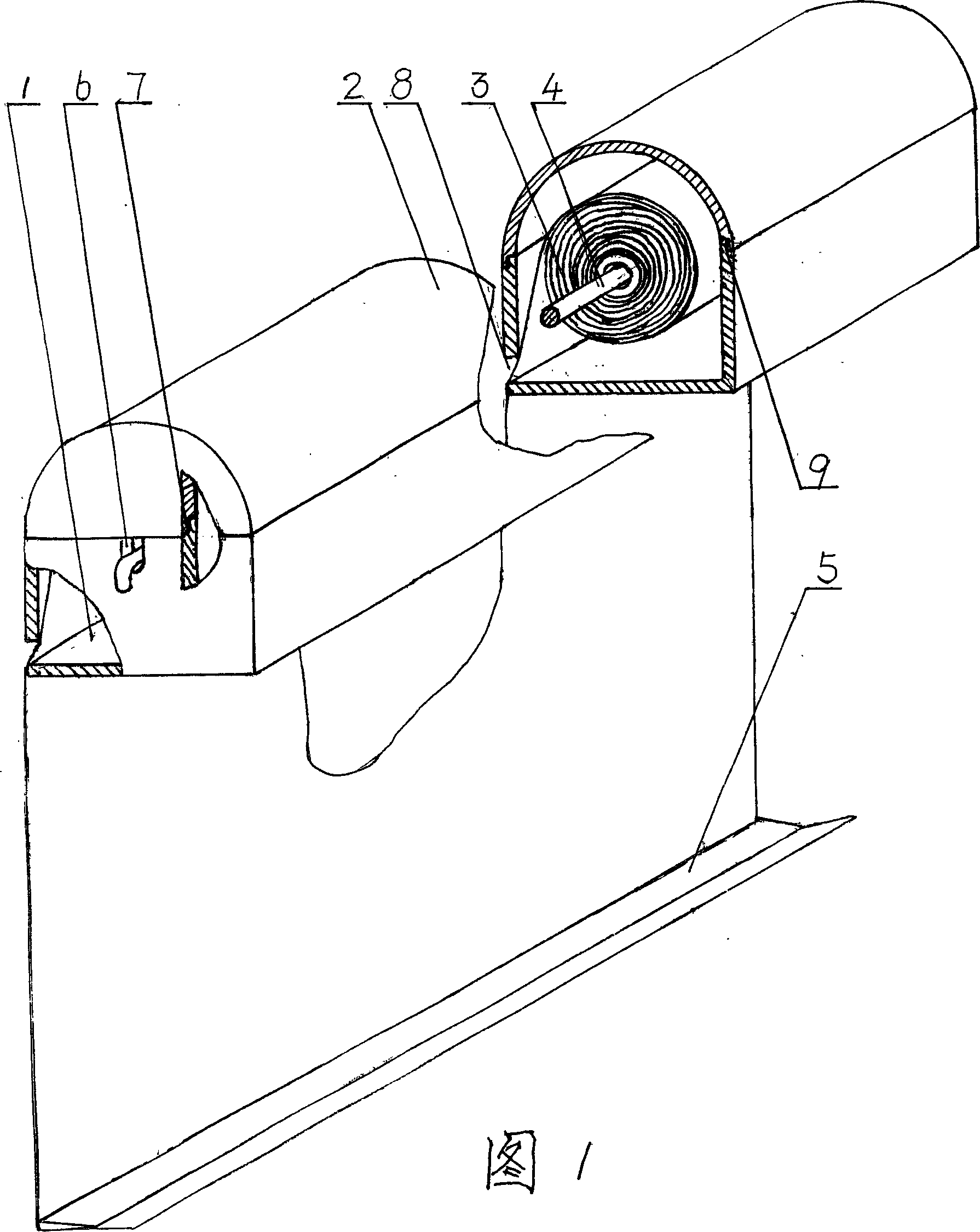

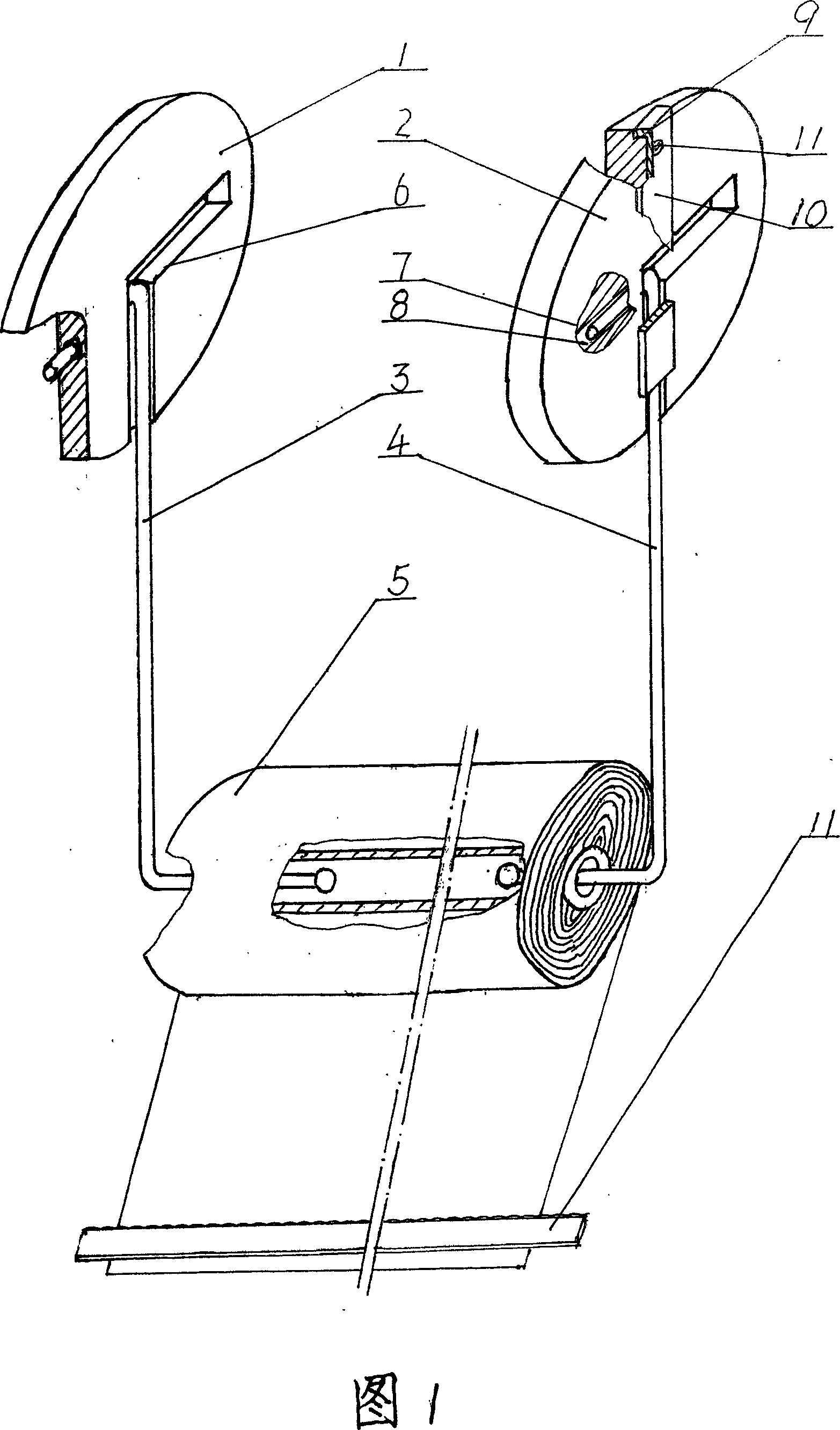

Box type oil absorbent paper roll device used in kitchen

InactiveCN1961795AReduce oil pollutionSimple structureKitchen equipmentArticle deliveryPulp and paper industryPaper sheet

The invention relates to a box oil adsorption paper cylinder, wherein two sides of box 1 have upright groove 6; the support axle 4 is at the middle; the top of box 1 has cut 7; the lower end has transverse long hole 8 whose length is same as the paper cylinder 3; the oil adsorption paper is drawn from the narrow long hole 8 to the kitchen table, to be compressed by paper cutter 5; the open arc end of box 2 has cut 9; the length of paper cylinder 3 is same as the width of smoke exhaust ventilator; the oil adsorption paper can be coiled on the cylinder. The invention has simple structure and low cost.

Owner:刘凤章

Metal water-based stamping liquid and preparation method thereof

The invention relates to metal water-based stamping liquid and a preparation method of the metal water-based stamping liquid. The metal water-based stamping liquid comprises the components by weight: 3-5% of lubricating extreme pressure agent, 2-4% of polyamide, 3-4% of triethanolamine, 0.1-0.2% of triazole fungicide, 0.1-0.5% of benzotriazole, 0.2-0.4% of hydroxypropyl methylcellulose, 0.05-0.1% of three-dimensional siloxane defoaming agent and the balance of distilled water. The preparation method comprises the main steps of: firstly, adding the distilled water, and then, orderly adding the lubricating extreme pressure agent, polyamide, triethanolamine, triazole fungicide, benzotriazole, hydroxypropyl methylcellulose and three-dimensional siloxane defoaming agent to mix. The action mechanism provided by the invention is simple and scientific; punch forming and anti-dusting effects of the metal achieve the optimal state by synergistic effect of the components; the water-based stamping liquid contains the triazole fungicide, so that decaying of the stamping liquid in storing and working processes can be effectively prevented; and the hydroxypropyl methylcellulose can assist film forming, and the fluid friction resistance is reduced, so that the water-based stamping liquid better protects the metal in the metal stamping and molding processes, and the anti-dusting time is more effectively increased after a workpiece is processed.

Owner:华阳新兴科技(天津)集团有限公司

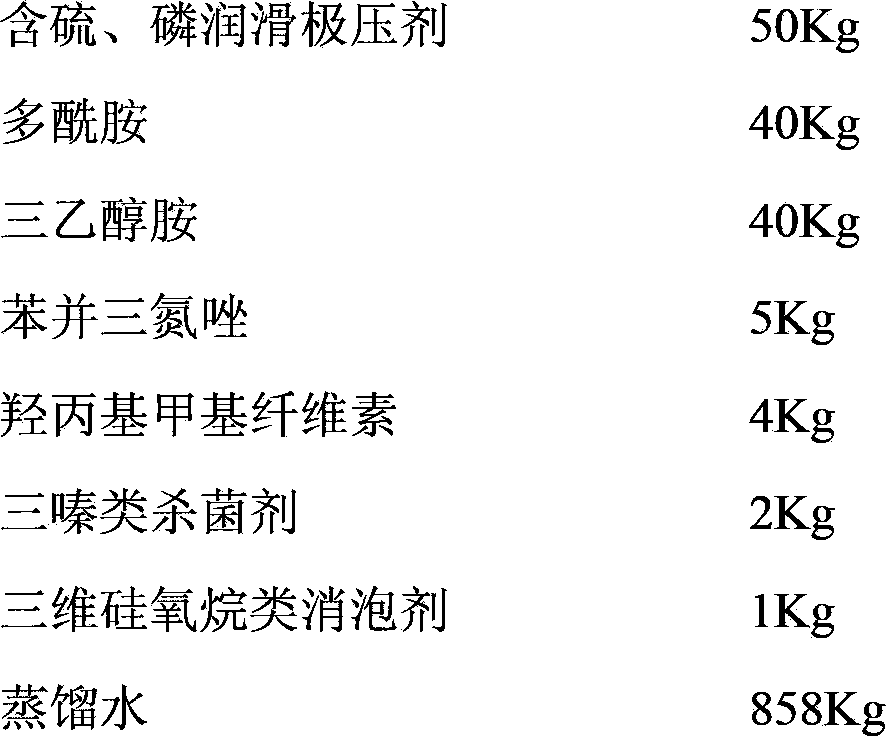

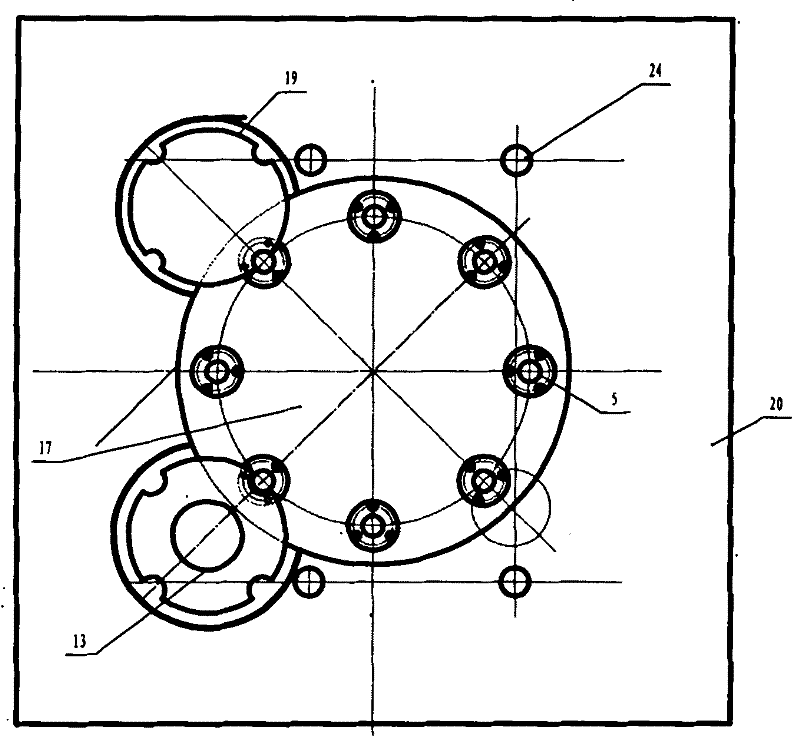

Rotary drawing machine

The invention discloses a rotary drawing machine for the production of aluminum anti-fake bottle cap, which comprises three parts, including a cap feeding part, a rotary drawing part and a cap returning part, wherein the cap feeding part is composed of a driving plate gear (11), a cap incoming driving plate (13) and a positioning disk (18); the rotary drawing part is composed of a motor gear (1),a mainshaft gear (2), a mainshaft (3), an upper rotator (16), a lower rotator (17), a core holder (8), a rolling bearing (9), a rolling guide rail (14), an upper cam (10), a material returning unit (4), a lower cam (12), a female die (5), a pressing ring (7), a male die (6) and a connecting block (22); and the cap returning part is composed of a tension spring (15), the material returning unit (4), the lower cam (12), a cap exiting driving plate (19) and an upper rotator bending plate (23); the rotary drawing machine greatly reduces the high noise phenomenon of equipment and achieves the advantages of fast production speed, high efficiency, small weight of equipment and small floor area, and the bottle caps are sequentially arrayed after being drawn, and accordingly, can be directly subject to the next procedure of knurling and cushioning, in addition, the rotary drawing machine simultaneously diminishes the possibility that the bottle caps are polluted by oil from the equipment and can also effectively lower mechanical damage of the equipment to human body.

Owner:LIPENG PACKING YANTAI CITY

Antibacterial composite tablecloth manufacturing method

InactiveCN107964160AImprove antibacterial propertiesImprove permeabilitySynthetic resin layered productsLaminationCotton clothChlorinated polyethylene

The invention discloses an antibacterial composite tablecloth manufacturing method, belongs to the field of tablecloth manufacturing and aims to solve the problem that the prior art is bad in antibacterial effect, high in cost and complex in manufacturing process. The method includes: (1), improving diatomite to obtain surface-modified diatomite powder; (2), processing the surface-modified diatomite powder for standby use; (3), feeding existing plastic into a chopper for chopping; (4), putting plastic fragments obtained by chopping into multi-section hot melting equipment for hot melting; (5),adding thermostabilizer, chlorinated polyethylene aid and composite additive into thermally-molten plastic; (6), mixing the surface-modified diatomite powder with plastic particles, and feeding intorolling equipment after going through an extruder to obtain a corresponding face film; (7), press-fitting the obtained face film with cotton cloth on the undersurface, embossing, cooling, and windingto obtain corresponding composite tabletop. The method has the advantages of simple process, good antibacterial effect and simplicity in manufacturing.

Owner:MAANSHAN JINZI TEXTILE OMAMENT

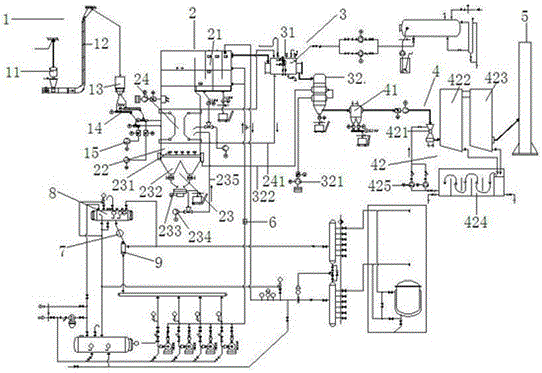

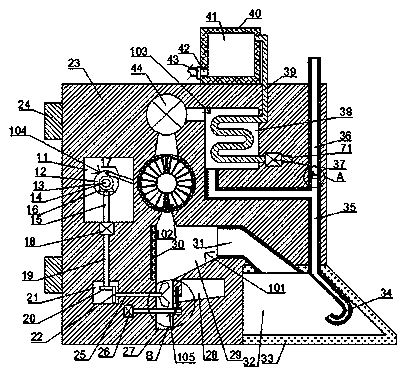

Small and medium size boiling type ready-packaged organic carrier heating furnace

ActiveCN106642092ABurn fullyImprove thermal efficiencyCombination devicesFluidized bed combustionAir preheaterProtection system

The invention discloses equipment comprising a feeding device, a hearth, a waste heat device, a tail gas treatment device and a chimney connected in sequence, wherein the lower portion in the hearth is a fuel combustion area connected with a quartz sand circulating system; a hot oil heater is arranged at the upper portion in the hearth, and connected with an oil feeding and draining device via an oil pipe; the outlet of the hot oil heater is connected with a steam generator of the waste heat device, and the outlet of the steam generator is connected with the inlet of an air preheater; the steam generator and a steam pipe forms a fluidized bed circular protection system arranged between the hot oil heater and the fuel combustion area; and the tail gas treatment device comprises a multi-pipe dust remover and circular cleaning equipment connected in sequence. The hearth, the waste heat device, the tail gas treatment device and the chimney are connected in sequence, so that ash generated during a combustion process in the hearth can be effectively deposited under the effect of the waste heat device and the tail gas treatment device, the thermal discharge temperature of the chimney can also be further reduced, and emission pollution generated by the heating furnace is reduced, and environment protection is facilitated.

Owner:JIANGSU JINCHENZHEN TEXTILE

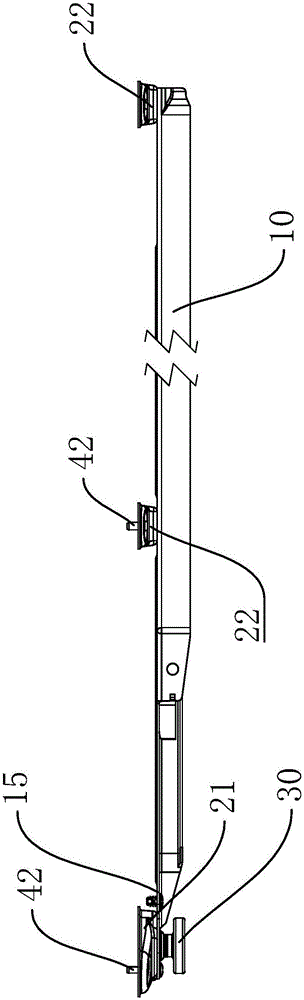

Mute sliding track with lubricating function

The invention provides a mute sliding track with a lubricating function. The mute sliding track with the lubricating function comprises a sliding track body, wherein the sliding track body comprises atop plate, a bottom plate and side plates; the top plate, the bottom plate and the side plates are stamped to form a chute; the sliding track body is provided with a first end and a second end; the first end is riveted with a first fixing portion; a second fixing portion is welded to the second end; a pulley is mounted at the first end, and is movably riveted to the first fixing portion; the first end is further provided with a buffering device; a wear-resistant layer is plated on the surface of the sliding track body; an oil film layer is attached to the inner wall of the chute; the oil filmlayer is formed by coating of grease, and is attached to the surface of the wear-resistant layer of the chute; an oil storage groove for storing oil for lubricating is formed in the inner wall of thebottom plate; an oil injecting hole is formed in the sliding track body and communicates with the oil storage groove; a first track strip is welded to the inner wall of the bottom plate; a second track strip is welded to the inner wall of the top plate; and oil film layers formed by grease are also attached to the surface of the first track strip and the surface of the second track strip.

Owner:HAINING JINMAO HARDWARE

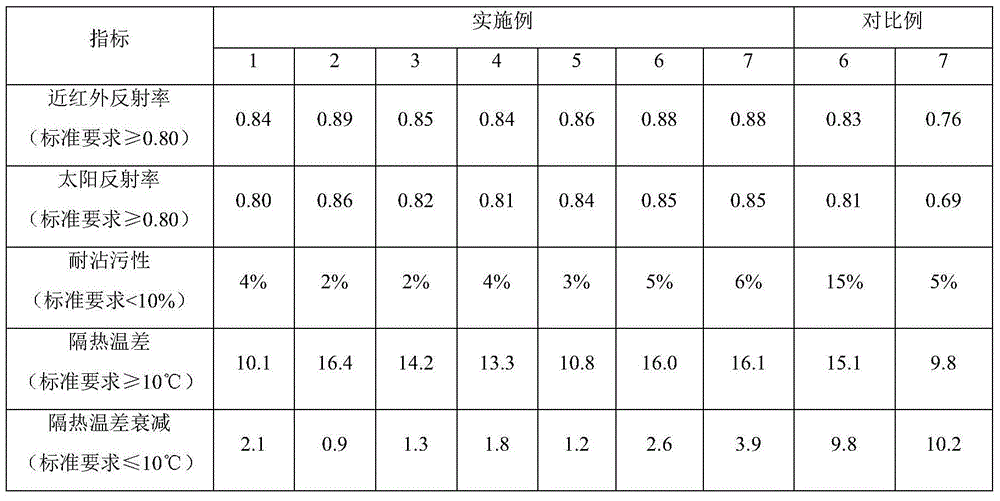

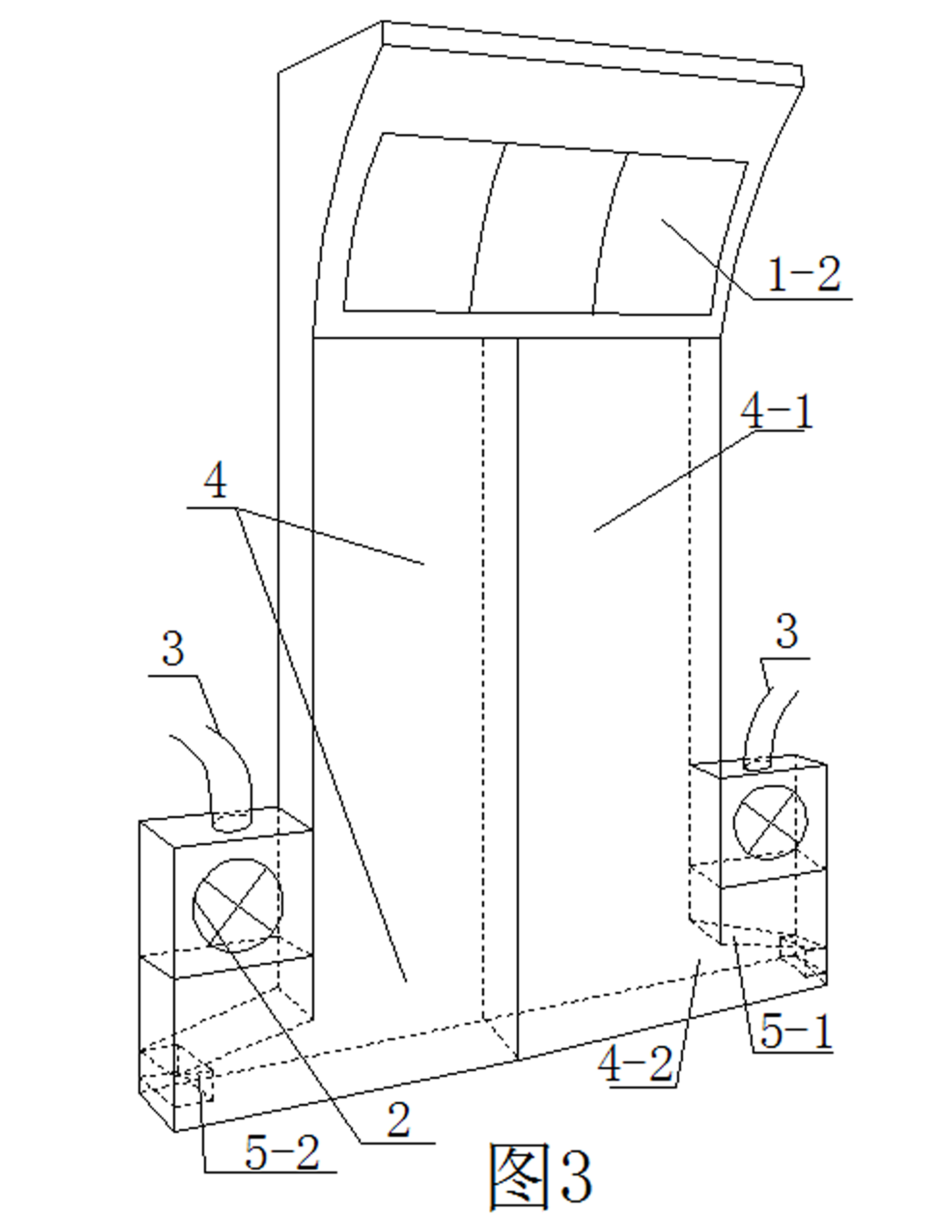

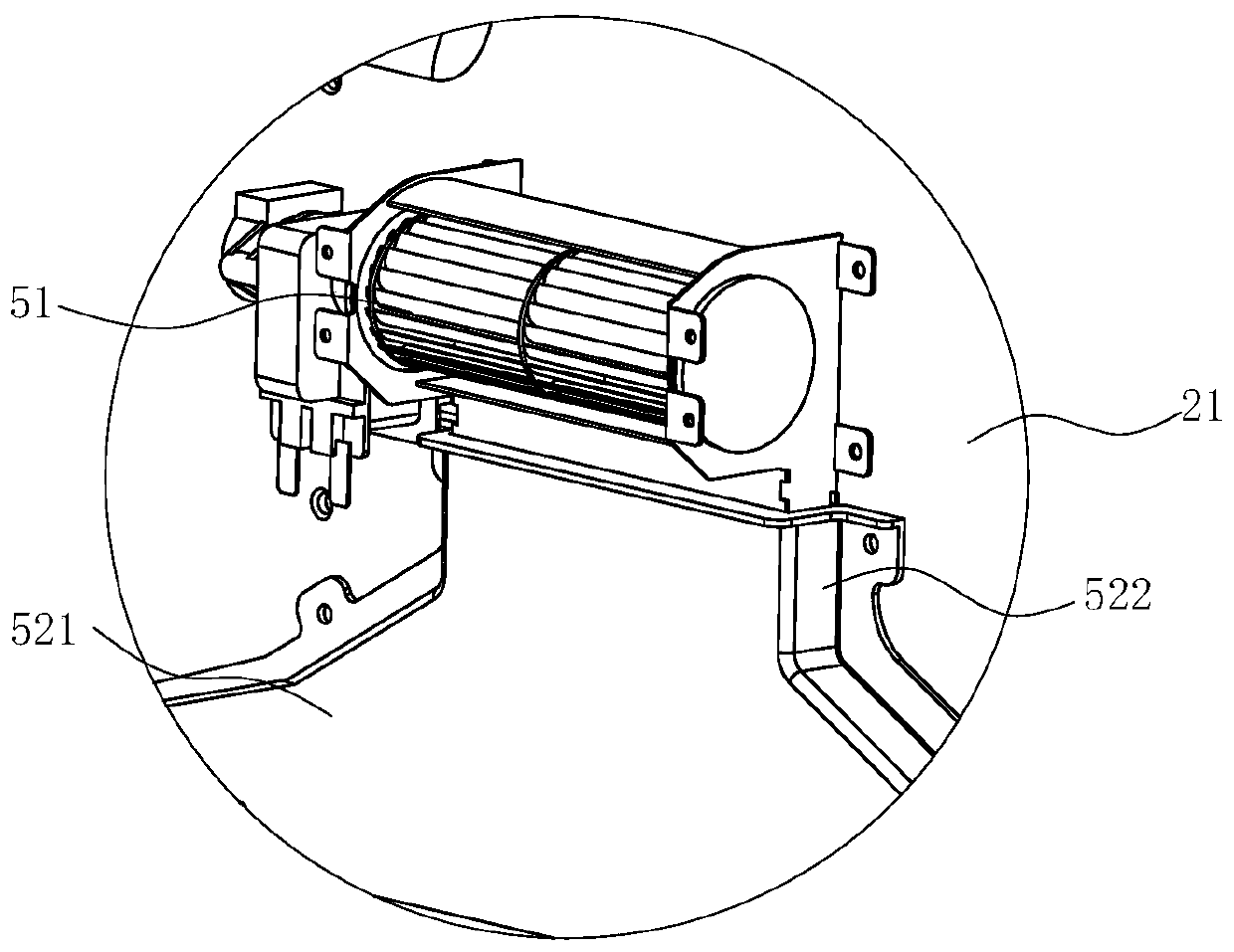

Range hood

ActiveCN110887079AReduce oil pollutionEliminate the problem of drippingDomestic stoves or rangesLighting and heating apparatusJet flowAir blower

The invention discloses a range hood which comprises a smoke collection cover, a smoke blocking plate and an air curtain device, wherein an air inlet is formed in the smoke collection cover; an air outlet is opened or closed selectively by the smoke blocking plate; and the air curtain device comprises an air blower and an air outlet device which jets out airflows sucked by the air blower. The range hood is characterized in that the air outlet device coats the smoke blocking plate exteriorly; and the air outlet device comprises a jet guide channel which is formed on one side, facing inside of the smoke collection cover, of the smoke blocking plate, and can jet airflows to the inner surface, facing inside of the smoke collection cover, of the smoke blocking plate. In comparison with the prior art, the range hood disclosed by the invention has the beneficial effects that through formation of uniform jet spraying gas on the inner surface of the smoke blocking plate, jet guide gas is formedby the jet spraying gas; and an air film is formed by both the gases, so oil smoke is isolated from the smoke blocking plate, oil stains on the lower surface of the smoke blocking plate are reduced and thus dripping of condensed oil on the smoke blocking plate can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

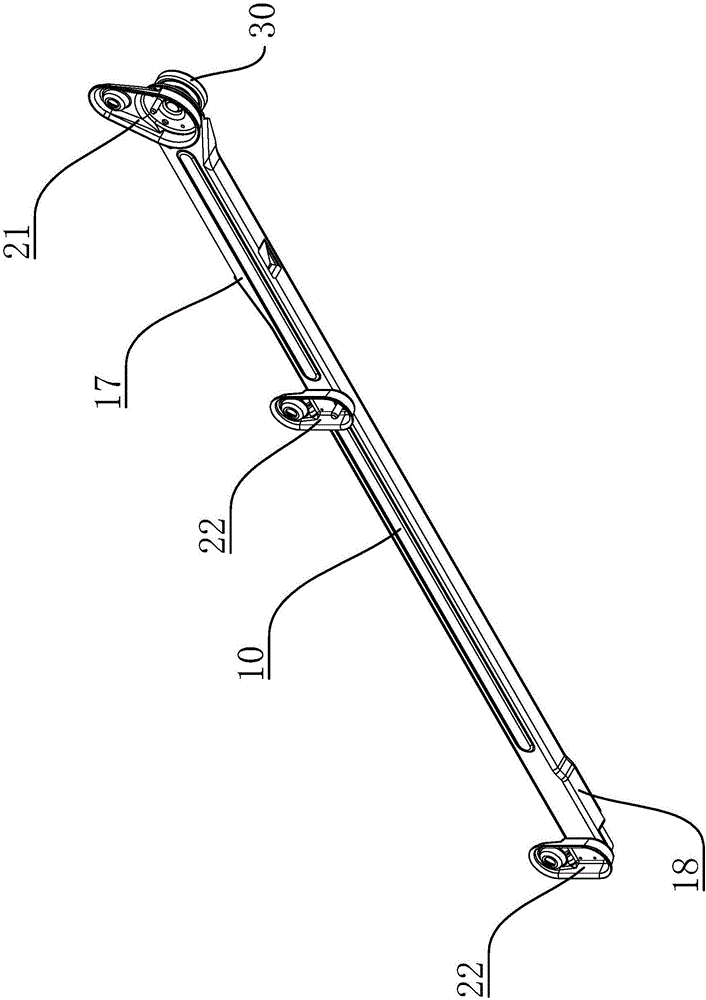

Robot three-dimensional drag chain

The invention discloses a robot three-dimensional drag chain. The robot three-dimensional drag chain is formed by connecting multiple sections of single chain links. Each single chain link is annular as a whole and is separated into a left chain link and a right chain link by a plane passing the midperpendicular of the single chain link, and the two ends of the left chain link and the right chain link are overlapped with each other at the partition part. One group of groove and hasp which are buckled with each other are arranged in the center of each single chain link, a left spherical surface connector is arranged in the middle of the groove, a right connecting ball is arranged in the middle of the lower part of the hasp, and the right connecting ball can be connected with the spherical surface of the left spherical surface connector in the single chain link below the right connecting ball. The right chain link comprises an inner cambered surface and an outer cambered surface, and the outer cambered surface at the upper part of the right chain link adopts a gradual change structure of which the two sides are thicker than the middle. The robot three-dimensional drag chain overcomes the problem that the traditional robot drag chain is difficult to bend due to the even design of outer ring surfaces in the single chain link structure and is therefore not portable enough when a cable is mounted in the drag chain and the cable in the drag chain is repaired and solves the problem that dust in the air, and oil stains, water stains and the like, produced during robot operation, enter the inner part of the drag chain and pollute the cable due to poor air tightness.

Owner:易格斯(上海)拖链系统有限公司

Suspended oil absorbent paper roll device used in kitchen

InactiveCN1961794AReduce oil pollutionSimple structureKitchen equipmentArticle deliveryAdhesivePulp and paper industry

The invention relates to a suspension oil adsorption paper cylinder device, which is formed by two support plates 1, 2; hooks 3, 4; and oil adsorption paper cylinder 5, wherein the support plates have L-shaped grooves 6, 7; the short edges of grooves 6, 7 have plug 8; two ends of hooks 3, 4 are bended, while one end is inserted into plug 8 and another end is inserted into the hole at the middle of cylinder 5; the upper end of support plate 2 has cut 9; one end of spring 10 is bended at the cut 9; the spring 10 via screw 11 is fixed on the support plate 2; the spring 10 compresses the hook 4; two support plates 1, 2 are fixed on two sides of smoke exhaust ventilator via adhesive; when the lower paper is oiled, it can be removed and the upper paper can be drawn down to be used. The invention has simple structure and low cost.

Owner:刘凤章

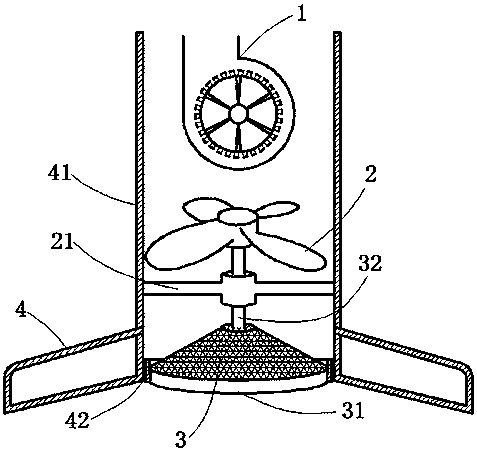

Restaurant circulation type ultra-filtration oil smoke purification device

ActiveCN110307573AReduce oil pollutionReliable effectDomestic stoves or rangesElectrostatic separationUltrafiltrationDouble filtration

The invention discloses a restaurant circulation type ultra-filtration oil smoke purification device. The device comprises a box body and a smoke cover, wherein a settling cavity is formed in the boxbody, a suction cavity with a downward opening is formed in the smoke cover, a connecting pipe is arranged between the settling cavity and the suction cavity, an electrostatic filtering mechanism withan electrostatic settlement filtering function and a waste residue treatment function is arranged in the settling cavity, a liquid storage cavity is formed in the lower side of the settling cavity, the liquid storage cavity is internally provided with a waste residue degrading liquid, and the liquid storage cavity can communicate with the settling cavity. According to the restaurant circulation type ultra-filtration oil smoke purification device, the double filtering effects are achieved, oil smoke generated by cooking of a kitchen in a restaurant can be effectively filtered, so that the discharged gas is more green and environment-friendly, the surrounding residents are not troubled by the restaurant oil smoke, and the device also can increase the suction force of the device by means ofthe purified and filtered gas.

Owner:山东国晟环境科技有限公司

Method for compositely repairing scraped polish rod of pumping unit

The invention relates to a method for compositely repairing a scraped polish rod of a pumping unit, and relates to the field of the manufacture of an oil field device. The method comprises the steps of washing, deoiling and derusting the scraped polish rod; selecting a repairable polish rod from the treated polish rods, carrying out the offset grinding repairing on a noncircular cross-sectional section of the repairable polish rod until the cross section is circular; carrying out filling repairing on a corroded surface of the polish rod; carrying out the delustering treatment on the surface of the repaired polish rod, and dotting and roughening the surface of the polish rod; nesting the dotted and roughened polish rod and a nickel-chromium alloy casing pipe, and carrying out the seamless rolling bonding on the polish rod and the casing pipe to obtain a finished product. By adopting the method, the scraped polish rod is reutilized, so that the production cost is saved; the outer casing pipe is compositely seamlessly connected with the polish rod, so that the strength of the composited polish rod is improved compared with the traditional polish rod; the casing pipe is made of the nickel-chromium alloy material, so that the corrosion resistance is high, the sealing effect is good, the service life of the polish rod is effectively prolonged, the replacement period of the polish rod is prolonged, and the manpower and production cost can be reduced.

Owner:孙伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com