Lower-suction range hood

A technology for range hoods and range hoods, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems of ceiling kitchen space pollution, smoke pipes are easy to crack and leak, and the ceiling is deformed and unsightly. Occupies the space of the hanging cabinet, convenient for packaging and transportation, and has the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

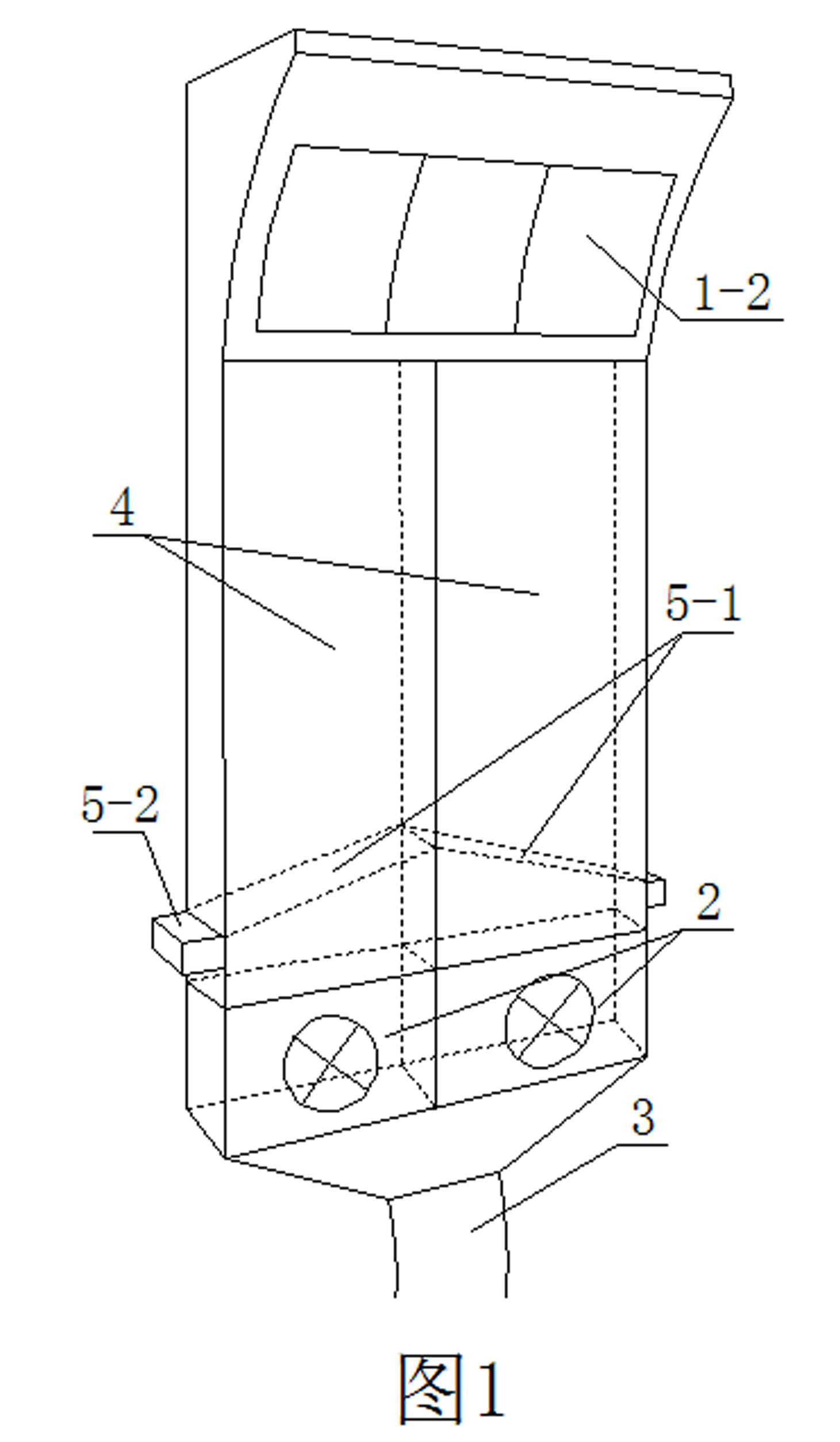

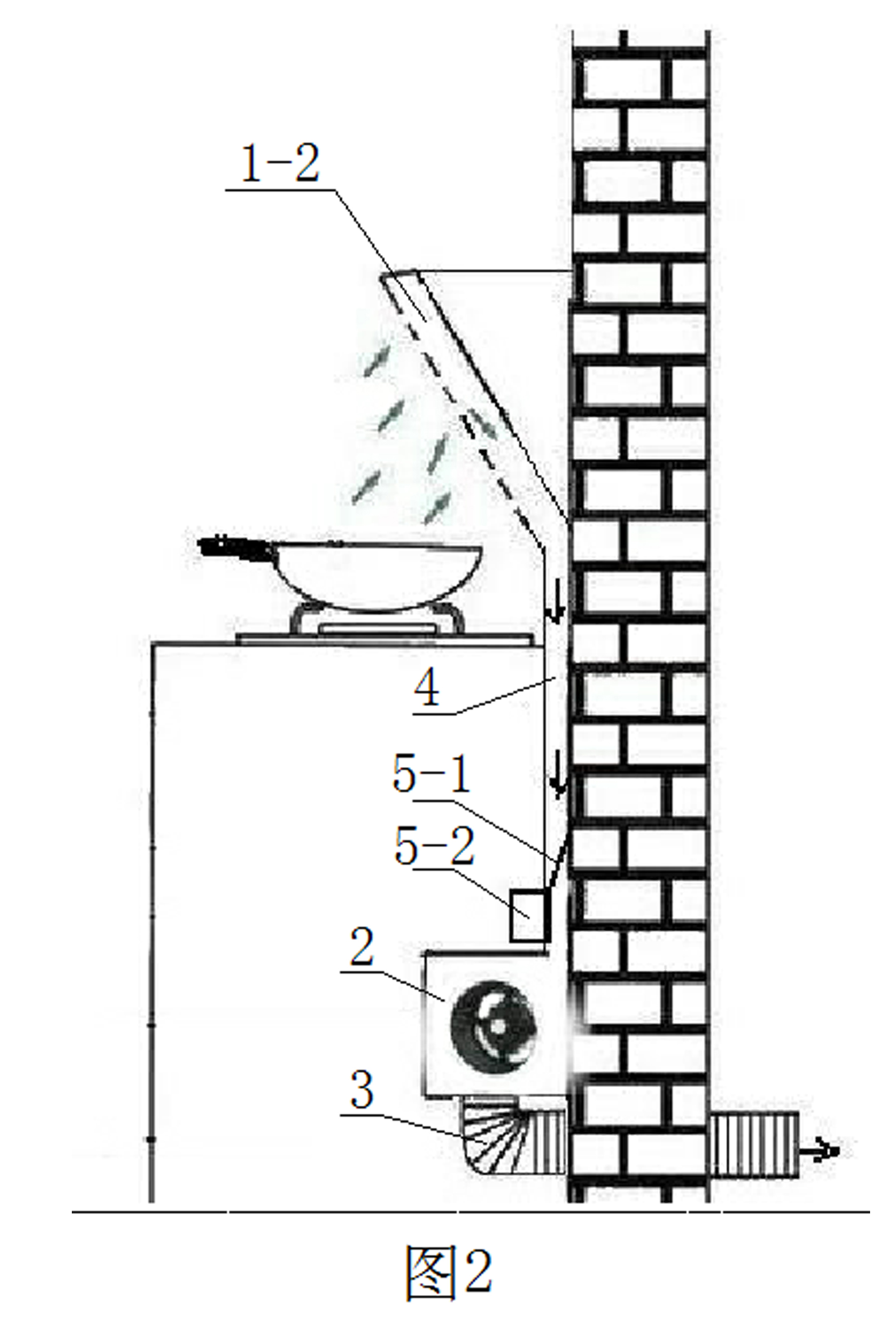

[0023] like figure 1 and figure 2 Shown is a schematic diagram of an embodiment of a lower suction range hood provided by the present invention, which includes an oil suction hood arranged above or on the side of the stove, an air extraction device 2 arranged below the oil suction hood, connecting the oil suction hood The connection channel 4 with the air extraction device 2 and the exhaust channel 3 connected with the air outlet of the air extraction device 2 .

[0024] Described air extraction device 2 is located at the bottom of the stove, and it includes more than one independently controlled air extraction motor, each air extraction motor is connected with the oil suction hood through an independent connection channel 4, or multiple air extraction motors are connected through a shared The connecting channel 4 is connected with the oil suction hood.

[0025] The connecting channel 4 is provided with an oil fume filtering device.

[0026] The oil fume filtering device i...

Embodiment 2

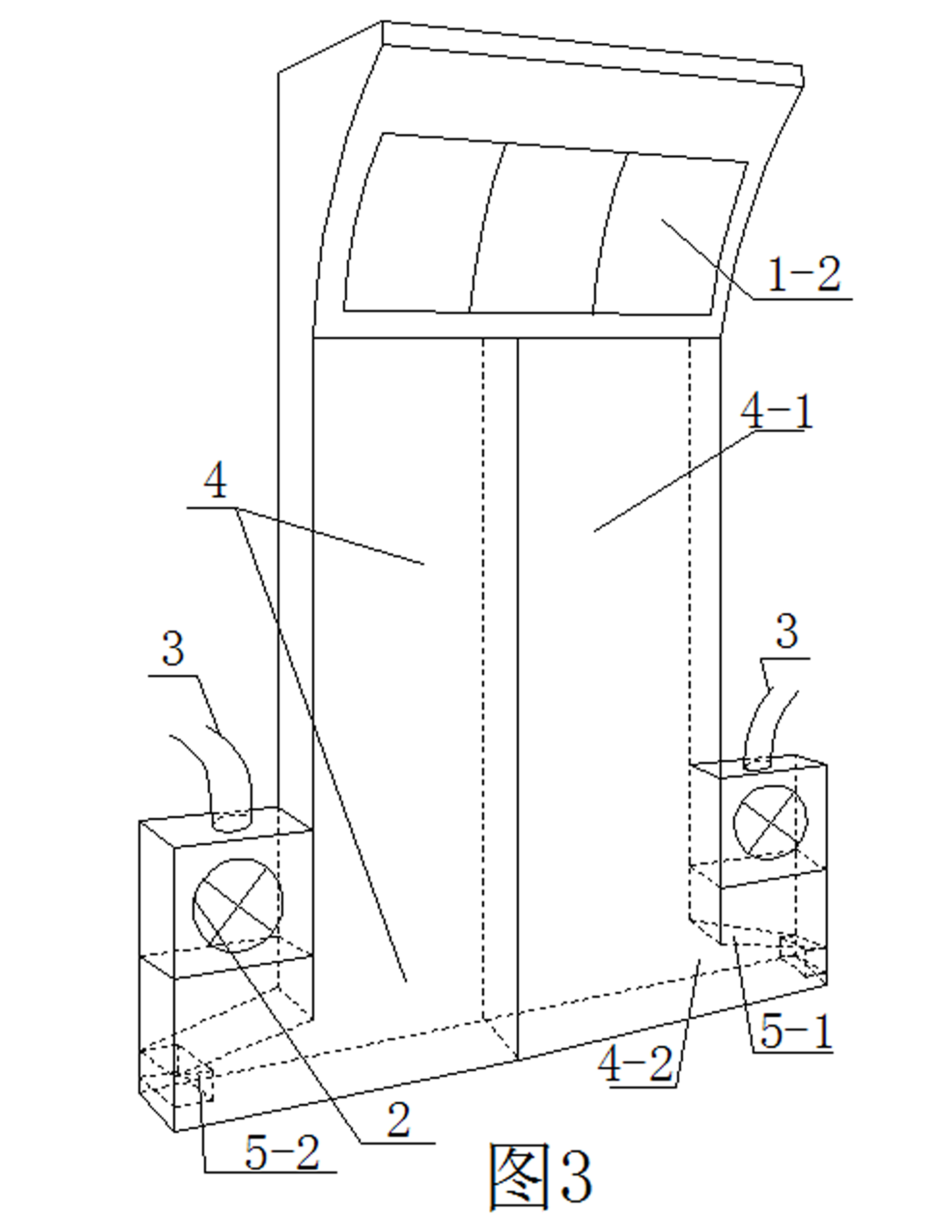

[0033] like image 3 Shown is a schematic diagram of an embodiment of Embodiment 2 of the present invention. The difference between Embodiment 2 and Embodiment 1 is that: the connecting channel 4 includes a vertical connecting channel section 4-1 and a circuitous connecting channel section 4-2 connected in sequence; The oil fume filtering device is located at the outlet end (or tail end) of the circuitous connecting channel section 4-1, the inlet end of the vertical connecting channel section 4-1 communicates with the oil suction hood, and the vertical connecting channel section The outlet end of the section 4-1 communicates with the inlet end of the circuitous connection channel section 4-2, the outlet end of the circuitous connection channel section 4-2 is higher than the inlet end, the suction device 2 and the circuitous connection channel section 4-2 connected to the outlet.

[0034] In the specific implementation, in order to facilitate the transformation of the existing...

Embodiment 3

[0036] like Figure 4 Shown is a schematic diagram of embodiment 3 of the present invention, the difference between embodiment 3 and embodiment 1 is: the oil suction hood is a hood type oil suction hood 1-1; the connecting channel 4 is near the upper side of the stove Have a plurality of oil suction smoke through holes 4-3. The hood type range hood 1-1 can adopt the cover body form of an existing hood type range hood. In order to facilitate cooking, a condiment rack can be installed on the connecting channel 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com