Sapphire/ceramic lens laser-cutting method

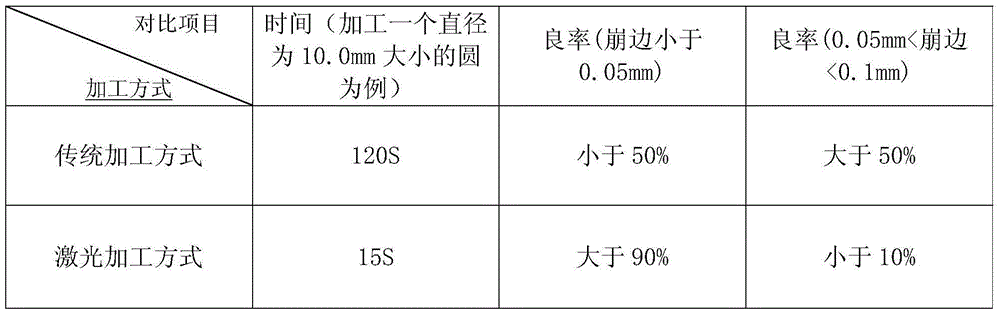

A laser cutting and ceramic lens technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost, non-environmental protection, long processing cycle, etc., achieve high product quality, protect the environment, and improve cutting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In this embodiment, the present invention is described in detail by taking cutting a circular hole on a sapphire lens as an example.

[0024] Firstly, the sapphire slice with a thickness of 0.7-0.9mm is vacuum-adsorbed to the jig; specifically, the jig is provided with a hollowed-out annular space at the bottom of the round hole to be cut in the sapphire slice, and the depth is above 10mm. There is a supporting fixture in the middle position for supporting the cut round waste.

[0025] Set the fixture on the workbench of the fiber laser machine, and set the air nozzle of the laser head at the position of 0.15mm-0.3mm on the upper surface of the product. During the process of cutting round holes, the workbench moves along the Y line of the system, and the laser head moves along the Y line of the system. The X-axis moves, and the circular tool path of the laser head to the lens is realized by simultaneous simultaneous movement in two directions. A distance of 0.02-0.03mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com