High-efficiency self-cleaning type range hood and manufacturing method thereof

A range hood and high-efficiency technology, applied in the field of oil fume purification, can solve the problems of inability to achieve 360° air intake, small exhaust volume, air pollution, etc. effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

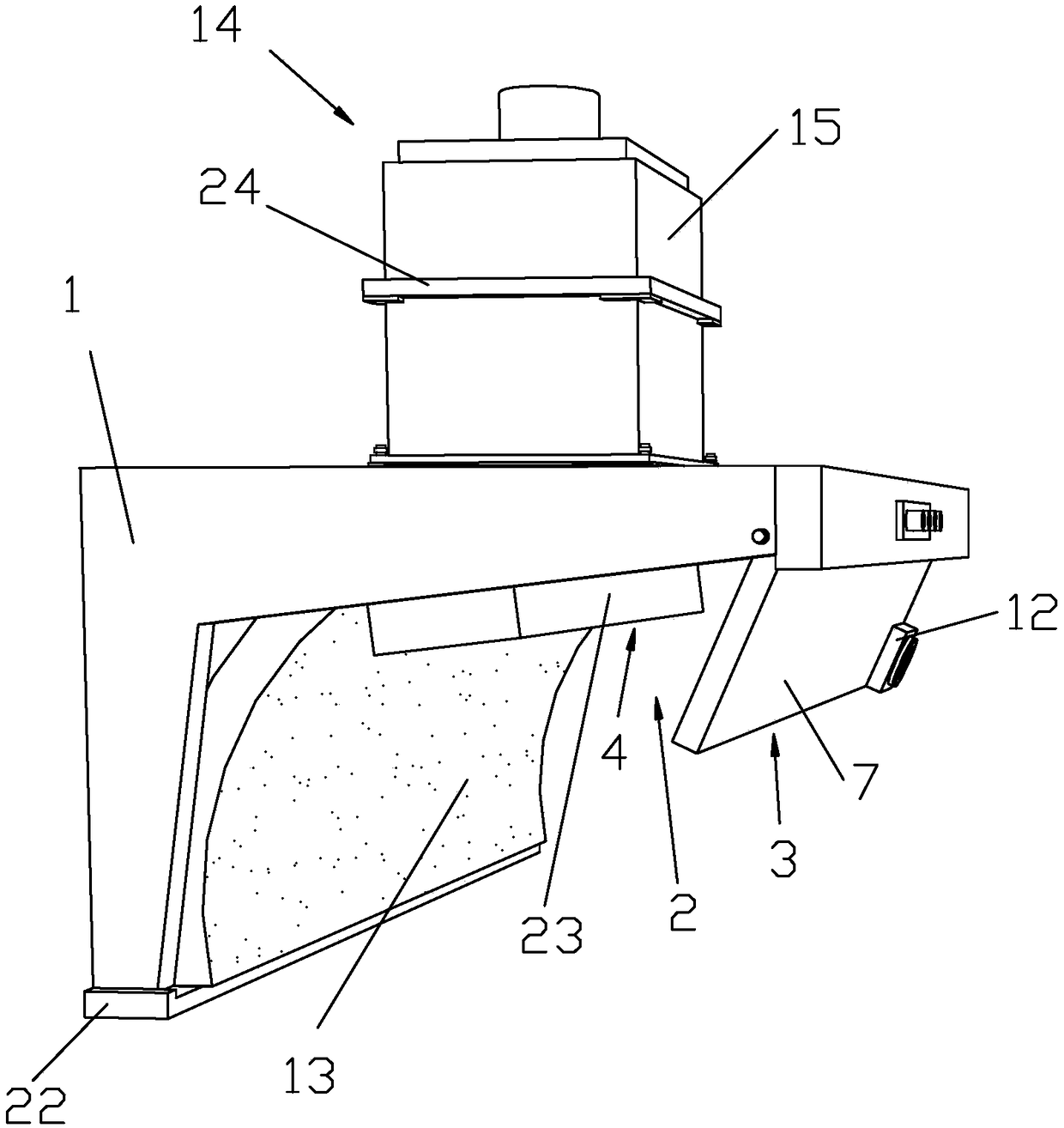

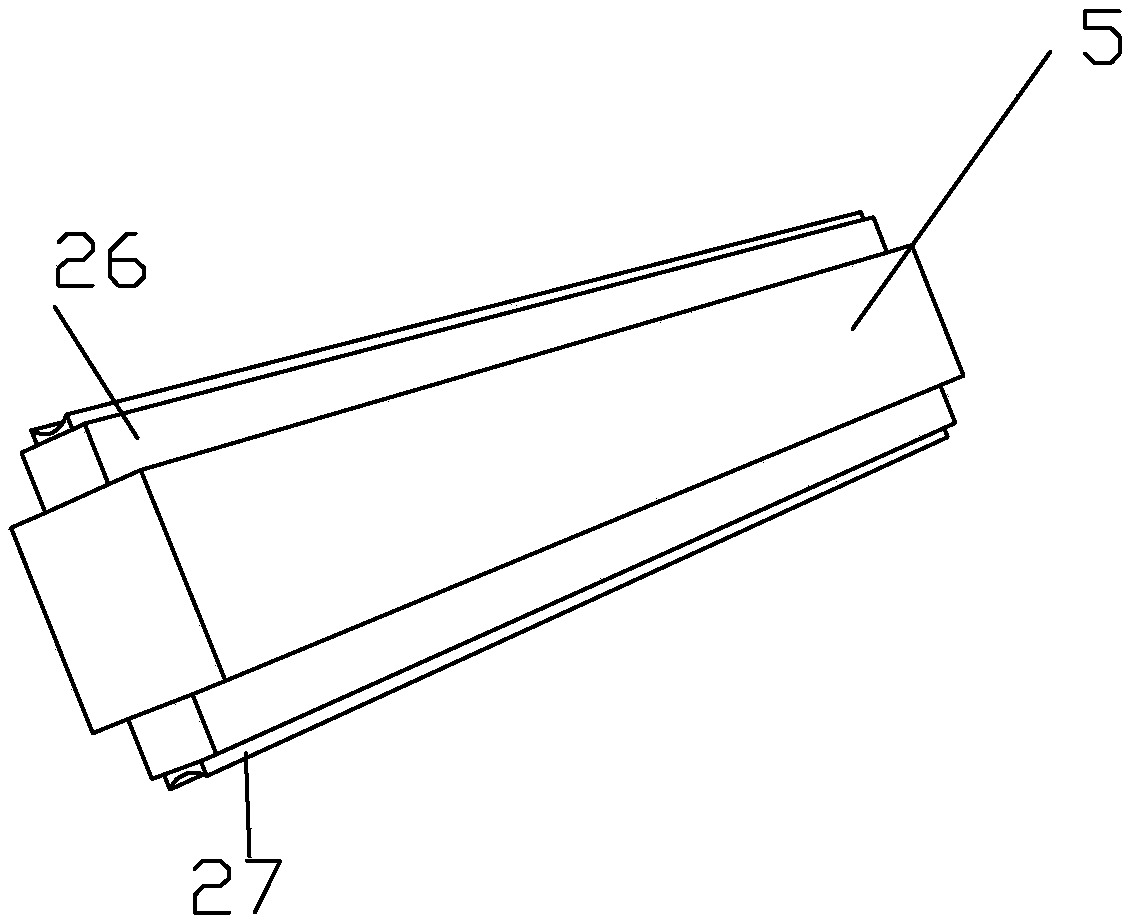

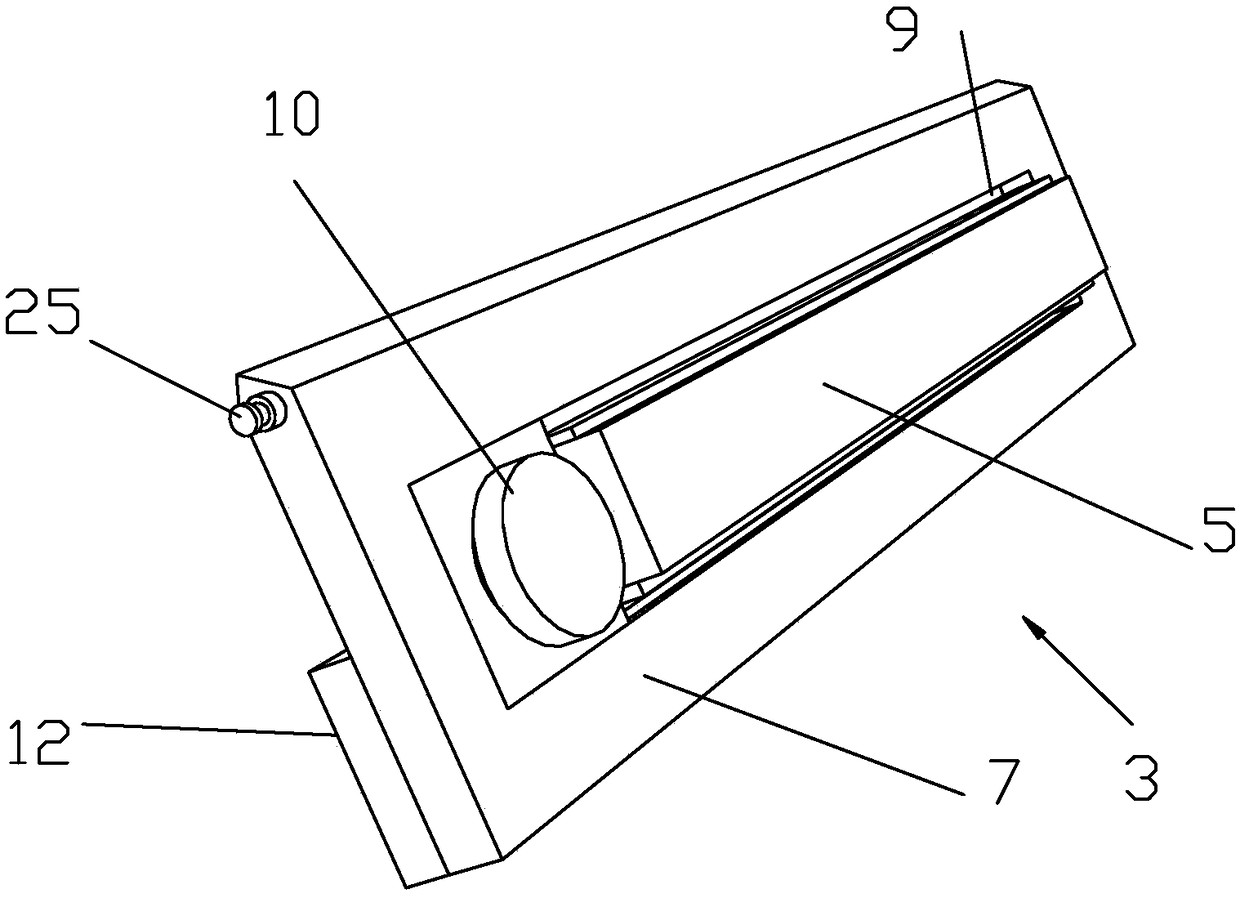

[0050] Such as Figure 1 to Figure 12 As shown, in order to solve the above technical problems, the present invention adopts the following technical solutions: a high-efficiency self-cleaning range hood, including a casing 1 and a smoke exhaust system 2, and the smoke exhaust system 2 includes a side suction device 3 and a top suction device 4. The side suction device 3, the top suction device 4 and the inside of the casing 1 are connected. The side suction device 3 includes the first cover plate 5, the first impeller assembly 28, the first side suction shell 7 and the impurity removal device 8. The second The first suction slot 9 is arranged on the side suction shell 7, the first cover plate 5 is engaged with the first suction slot 9, the impurity removal device 8 includes a filter box 10, and the first side suction shell 7 is provided with a hose An interface 12, an arc-shaped cover plate 13 is installed on the inner surface of the casing 1, the size of the arc-shaped cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com