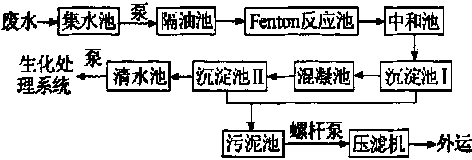

High-concentration spinning oil wastewater pretreatment system

A spinning oil, high-concentration technology, used in seawater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high COD concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The daily discharge of spinning oil wastewater from the simulated enterprise is about 35m 3 / d, considering a certain margin, therefore, the design wastewater treatment scale is 48m 3 / d.

[0010] The oily waste water produced in the production workshop of this enterprise is used in 1m 3 The oily waste water in the barrel is transported by a forklift and poured into the sump; the sump is agitated by air to ensure that the oily waste water in the sump can be fully mixed, and then it is sent into the grease trap by the lifting pump and scraped The oiler separates and collects the floating oil floating on the water surface; the waste water after oil separation flows into the Fenton reaction tank, and at the same time, the hydrogen peroxide and ferrous sulfate are quantitatively fed by the metering pump, and react under the mixing action of the agitator, and the Fenton reaction destroys the emulsifier The charge balance of the organic molecules makes the organic molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com