Metal water-based stamping liquid and preparation method thereof

A stamping fluid and water-based technology, applied in the field of metal stamping, can solve problems such as poor anti-rust effect, easy skin cancer, and no published patent documents have been found, and achieve the effects of safe use, shortened production time, and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

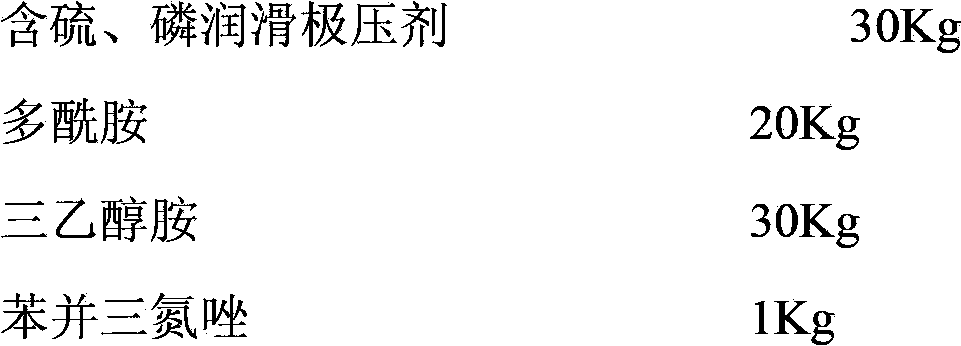

[0032] A metal water-based stamping fluid, its composition is (take 1000Kg water-based stamping fluid as an example):

[0033]

[0034]

[0035] A method for preparing metal water-based stamping fluid, the steps are as follows:

[0036] ⑴ Add metered distilled water into the reaction kettle, add lubricating extreme pressure agent and stir for 15 minutes;

[0037] (2) Add polyamide and triethanolamine in turn to the reaction kettle, and stir for 15 minutes;

[0038] (3) When the liquid phase in the reaction kettle is uniform and transparent, add benzotriazole, stir for 10 minutes, then add hydroxypropyl methylcellulose, stir for 30 minutes until the cellulose is completely dissolved;

[0039] (4) Finally, add triazine fungicides and three-dimensional siloxane defoamers, stir for 10 minutes, and stop stirring.

Embodiment 2

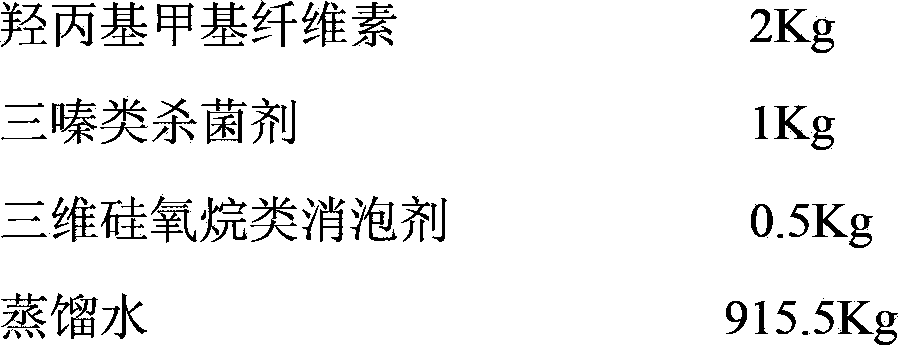

[0041] A metal water-based stamping fluid, its composition is (taking 1000Kg water-based rust inhibitor as an example):

[0042]

[0043] The steps of its preparation method are the same as in Example 1.

[0044] Mechanism of action of the present invention:

[0045] The first is to add lubricating extreme pressure agent and polyamide into the water to form the body of the stamping fluid. The added triethanolamine provides a stable pH value and plays a synergistic anti-rust effect with polyamide; benzotriazole synergistically prevents rust with anti-rust agent In addition to the effect of rust, it also protects copper against corrosion. Triazine fungicides prevent stamping fluid from corrupting and inhibit the growth of bacteria; hydroxypropyl methylcellulose assists in film formation and increases The thickening, lubricating and dispersing functions enable the stamping fluid to remain evenly on the metal surface, and the stamping effect can be optimized through the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com