High-efficiency range hood

A range hood, high-efficiency technology, applied in the field of kitchen appliances, can solve the problems of increasing the frequency of cleaning the filter screen, limited filtering effect, limited probability of contact between the filter screen and oil, etc., to reduce the frequency of cleaning the filter screen and increase the contact probability , The effect of improving the ability to capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

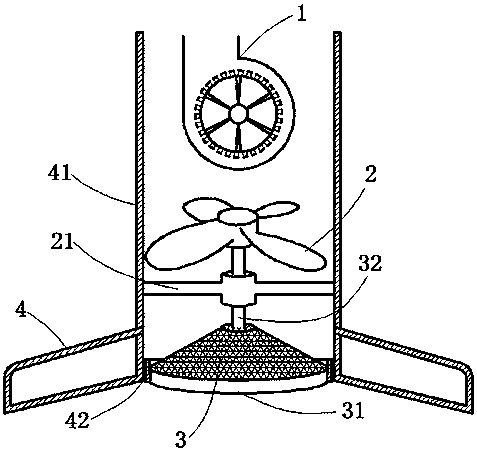

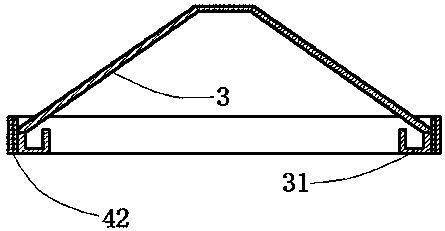

[0013] exist figure 1 , figure 2 In the shown embodiment one, the high-efficiency range hood includes a fan 1, a smoke collection hood 4, an air duct 41, a filter screen 3 and an oil cup 31; the air duct 41 is connected above the smoke collection hood 4; A blower fan 1 is arranged above the inside of the air duct 41; a bracket 21 is provided below the fan 1, and a follower shaft 32 coincident with the axis of the air duct 41 is provided on the support 21, and the upper end of the follower shaft 32 is connected There is a rotating fan blade 2, and the filter screen 3 is connected to the lower end; the filter screen 3 is in the shape of a trumpet with its mouth opening downward, and the circular lower edge of the filter screen 3 is connected to the inner wall of the air duct 41 The middle part of the bearing inner ring of the annular bearing 42; the oil cup 31 is in the shape of an annular groove, and its outer wall is inserted into the inner ring of the bearing 42.

[0014] ...

Embodiment 2

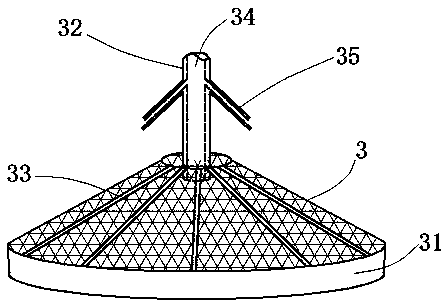

[0016] Such as image 3 As shown, for the second embodiment of the high-efficiency range hood, the difference from the first embodiment is that: the filter screen 3 is also circumferentially evenly distributed with protrusions extending from the center of the filter screen 3 to the outer edge of the filter screen 3 The separator strips 33 on the upper and lower surfaces of the filter screen 3 are used to suppress the circumferential movement of the oil on the surface of the filter screen 3 and make the oil move radially outward as much as possible.

[0017] In addition, the inside of the follow-up shaft 32 also has an axial hole 34, and the axial hole 34 extends to the lower end surface of the follow-up shaft 32; while the upper end of the axial hole 34 only extends below the bracket 21, and Connect with the blowpipe 35 that is evenly distributed around the rotating shaft 32; the axis of the blowpipe 35 intersects with the outer edge of the filter screen 3; thus, during the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com