Numerical control molding system of spinning frame

A technology of spinning frame and transmission system, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problems of low automation of spinning frame, achieve low noise, convenient operation and clean workshop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

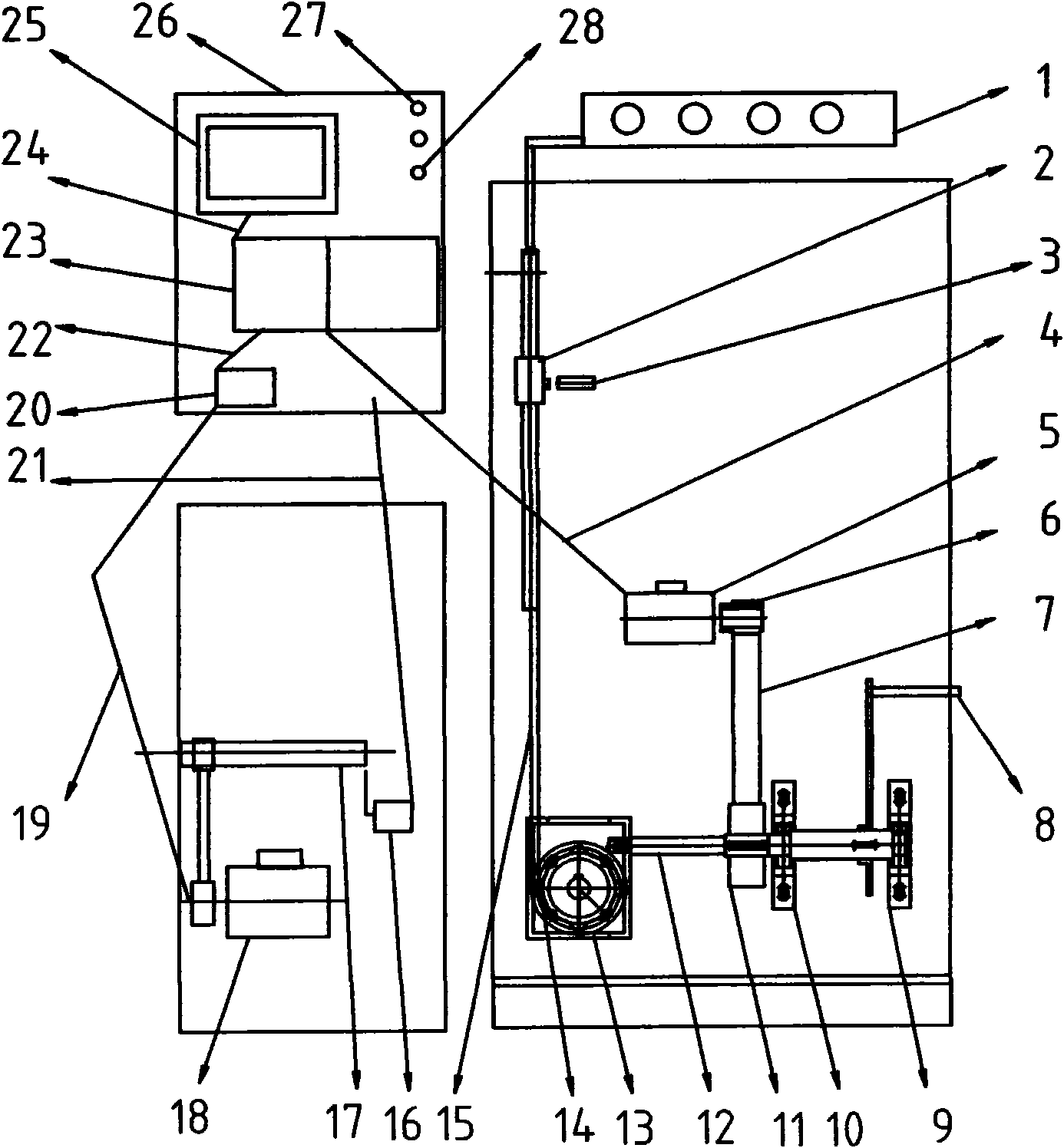

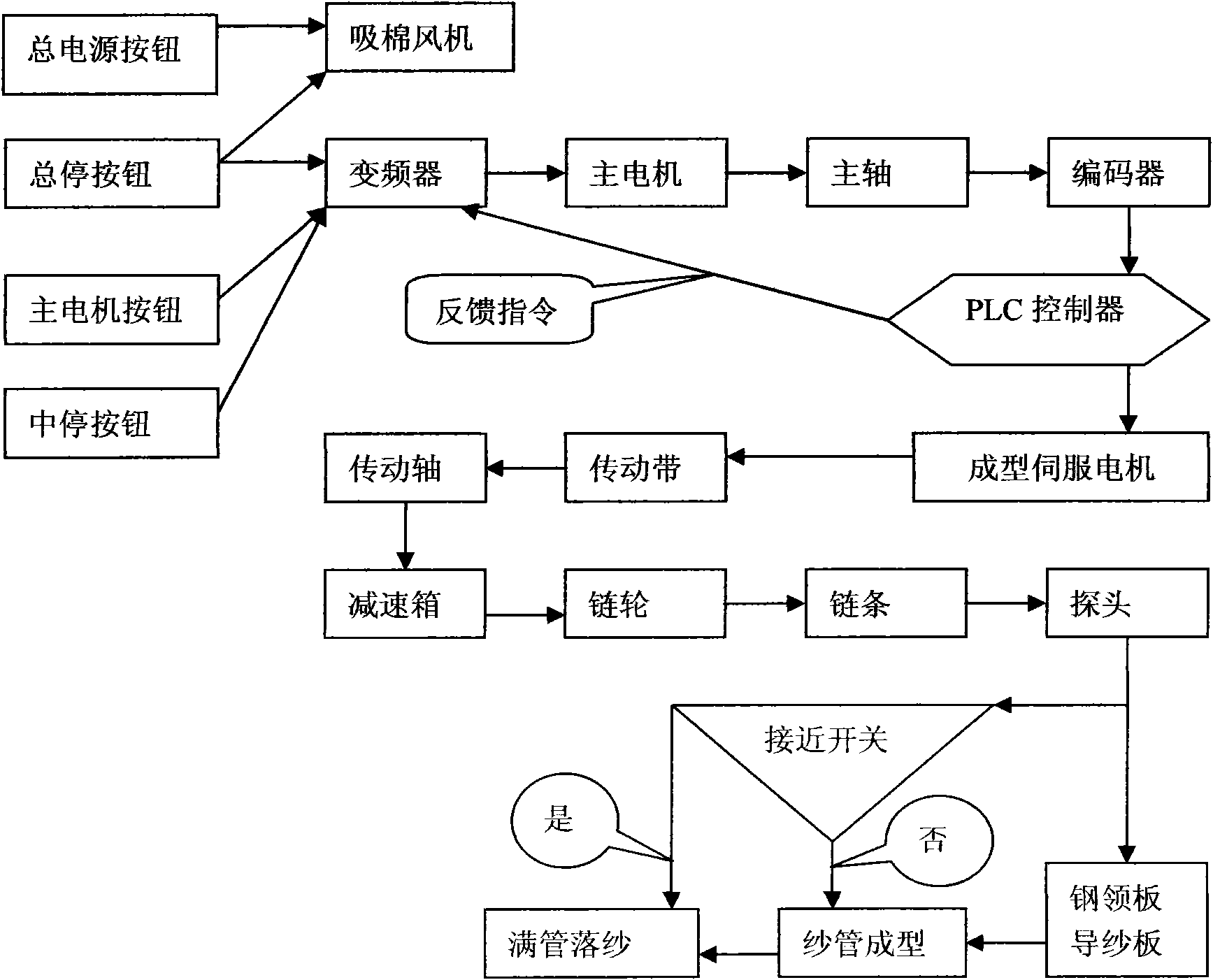

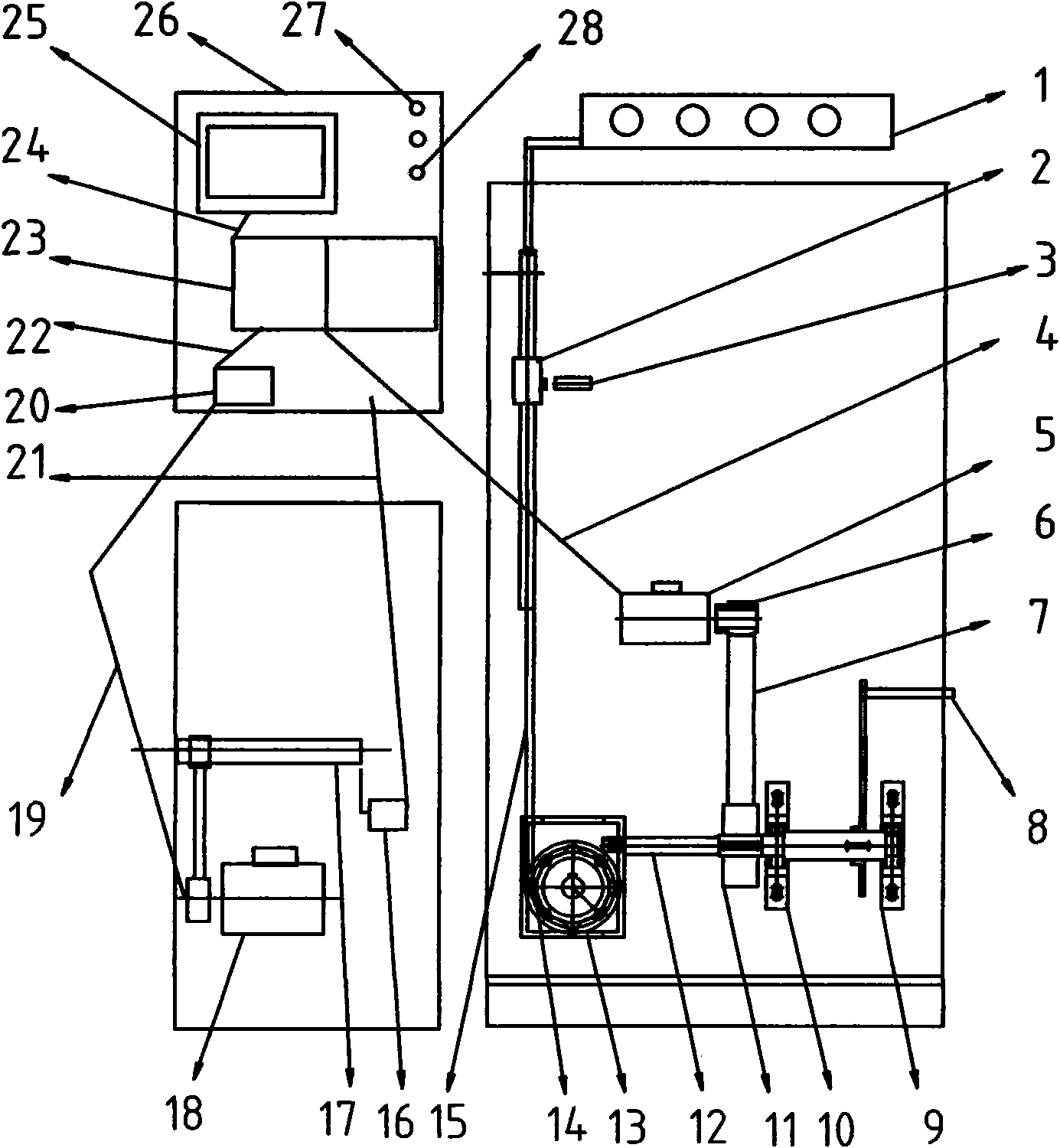

[0016] Choose or manufacture such as figure 1 The various components in: steel ring plate and yarn guide plate 1, probe 2, proximity switch 3, servo motor control line 4, forming servo motor 5, driving wheel 6, transmission belt 7, hand device 8, thrust support bearing 9. Support bearing 10, driven wheel 11, drive shaft 12, worm gearbox 13, sprocket 14, chain 15, encoder 16, main shaft 17, main motor 18, power line 19, frequency converter 20, signal line 21 , Inverter control line 22, PLC controller 23, data line 24, man-machine dialogue control panel 25, control box 26, main power button 27, main motor button 28.

[0017] Wherein, the proximity switch 3 and the probe 2 work in cooperation, and the probe 2 is fixed at a suitable position on the chain with fasteners. The driving wheel 6 and the driven wheel 11 are synchronous wheels, the transmission belt 7 is a synchronous belt, the sprocket 14 is coaxial with the worm wheel of the worm gear box 13, and the models and specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com